Thermosol dyeing method taking decamethylcyclopentasiloxane (D5) as medium

A technology of decamethylcyclopentasiloxane and methylcyclopentasiloxane is applied in the field of hot melt dyeing of disperse dyes, which can solve the problems of a large number of dispersants, high water consumption, sewage discharge, etc. Harm, improve utilization rate, reduce the effect of waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

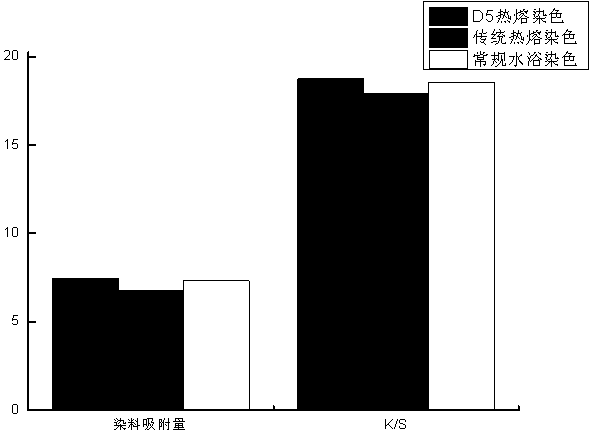

Embodiment 1

[0029] A kind of heat-melt dyeing method taking D5 as medium, method is as follows:

[0030] (1) Pretreatment of polyester fabric:

[0031] The polyester fabric is pretreated, and the treatment process is as follows: the fabric weighs 50g, is treated in 30°C water for 1.5 hours, and then dried at 25°C for 30 minutes.

[0032] (2) Dyeing formula:

[0033] Disperse Dyes (C.I Disperse Carnelian): 1.0% (o.w.f);

[0034] Fabric weight: 50g;

[0035] Bath ratio: 1:20;

[0036] Dyeing time: 30min.

[0037] (3) Dyeing process:

[0038] Dye in an overflow dyeing machine, enter the dyeing at room temperature, raise the temperature to 90°C at 3°C / min, then raise the temperature to 190°C at 2°C / min and keep the temperature for 30 minutes for hot-melt color fixation, and cool down at 2°C / min After reaching 60°C, carry out reduction cleaning, and finally wash with water and dry.

[0039] (4) Reduction cleaning:

[0040] The dyed fabric is subjected to reduction cleaning according to...

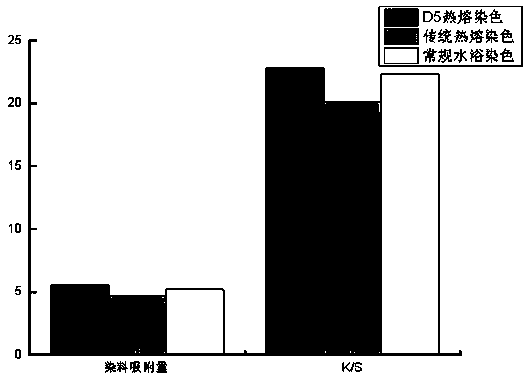

Embodiment 2

[0045] A kind of heat-melt dyeing method taking D5 as medium, method is as follows:

[0046] (1) Pretreatment of polyester fabric:

[0047] The polyester fabric is pretreated, and the treatment process is as follows: the fabric weighs 50g, is treated in 30°C water for 1.5 hours, and then dried at 25°C for 30 minutes.

[0048] (2) Dyeing formula:

[0049] Disperse dyes (C.I Disperse Blue 183): 1.0% (o.w.f);

[0050] Fabric weight: 50g;

[0051] Bath ratio: 1:20;

[0052] Dyeing time: 30min.

[0053] (3) Dyeing process:

[0054] Dye in an axial flow dyeing machine, enter the dyeing at room temperature, heat up to 90°C at 3°C / min, then heat up to 190°C at 2°C / min and keep the temperature for 30 minutes for heat-melt color fixation, and cool down at 2°C / min After reaching 60°C, carry out reduction cleaning, and finally wash with water and dry.

[0055] (4) Reduction cleaning:

[0056] The dyed fabric is subjected to reduction cleaning according to the GB2394-80 method. The ...

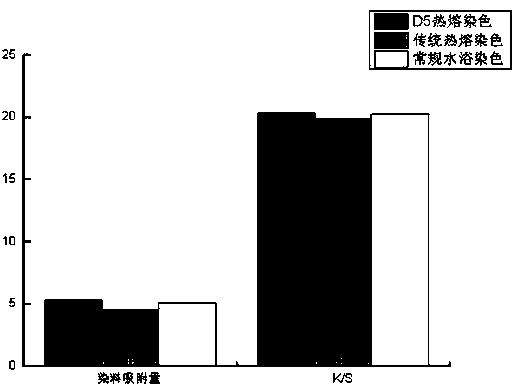

Embodiment 3

[0060] A kind of heat-melt dyeing method taking D5 as medium, method is as follows:

[0061] (1) Pretreatment of polyester fabric:

[0062] The polyester fabric is pretreated, and the treatment process is as follows: the fabric weighs 50g, is treated in 30°C water for 1.5 hours, and then dried at 25°C for 30 minutes.

[0063] (2) Dyeing formula:

[0064] Disperse dyes (C.I Disperse Blue 79): 1.0% (o.w.f);

[0065] Fabric weight: 50g;

[0066] Bath ratio: 1:20;

[0067] Dyeing time: 30min.

[0068] (3) Dyeing process:

[0069] Dye in a jet dyeing machine, enter the dyeing at room temperature, raise the temperature to 90°C at 3°C / min, then raise the temperature to 190°C at 2°C / min and keep the temperature for 30 minutes for hot-melt color fixation, and cool down to 2°C / min After 60°C, carry out reduction cleaning, and finally wash with water and dry.

[0070] (4) Reduction cleaning:

[0071] The dyed fabric is subjected to reduction cleaning according to the GB2394-80 me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com