Vacuum dyeing device based on fast fabric printing and dyeing

A dyeing device and fast technology, which is applied in the processing of textile materials, processing textile material drums, processing textile material carriers, etc., can solve the problems of uneven dyeing, poor dyeing effect, and low work efficiency, and achieve high dyeing efficiency and work efficiency. High efficiency and reduced time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

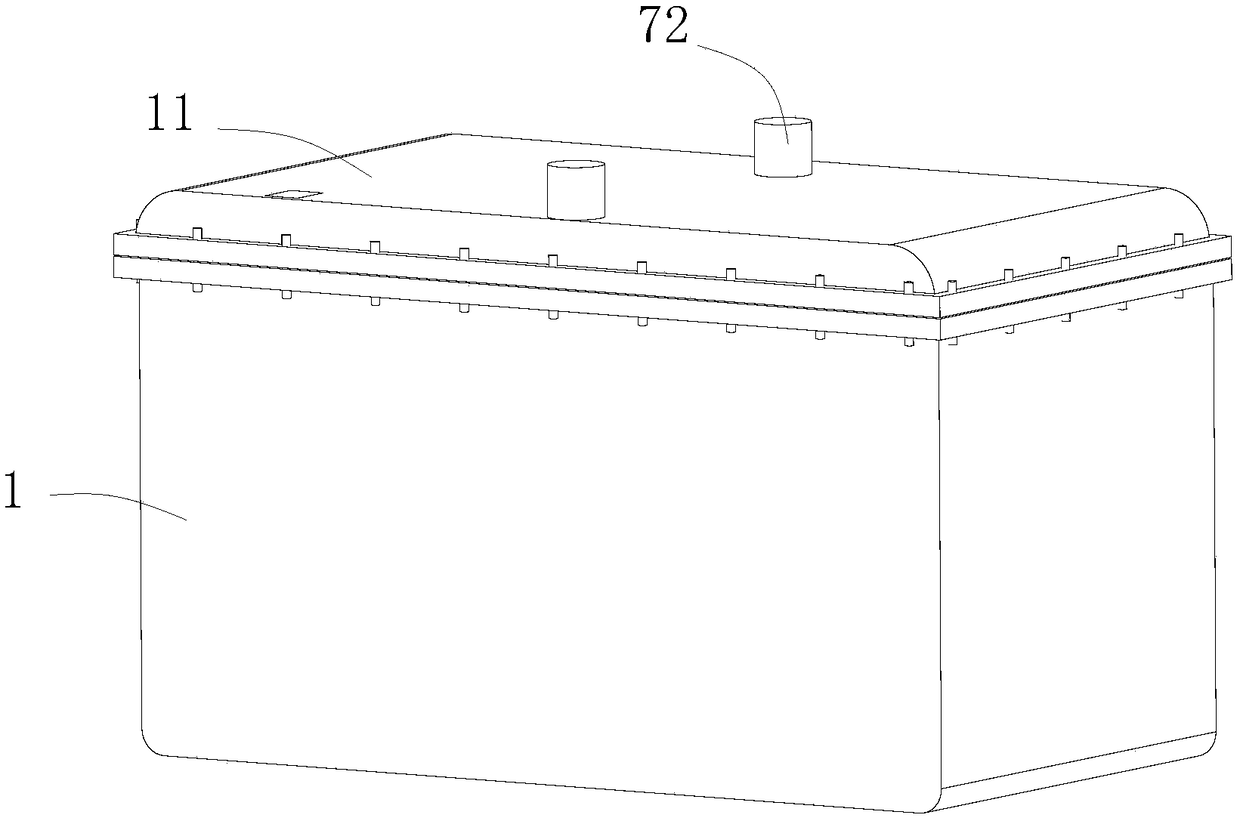

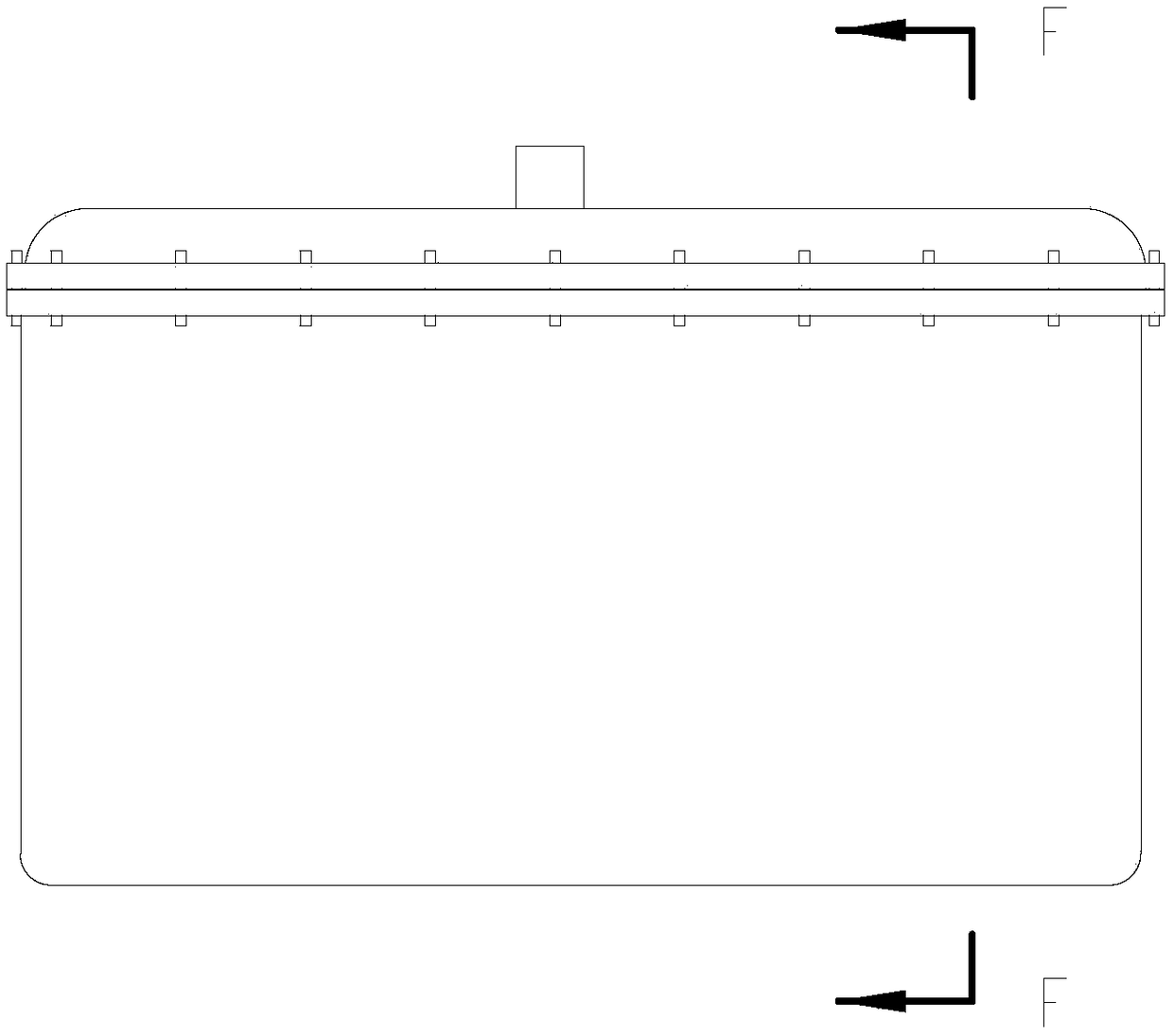

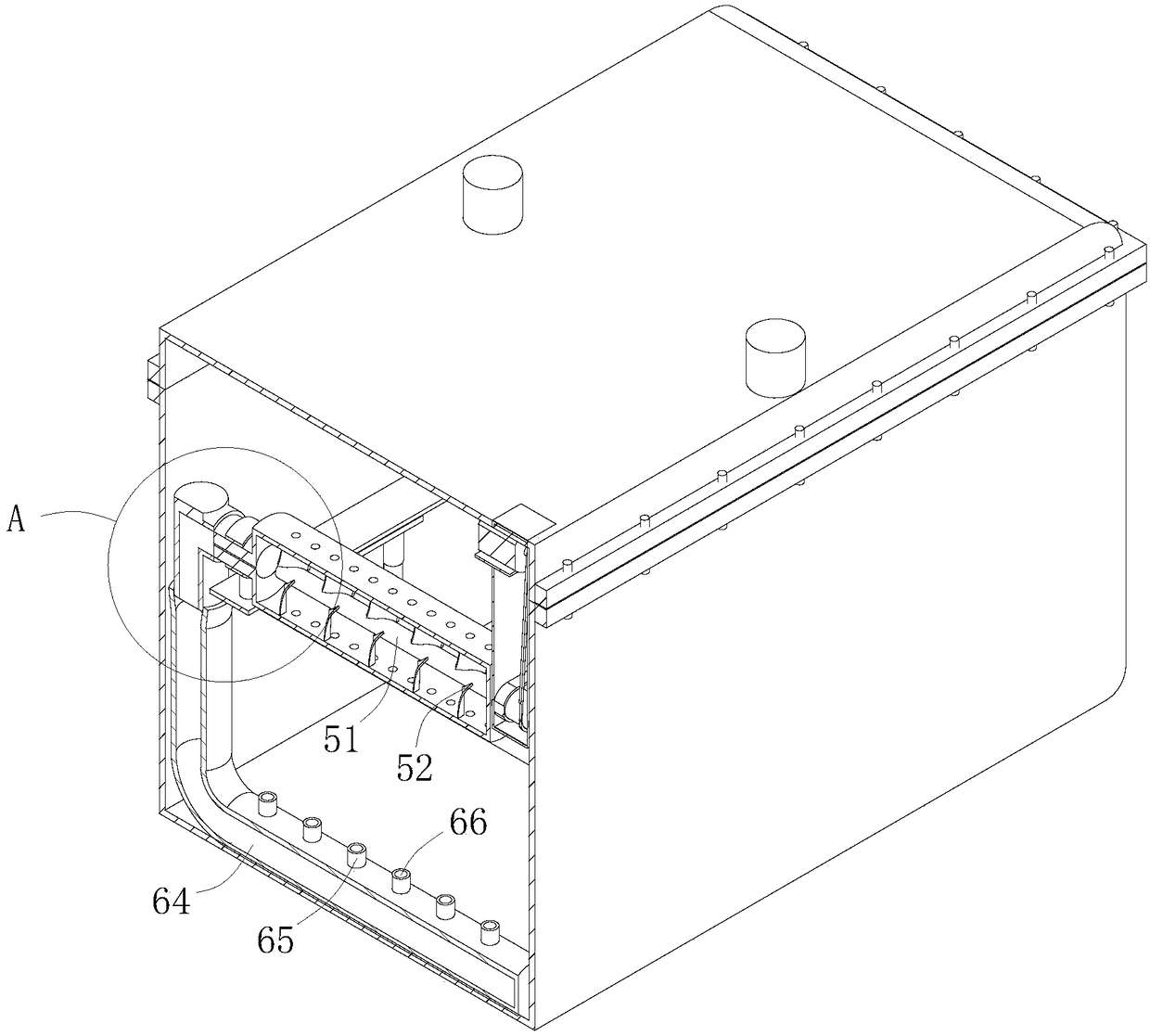

[0033] Such as figure 1As shown in -12, a vacuum dyeing device based on rapid printing and dyeing of cloth, including a dyeing chamber 1, a cover 11, two dyeing rolls 2, a driving part, a plurality of driven rollers 3, a penetrating part and a dyeing liquor stirring device, Both the dyeing chamber 1 and the cover 11 are made of stainless steel, and the cover 11 can be sealed with the dyeing chamber 1, so that the dyeing chamber 1 and the cover can form a closed space, so that the inside of the dyeing chamber 1 can be protected. Carry out vacuum treatment; the two dipping cloth rolls 2 can be forwardly or reversely rotated and installed in the dyeing chamber 1, and there is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com