Burnishing and modifying treatment method for maple wood

A treatment method and technology of maple, which is applied in the direction of wood treatment, wood treatment details, wood processing appliances, etc. It can solve the problems of wood color stability and durability, waste water and waste gas pollution, harmful substances, etc., and achieve mildew resistance. Good anti-corrosion effect, full color and beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

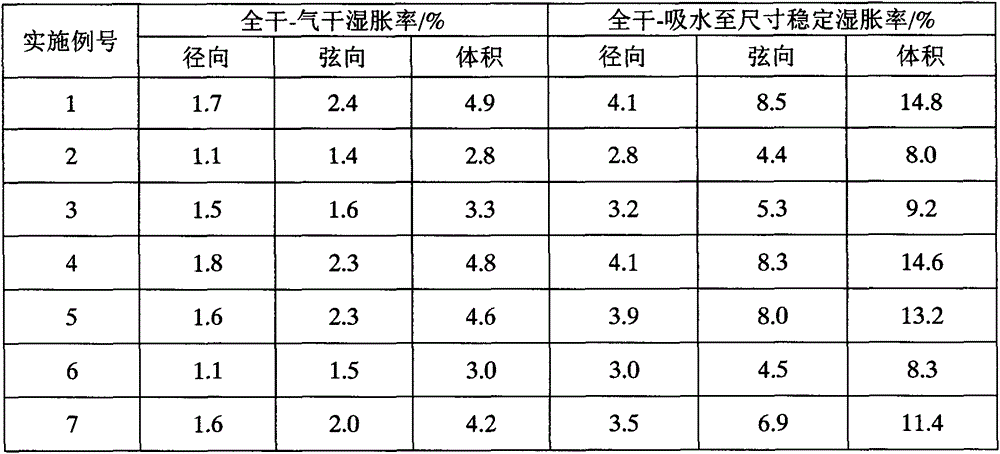

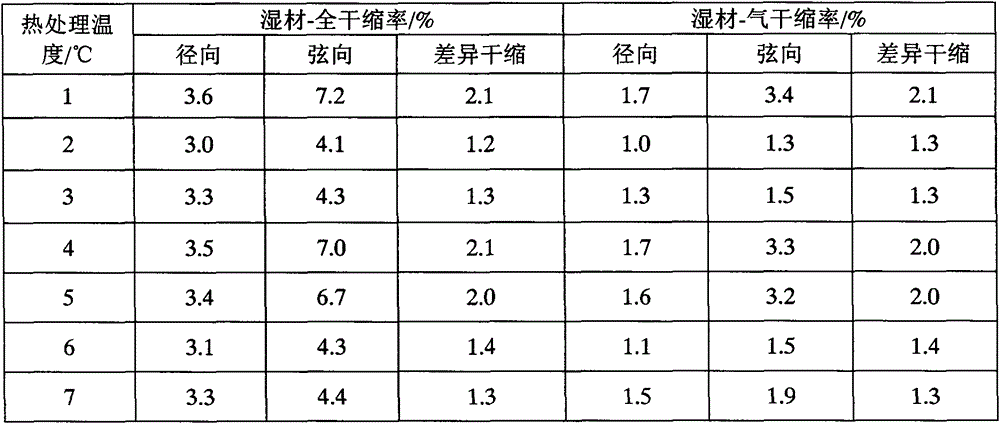

Examples

Embodiment 1

[0012] 1) Color enhancement modification treatment

[0013] The maple wood is made into a sample with a specification of 500×120×20 mm (length×width×thickness). The steps of the method for color enhancement and modification of maple wood in this embodiment are as follows.

[0014] Maple cooking treatment: use water vapor as the heating medium, remove the air content in the treatment tank to within 5%; the first stage, quickly raise the temperature to 100°C, the pressure is 0MPa, and the holding time is 2h; the second stage, raise the temperature to 110°C, 0.2 MPa, holding time 4h; the third stage, cooling to less than 90°C, drying to moisture content of 3%, and naturally cooling to room temperature. Maple supercritical treatment: Cooked maple is placed in supercritical equipment for production, the pressure is 20MPa, the temperature is 50°C, the medium is carbon dioxide, and the supercritical treatment time is 5min. Color-enhancing modification treatment: put supercritically ...

Embodiment 2

[0019] 1) Color enhancement modification treatment

[0020] The maple wood is made into a sample with a specification of 500×120×20 mm (length×width×thickness). The steps of the method for color enhancement and modification of maple wood in this embodiment are as follows.

[0021] Maple cooking treatment: use water vapor as the heating medium, remove the air content in the treatment tank to less than 5%; the first stage, quickly raise the temperature to 120°C, the pressure is 0.2MPa, and the holding time is 4h; the second stage, heat up to 120°C, 0.5MPa, holding time 8h; the third stage, cooling to less than 90 ℃, drying to moisture content of 2%, naturally cooling to room temperature. Supercritical treatment of maple wood: the cooked maple wood is placed in supercritical equipment for production, the pressure is 30MPa, the temperature is 70°C, the medium is carbon dioxide, and the supercritical treatment time is 10min. Color-enhancing modification treatment: put supercritica...

Embodiment 3

[0026] 1) Color enhancement modification treatment

[0027] The maple wood is made into a sample with a specification of 500×120×20 mm (length×width×thickness). The steps of the method for color enhancement and modification of maple wood in this embodiment are as follows.

[0028] Maple cooking treatment: use water vapor as the heating medium, remove the air content in the treatment tank to less than 5%; the first stage, quickly raise the temperature to 110°C, the pressure is 0.1MPa, and the holding time is 3h; the second stage, heat up to 110°C, 0.35MPa, holding time 6h; in the third stage, cool down to less than 90°C, dry to a moisture content of 4%, and cool naturally to room temperature. Maple supercritical treatment: Cooked maple is placed in supercritical equipment for production, the pressure is 25MPa, the temperature is 60°C, the medium is carbon dioxide, and the supercritical treatment time is 7.5min. Color-enhancing modification treatment: put the supercritically tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com