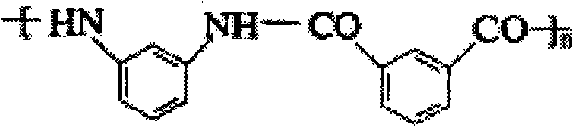

Normal-pressure dyeing method of meta-aramid yarn

A aramid yarn, atmospheric dyeing technology, applied in the field of textile printing and dyeing, can solve the problems of strict equipment requirements, fragile and fiber, waste of energy, etc., to achieve ideal flame retardancy, excellent heat resistance, physical and chemical Stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A) Coarsening of meta-aramid yarns, the roughening process is: sodium hydroxide 20g / L, penetrating agent JFC 2g / L, bath ratio 1:20, temperature 95°C, time 30min, after roughening, heat Washing with water to a pH of 9-10 to obtain a meta-aramid yarn with a roughened fiber surface. This step can roughen and etch the surface of the meta-aramid fiber, increase the surface area of the fiber, and at the same time relieve the fiber itself;

[0032] B) Activation of the meta-aramid yarn, the activation of the meta-aramid yarn whose fiber surface is roughened by step A), the specific process is: adding a cationic modifier (polyepichlorohydrin aminate) 15g / L, liquor ratio 1:20, temperature 60°C, and time 40min. After activation, the preferred solution is to fully wash with water to obtain meta-aramid yarn to be dyed. The function of this step is to Cationic groups are introduced into the rayon yarn, so that the surface of the meta-aramid yarn is positively charged, and the elec...

Embodiment 2

[0035]A) Coarsening of meta-aramid yarns, the roughening process is: sodium hydroxide 10g / L, penetrant JFC 1g / L, bath ratio 1:15, temperature 98°C, time 20min, and the rest are the same as in Example 1 a description of step A);

[0036] B) Activation of meta-aramid yarn, the activation process is as follows: the amount of cationic modifier is changed to 20g / L, the bath ratio is 1:25, the temperature is changed to 90°C, and the time is changed to 30min. After the activation, this step The content not involved in is all the same as the description to step B) of embodiment 1;

[0037] C) Dyeing of meta-aramid yarn, this step adopts direct dye for dyeing, and the specific process is: direct brown 5G dye 4% (o.w.f), Yuanming powder 12g / L, pH control is 6, liquor ratio 1: 20. The dyeing temperature is 92° C., the dyeing time is 60 min, and the rest are the same as the description of step C) in Example 1.

Embodiment 3

[0039] A) Coarsening of meta-aramid yarns, the roughening process is: mass percentage concentration is 85% phosphoric acid 15g / L, bath ratio 1: 12, temperature 90 ℃, time 25min, all the other are the same as step A of embodiment 1 )description of;

[0040] B) Activation of meta-aramid yarn, the activation process is: cationic modifier 10g / L, bath ratio 1:30, temperature 80°C, time 35min, the content not involved in this step is the same as that of Example 1 a description of step B);

[0041] C) Dyeing of meta-aramid yarns, the specific process is: Nylon mountain red N-3BL dye 5% (o.w.f), adjust pH to 6 with glacial acetic acid, sodium sulfate 20g / L, bath ratio 1: 15, The dyeing temperature is 98° C., and the dyeing time is 40 min. The content not involved in this step is the same as the description of step C) of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com