A kind of acid color fixing agent and preparation method thereof

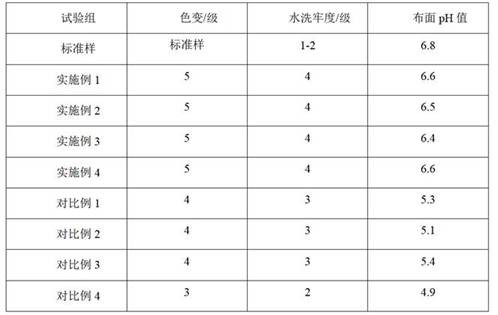

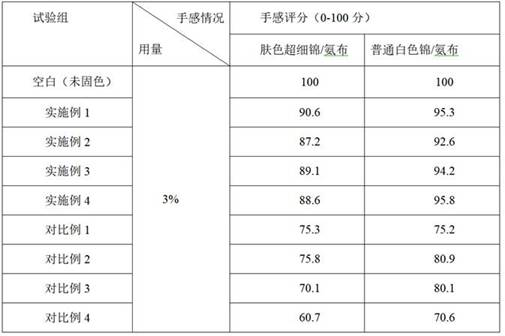

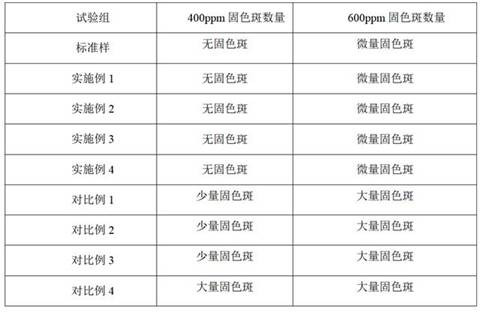

An acid fixative and modified technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of unsustainable fixation effect, decreased color brightness of dyed fabrics, hard fiber feel, etc., to achieve good performance and storage. Stability, good pH control ability, effect of improving washing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this embodiment, the acidic color-fixing agent, in parts by weight, includes the following components: 15 parts of polyethyleneimine, 70 parts of modified polyacrylic acid, 15 parts of sodium citrate, salicylic acid 10 parts of sodium, 3 parts of sodium laureth sulfate, 9 parts of sodium stearate, and 5 parts of sodium phenolsulfonate.

[0042] In this embodiment, the raw materials for the preparation of the modified polyacrylic acid include: 20 parts of methacrylic acid, 3 parts of sodium 2-acrylamido-2 methylpropanesulfonate, 0.07 parts of sodium bisulfite, 0.08 parts of ammonium persulfate, 0.015 parts of azobisisobutylimidazoline hydrochloride, 6 parts of dispersant, 35 parts of ammonium sulfate, and 85 parts of water.

[0043] Preparation of dispersant:

[0044] Selected raw materials: in parts by weight, the raw materials for the preparation of the dispersant include: 6 parts of methacrylic acid, 94 parts of water, and 0.03 parts of azobisisobutylimidazoline ...

Embodiment 2

[0051] In this embodiment, the acidic color-fixing agent, in parts by weight, includes the following components: 10 parts of polyethyleneimine, 60 parts of modified polyacrylic acid, 10 parts of sodium citrate, salicylic acid 5 parts sodium, 1 part sodium laureth sulfate, 2 parts sodium stearate, 1 part sodium phenolsulfonate.

[0052] In this embodiment, the raw materials for the preparation of the modified polyacrylic acid include: 10 parts of methacrylic acid, 1 part of sodium 2-acrylamido-2 methylpropanesulfonate, 0.1 part of sodium bisulfite, 0.1 part of ammonium persulfate, 0.01 part of azobisisobutylimidazoline hydrochloride, 5 parts of dispersant, 30 parts of ammonium sulfate, and 80 parts of water.

[0053] Preparation of dispersant:

[0054] Selected raw materials: in parts by weight, the raw materials for the preparation of the dispersant include: 5 parts of methacrylic acid, 95 parts of water, and 0.02 parts of azobisisobutylimidazoline hydrochloride.

[0055] T...

Embodiment 3

[0061] In this embodiment, the acidic color-fixing agent, in parts by weight, includes the following components: 20 parts of polyethyleneimine, 90 parts of modified polyacrylic acid, 20 parts of sodium citrate, salicylic acid 15 parts of sodium, 5 parts of sodium laureth sulfate, 10 parts of sodium stearate, 6 parts of sodium phenolsulfonate.

[0062] In this embodiment, the raw materials for the preparation of the modified polyacrylic acid include: 30 parts of methacrylic acid, 5 parts of sodium 2-acrylamido-2 methylpropanesulfonate, 0.05 parts of sodium bisulfite, 0.05 parts of ammonium persulfate, 0.02 parts of azobisisobutylimidazoline hydrochloride, 10 parts of dispersant, 40 parts of ammonium sulfate, and 90 parts of water.

[0063] Preparation of dispersant:

[0064] Selected raw materials: in parts by weight, the raw materials for the preparation of the dispersant include: 10 parts of methacrylic acid, 90 parts of water, and 0.05 parts of azobisisobutylimidazoline hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com