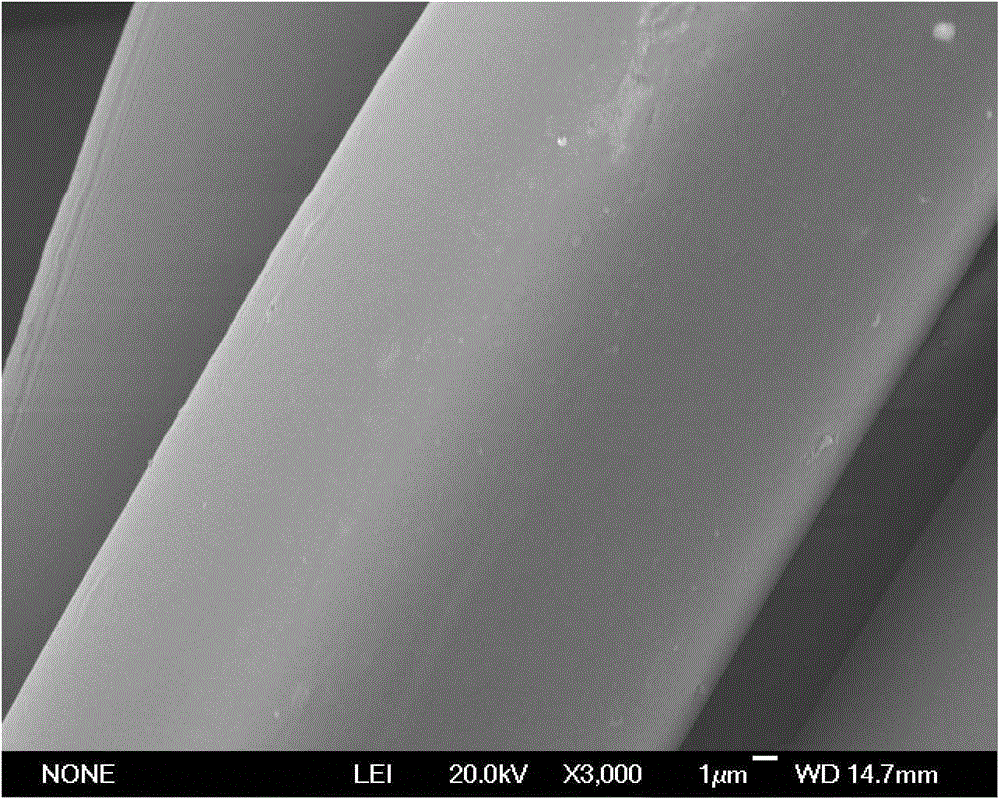

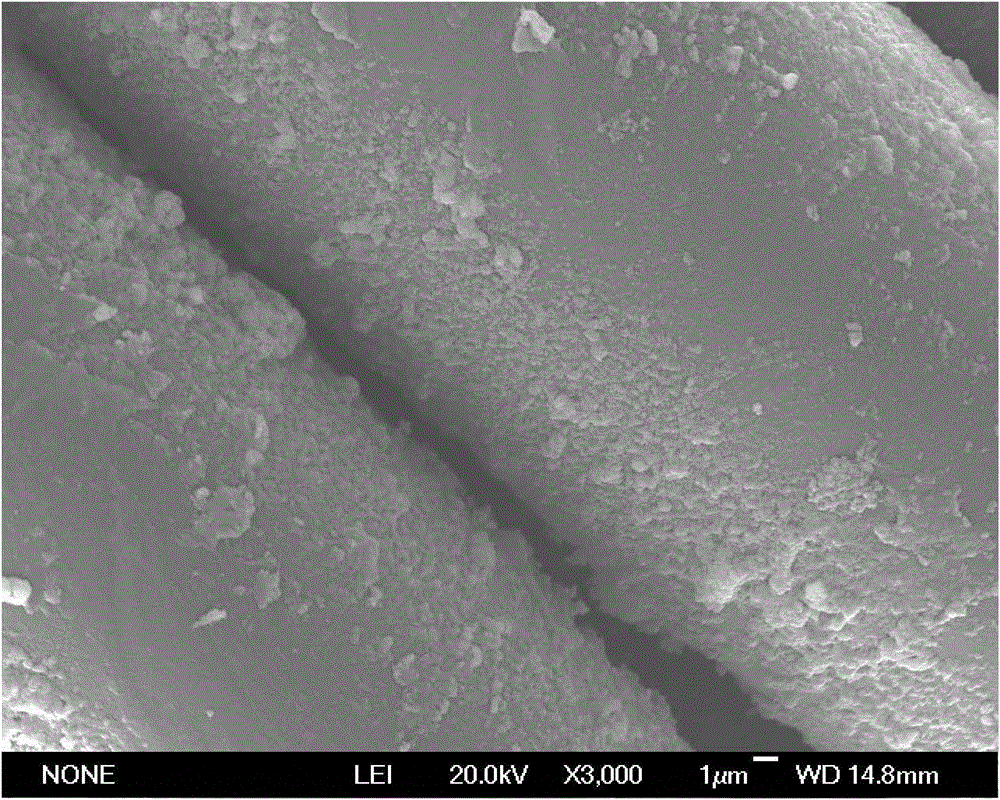

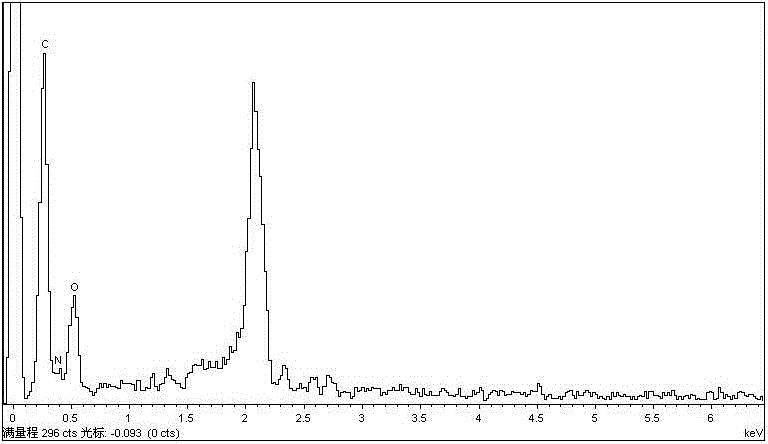

Modification of Nylon Swimsuit Fabric and Dyeing Composite Finishing Method

A technology for brocade swimwear and fabrics, which is applied to the modification and dyeing compound finishing of brocade swimsuit fabrics, UV protection, antibacterial, waterproof modification and dyeing compound finishing of brocade swimsuit fabrics, so as to achieve complete development and less reunion. , the effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Weigh sodium hydroxide, dissolve the weighed sodium hydroxide in deionized water, prepare a sodium hydroxide solution with a mass-volume concentration of 5g / L, and soak 3.25g of nylon swimsuit fabric according to the bath ratio of 1:50 In 162.5mL of sodium hydroxide solution with a mass-volume concentration of 5g / L, treat it at 80°C for 40 minutes, then rinse the pretreated nylon swimsuit fabric once with deionized water, and then follow the bath ratio of 1: 20. Soak the nylon swimsuit fabric in 95% absolute ethanol solution, treat it at 35°C for 30 minutes, wash it once with deionized water, and dry it at 80°C;

[0078] Weigh 0.52g of tetrabutyl titanate, 0.65g of water repellent AG-7620, 0.039g of silver nitrate, 0.52g of sodium dodecylbenzenesulfonate, and 0.016g of shannalan gray NHF-S Acid dye: Take a 95% ethanol solution, dissolve 0.52g of tetrabutyl titanate in 10mL of ethanol solution, and keep stirring to form tetrabutyl titanate ethanol solution A, then add it...

Embodiment 2

[0083] Weigh sodium hydroxide, dissolve the weighed sodium hydroxide in deionized water, prepare a sodium hydroxide solution with a mass-volume concentration of 10g / L, and soak 1.5g of nylon swimsuit fabric according to the bath ratio of 1:80 In 120mL of sodium hydroxide solution with a mass-volume concentration of 10g / L, treat it at 100°C for 60min, then rinse the pretreated nylon swimsuit fabric with deionized water for 3 times, and then follow the bath ratio of 1:40 , Soak the nylon swimsuit fabric in 95% absolute ethanol solution, treat it at 45°C for 50 minutes, wash it with deionized water three times, and dry it at 100°C;

[0084] Weigh 0.54g of tetrabutyl titanate, 0.9g of water repellent AG-7620, 0.09g of silver nitrate, 0.72g of sodium dodecylbenzenesulfonate, and 0.03g of shannalan gray NHF-S Acid dye: take a 95% ethanol solution, dissolve 0.54g of tetrabutyl titanate in 10mL of ethanol solution, and keep stirring to form tetrabutyl titanate ethanol solution A, then...

Embodiment 3

[0089] Weigh sodium hydroxide, dissolve the weighed sodium hydroxide in deionized water, prepare a sodium hydroxide solution with a mass-volume concentration of 8g / L, and soak 2.2g of nylon swimsuit fabric according to the bath ratio of 1:60 In 132mL of sodium hydroxide solution with a mass-volume concentration of 8g / L, treat it at 90°C for 50min, then rinse the pretreated nylon swimsuit fabric twice with deionized water, and then rinse it according to the bath ratio of 1:30 , Soak the nylon swimsuit fabric in 95% absolute ethanol solution, treat it at 40°C for 40 minutes, wash it twice with deionized water, and dry it at 90°C;

[0090] Weigh 0.55g of tetrabutyl titanate, 0.75g of water repellent AG-7620, 0.07g of silver nitrate, 0.65g of sodium dodecylbenzenesulfonate, and 0.022g of shannalan gray NHF-S Acid dye: take 95% ethanol solution, dissolve 0.55g tetrabutyl titanate in 10mL ethanol solution, and keep stirring to form tetrabutyl titanate ethanol solution A, then add it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com