Microcapsule dyeing method of poly lactic acid fibers and/or poly lactic acid fiber product

A technology of polylactic acid fiber and dyeing method, which is applied in dyeing, textile and papermaking, etc., can solve the problems of fiber damage and the strength of fiber fabrics and non-woven fabrics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

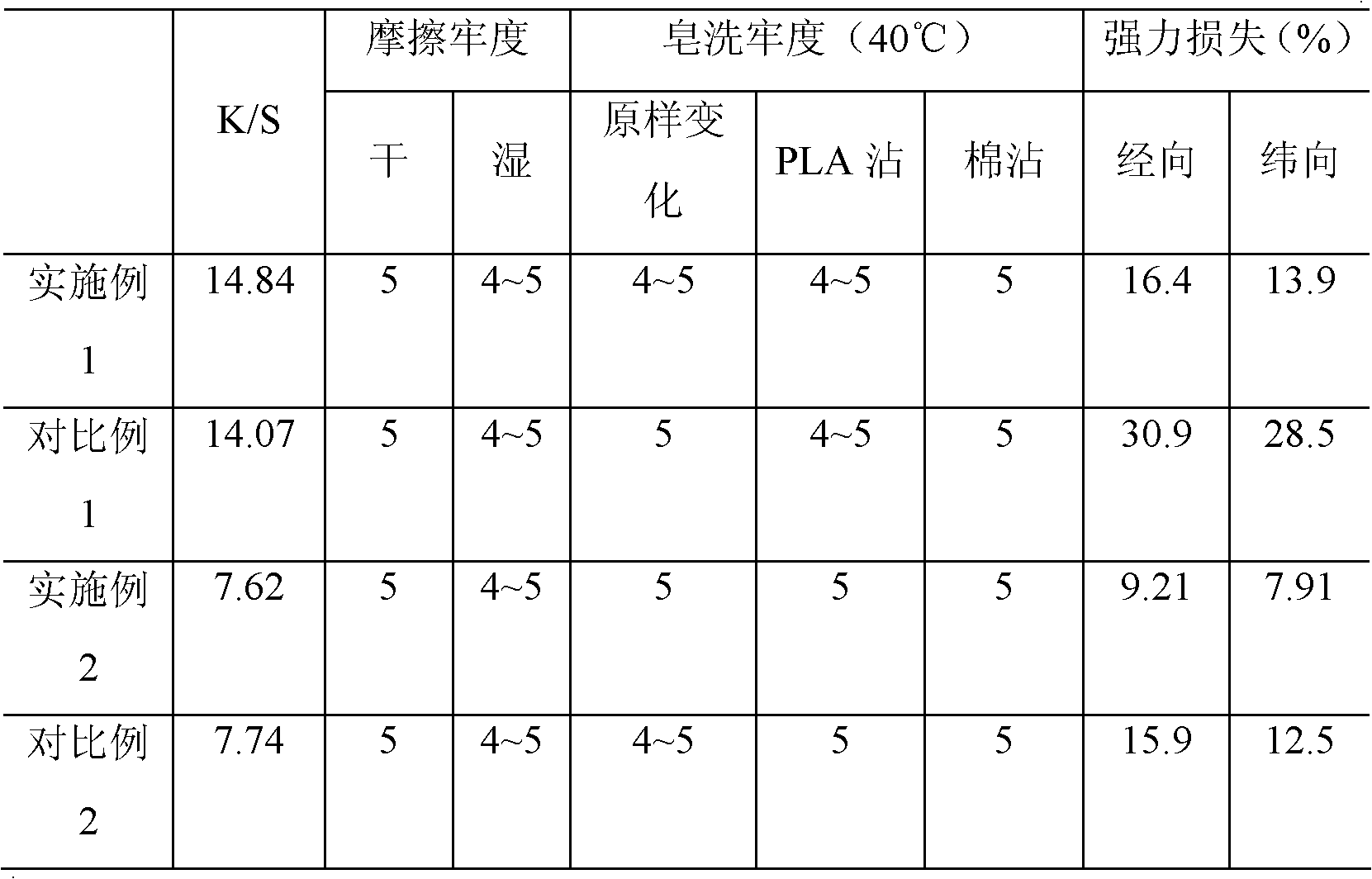

Embodiment 1

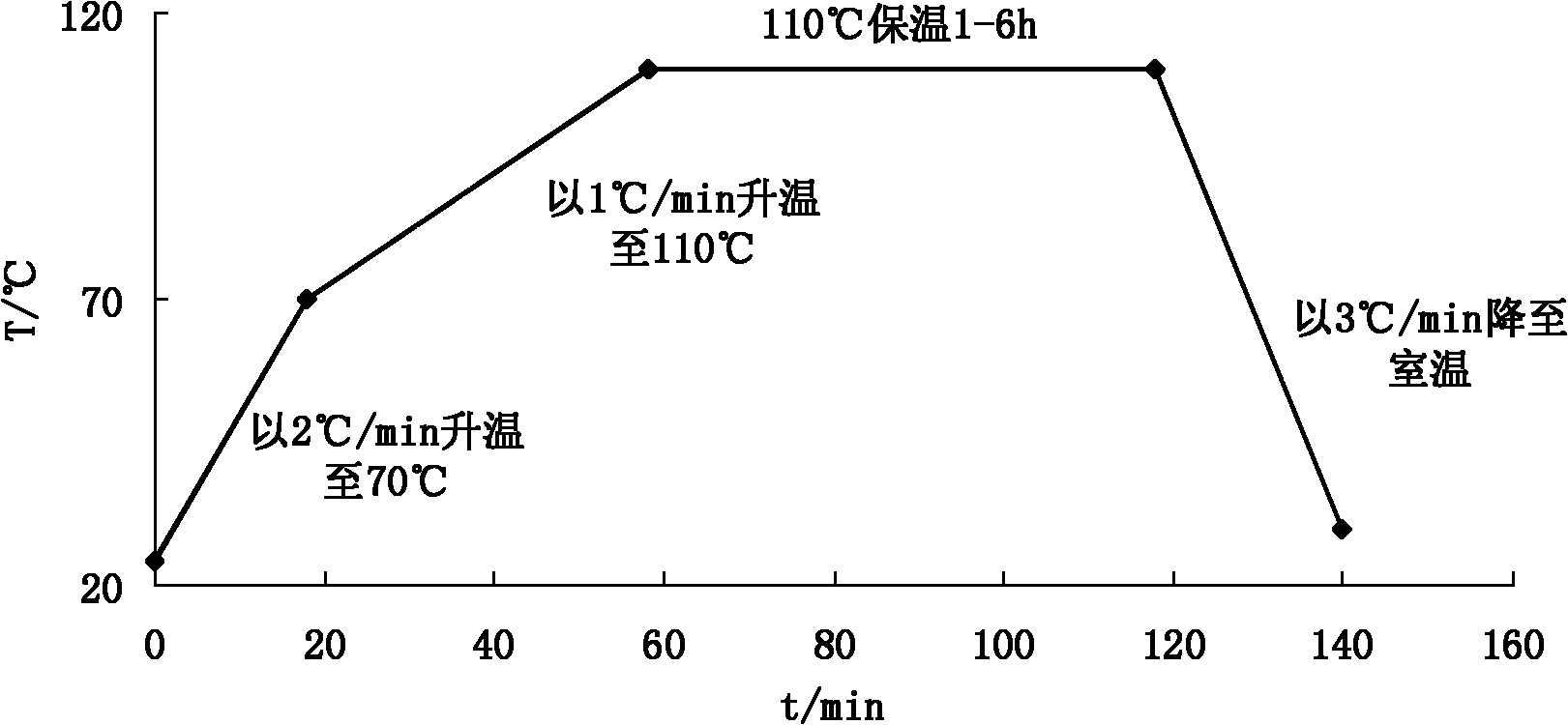

[0032] Weigh 1g (accurate to 0.001g) of PLA fiber nonwoven fabric, weigh 0.04g of disperse dye microcapsule blue with a core-wall ratio of 1:1 by 2 o.w.f.%, and take 60ml dyeing solution (0.5ml / L of HAc) into the dyeing tank; start from room temperature and heat up to 70°C within 20 minutes; then use 45 minutes to raise the temperature to 115°C; keep the temperature for 40min after the temperature reaches 115°C; dye the PLA fiber nonwoven fabric Put 60ml of dye solution [dyeing bath that has been recycled after simple treatment (filtering out capsules)], and then treat it at 115°C for 15 minutes; take out the nonwoven fabric sample after 15 minutes, wash it with clean water, and dry it to get the finished product . The dyeing wastewater is colorless and transparent after being filtered, and meets the national first-level discharge standard.

Embodiment 2

[0036]Weigh 1g (accurate to 0.001g) of PLA fiber nonwoven fabric, weigh 0.04g of disperse blue (C.I. disperse blue 56) microcapsules with a core-wall ratio of 1:1 at 2 o.w.f.%, and take 60ml with a bath ratio of 60:1 Dye liquor (0.5ml / L HAc) is loaded into the dyeing tank; from room temperature, the temperature is raised to 70°C within 20 minutes; the temperature is raised to 90°C in another 20 minutes; after the temperature reaches 90°C, it is kept for 40 minutes; after dyeing, the nonwoven Put the cloth swatch into 60ml of dye solution [dyeing bath after simple treatment (filtering out the capsules) and reuse it], and then treat it at 90°C for 15 minutes; take out the cloth swatch after 15 minutes, wash it with clean water, and dry it to get the finished product .

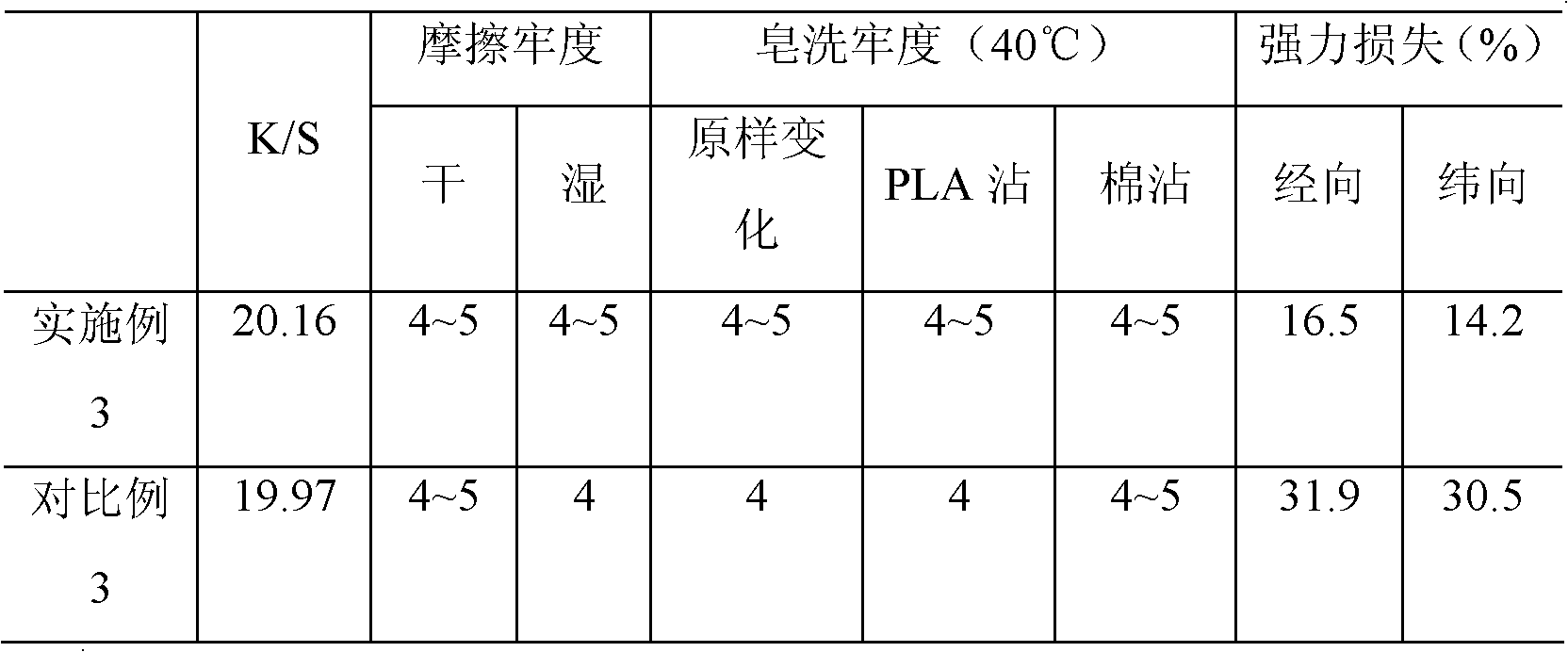

Embodiment 3

[0044] Weigh 1g (accurate to 0.001g) of PLA fiber nonwoven fabric, weigh 0.08g of disperse blue (C.I. disperse blue 56) microcapsules with a core-wall ratio of 1:1 at 4 o.w.f.%, and take 60ml with a bath ratio of 60:1 Dye solution (0.5ml / L HAc) into the dyeing tank; start from room temperature and heat up to 70°C within 20 minutes; then raise the temperature to 115°C in 45 minutes; keep warm for 1 hour after the temperature reaches 115°C, and then cool down; After washing the nonwoven fabric sample with acid, put it into 60ml of dye solution (0.5ml / L HAc), and then treat it at 115°C for 15 minutes; take out the nonwoven fabric sample after 15 minutes, wash it with water, and dry it in the air. Get the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com