Pigment dyeing method for improving leveling property and cloth cover effect

A paint dyeing and cloth surface technology, which is applied in dyeing, textiles and papermaking, enzyme/microbial biochemical treatment, etc., can solve the problems of a large amount of hydropower resources and poor effect, uneven paint anions, waste of time, etc., to reduce The number of washing times, the texture of the cloth surface is clear, and the fabric comfort is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Cotton one-sided fabric dyeing, using overflow dyeing machine, its technological process and formula:

[0025] (1) Pre-processing:

[0026] DM-1155 0.6g / L

[0027] DM-1404 1.0g / L

[0028] Solid NaOH 2.0 g / L

[0029] 30 %H 2 o 2 5.0g / L

[0030] The bath ratio is 1:10, the temperature is raised at 2°C / min, and the temperature is kept at 98°C for 45 minutes. After the tank is drained, it is washed with hot water at 90°C for 10 minutes to neutralize and remove oxygen.

[0031] (2) Neutral cellulase polishing:

[0032] DM-8688 0.3 g / L to adjust the pH to about 6.0, keep warm at 60 ℃ for 60 min, and drain.

[0033] (3) Dust and hair removal:

[0034] 550 2~5 g / L, bath ratio 1:8~10, 80~85 ℃×20 min, washing with water→to be modified.

[0035] (4) Modified pretreatment

[0036] DM-2019 2 g / L, liquor ratio 1:30, add cationic modifier, treat at 70 ℃ for 20 min, wash in cold water, and wait for the next step of paint dyeing.

[0037] (5) Paint dyeing and color fixing

...

Embodiment 2

[0043] Cotton double-sided fabric dyeing, using overflow dyeing machine, its process and formula:

[0044] (1) Pre-processing:

[0045] DM-1155 0.6g / L

[0046] DM-1404 1.0g / L

[0047] Solid NaOH 2.0 g / L

[0048] 30%H 2 o 2 5.0 g / L

[0049] The bath ratio is 1:10, the temperature is raised at 2°C / min, and the temperature is kept at 98°C for 45 minutes. After the tank is drained, it is washed with hot water at 90°C for 10 minutes to neutralize and remove oxygen.

[0050] (2) Neutral cellulase polishing:

[0051] DM-8688 0.3 g / L to adjust the pH to about 6.0, keep warm at 60 ℃ for 60 min, and drain.

[0052] (3) Dust and hair removal:

[0053]550 2~5 g / L, bath ratio 1:8~10, 80~85 ℃×20 min, washing with water→to be modified.

[0054] (4) Modified pretreatment

[0055] DM-2019 2g / L

[0056] The bath ratio is 1:30, add cationic modifier and treat at 70 ℃ for 20 minutes, wash in cold water, and wait for the next step of paint dyeing.

[0057] (5) Paint dyeing and color f...

Embodiment 3

[0062] Garment paint dyeing, using industrial washing machine, its process flow and formula:

[0063] (1) Pre-processing:

[0064] Hot water washing: 1:20, 80 ℃ hot water washing for 5 minutes, dehydration, pending further modification.

[0065] (2) Modified pretreatment

[0066] DM-2019 2g / L

[0067] The bath ratio is 1:30, add cationic modifier and treat at 70 ℃ for 20 minutes, wash in cold water, and wait for the next step of paint dyeing.

[0068] (3) Paint dyeing and color fixing

[0069] Paint black 2.5 g / L

[0070] Paint red 0.2 g / L

[0071] Paint yellow 0.75 g / L

[0072] Binder 3 g / L

[0073] Liquor ratio 1:20, dye the paint at 70 ℃ for 20~30 minutes, add solid slurry DM-5123 in two times, keep warm for 10 minutes, take it out, dry, set the shape, the color is uniform, excellent fastness, soft feel, fabric texture clear.

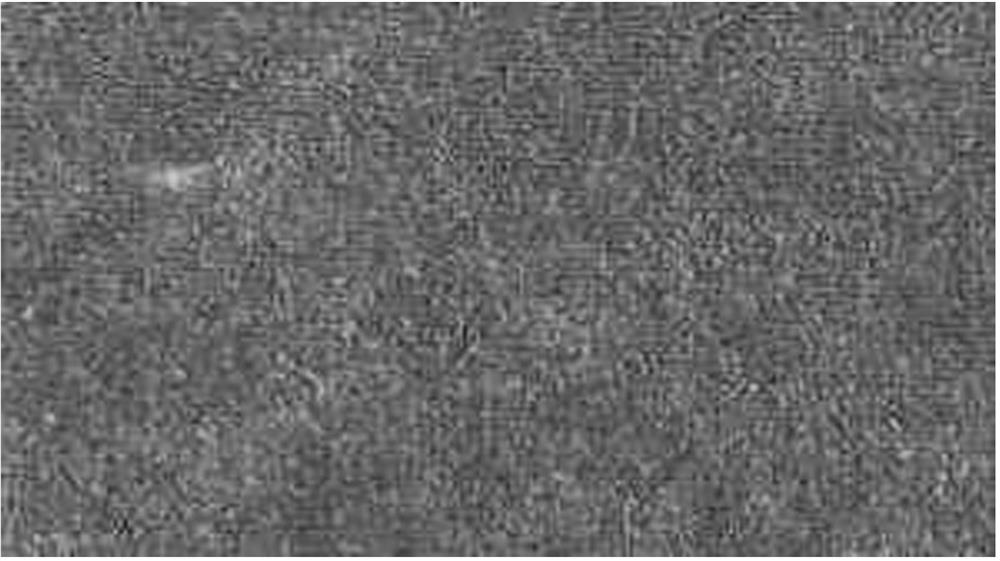

[0074] According to the above-mentioned process, after treatment, the residual liquid, cloth surface effect, rubbing fastness, soaping fast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com