Dyeing device for cloth processing

A dyeing device and fabric technology, applied in textile processing machine accessories, equipment configuration for processing textile materials, processing of textile materials, etc., can solve problems such as affecting the dyeing effect of fabrics, stacking fabrics, and uneven dyeing of fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A dyeing device for fabric processing, such as figure 1 As shown, it includes a base plate 1, a first support frame 2, a cylinder 3, a charging frame 4, a rack material mechanism 5 and a dyeing mechanism 6. The left rear side of the base plate 1 is provided with a first support frame 2, and the first support frame 2 Top front side is equipped with cylinder 3, is provided with frame material mechanism 5 on the telescoping rod of cylinder 3, is provided with dyeing mechanism 6 on base plate 6, is provided with charging frame 4 on dyeing mechanism 6.

[0065]When people need to dye cloth, they can use this dyeing device for cloth processing. First, people will pour the dye to be dyed into the charging frame 4, then hang the cloth on the rack mechanism 5, and then start the air cylinder 3. After the cylinder 3 is started, the operation of the cylinder 3 drives the racking mechanism 5 to run, so that the racking mechanism 5 sends the cloth to the loading frame 4, and dyes th...

Embodiment 2

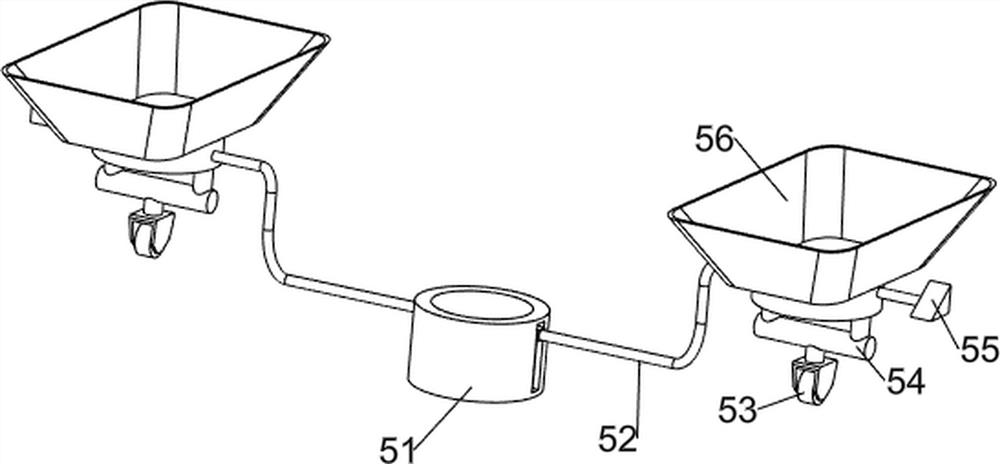

[0067] On the basis of Example 1, such as figure 2 and image 3 As shown, the rack material mechanism 5 includes a rack material plate 51, a connecting rod 52 and a lower pressing block 53, the telescopic rod of the cylinder 3 is provided with a rack material plate 51, and the middle bottom of the rack material plate 51 is provided with a connecting rod 52, and the connecting rod 52 bottoms are provided with pressing block 53.

[0068] People need to hang the cloth on the four sides of the shelf plate 51 first, and then start the cylinder 3. After the cylinder 3 is started, the telescopic rod of the cylinder 3 moves downward to drive the shelf plate 51 to move downward, thereby driving the connecting rod 52 to move downward. , and then drive the lower pressing block 53 to move downward, and the downward movement of the racking plate 51 can send the cloth to the charging frame 4 to realize the effect of racking the material. When the dyeing is completed, the upward movement o...

Embodiment 3

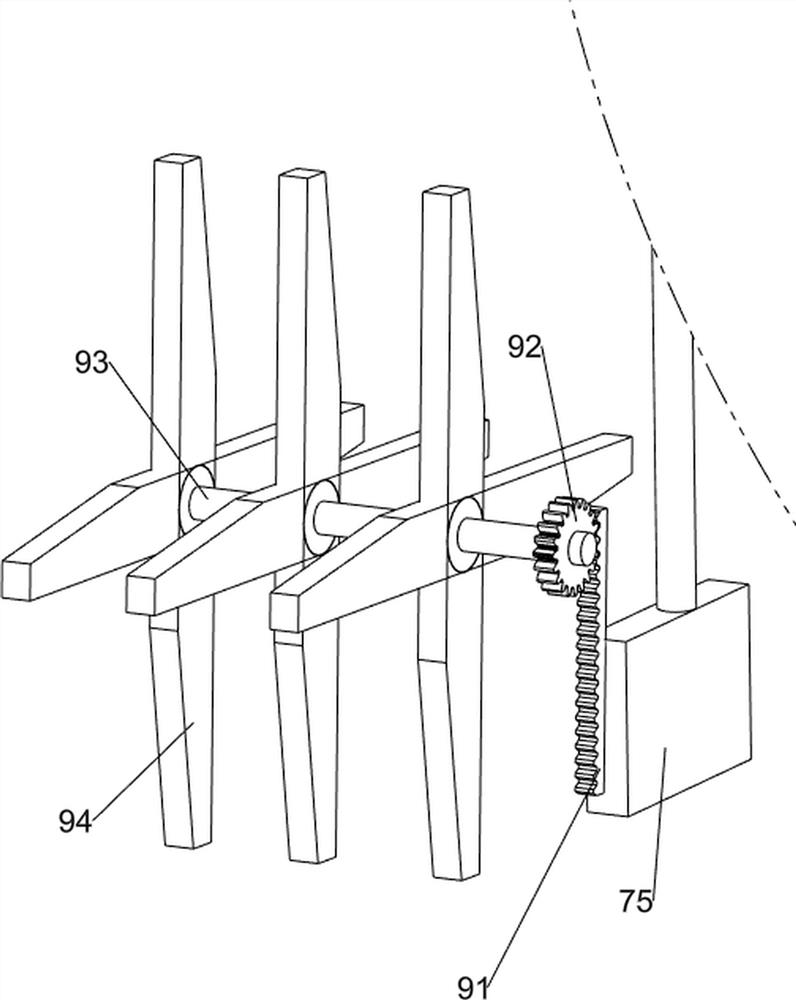

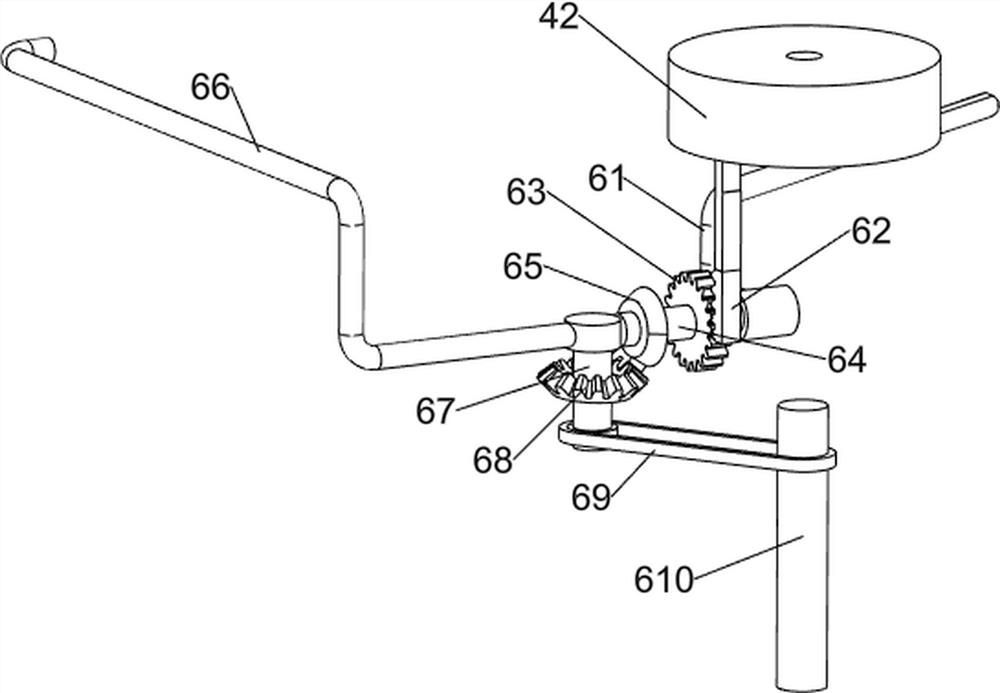

[0072] On the basis of Example 2, such as Figure 4-Figure 7 As shown, a transmission mechanism 7 is also included, and the transmission mechanism 7 includes a second support frame 71, a first rack 72, a one-way gear 73, a first rotating shaft 74, a missing bevel gear 75, a third support frame 76, a second Rotating shaft 77, the first bevel gear 78, belt assembly 79 and the 3rd rotating shaft 710, the first supporting frame 2 upper front side is provided with the second supporting frame 71, and the left side of lower pressing block 53 is provided with the first rack 72, the second The front side of the support frame 71 is rotatably provided with a first rotating shaft 74, the rear side of the first rotating shaft 74 is provided with a one-way gear 73, the one-way gear 73 meshes with the first rack 72, and the front side of the first rotating shaft 74 is provided with a missing bevel gear 75, the front side of the bottom plate 1 is provided with a third support frame 76, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com