High-fastness blue-to-black disperse dye composition and dye product

A technology of black dyes and disperse dyes, applied in the direction of organic dyes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

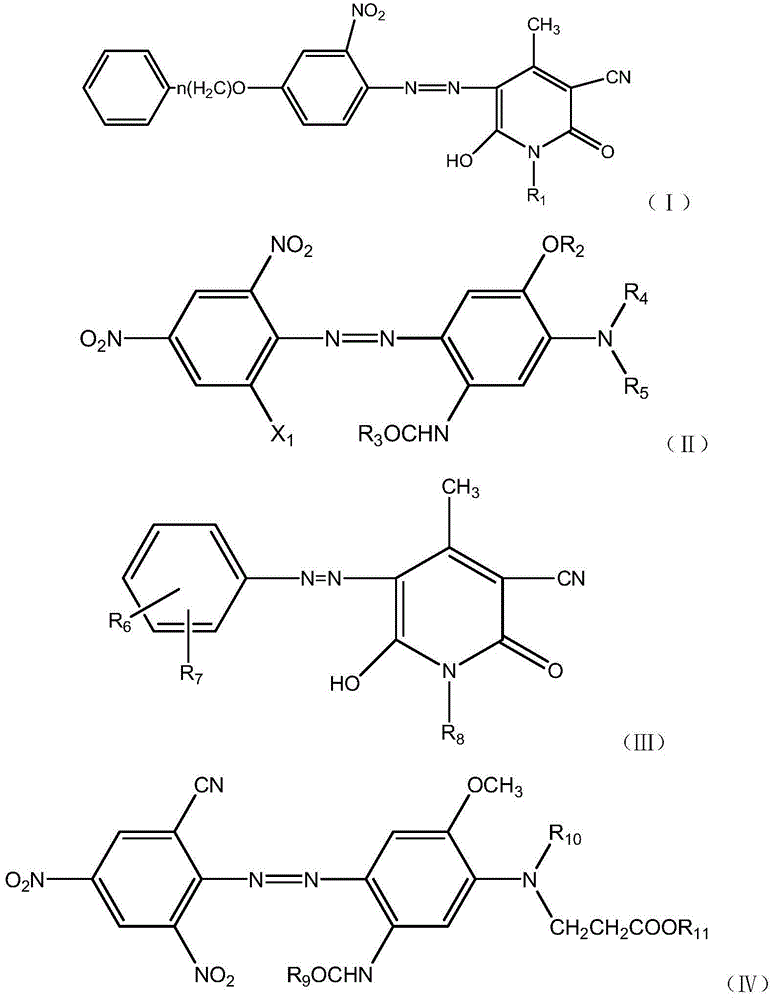

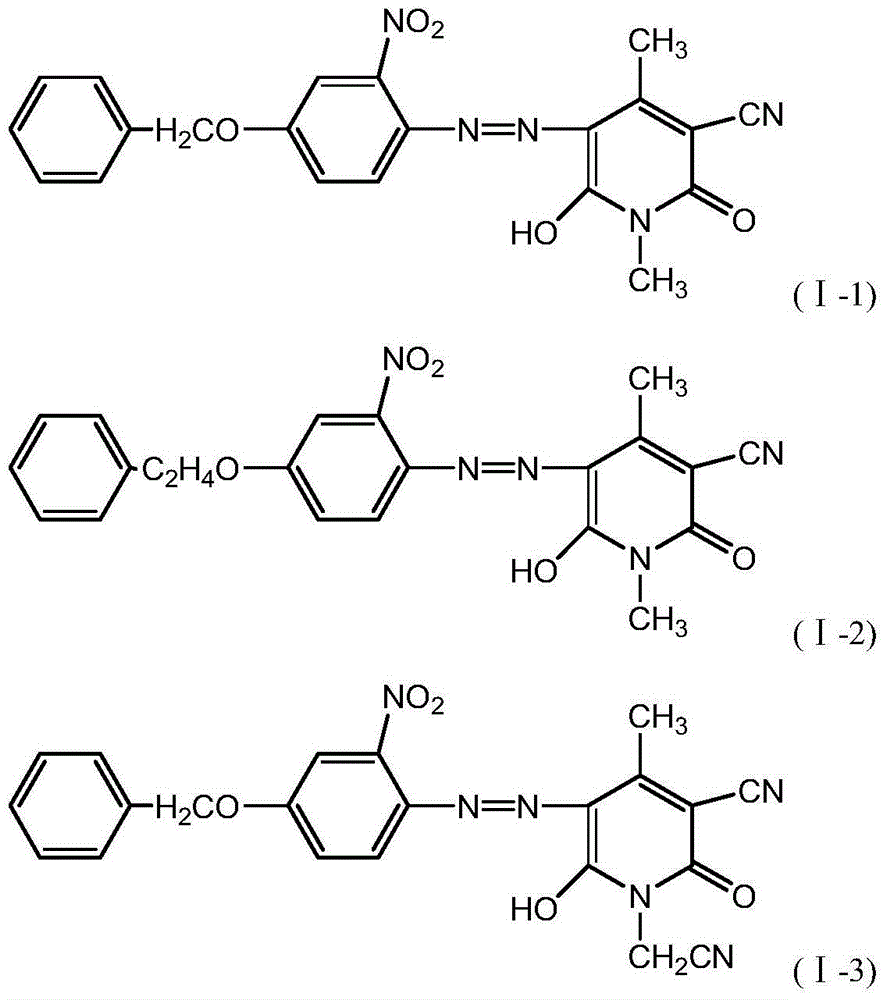

Method used

Image

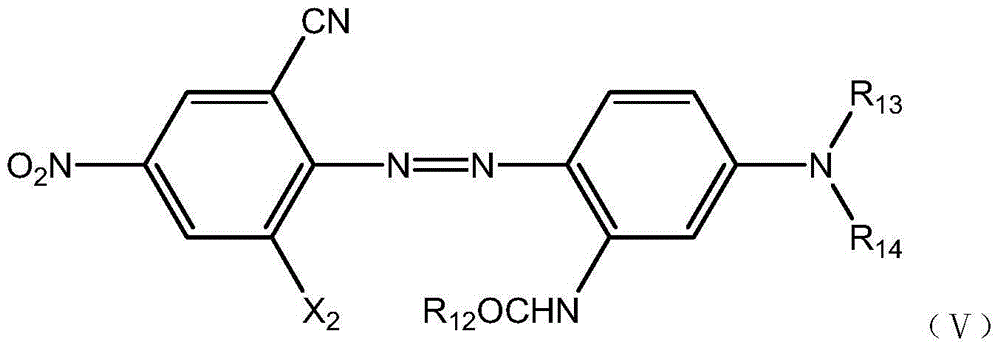

Examples

Embodiment 1

[0063] Disperse 25 g formula (Ⅰ-1), 21 g formula (Ⅱ-1), 12 g formula (Ⅲ-1), 26 g formula (Ⅳ-1), 16 g formula (Ⅴ-1) and 200 g After adding 650 grams of water to mix MF, grind, disperse and dry, the finished product is obtained. This dye can provide the fabric with black with excellent fastness properties.

[0064]

[0065]

Embodiment 2

[0067] Disperse 15 g formula (Ⅰ-1), 40 g formula (Ⅱ-2), 5 g formula (Ⅲ-3), 35 g formula (Ⅳ-2), 5 g formula (Ⅴ-1) and 200 g After adding 650 grams of water to MF, grind, disperse and dry, the finished product is obtained. The dye can provide the fabric with blue color with excellent fastness properties.

[0068]

[0069]

Embodiment 3~15

[0071] According to the method described in Example 1, the difference is that the structure and weight of components A to E in Table 1 are used, 250 grams of additives (dispersant MF is 200 grams, and sodium lignosulfonate is 50 grams), and water is added. 800 grams are mixed and mixed into a slurry, ground, dispersed, and dried to obtain a finished product. The dye can provide the fabric with blue to black tones with excellent fastness properties.

[0072] Table 1

[0073]

[0074]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com