Patents

Literature

92results about How to "Floating less" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

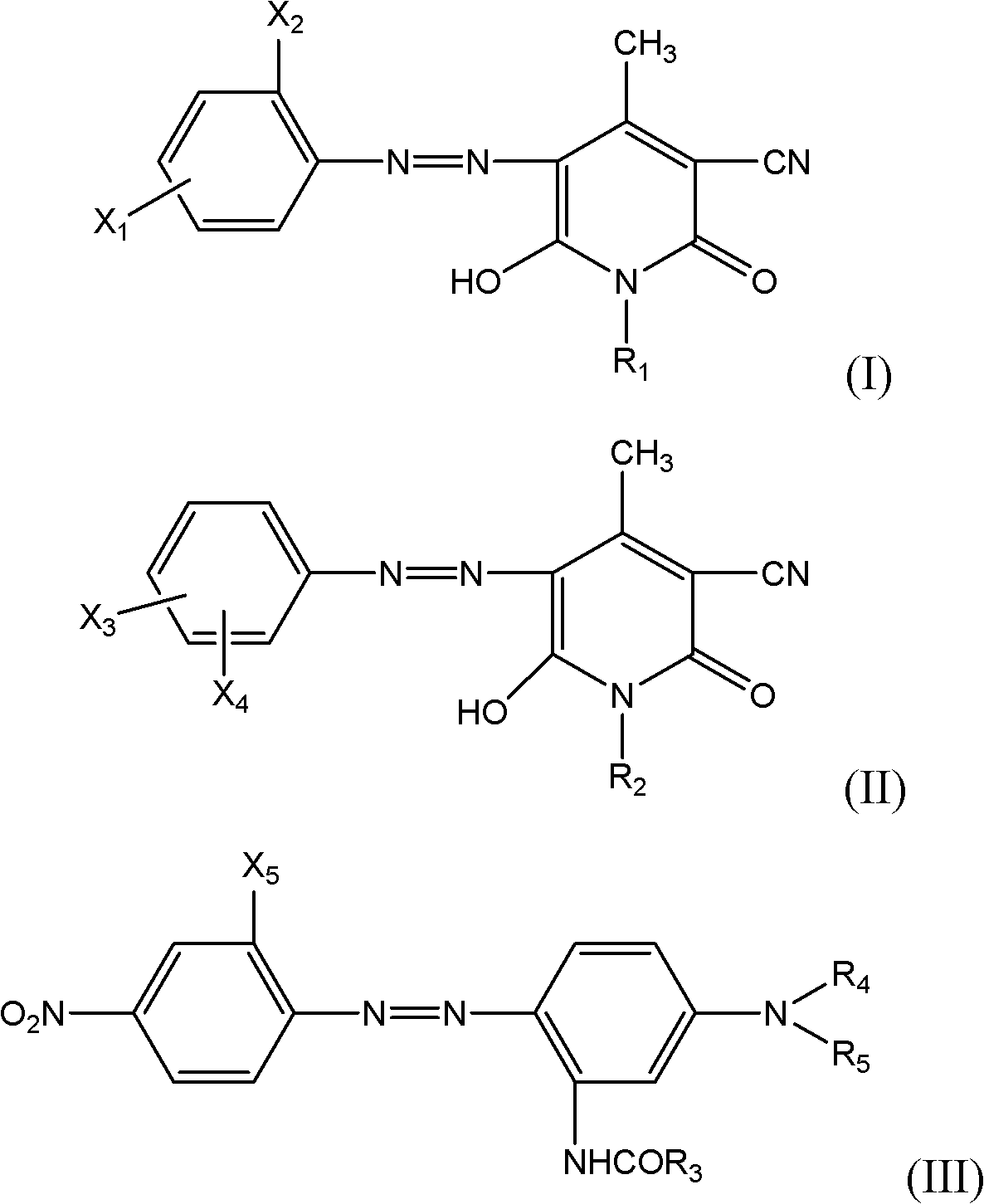

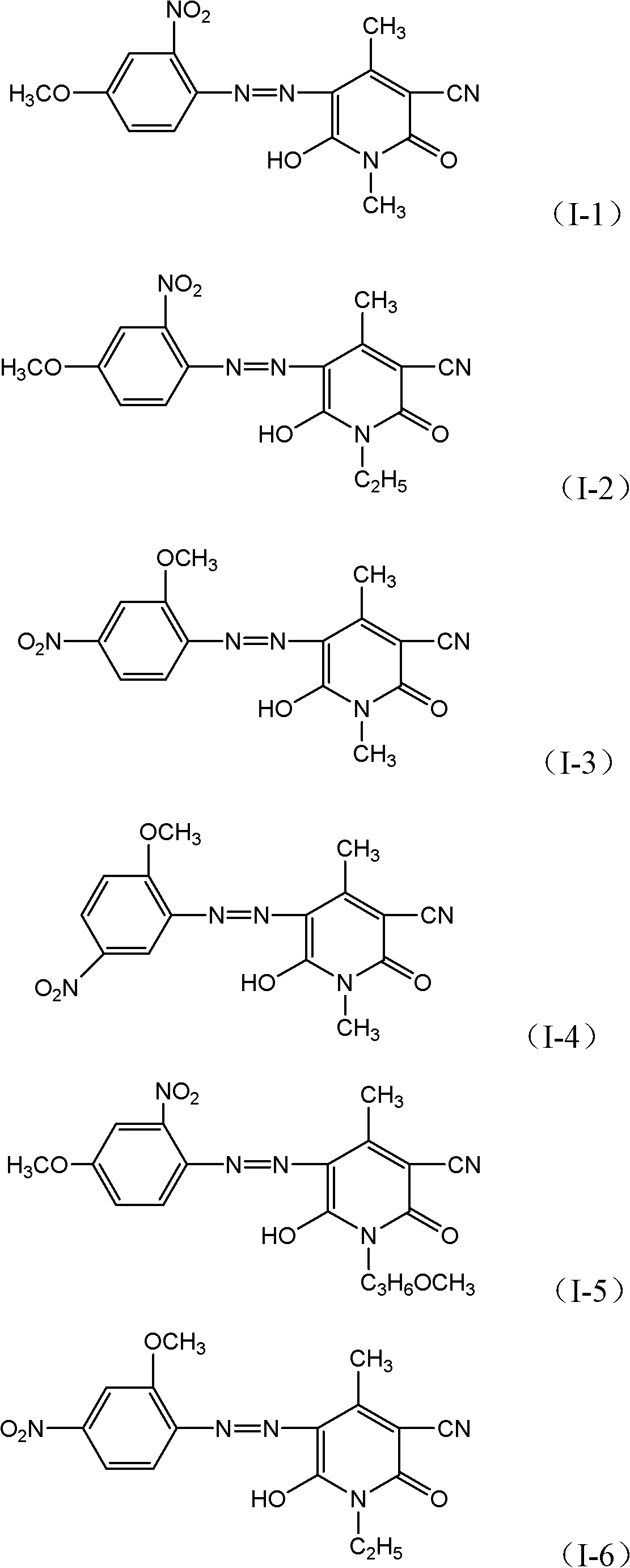

Yellow-to-orange disperse dye composition

ActiveCN101880476ADye residue clearFloating lessOrganic dyesDyeing processDisperse dyePolymer science

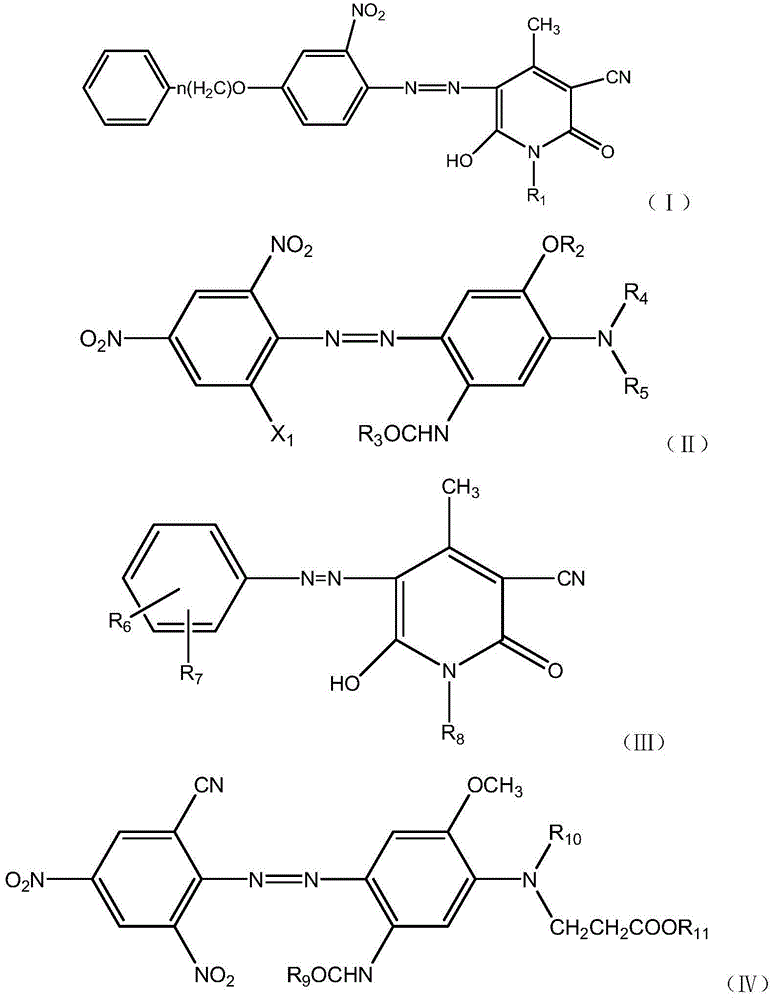

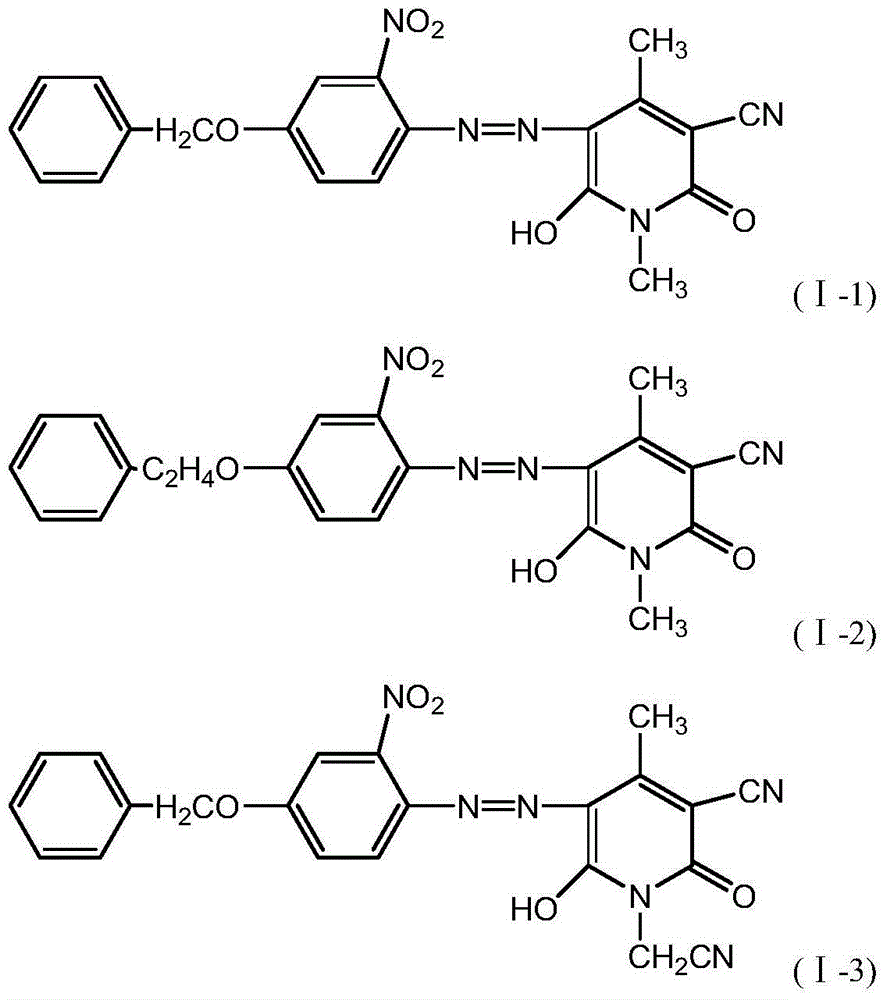

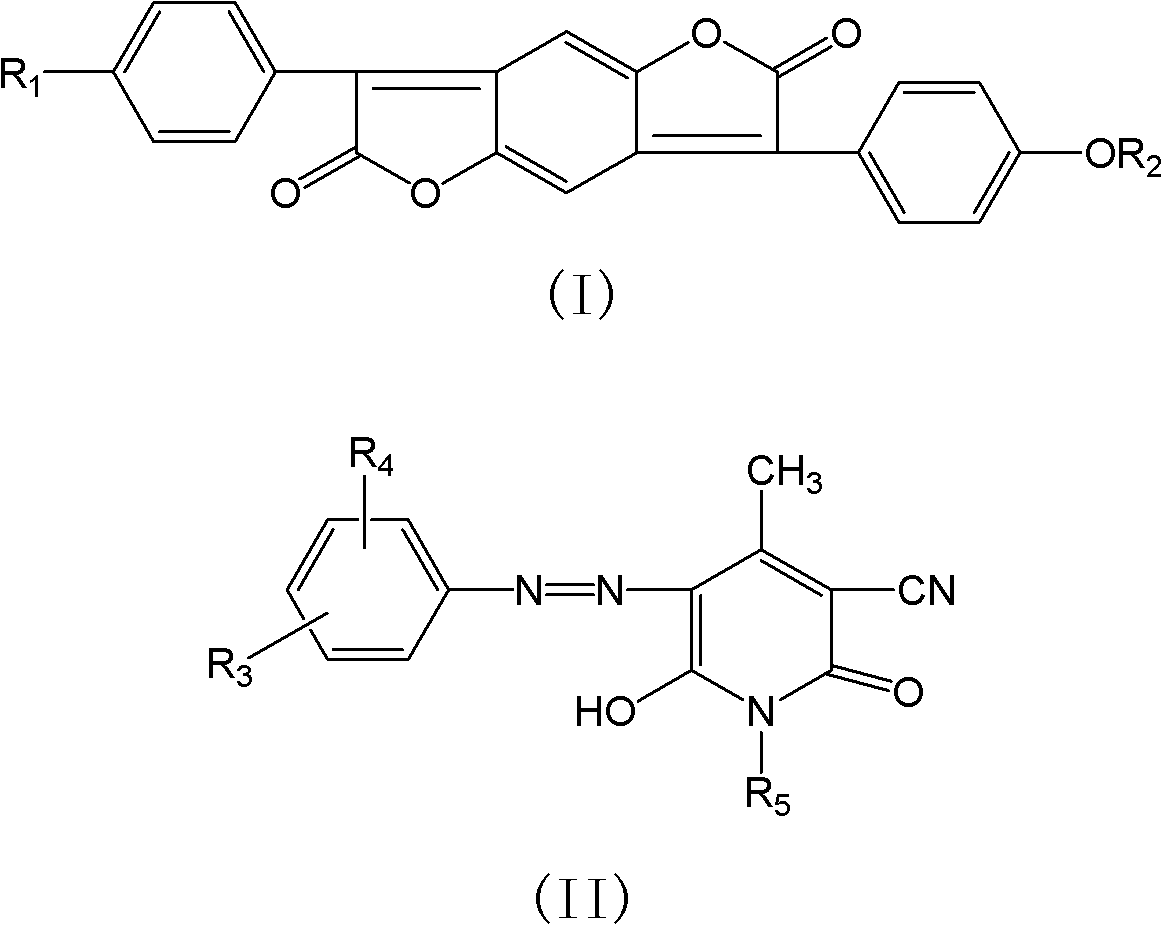

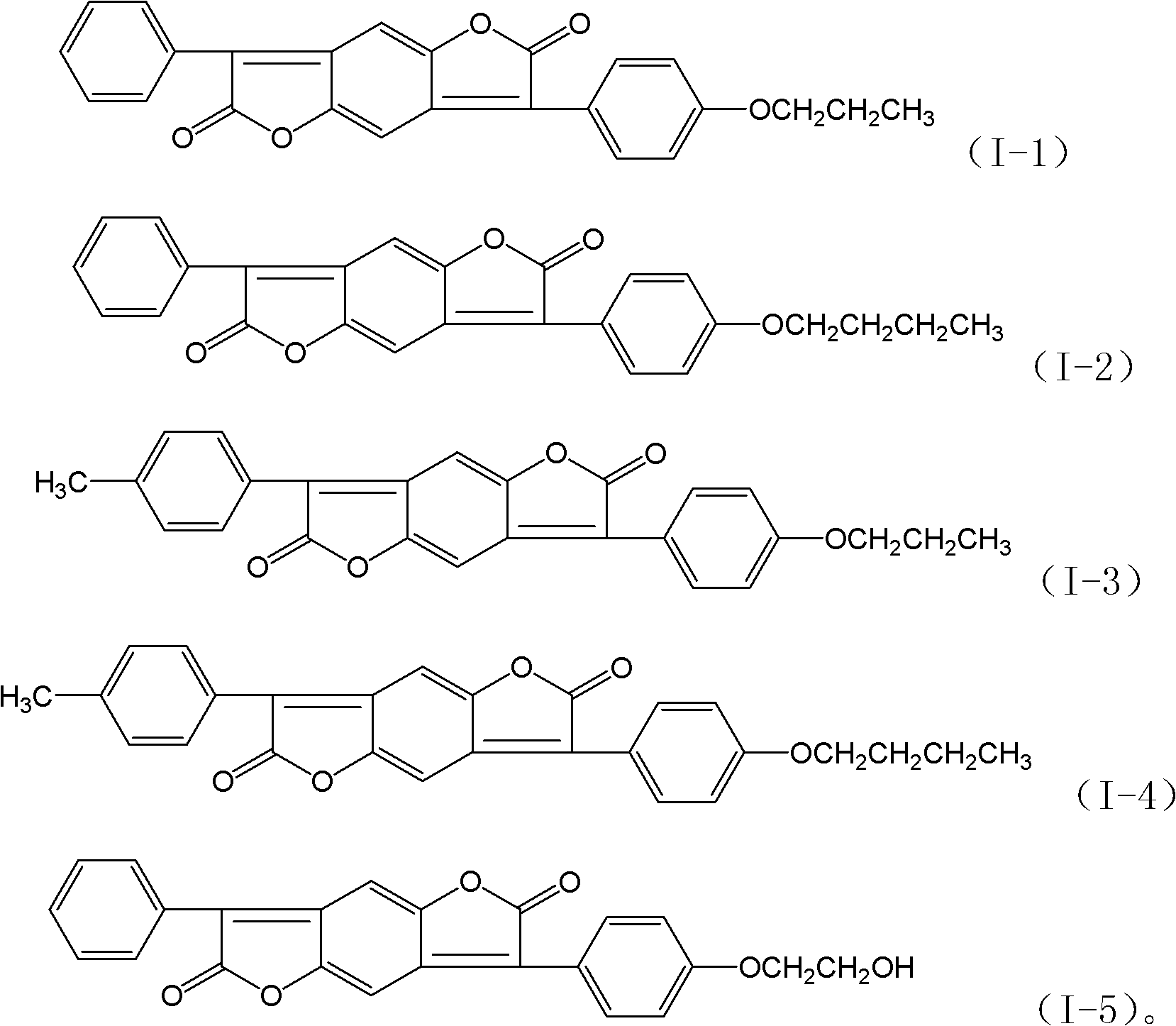

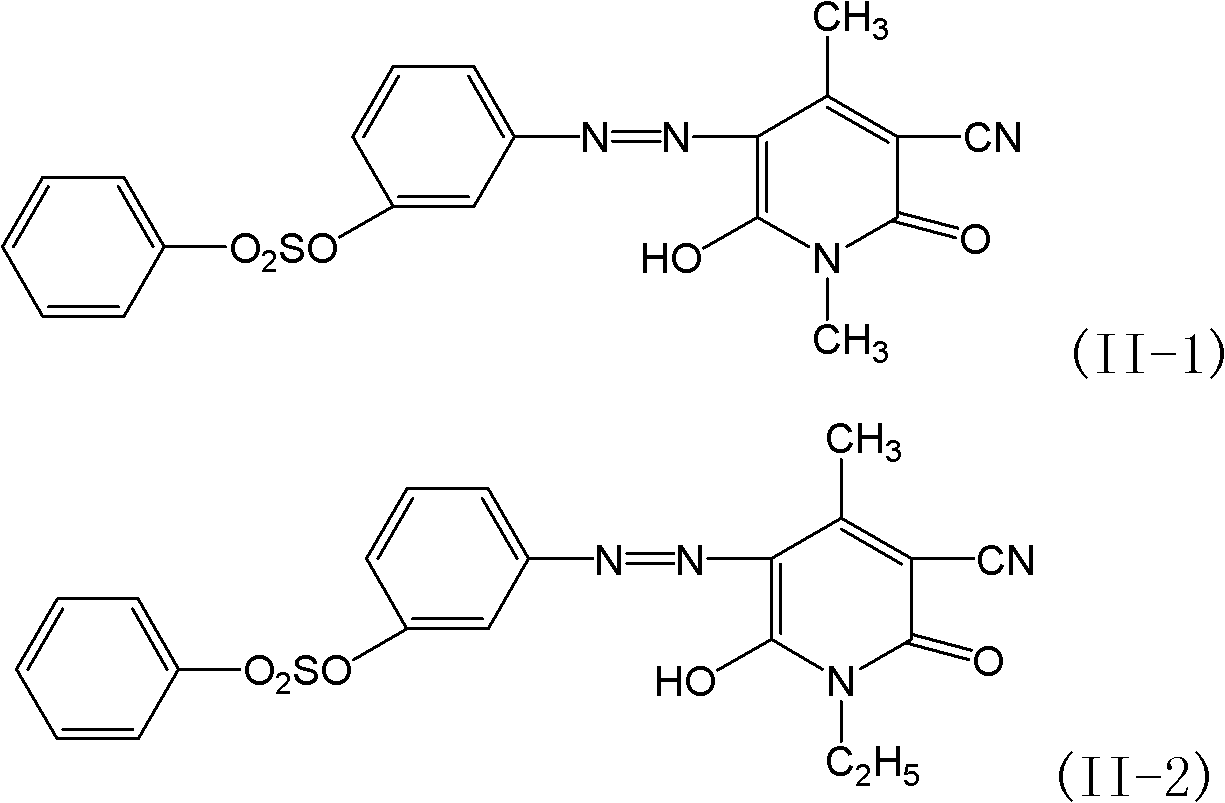

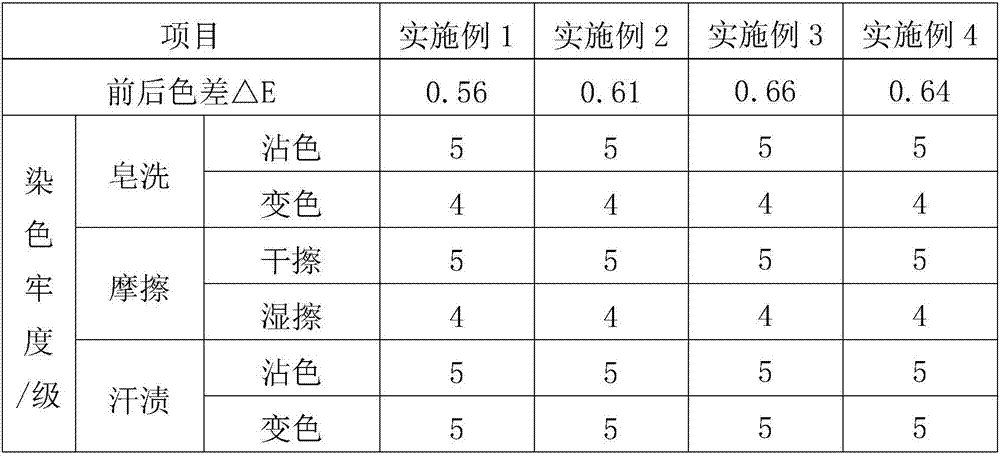

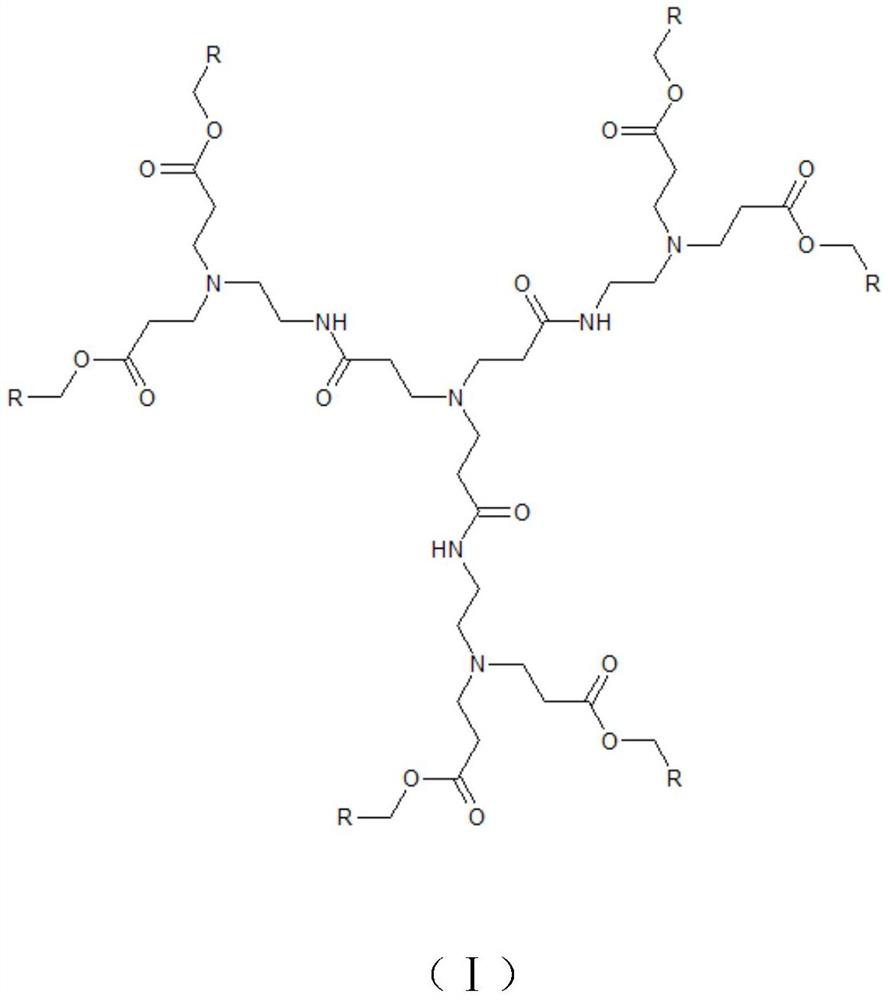

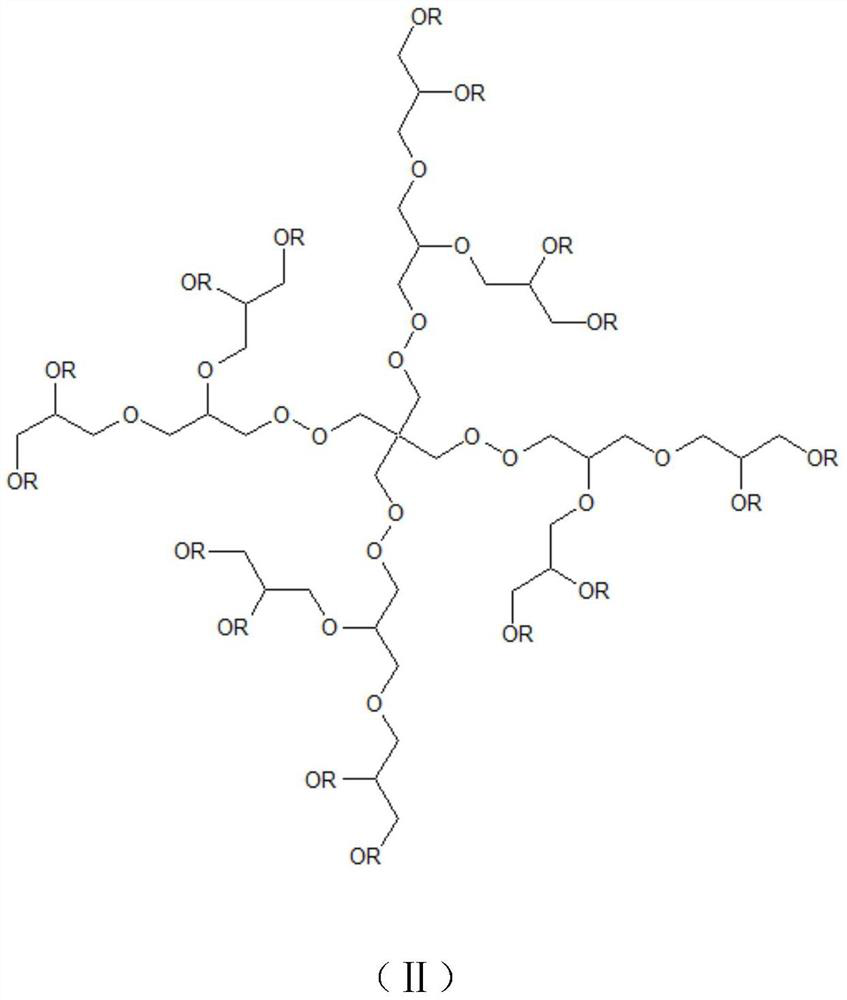

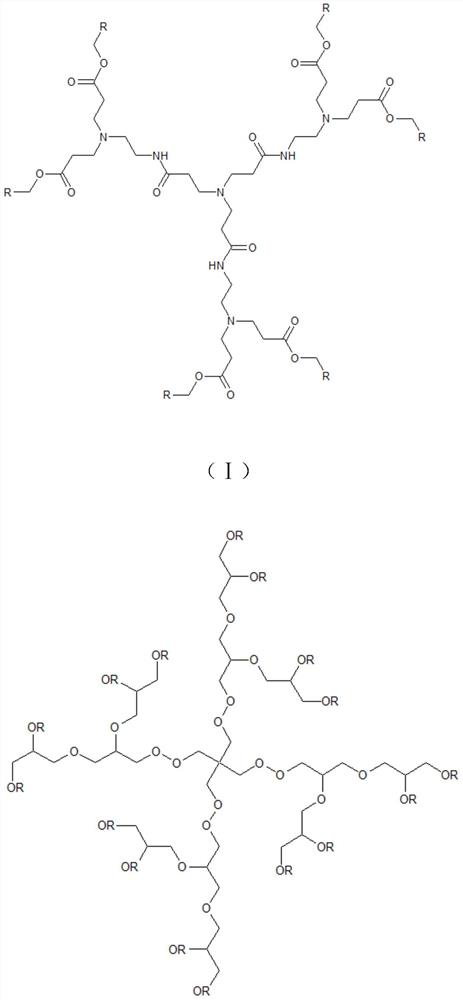

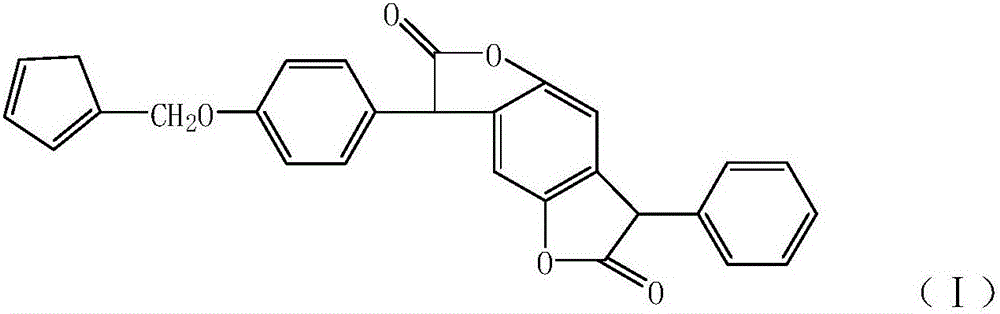

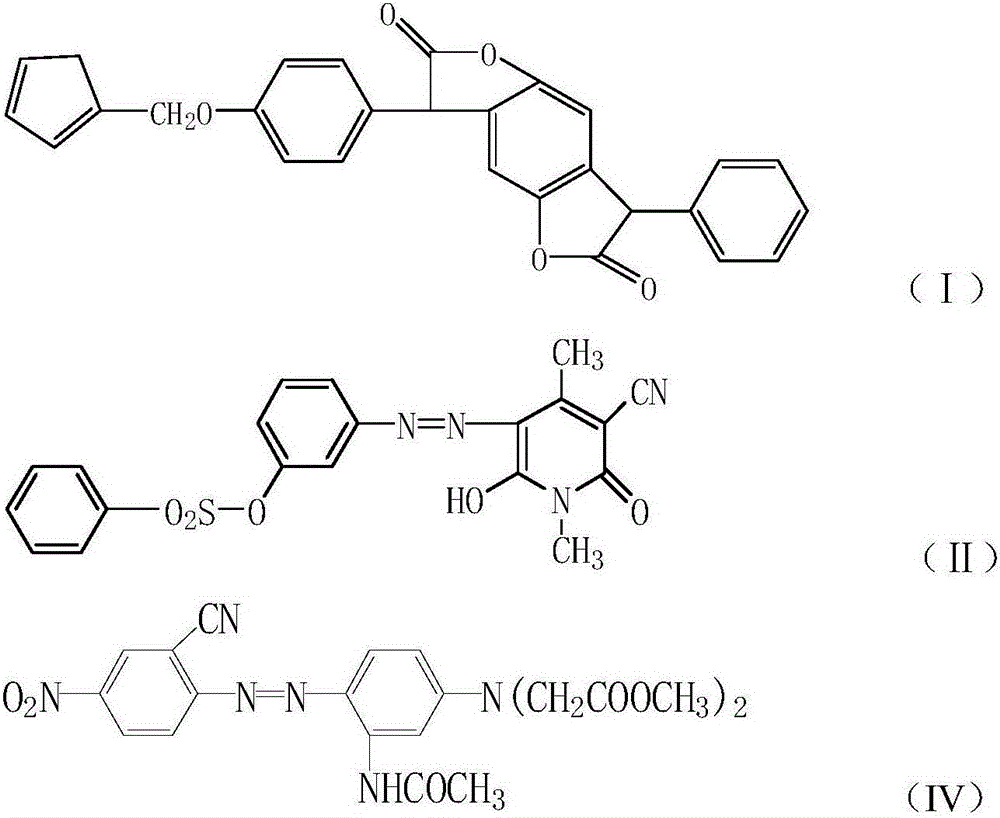

The invention provides a yellow-to-orange disperse dye composition which mainly comprises one or a plurality of components A the structures of which are shown as a formula (I), one or a plurality of components B the structures of which are shown as a formula (II) and one or a plurality of components C the structures of which are shown as a formula (III). Based on the components A, the components B and the components C, the mass percent of the components A is 0.1 to 99 percent, the mass percent of the components B is 0.1 to 99 percent, and the mass percent of the components C is 0 to 60 percent; when the dispersive yellow-to-orange dye is used for dyeing a hydrophobic fibre material, residual dyeing liquid is clear, and scums are little; especially, after high-temperature shaping, very high washing fastness still can be ensured; and the invention effectively solves the problem that the washing fastness of conventional dispersive yellow-to-orange dye is greatly lowered under high-temperature after finishing, and is very suitable for printing and dyeing middle-grade / high-grade fabrics, such as superfine-denier fabrics and blended fabrics of dacron / cotton, dacron / spandex and the like.

Owner:ZHEJIANG LONGSHENG GROUP +2

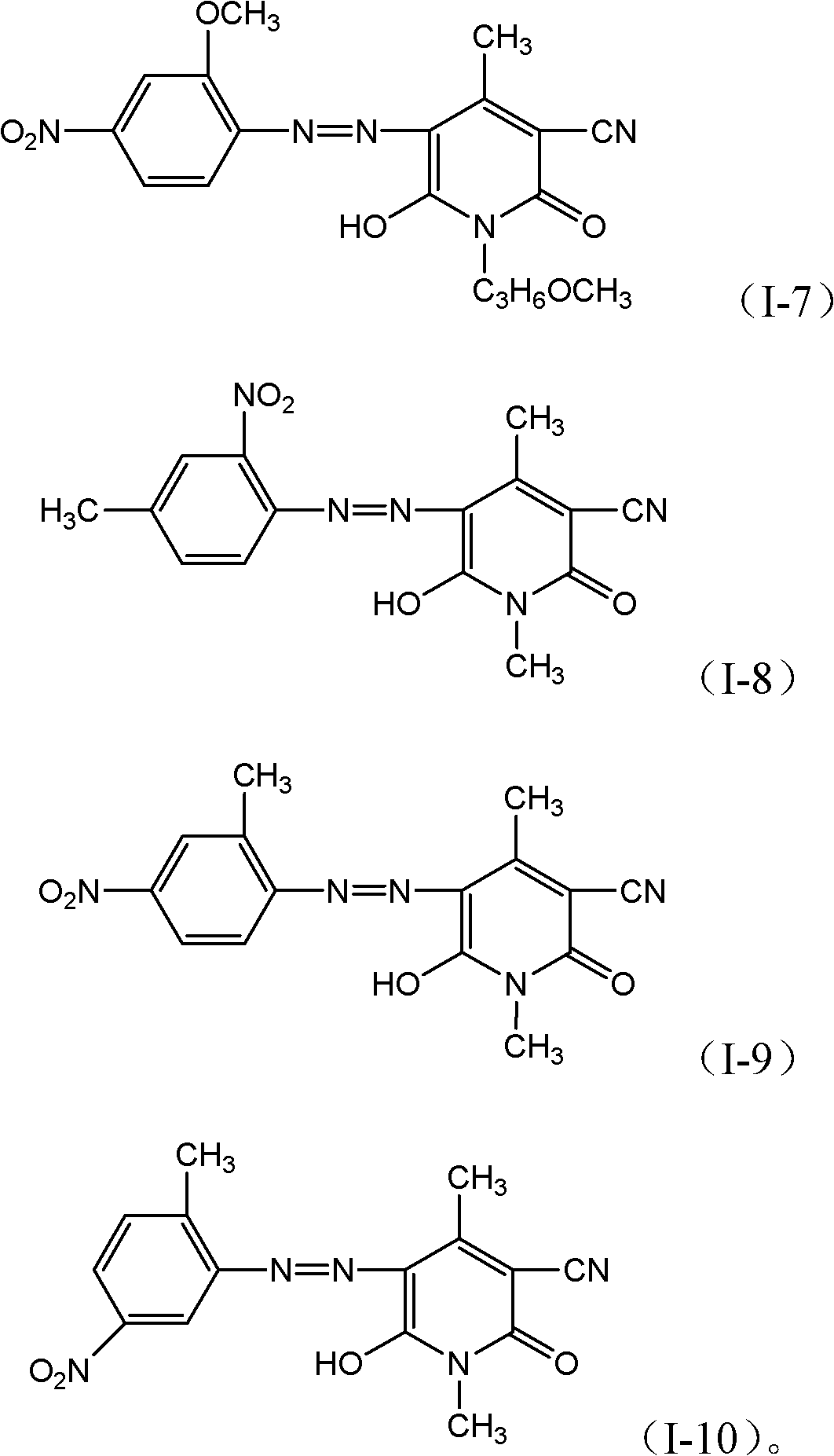

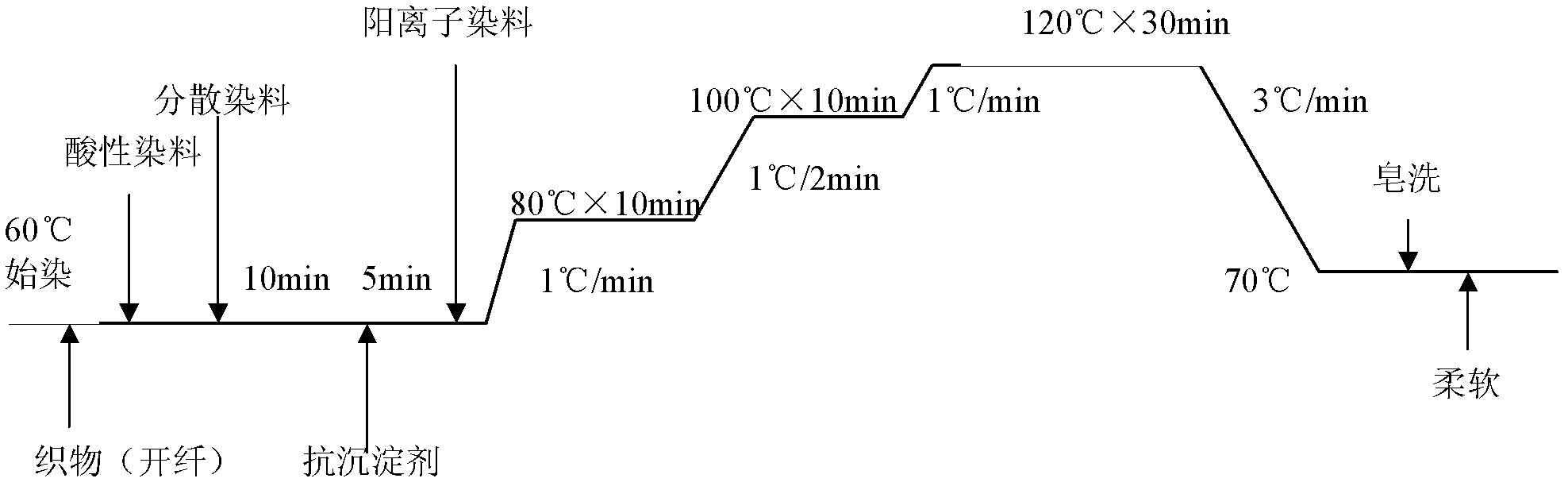

One-bath, multi-color dyeing method for multi-component superfine fibers

The invention relates to a one-bath, multi-color dyeing method for multi-component superfine fibers. At present, the two-bath, two-step method is usually adopted as the dyeing method for multi-component superfine fibers, the flow is long, the production cost is high, a great deal of time and energy are consumed, and the production efficiency is low. Colors are matched according to the coloring laws of dyes and fibers, i.e., with superfine polyester fibers, superfine polyester-cotton compound fibers and cationic dyeable superfine polyester fibers as materials and disperse dye, acid dye and cationic dye as dyes, multi-color schemes are combined and mixed; and by means of the sequential arrangement of feeding, the preparation and usage of anti-setting agent and a multi-stage heating process realizing the separate dyeing of the fibers corresponding to the dyes, the one-bath, multi-color dyeing of the multi-component superfine fibers are realized. The products dyed by the method disclosed by the invention have two or more different colors and good washing fastness and rubbing fastness, and are vivid, the dyeing effect is equal to the dyeing effect of the two-bath method, however, the dyeing process is simplified, and the consumption of chemicals, water and steam is reduced.

Owner:山东恒泰纺织有限公司

High-fastness blue-to-black disperse dye composition and dye product

InactiveCN104559316AGood thermal migration resistanceImprove washing fastnessOrganic dyesDisperse dyeRubbing

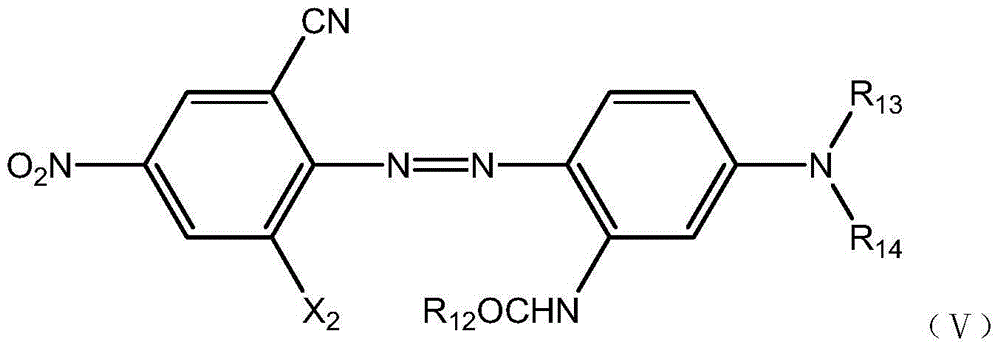

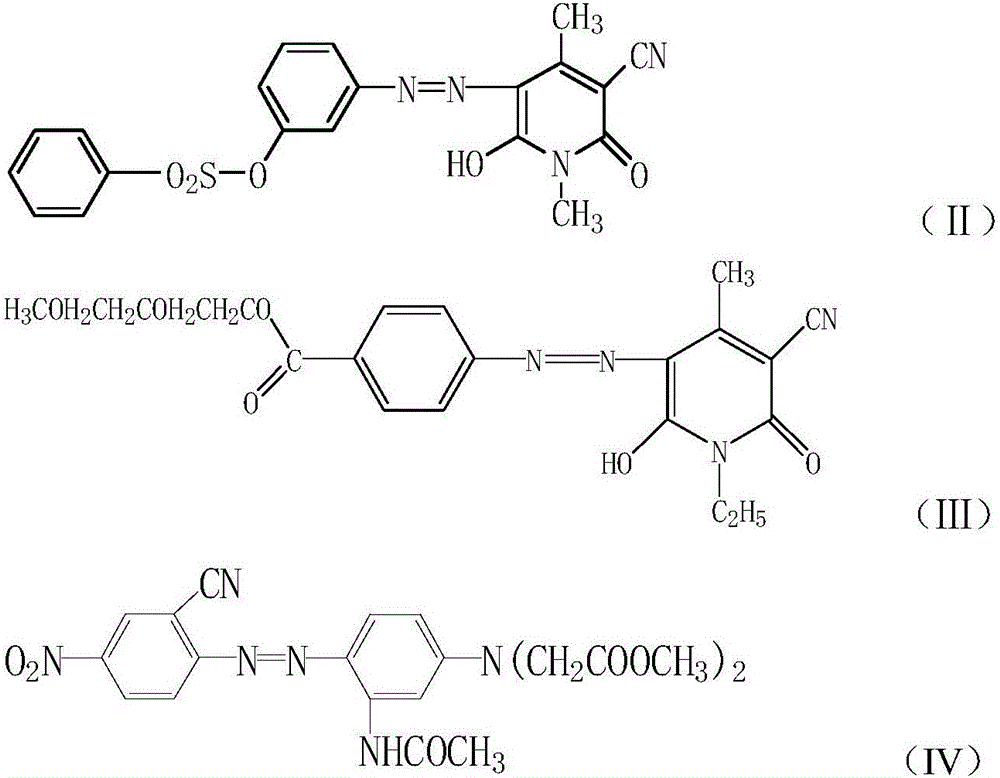

The invention relates to a disperse blue-to-black dye composition and dye product. The composition is mainly composed of a component A, a component B, a component C, a component D and a component E, wherein the component A is selected from one or more of compounds disclosed as Formula (I), the component B is selected from one or more of compounds disclosed as Formula (II), the component C is selected from one or more of compounds disclosed as Formula (III), the component D is selected from one or more of compounds disclosed as Formula (IV), and the component E is selected from one or more of compounds disclosed as Formula (V). The dye product is mainly composed of the composition and assistants. When being used for hydrophobic fiber material dyeing and after-finishing, the dye product has excellent fastness to washing and fastness to rubbing, and is very suitable for printing and dyeing of high-grade textiles.

Owner:ZHEJIANG LONGSHENG GROUP

Disperse red dye composition

ActiveCN101899229AGood thermal migration resistanceImprove washing fastnessOrganic dyesDyeing processPolyesterFiber

The invention provides a disperse red dye composition, which mainly comprises one or more of component A with structure shown as a formula (I) and one or more of component B with structure shown as a formula (II). Based on the component A and the component B, the component A accounts for 40 to 99 percent by weight, and the component B accounts for 1 to 60 percent by weight. When the disperse red dye composition is used for dyeing a hydrophobic fiber material, residual dyeing fluid is clear and has small flooding. By regulating the proportion among different compositions, a red fabric with bright color, good thermal migration resistance and prominent washing fastness can be obtained, in particular, higher washing fastness can still be ensured after high-temperature setting, and the problemthat the washing fastness of the conventional disperse red dye is greatly reduced after high temperature finishing is effectively solved. The disperse red dye composition is suitable for dyeing medium-high fabrics, such as superfine fabrics, polyester / cotton, polyester / ammonia and other blending fabrics.

Owner:ZHEJIANG LONGSHENG GROUP +2

Preparation method of liquid plant dye

The invention discloses a preparation method of a liquid plant dye, comprising the following steps of: firstly selecting plant materials, crushing, then adding fermenting strain and alcohol solution for fermentation, extracting the obtained solution, reducing pressure, concentrating, distilling, preparing dye concentrated solution, adding an auxiliary agent in the dye concentrated solution and preparing liquid dye. The invention has rich resource of utilized plants and simple preparation method, and does not cause pollution of chemical synthetic dye to the environment in the preparation process; the prepared dye has natural and elegant color, does not have hazardous effect on human body, is applied to clean production in the textile industry and can be produced in large scale; and based on the traditional process, the invention adopts modern means and improves the extraction process so as to facilitate the storage and transportation.

Owner:WUYI UNIV

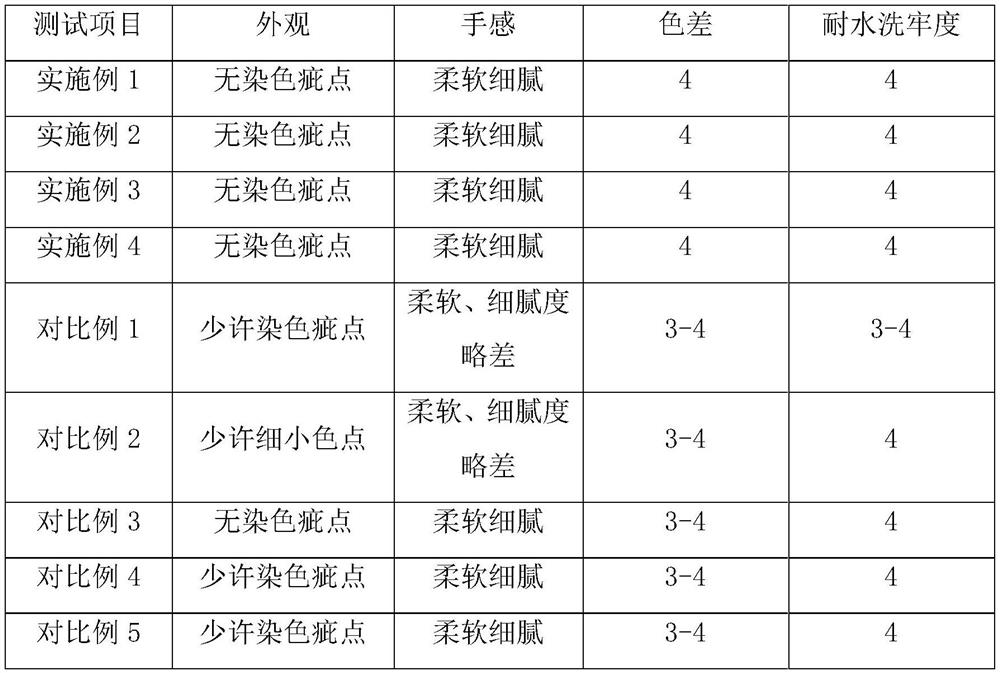

Dyeing and finishing process for polyester interweaved fabric

ActiveCN107059384AGood removal effectHigh whitenessHeat resistant fibresBiochemical treatment with enzymes/microorganismsPhenolsPh buffering

The invention discloses a dyeing and finishing process for polyester interweaved fabric. The dyeing and finishing process comprises the following steps: S1) pre-treating: performing scouring and bleaching and enzyme washing treatment on the polyester interweaved fabric in turn; S2) pre-shaping: performing pre-shaping treatment on the polyester interweaved fabric; S3) dyeing: soaking the polyester interweaved fabric into a dye liquor at a liquor ratio of 1:(10-30), wherein the dye liquor comprises 1-3% of reactive dyes, 2-5% of rare-earth complex micro-encapsulation disperse dyes, 5-15g / L anhydrous sodium sulphate, 1.5-3.5g / L pH buffering agent, 0.1-0.3g / L organic phenol halide and 0.01-0.05g / L organic fluorinated surfactant; and S4) finishing: performing softening and flame-proof treatment on the fabric in turn. The dyeing and finishing process for polyester interweaved fabric, disclosed by the invention, not only can obviously improve the performances, such as, hand feel and elasticity, of the fabric but also can achieve the effects of uniform dyeing, high color fastness and abundant color and luster.

Owner:宣城加特林机械有限公司

Polyester fiber DTY (draw textured yarn) with high dyeing rate and preparation method thereof

ActiveCN104499082AImprove dye uptakeGood flexibilityNew-spun product collectionMelt spinning methodsYarnPolyester

The invention relates to a polyester fiber DTY (draw textured yarn) with high dyeing rate and a preparation method thereof. The polyester fiber polyester fiber DTY with high dyeing rate is made from modified polyester, the modified polyester is composed of polyester and aminoadipic acid gylcol ester, the aminoadipic acid gylcol ester is dispersed among molecular chains of the polyester, hydrogen-bond interaction exists between the aminoadipic acid gylcol ester and the molecular chains of the polyester, and the relative position of the aminoadipic acid gylcol ester and the molecular chains of the polyester is fixed; the free volume space among the molecular chains inside the fiber is increased by 20-30v / v% when the polyester fiber DTY with high dyeing rate is at 90-130 DEG C, the dying rate of the polyester fiber DTY with high dyeing rate is higher than that of the common fiber when the polyester fiber DTY with high dyeing rate adopts the same dyes such as disperse red 3B, disperse blue SE-2R, disperse bright blue S-GL and the like, less surface dyeing is formed after dyeing, and the polyester fiber DTY with high dyeing rate can be used for garment materials, bedding article decoration and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Multi-color roller gravure printing production method of textile dye

ActiveCN102785495AExtended door widthShorten the printing processDuplicating/marking methodsOther printing apparatusFiberWastewater

The invention relates to a multi-color roller gravure printing production method of a textile dye. According to the traditional printing method, more floating colors exist in the washing process, and the excessive wastewater discharge is easily caused. The invention comprises the following steps that: (1) pre-treatment working solutions are selected according to textiles of different types of fibers; (2) the pre-treatment working solutions of different concentrations are padded under the conditions that the immersion time is 5-30 seconds, the expression is between 50% and 100% and the speed is 10 to 40m / min, and are dried; (3) a special dye ink for gravure printing is selected; (4) through an improved multi-color roller gravure printing machine with adjustable printing thickness, lengthened width, enhanced drying and the like, the special dye ink is printed to the textile which is padded with the pre-treatment working solutions and is dried at a speed of 10-40 m / min and is dried; (5) the printed textile enters steaming equipment for steaming fixation; and (6) after fixation, the printed textile is subjected to washing, drying and other treatment processes to complete the entire printing production process of the textile.

Owner:ZHEJIANG YIDE CHEM

Supercritical carbon dioxide dyeing technology for low-temperature-plasma pretreatment of aramid fiber/viscose glue blended fabric

InactiveCN104278567AShort dyeing timeShorten the production cyclePhysical treatmentDyeing processPre treatmentDyeing

The invention relates to a supercritical carbon dioxide dyeing technology for low-temperature-plasma pretreatment of aramid fiber / viscose glue blended fabric. The technology employs supercritical CO2 as a medium to dye fabric, and is a novel waterless dyeing technology. Compared with conventional dyeing methods, the technology has the advantages of water saving, environment protection, energy saving, dispensing with auxiliary agents and the like, is short in dyeing time, and is capable of shortening production period and improving economic benefit.

Owner:WUXI XINGLIN DYEING ENVIRONMENTAL PROTECTION EQUIP

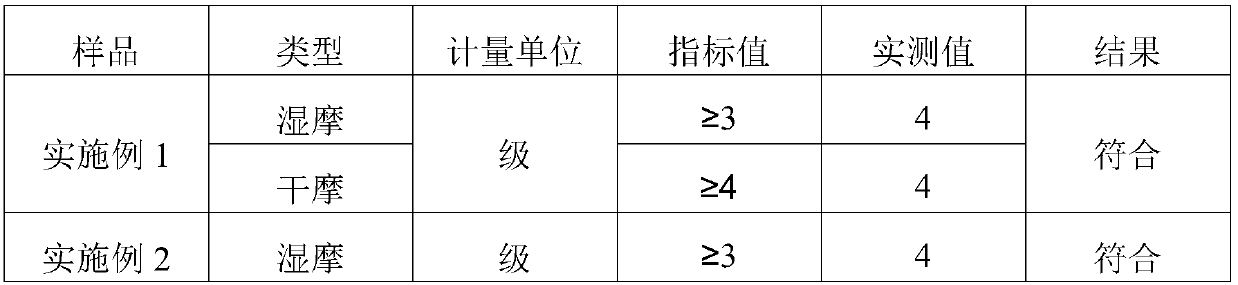

Process method for improving woven dark cloth wet rubbing fastness

ActiveCN107916518AImprove wet rubbing fastnessTightly bondedTextile storage in superimposed formLiquid/gas/vapor open-width material treatmentSurface finishProduct inspection

The invention discloses a process method, and particularly relates to a process method for improving woven dark cloth wet rubbing fastness. The process method includes the steps: (1) cloth distribution; singeing, cooling reaction and desizing; scouring and bleaching; mercerizing; pad dyeing or jig dyeing; wet rubbing fastness improver and auxiliary selection and preparation; wet rubbing fastness improver finishing; over-soft sizing; pre-shrinking; finished product inspection. According to the process method for improving the woven dark cloth wet rubbing fastness, production processes of all procedures are controlled, the capillary effect of a fabric is effectively improved, the surface finish degree of the fabric is improved, friction resistance is reduced, surface dyeing is decreased by strengthening soaping and washing after dyeing, wet rubbing fastness improvers of waterborne polyurethane complexes (Jiangxi Luxi County Xianghua Fine Chemical Co., Ltd., similarly hereinafter) are added after dyeing, under the assistant effects of assistant stabilizers 203 and cracking agents 109, the process method effectively solves the problem that oil floating points are generated in continuous production for 2000 meters or more when single wet rubbing fastness improvers are added in the past, the wet rubbing fastness of dark dyed cloth is improved by one level or more, corresponding washing fastness is improved, pH (potential of hydrogen) values meet requirements, continuous production and product quality are ensured, and a cloth surface has a certain color-deepening effect and softening effect, so that customer satisfaction is achieved.

Owner:佛山市顺德金纺集团有限公司

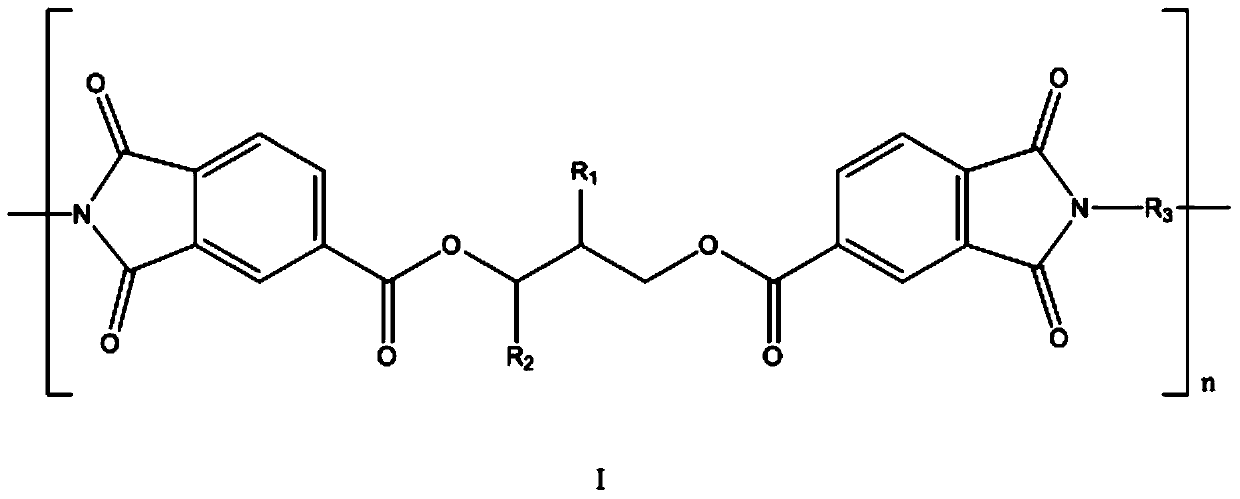

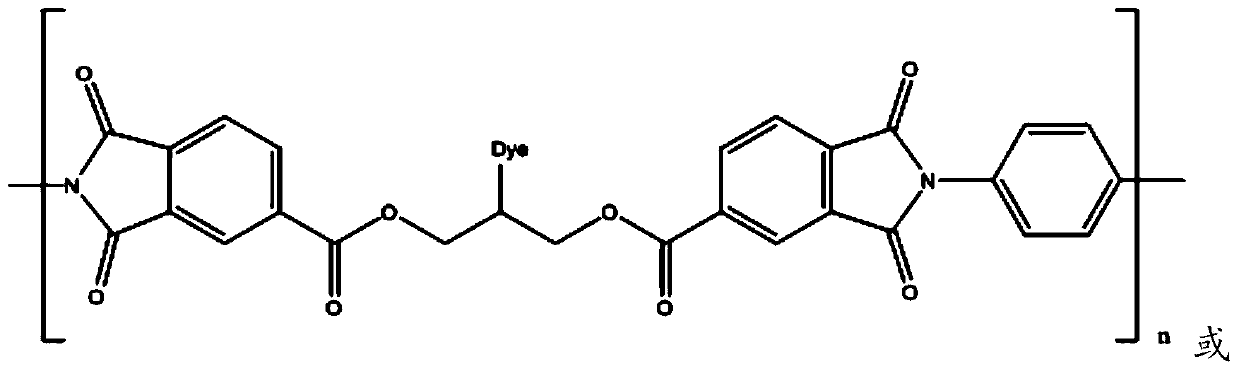

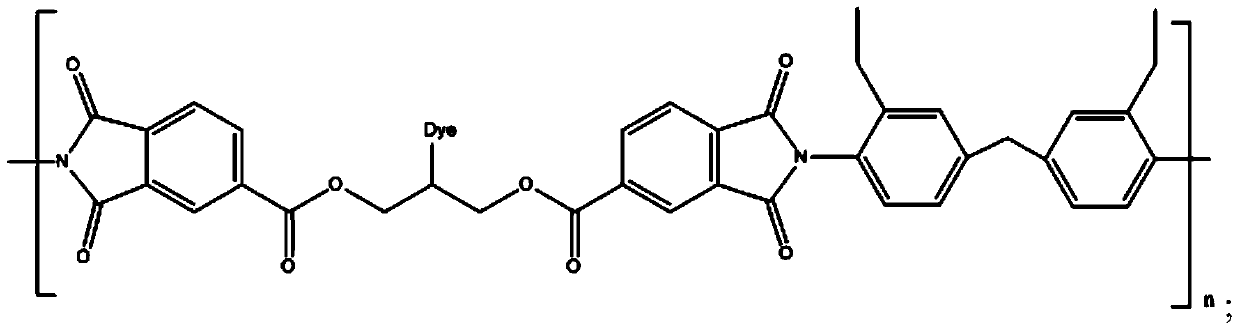

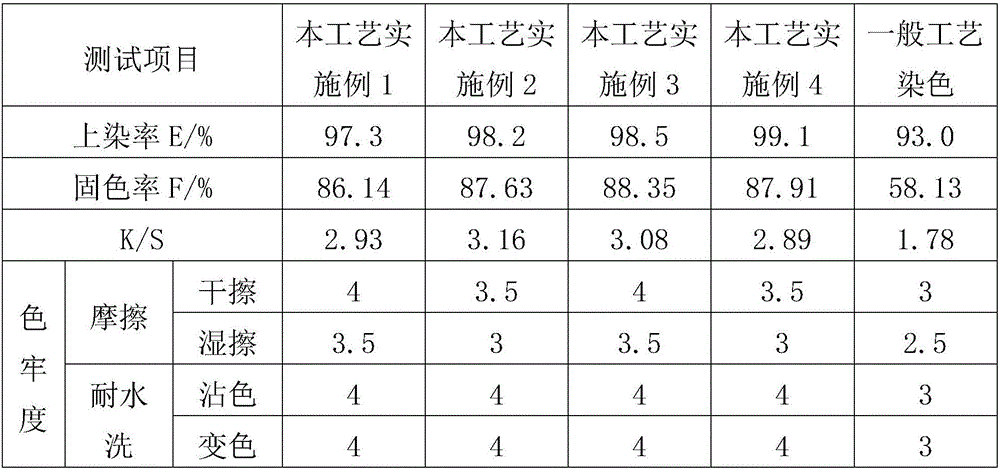

Polymer dye, photoresist composition and preparation method and application of photoresist composition

The invention relates to the technical field of display and in particular relates to a polymer dye and a preparation method thereof, a photoresist composition and a preparation method thereof as well as application of the photoresist composition in color resist, a color film substrate and a display device. The structural formula of the polymer dye is shown in a formula I, wherein R1 refers to a dye group containing aromatic hydroxyl or aromatic amido, and R2 refers to a hydrogen atom, or R2 refers to a dye group containing aromatic hydroxyl or aromatic amido, and R1 refers to a hydrogen atom; R3 is aryl; n ranges from 5 to 100. Because the dissolubility of the polymer dye of large molecular weight is lower than the dissolubility of a pure dye molecule, the polymer dye is difficultly dissolved out again, surface dyeing is further avoided, and the display quality of the display is improved. The structural formula is as shown in the specification.

Owner:BOE TECH GRP CO LTD

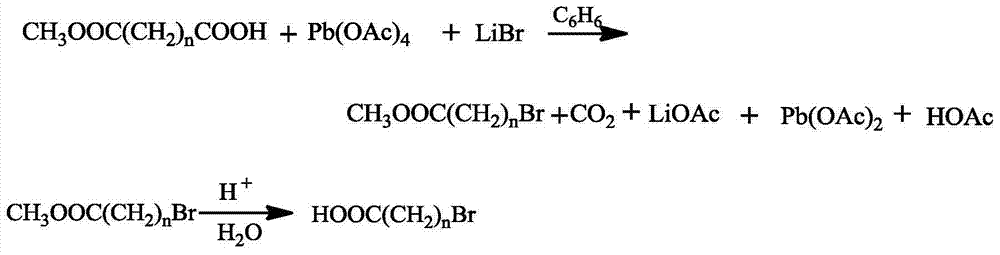

Pure cotton fabric dyeing assistant and preparation method thereof

InactiveCN105463885AReduces floating color after dyeingReduce soaping and washing burdenDyeing processChemistrySodium carboxymethylcellulose

The invention discloses a pure cotton fabric dyeing assistant and a preparation method thereof, relating to the technical field of dyeing assistants. The pure cotton fabric dyeing assistant is prepared from the following raw materials in parts by weight: 15-20 parts of attapulgite, 12-17 parts of charcoal ash, 10-15 parts of sodium carboxymethylcellulose, 10-15 parts of alkyl glycoside, 8-12 parts of rosin, 6-10 parts of rice bran wax, 6-10 parts of di-octadecyl dimethyl ammonium chloride, 5-8 parts of ethylenediaminetetraacetic acid disodium salt, 5-8 parts of nanometer bentonite, 4-6 parts of antibacterial agent, 3-5 parts of sodium citrate, 2-3 parts of rare earth, 2-3 parts of nanometer aluminium oxide, 1-2 parts of magnesium stearate, 7-13 parts of triethanolamine and 100-150 parts of water. The dyeing assistant can effectively reduce surface dyeing after dyeing, reduce the burden of soaping and washing, and improve the dye-uptake and colour fastness of an activated dye, fully plays a role in assisting dyeing, and thus improves the color and lustre, appearance quality and handfeel softness of a pure cotton fabric; besides, the use amount of the activated dye can be effectively reduced, and wastewater discharge and processing cost are reduced.

Owner:安徽三宝棉纺针织投资有限公司

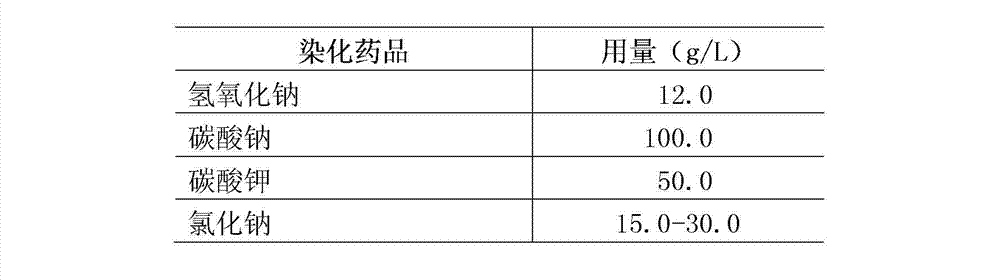

Dyeing process for dyeing different colors for blended fabric in one dyeing bath by using reactive dyes used for cotton

The invention relates to a dyeing process for dyeing different colors for blended fabric in one dyeing bath by using reactive dyes used for cotton, which uses the principle that, aiming at the reactive dyes used for cotton, different fibers of the blended fabric have different dyeing rates in the same dyeing bath, thereby generating different color effects. Under the condition of room temperature,by the steps of adding a leveling agent, adding reactive dyes used for cotton, selecting samples, adding Glauber's salt, and increasing the temperature and adding soda for fixation, and by adopting the reasonable blending scheme, time intervals and temperature setting, the dyes form stable chemical bonds on different materials of the blended fabric for fixation, and the use of the soda improves the leveling property, the reproducibility and the dye yield of dyeing, thus the fabric achieves excellent effects. The method has simple processes, reduces the consumption of energy sources and the discharge amount of waste water, is favorable for environment protection, has vivid dyed color, less loose color and good fastness, and saves the production cost.

Owner:ZHEJIANG GRACE TOWEL

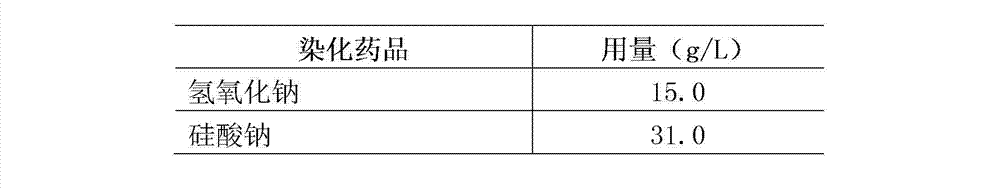

Process for cotton reactive dye applying in silk broadcloth dying

The invention relates to a technique for dyeing silk fabrics by a cotton reactive dye. The technical problem to be solved is that the technique needs to dye silk fabrics by the cotton reactive dye effectively, has the characteristics that the dye uptake is high, the fixation ratio is high, the color depth of the product is increased greatly, the coloring matter is saved and the dyeing quality is high; moreover, the residual liquid discharge concentration is decreased and the environment is protected. The technical proposal is to adopt the cotton reactive dye for dyeing silk fabrics and has the following steps that: 1) the silk broadcloth after the pre-treatment is placed into a dye vat, a dye solution is prepared and is added into the dye vat to dye, the dye solution has a pH value ranging from 6.5 to 7.5, the dye temperature ranges from 85 to 98 DEG C, the dye time lasts one to two hours; 2) the dye residual solution is discharge partially or completely, clear water is added, the temperature is adjusted to 50 to 60 DEG C; 3) certain amount of ammonium polycarylate is added to fix the color, the pH value is kept to be 9 to 10, the fixation time lasts one to two hours, the temperature of the clear water ranges from 4 to 20 DEG C.

Owner:HIGH FASHION CHINA CO LTD

Double-temperature dyeing method of chloro-s-triazine and vinyl sulfone double-active group active dye

The invention discloses a double temperature dyeing method for a reactive dye with double active groups of monochlorotriazine and vinyl sulfone. The formulas of the double temperature dyeing method are as follows respectively: 0.01 to 10 percent of M or B type reactive dye (the weight relative to that of fabrics or yarns), 10 to 100g / L of glauber salt or common salt, and 2 to 30g / L of calcined soda, wherein the bath ratio is between 1 to 6 and 1 to 15; or 0.01 to 10 percent of M or B type reactive dye, 10 to 100g / L of glauber salt or common salt, and 2 to 4g / L of base substituent 310-F, wherein the bath ratio is between 1 to 6 and 1 to 15; or 0.01 to 10 percent of M or B type reactive dye, 10 to 100g / L of glauber salt or common salt, 1 to 2g / L of base stabilizer 310, and 0.8 to 2g / L of sodium hudroxide, wherein the bath ratio is between 1 to 6 and 1 to 15. The dying process is as follows: cotton, hemp or an adhesive fabric, double temperature dyeing, soaping, and finishing. The utilization rate of the dye is improved by between 2 and 5 percent; the using amount of an alkaline agent can save 20 to 30 percent; and after the dyeing, the stage temperature is increased, the desorption rate of the hydrolised dye is increased, the loose color on fiber is reduced, and the water scrubbing is reduced after the soaping. The method reduces the drainage of sewage, and is favorable to the environmental protection.

Owner:ZHEJIANG SCI-TECH UNIV

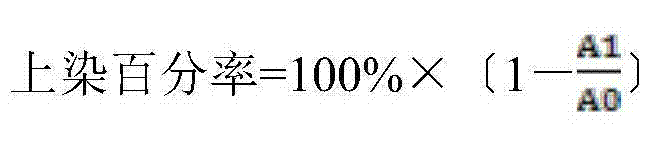

Dyeing method of reactive dye with high color fixation rate

ActiveCN106192470AImprove dye uptakeHigh color fixing rateDyeing processPhotochemistryChemical substance

The invention discloses a dyeing method of a reactive dye with a high color fixation rate. The dyeing method comprises the following steps: S1, pretreatment: padding a texture to be dyed in a finishing solution containing chitosan quaternary ammonium salt, dipping for two times, rolling for two times, prebaking at the temperature of 80 to 100DEG C, baking at the temperature of 110 to 130DEG C, washing with cold water and then drying; S2, reactive dyeing: immersing into a dyeing solution of the reactive dye, dyeing at the temperature of 20 to 30DEG C, raising the temperature to be 50 to 70DEG C, then adding an organic solvent B, and raising the temperature to be 80 to 100DEG C; adding sodium carbonate according to the volume of the dyeing solution of the reactive dye, insulating heat and reducing to room temperature; S3, performing after treatment, water washing, soaping, water washing and drying in air. The dyeing method of the reactive dye with the high color fixation rate, provided by the invention, has the advantages of high color fixation rate and good level-dyeing property; in addition, the process is simple, and industrial implementation is easily realized; meanwhile, chemical substances with high price and greater toxicity are prevented from being used.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

High-fixation-rate nano liquid disperse dye as well as preparation method and application thereof

InactiveCN112126247AUniform and stable dispersionDispersion system is stableOrganic dyesDyeing processDisperse dyeTextile printer

The invention discloses a preparation method of a high-fixation-rate nano liquid disperse dye. The method comprises the following steps of: mixing a grinding aid with a certain amount of deionized water to fully swell the grinding aid; adding a disperse dye, propylene glycol, a basic dispersing agent and a wetting agent, carrying out pre-grinding; and adding the residual deionized water; adding ahyperbranched dispersant into the ground system, and perform further grinding; carrying out suction filtration by using a filter screen; adding an anti-flocculating agent and a preservative into a filtrate; and carrying out high-speed shearing emulsification to obtain the high-fixation-rate nano liquid disperse dye. The liquid disperse dye is applied to the printing process of polyester fiber fabric; the fixation rate of the liquid disperse dye on the fabric can be increased; color flooding on the surface of the fabric is prevented; the effect of wash-free printing is achieved; the printed fabric can be endowed with good wearing fastness; the soft hand feeling of the fabric can be guaranteed; and the discharge amount of printing and dyeing wastewater can be reduced.

Owner:菲诺染料化工(无锡)有限公司

Dyeing process and dyeing apparatus for collagen fiber regenerated leather

ActiveCN103255653BEffective penetrationUniform dyeing effectTextile treatment machine partsDyeing processPolymer scienceCollagen fiber bundle

The invention relates to a dyeing process for collagen fiber regenerated leather. The process successively comprises at least two dyeing treatment, at least one fixation treatment, at least one handfeel modification and drying treatment, wherein dyeing, fixation and handfeel modification are all carried out in an supersonic sound field, so a coloring agent, a fixing agent and a handfeel modifier can effectively penetrate into collagen fiber bundles so as to obtain a more uniform dyeing effect. The concentration of the coloring agent in sequentially used bath liquids increasingly decreases, temperatures of the bath liquids gradually increase, the power of the supersonic sound field increasingly decreases, so bath liquids with high concentration can infiltrate into a leather blank at first, and flooding which is serious in the process of filtration can be eliminated in subsequent dipping in liquids with low concentration; thus, flooding generated in subsequent procedures increasingly decreases, and uniform dyeing of the leather blank is realized. Moreover, surface flooding is eliminated in virtue of a brush of a brush roller in the invention. The invention also relates to a dyeing apparatus capable of realizing continuous uniform dyeing of cloth and leather.

Owner:JIANGYIN JUNHUA TEXTILE TECH

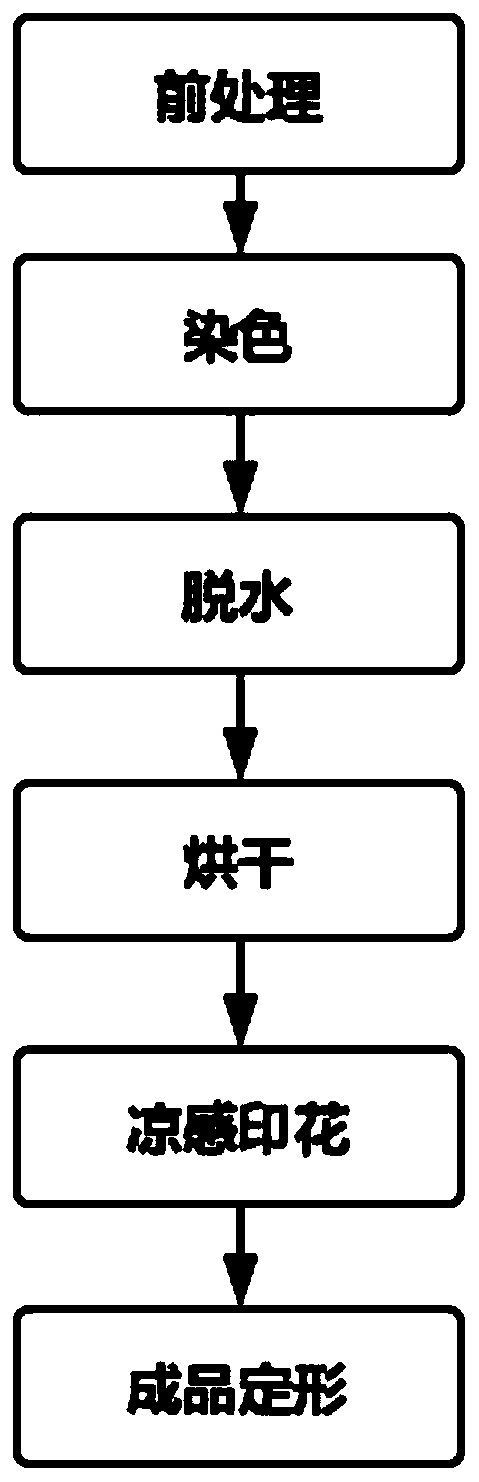

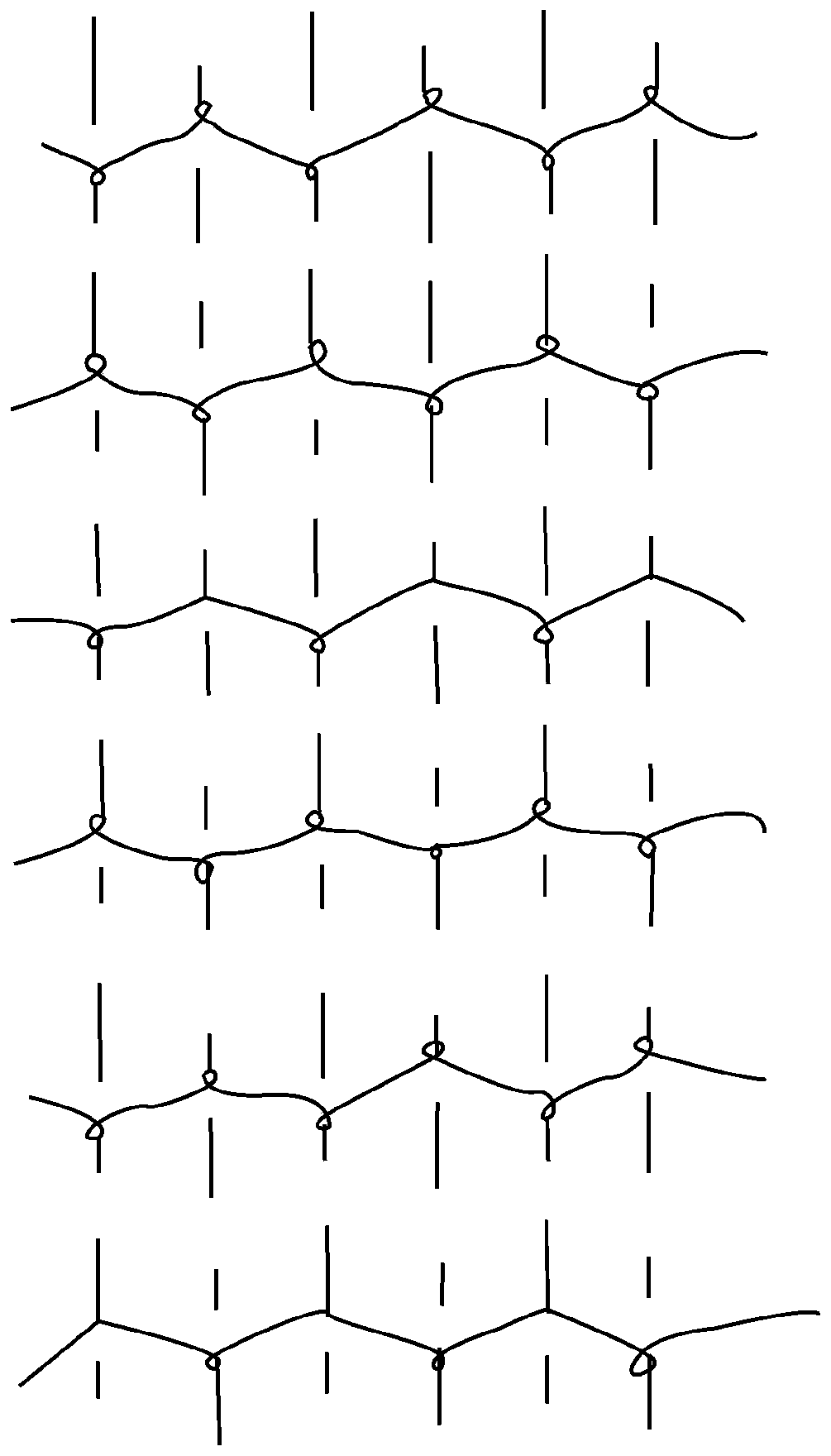

Preparation method of knitted fabric with moisture absorption and sweat releasing and continuous cool feeling functions

InactiveCN111058168AGood moisture absorptionFunction increaseWeft knittingDyeing processPolyesterColour fastness

The invention discloses a preparation method of a knitted fabric with moisture absorption and sweat releasing and continuous cool feeling functions. According to the preparation method, chemically andphysically modified polyester filaments are taken as raw materials, a weaving process and a dyeing and finishing process are adopted, and the knitted fabric is designed into a honeycomb or mesh double-sided tissue structure; and a printing paste is prepared by adopting a cool feeling finishing agent with strong cooling effect and water washing resistance, and the printing paste is transferred tothe fabric in a printing mode. The preparation method has the beneficial effects that by testing the basic performance, the burst strength, the color fastness, the moisture absorption quick-drying performance and the moisture absorption and cool feeling performance of the knitted fabric, the result shows that the knitted fabric has excellent moisture absorption and quick-drying performance, and iscapable of effectively relieving discomfort and wet cold feeling of people caused by damp sweat; and moreover, the knitted fabric also has excellent moisture absorption and cooling performance, and all performances meet standard values.

Owner:JIANGSU JINCHENZHEN TEXTILE

Auxiliary-free dyeing method by use of disperse dye

The invention belongs to the technical field of dyeing and finishing and relates to an auxiliary-free dyeing method by use of a disperse dye. The auxiliary-free dyeing method by use of the disperse dye comprises the following steps: (1) taking a high temperature resistant container, putting disperse dye and water into the container and sealing the disperse dye and the water in the container by use of a microporous membrane; (2) putting the sealed container into a dye vat for high-temperature and high-pressure dyeing, meanwhile, putting fibers (polyester fibers, acrylic fibers, polyamide fibers, polyurethane fibers, polypropylene fibers and the like) into the dye vat, dyeing the fibers by use of a high-temperature and high-pressure dyeing method, and then washing with water; (3) cooling the dye liquor in the container to room temperature and recovering the disperse dye by use of a suction filtration method. The auxiliary-free dyeing method by use of the disperse dye is simple in process and convenient to operate; no any auxiliary needs to be added during dyeing and the pollution to the auxiliary and the pollution to water caused by the auxiliary during dyeing are avoided, the sewage treatment difficulty is reduced, and the effects of energy conservation and environmental protection are achieved; besides, the dye in the residual liquor can be recycled.

Owner:DONGHUA UNIV

Dyeing and post-finishing process of woolen bamboo polyester fabrics

InactiveCN102517754AUniform coloring effectGuaranteed color fastnessSingeingDry-cleaning apparatus for textilesPolyesterFiber

The invention discloses a dyeing and post-finishing process of woolen bamboo polyester fabrics, which includes steps: firstly joining ends of gray fabrics, namely using a splicer to joining the ends of the gray fabrics; secondly, singeing, brushing and shearing; thirdly, desizing, boiling off and using an open-width washing machine for scouring; fourthly, preshrinking for shaping; fifthly, using the high-temperature two-bath method for dyeing, namely using reactive dye of CibacronFN cotton at 60-65 DGE C for 50-60 minutes first, and then using acid dye to dye at 130-135 DEG C for 40-50 minutes; sixthly, soft finish shaping, namely performing soft finish shaping twice; seventhly, decatizing for shaping, wherein the internal pressure of a decatizing machine is 0.5-1.2bar, and the cold drawing time is 1-1.5 minutes; and eighthly, light decatizing for shaping, wherein the internal pressure of a decatizing machine is 0.4-0.5bar, and the cold drawing time is 1-1.5 minutes. By the dyeing and post-finishing process, loose colour of fabrics can be reduced, color fastness can be guaranteed, coloring is uniform, the characteristics of bamboo fiber products such as softness and moisture absorption are kept, hand touch is improved and woolen surfaces of the fabrics are flat, smooth and clear in texture.

Owner:HANGZHOU FUEN TEXTILE

Production technology for indigo cotton yarn

The invention discloses a production technology for indigo cotton yarn. The production technology comprises the steps of blowing, carding, first drawing, second drawing, third drawing, roving, spinning and post processing, and specifically comprises the steps that firstly, indigo dye coating is molten to be prepared into a leuco body for use; secondly, preprocessed cotton is put into the indigo dye coating, the temperature is increased to 35 DEG C at a speed of 3 DEG C / min, temperature keeping is conducted for 30 min, the temperature is increased to 120 DEG C at a speed of 2 DEG C / min, dyeing continues to be conducted for 20 min, the temperature is decreased to 40 DEG C at a speed of 3 DEG C / min, and the cotton is taken out; thirdly, blowing, carding, first drawing, second drawing, third drawing, roving and spinning are conducted on the dyed cotton so that the cotton can be spun into cotton yarn for use; fourthly, post processing is conducted on the dyed cotton yarn, and post processing comprises drafty oxidation for 5 min, soaping and stoving, soap washing liquor is formed by adopting anhydrous sodium carbonate of 2 g / L and standard soap flakes of 5 g / L, the temperature is 60 DEG C, time is 20 min, and soap boiling, washing and stoving are conducted on the oxidized fabric.

Owner:源兴纺织(深圳)有限公司

Disperse red dye composition and dye product

ActiveCN106433213AGood lifting effectImprove washing fastnessOrganic dyesDyeing processPolyesterFiber

The invention relates to one disperse red dye composition and dye products, disperse red dye composition is prepared from three or four of component A, component B, component C and compounded D of compounded products, dye product comprises dye and auxiliary two sorts and is mixed prepared. Dye composition is widely used in hydrophobic fiber materials such as polyester fiber and superfine polyester dyeing, especially suitable for the dyeing of polyester / polyurethane elastic fabric with high requirements on fabric color fastness.

Owner:LEPING SAFELY PHARMA

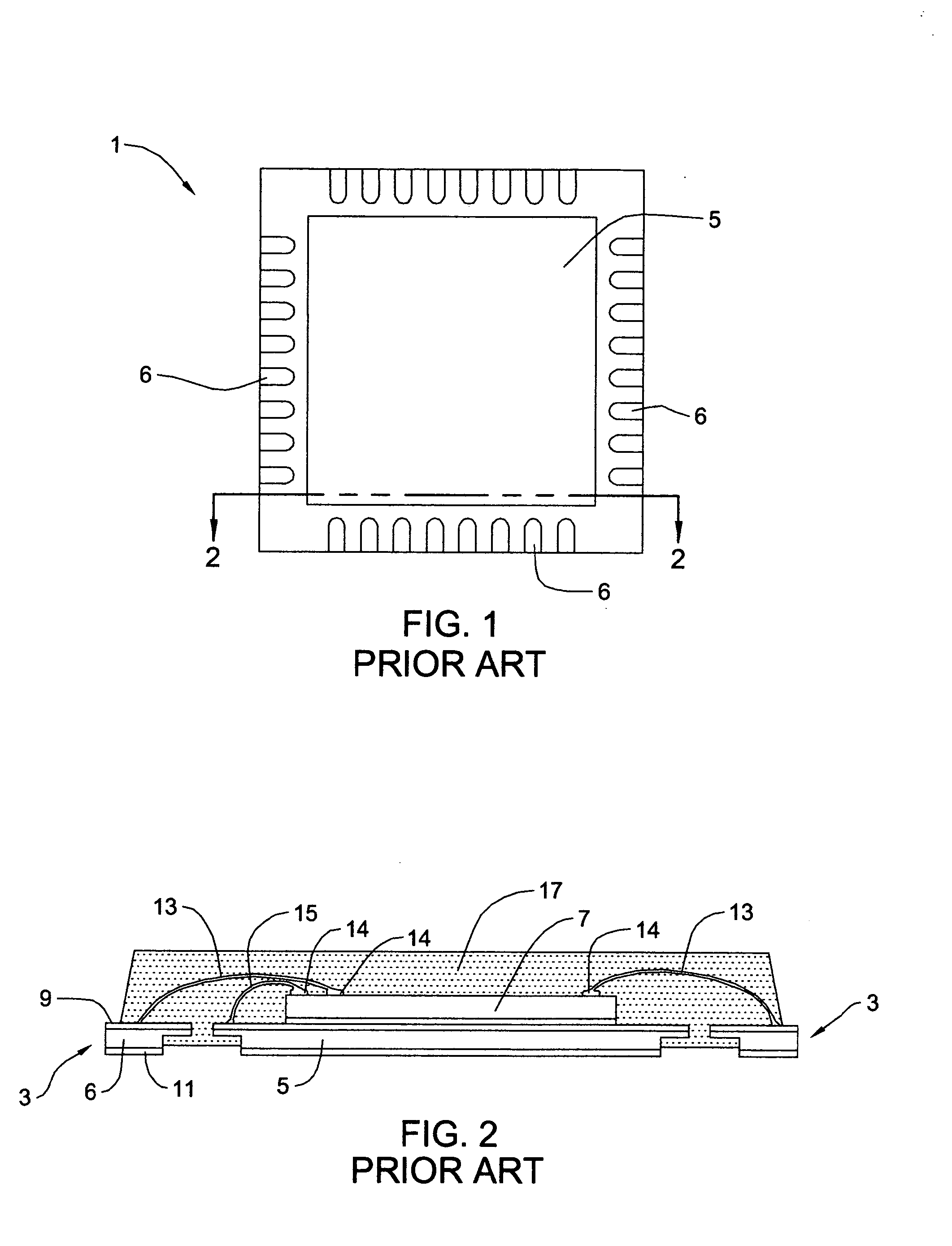

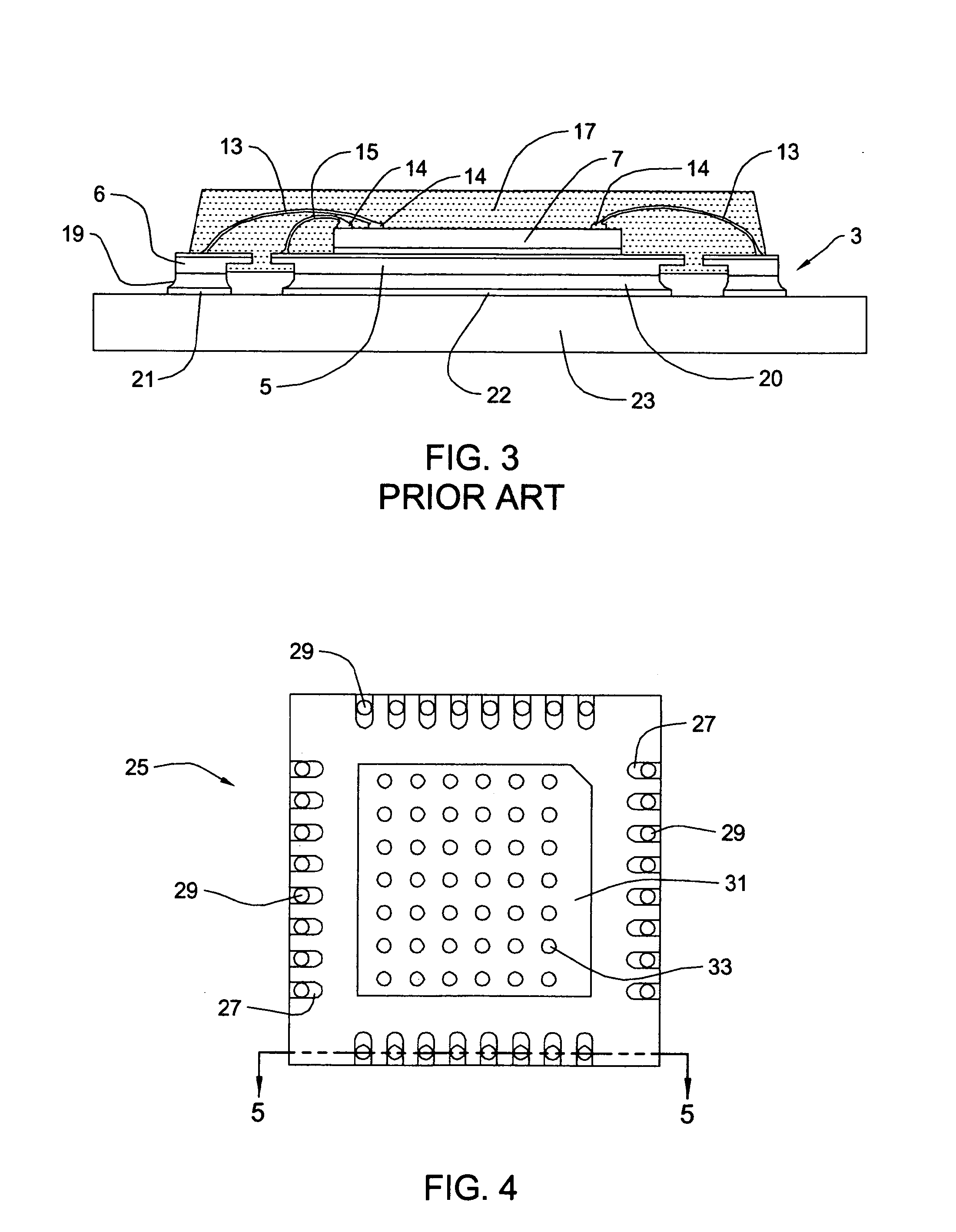

Quad flat no-lead chip carrier with stand-off

InactiveUS20080203546A1Increase productionIncrease the welding areaFinal product manufactureSemiconductor/solid-state device detailsEngineeringCopper

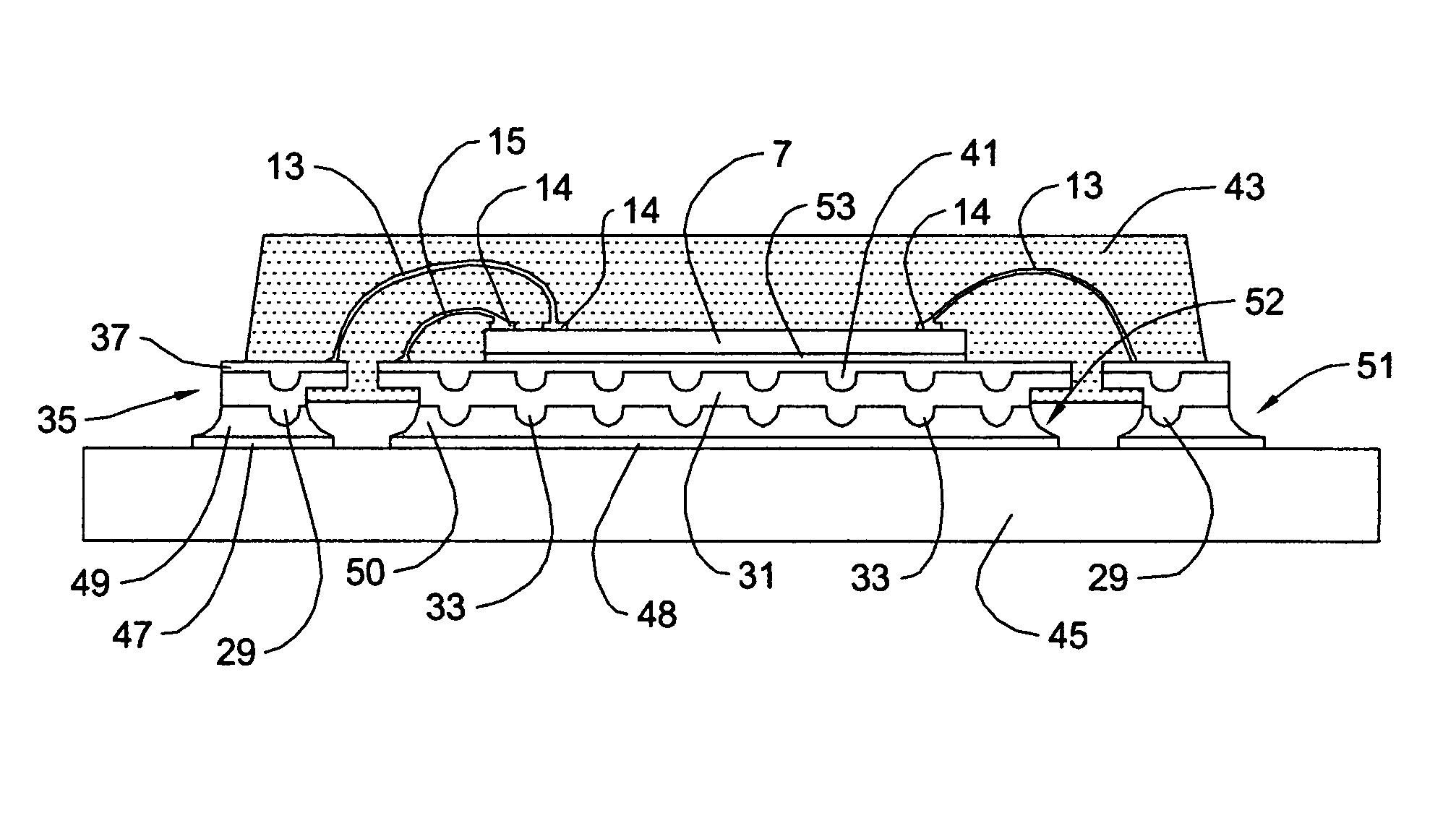

A QFN package with improved joint solder thickness for improved second level attachment fatigue life. The copper leadframe of a QFN chip carrier is provided with rounded protrusions in both the chip attach pad region and the surrounding lead regions before second level attachment. The rounded stand-off protrusions are formed from the copper itself of the copper of the leadframe. This may be achieved by punching dimples into one surface of the copper plate of the leadframe before plating to form protrusions on the opposing surface. This method of forming the rounded protrusions simplifies the process of forming stand-offs. The protrusions provide a structure that increases wetting area and allows the use of a larger quantity of solder for increased solder joint thickness and better die paddle solder joint area coverage. As a result of the increased solder joint thickness, second level fatigue life is significantly improved. As a result of the improved die paddle solder joint area coverage, improved thermal performance of the chip carrier is also significantly improved.

Owner:GLOBALFOUNDRIES INC

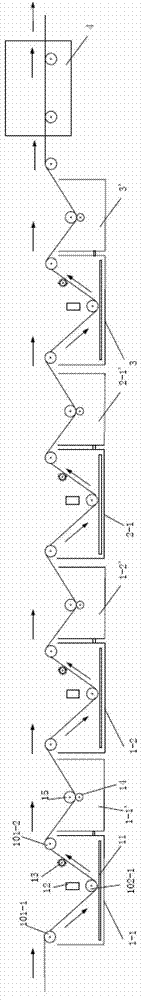

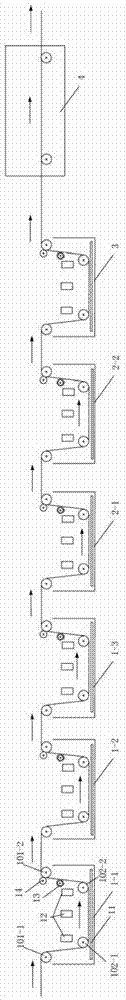

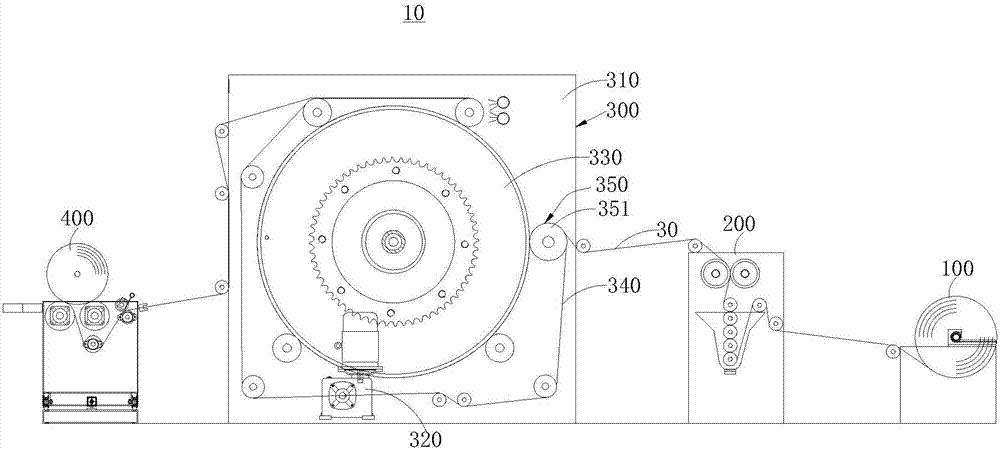

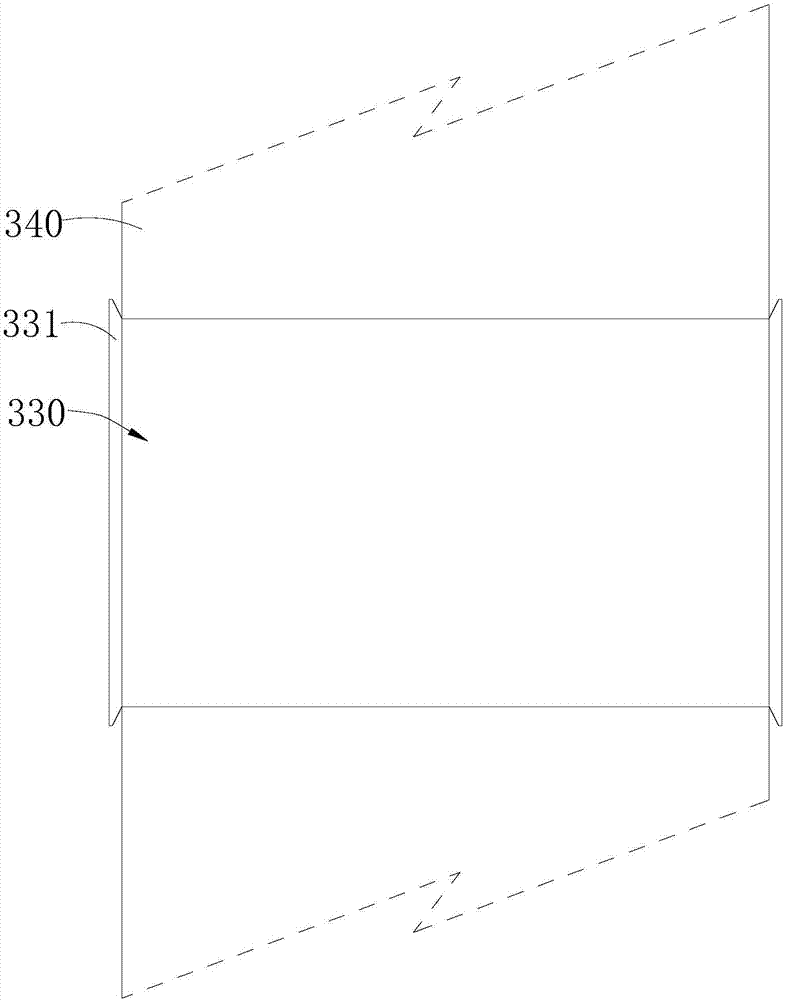

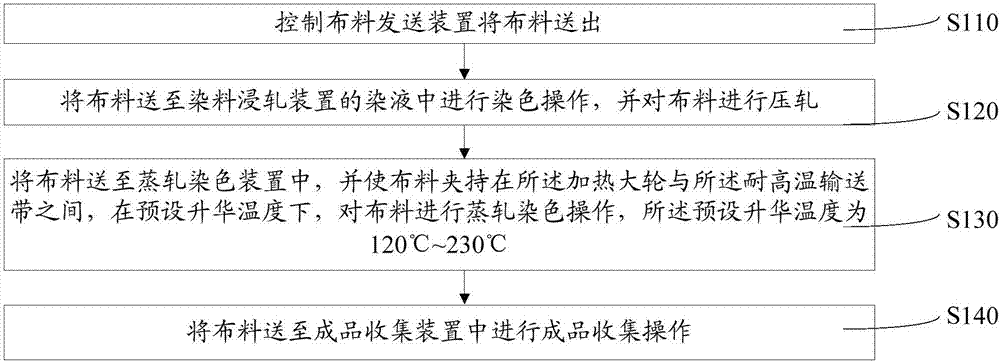

Pad-steam dyeing equipment and method thereof

ActiveCN107119408AIncrease profitImprove adsorption capacitySucessive textile treatmentsTextile treatment machine arrangementsSewageEngineering

The invention relates to pad-steam dyeing equipment. The pad-steam dyeing equipment comprises a cloth sending device, a dye padding device, a pad-steam dyeing device and a finished product collection device which are sequentially arranged along the sending direction of the cloth. The pad-steam dyeing device consists of a rack, a power assembly, a large heating wheel, a high-temperature-resistant conveyor belt and a supporting guide wheel group. The power assembly is arranged on the rack and connected with the large heating wheel and used for driving the large heating wheel to rotate. The supporting guide wheel group comprises a plurality of supporting guide wheels, the high-temperature-resistant conveyor belt is respectively sheathed on each supporting guide wheel, and sheathed outside the large heating wheel, the large heating wheel and the high-temperature-resistant conveyor belt are used for clamping the cloth and performing pad-steam dyeing operation to the cloth. Due to the cladding of the high-temperature-resistant conveyor belt, the dye is difficultly escaped into the atmosphere after sublimation, thus being beneficial to dyeing. The pad-steam dyeing equipment is used for pad-steam dying the cloth containing dyeing solution, the dye utilization rate is high, the dye yield is deep, the color firmness is higher, the flooding on the surface of the cloth is less, and the discharge of waste water is less.

Owner:李裕

Dyeing process for dyeing different colors for blended fabric in one dyeing bath by using reactive dyes used for furs

InactiveCN101654874AEmission reductionGood level dyeingBleaching apparatusDyeing processFiberColor effect

The invention relates to a dyeing process for dyeing different colors for blended fabric in one dyeing bath by using reactive dyes used for furs, which uses the principle that, aiming at the reactivedyes used for furs, different fibers in the blended fabric have different dyeing rates in the same dyeing bath, thereby generating different color effects. Under the condition of room temperature, bythe steps of adding Glauber's salt in batches, adding reactive dyes used for furs, selecting samples and increasing the temperature and adding soda for fixation, and by adopting the reasonable blending scheme, time intervals and temperature setting, the dyes form stable chemical bonds on different materials of the blended fabric for fixation, and the use of the soda improves the leveling property,the reproducibility and the dye yield of dyeing, thus the fabric achieves excellent effects. The method has simple processes, reduces the consumption of energy sources and the discharge amount of waste water, is favorable for environment protection, has vivid dyed color, less loose color and good fastness, and saves the production cost.

Owner:ZHEJIANG GRACE TOWEL

Nano disperse dye color paste suitable for polyester printing and dyeing and preparation method thereof

The invention discloses a nano disperse dye color paste suitable for polyester printing and dyeing and a preparation method thereof. The nano disperse dye color paste is specifically prepared from, bymass, 5-25 parts of a commercial disperse dye, 2-5 parts ofa surfactant, 1-5 parts of a polymer dispersant, 0.5-2 parts of a protective colloid, 0.5-5 parts of an acid-base regulator and the balancedeionized water. The preparation method comprises the following steps: firstly, adding the metered deionized water into a grinder, then adding auxiliaries in sequence, finally adding the commercial disperse dye, controlling the grinding speed to 5000-10000 rpm, and executing grinding for 3-5 hours. By testing the particle size distribution of the disperse dye, if it is at 100-300 nm, it is indicated that the disperse dye meets the requirements of color paste indexes. The disperse dye paste has the nanoscale dye particle size, is high in stability, is easily adsorbed and penetrates into grey cloth, can reduce surface dyeing and significantly improves the color fastness on the grey cloth.

Owner:常州安达环保科技有限公司 +1

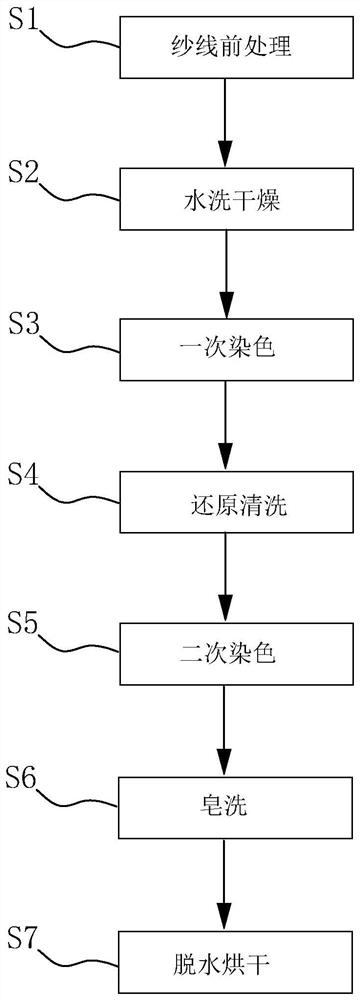

Polyester-cotton blended yarn dyeing process

The invention relates to the technical field of yarn dyeing and finishing, and particularly discloses a polyester-cotton blended yarn dyeing process. The polyester-cotton blended yarn dyeing process comprises the following steps of S1, performing yarn pretreatment; S2, performing washing and drying; S3, performing primary dyeing: adding 1.5-3 g / L of a disperse dye leveling agent into a primary dyeing bathtub, performing heating to 75 DEG C, adding a disperse dye, then performing heating to 85 DEG C, sending the washed and dried yarns into primary dyeing liquid for dip dyeing at a bath ratio of1: (9-11), and performing heat preservation dyeing for 45-55min; S4, performing reduction cleaning; S5, performing secondary dyeing, wherein the bath ratio is 1: (9-11), the temperature is increasedto 75-85 DEG C, heat preservation is performed for 18-22 min, then the temperature is increased to 90 DEG C, heat preservation dyeing is performed for 30-35 min, and secondary dyeing liquid is activedyeing liquid; S6, performing soaping; and S7, performing dehydration and drying, wherein pretreatment liquid comprises the following components in parts by weight: 3-6 parts of pectinase, 4-8 parts of alpha-amylase, 4-7 parts of hydrogen peroxide, 0.5-1 part of sodium silicate, 1-3 parts of a penetrant, 0.5-1 part of cocamidopropyl hydroxy sulfobetaine and 65-85 parts of deionized water. The method has the advantages of effectively improving the dyeing uniformity of the cotton-polyester blended yarns and improving the yarn quality.

Owner:南通云花色织有限公司

Color paste for blending cotton chemical fiber dyeing and blending cotton dyeing method

The invention discloses color paste for blending cotton chemical fiber dyeing. The color paste comprises 3 to 14% of disperse dyes, 0.6 to 1.7% of a surface active agent, 0.3 to 0.8% of a cosolvent, 0.7 to 1.2% of polyacrylate, 0.1 to 0.3% of modified starch TGS5-C, and the balance of deionized water. The surface active agent is formed through mixing of an anionic surfactant and a nonionic surfactant, the dye grain fineness is 0.7 to 1.5 micrometers, and the invention further discloses a blending cotton dyeing method. The blending cotton dyeing method comprises the steps of S1, color paste configuration, S2, pre-treatment, S3, cotton dyeing, S4, washing treatment, S5, chemical fiber dyeing and S6 drying. The color paste for blending cotton chemical fiber dyeing is applied into the blendingcotton dyeing method, the washing step is omitted, the dyeing machining efficiency is improved, meanwhile, the discharge amount of sewage can be reduced, and environment friendliness is achieved.

Owner:佛山市南海区今易德纺织有限公司

Supercritical carbon dioxide dyeing process for finishing and pre-treating aramid fiber/viscose blended fabric polyethylene glycol

InactiveCN104278568AAvoid stainsIncreased and improved dyeabilityDyeing processVegetal fibresPolyethylene glycolPre treatment

The invention relates to a supercritical carbon dioxide dyeing process for finishing and pre-treating aramid fiber / viscose blended fabric polyethylene glycol. A good washing fastness is achieved after dyeing aramid fiber / viscose by supercritical carbon dioxide; the K / S value of the dyed fabric reaches 17; the dry rubbing fastness reaches a grade V; the wet rubbing fastness reaches the grade IV-V; the high-temperature color distortion fastness reaches a grade V. The supercritical CO2 dyeing process causes no damage to the warp and weft breakage strength of the fabric; conversely, the strength of the dyed fabric is higher than that of the fabric in the prior art; the fabric is few in surface floating color, so that the operation for washing the floating color is not required.

Owner:WUXI XINGLIN DYEING ENVIRONMENTAL PROTECTION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com