Color paste for blending cotton chemical fiber dyeing and blending cotton dyeing method

A dyeing method and color paste technology are applied in the field of color paste for dyeing blended cotton chemical fiber and blended cotton dyeing, which can solve the problems of cumbersome dyeing process, affect processing efficiency, etc., reduce process steps, reduce color spots and floating color, increase Wetting and Solubility Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

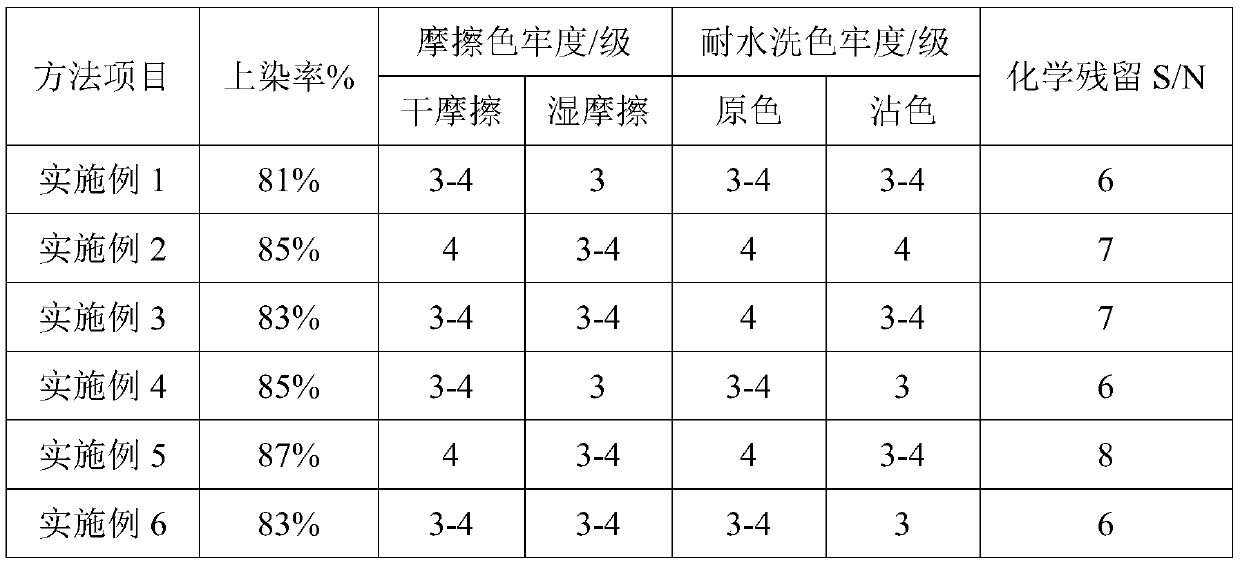

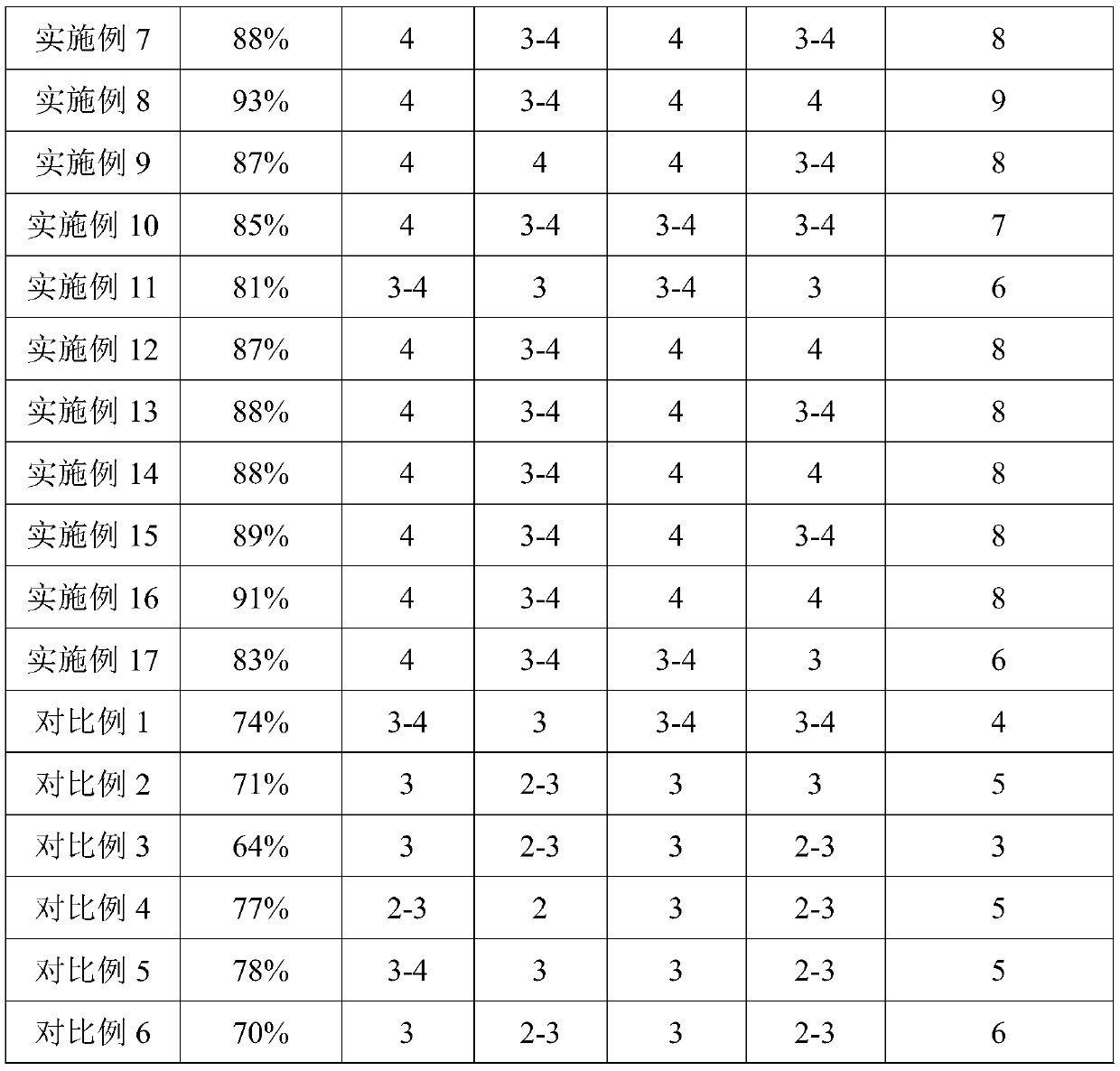

Examples

Embodiment 1

[0058] A dyestuff for dyeing blended cotton chemical fibers, which is mainly prepared from the following raw materials in mass percentages:

[0059] Disperse dyes: 3%;

[0060] Surfactant: 0.7%;

[0061] Sodium Benzoate: 0.3%;

[0062] Polyacrylate: 0.9%;

[0063] Modified starch TGS5-C: 0.1%;

[0064] Yuanming powder: 1.2%;

[0065] Deionized water: balance;

[0066] Among them, the disperse dye is disperse black ECT300%, the surfactant is mixed by anionic surfactant and nonionic surfactant in a ratio of 1:3, and the anionic surfactant is sodium methylene bis-naphthalene sulfonate, nonionic The surfactant is stearyl polyoxyethylene ether, and the particle size of the disperse dye is 0.8 μm.

[0067] A kind of dyeing method of blended cotton, adopts a kind of dyestuff for dyeing blended cotton chemical fiber in above-mentioned embodiment, comprises the following steps:

[0068] S1. Configure the color paste: add sodium methylene bis-naphthalene sulfonate, stearyl polyox...

Embodiment 2

[0075] A dye for dyeing blended cotton chemical fibers, which is mainly prepared from the following raw materials in mass percentages:

[0076] Disperse dyes: 8%;

[0077] Surfactant: 1.7%;

[0078] p-aminobenzoic acid: 0.8%;

[0079] Polyacrylate: 1.2%;

[0080] Modified starch TGS5-C: 0.3%;

[0081] Yuanming powder: 1.1%;

[0082] Deionized water: balance;

[0083] Among them, the disperse dye is disperse black ECT300%, the surfactant is mixed by anionic surfactant and nonionic surfactant in a ratio of 1:3, and the anionic surfactant is sodium methylene bis-naphthalene sulfonate, nonionic The surfactant is fatty acid polyoxyethylene ester, and the particle size of disperse dye is 0.7 μm.

[0084] A kind of dyeing method of blended cotton, adopts a kind of dyestuff for dyeing blended cotton chemical fiber in above-mentioned embodiment, comprises the following steps:

[0085] S1. Configure color paste: Add 20% deionized sodium methylene bis-naphthalene sulfonate, polyox...

Embodiment 3

[0092] A dye for dyeing blended cotton chemical fibers, which is mainly prepared from the following raw materials in mass percentages:

[0093] Disperse dyes: 14%;

[0094] Surfactant: 1.3%;

[0095] Acetamide: 0.3%;

[0096] Polyacrylate: 1%;

[0097] Modified starch TGS5-C: 0.1%;

[0098] Yuanming powder: 0.5%;

[0099] Deionized water: balance;

[0100] Among them, the disperse dye is disperse black ECT300%, the surfactant is mixed by anionic surfactant and nonionic surfactant in a ratio of 1:3, and the anionic surfactant is sodium methylene bis-naphthalene sulfonate, nonionic The surfactant is octal polyoxyethylene ether, and the particle size of the disperse dye is 1.5 μm.

[0101] A kind of dyeing method of blended cotton, adopts a kind of dyestuff for dyeing blended cotton chemical fiber in above-mentioned embodiment, comprises the following steps:

[0102] S1. Configure the color paste: Add 20% deionized sodium methylene bis-naphthalene sulfonate, octyl polyoxye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com