Synthesis and application of durable flame retardant of nitrogen-phosphorus synergistic system for cotton without halogen and formaldehyde release

A formaldehyde release, durable flame retardant technology, applied in the periodic table group 5/15 element compounds, plant fibers, organic chemistry and other directions, can solve the problems of long time, high reaction temperature, complexity, etc. The effect of high flame retardant efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Put 170 grams of N, N-methylene bisacrylamide into a four-necked flask, heat and melt, then add 124 grams of dimethyl methyl phosphate, and add 0.05 grams of catalyst dibutyltin dilaurate at the same time, while stirring Raise the temperature to 75-80°C, keep the temperature for about 2 hours, and cool down to room temperature to obtain Intermediate A;

[0020] 2. Put 300 grams of intermediate A obtained above into a four-necked flask, add a certain amount of aqueous solution, first adjust the pH to 8-9 with triethanolamine, raise the temperature of the reaction solution to 85-90°C, and slowly add it dropwise while stirring 130 g of 1,4-dichlorobutane was incubated and reacted for 2 hours to obtain the final product B.

Embodiment 2

[0022] 1. Put 175 grams of N, N-methylene bisacrylamide into a four-necked flask, heat and melt, then add 128 grams of dimethyl methyl phosphate, and add 0.06 grams of catalyst dibutyltin dilaurate at the same time, while stirring Raise the temperature to 75-80°C, keep the temperature for about 3 hours, and cool down to room temperature to obtain Intermediate A;

[0023] 2. Put 300 grams of intermediate A obtained above into a four-necked flask, add a certain amount of aqueous solution, first adjust the pH to 8-9 with triethanolamine, raise the temperature of the reaction solution to 85-90°C, and slowly add it dropwise while stirring 135 g of 1,4-dichlorobutane was incubated and reacted for 3 hours to obtain the final product B.

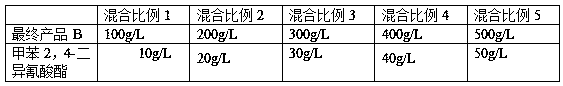

[0024] Application method of a halogen-free and formaldehyde-free nitrogen-phosphorus synergistic system for cotton durable flame retardant (Example 1 final product B: toluene 2,4-diisocyanate)

[0025]

[0026] The product obtained in the above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com