Polymer dye, photoresist composition and preparation method and application of photoresist composition

A polymer and composition technology, applied in organic dyes, optics, nonlinear optics, etc., can solve the problems of display panel display quality degradation, dyes are easy to form floating colors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The embodiment of the present invention also provides a preparation method of the above-mentioned polymer dye, comprising:

[0067] Step a, performing a substitution reaction with a dye containing an aromatic hydroxyl group or an aromatic amino group and a monohalogenated glycerol under alkaline conditions to remove water to generate a glycerolated dye;

[0068] Step b, performing a substitution reaction between the glycerolated dye and chlorinated trimellitic anhydride to dehydrochloride to generate a dianhydrided dye;

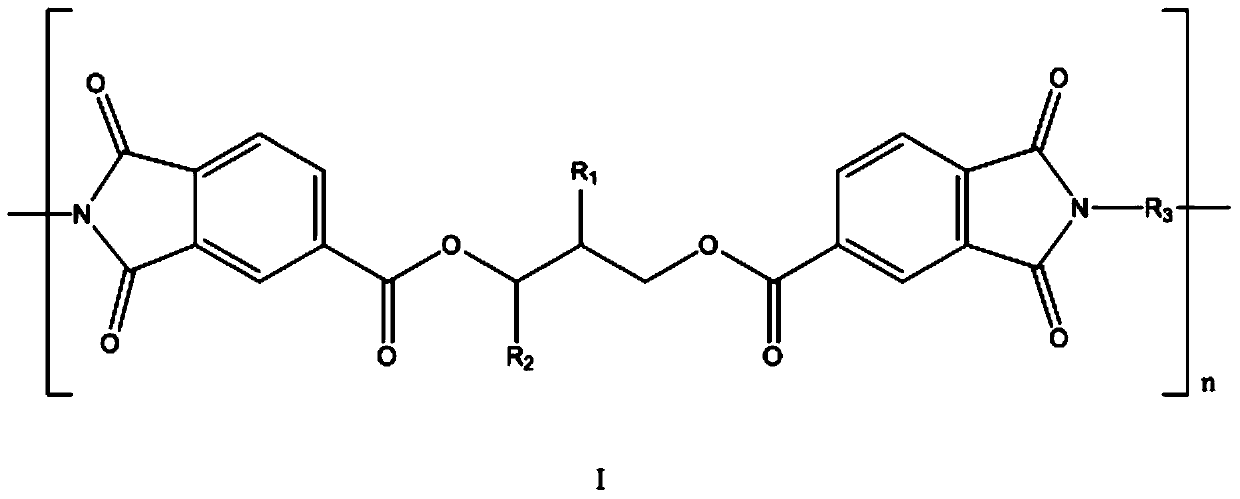

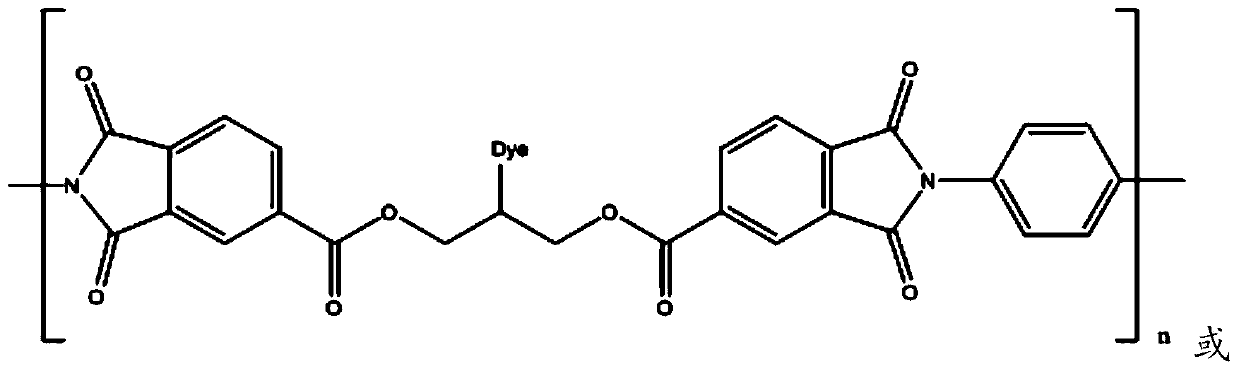

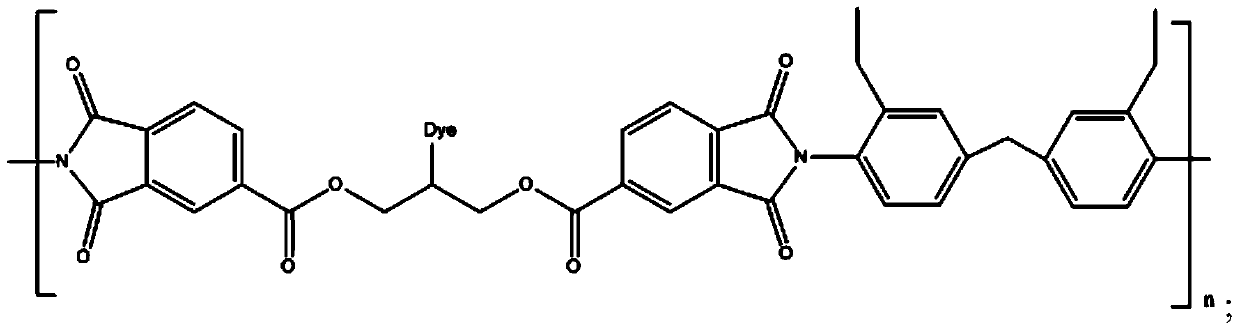

[0069] Step c, polymerizing the diacid anhydride dye and aromatic diamine to generate the polymer dye shown in formula I.

[0070] The embodiment of the present invention also provides a preparation method of any one of the photoresist compositions described above, the preparation method comprising:

[0071] The colorant, alkali-soluble resin, multifunctional monomer, photoinitiator, auxiliary agent and organic solvent are taken in parts by weight, di...

Embodiment 1

[0074] In a three-neck flask equipped with a thermometer, a stirrer and a reflux tube, add 1.05 molar parts of 2-bromoglycerol (163 parts by weight), 2 molar parts of potassium carbonate (276 parts by weight), 1 molar part of acid blue 90 dye (702 parts by weight), 2000 parts by weight of propylene glycol methyl ether acetate (PMA) and 2000 parts by weight of toluene. After the dropwise addition was complete, stir and heat to reflux. After reacting for 8 hours, the reaction solution was washed and extracted with water, and the water phase was further salted out with 21% brine for 2 hours. After filtering, the filter cake was washed with saturated brine, and recrystallized twice to obtain glycerolated dye with a yield of 60%. In this reaction, the hydrogen atom in -NH- in the acid blue 90 dye molecule and the bromine atom in 2-bromoglycerol form hydrogen bromide and take off.

[0075] In a three-necked flask equipped with a thermometer, a stirrer and a dropping bottle, 1.05 m...

Embodiment 2

[0079] In a three-neck flask equipped with a thermometer, a stirrer and a reflux tube, add 1.05 molar parts of 2-bromoglycerol (163 parts by weight), 2 molar parts of potassium carbonate (276 parts by weight), 1 molar part of acid blue 90 dye (702 parts by weight), 2000 parts by weight of PMA and 2000 parts by weight of toluene. After the dropwise addition was complete, stir and heat to reflux. After reacting for 8 hours, the reaction solution was washed and extracted with water, and the water phase was further salted out with 21% brine for 2 hours. After filtering, the filter cake was washed with saturated brine, and the obtained solid was recrystallized twice to obtain a glycerolated dye with a yield of 60%.

[0080] In a three-necked flask equipped with a thermometer, a stirrer and a dropping bottle, 1.05 mole parts of trimellitic anhydride monoacyl chloride small particles (221 parts by weight), 800 parts by weight of PMA and 800 parts by weight of toluene were added. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com