High-fixation-rate nano liquid disperse dye as well as preparation method and application thereof

A technology of liquid disperse dyes and high color fixation rate, applied in dyeing, organic dyes, textiles and papermaking, etc., can solve the problems of small number of varieties and high price, reduce the generation of floating color and improve color fastness , the effect of reducing the processing burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] S11: Preparation of Nano Liquid Disperse Dyes with High Fixation Rate

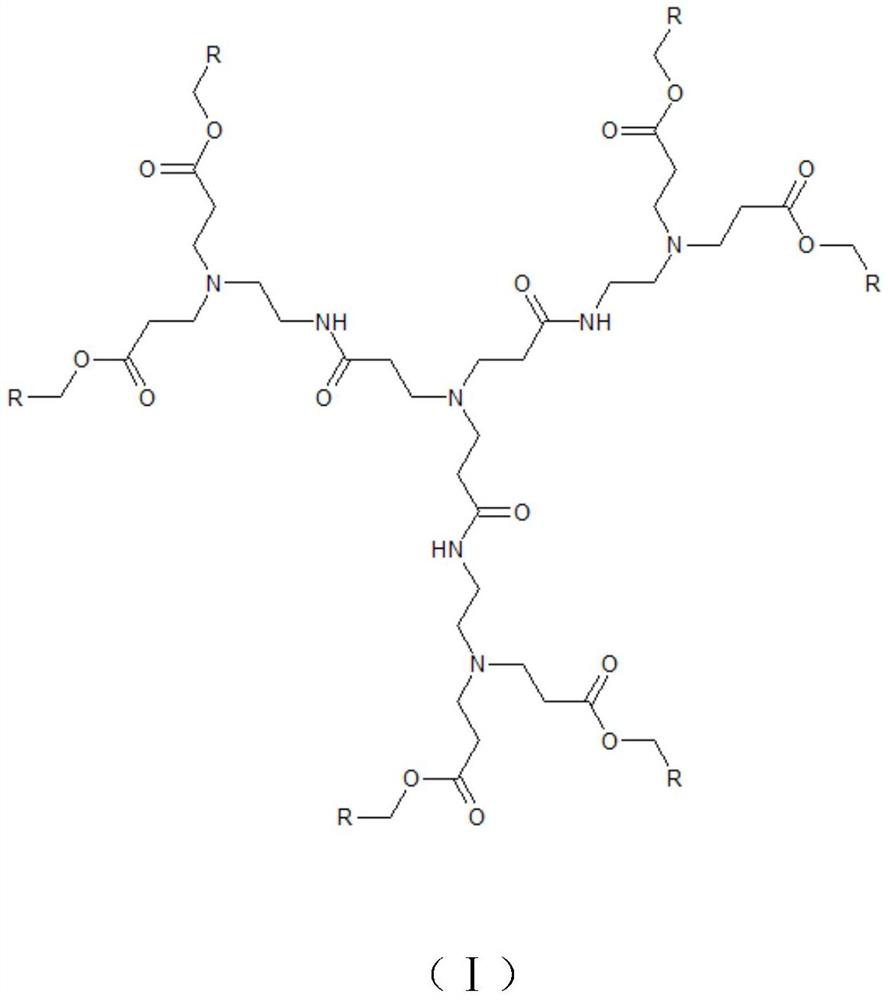

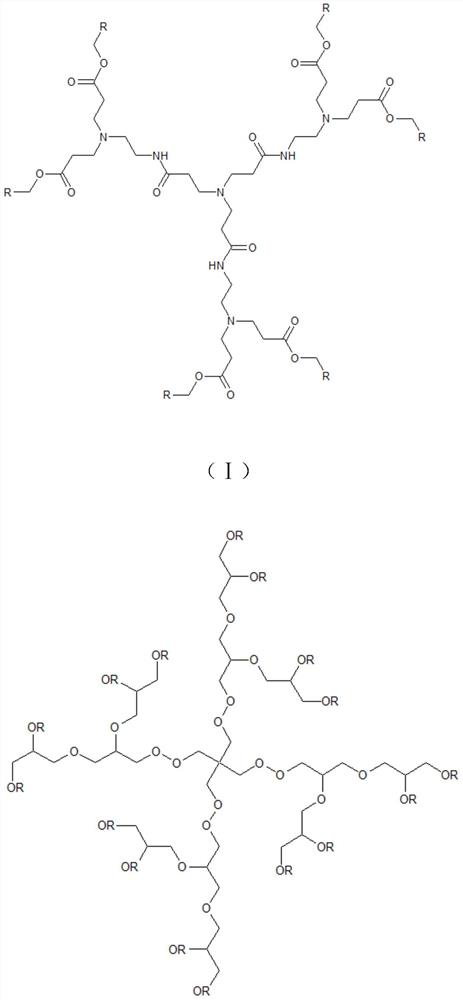

[0033] Add 3% bentonite, a grinding aid, into deionized water, mix evenly, and make it fully swell. Then add 30% disperse red 167 dyestuff filter cake, 6% lignosulfonate, 5% alkylphenol polyoxyethylene ether, at rotating speed is 1500rpm, and grinding ball adopts the zirconium pearl that diameter is 1.4mm, and ball-to-material ratio is After grinding for 3 hours in a 2:1 ball mill, add a surplus of deionized water to form a pre-ground dye system, add 2% polyurethane type hyperbranched dispersant (shown in chemical structural formula (Ia)) to the system, and Continue to grind for 2 hours in a ball mill at 2000rpm, and then filter through a 1μm filter to obtain a filtrate. Add 4% sodium polyacrylate and 0.5% methylisothiazolinone to the filtrate, and obtain a high color fixation rate after high-speed shear emulsification Nano liquid disperse dyes. Wherein, the percentages of all components are mass ...

Embodiment 2

[0038] S21: Preparation of Nano Liquid Disperse Dyes with High Fixation Rate

[0039] Add 3% bentonite, a grinding aid, into deionized water, mix evenly, and make it fully swell. Then add 25% disperse blue 183:1 dye filter cake, 4% lignin sulfonate, 5% alkylphenol polyoxyethylene ether, at 1500rpm at the rotating speed, the zirconium bead of 1.4mm is that the grinding ball adopts diameter, and ball material After grinding for 3 hours in a ball mill with a ratio of 2:1, add a surplus of deionized water to form a pre-ground dye system, and add 2% polyurethane type hyperbranched dispersant (shown in chemical structural formula (Ib)) to this system , continue to grind for 2 hours in a ball mill with a rotating speed of 2000rpm, and then filter through a 1 μm filter screen to obtain a filtrate. Add 6% sodium polyacrylate and 0.5% methylisothiazolinone to the filtrate, and obtain a high-speed shear emulsification. Fixation rate nano liquid disperse dyes. Wherein, the percentages o...

Embodiment 3

[0044] S31: Preparation of Nano Liquid Disperse Dyes with High Fixation Rate

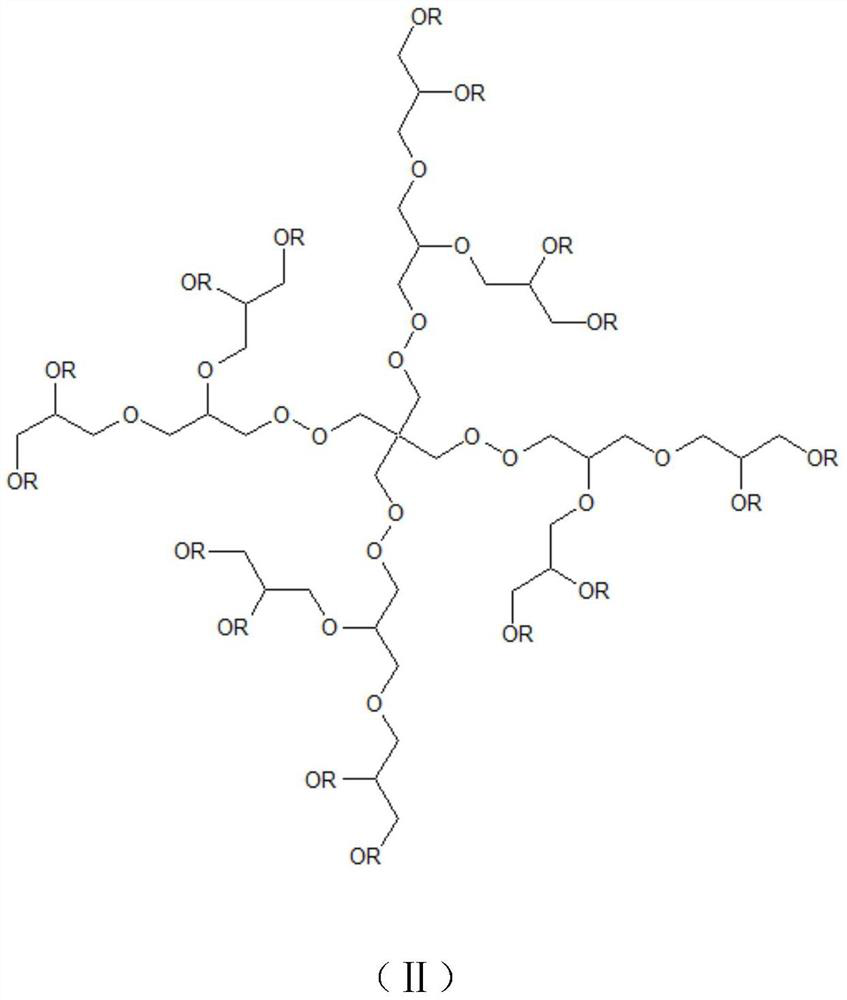

[0045] Add 3% bentonite, a grinding aid, into deionized water, mix evenly, and make it fully swell. Then add 20% disperse yellow 114 dyestuff filter cake, 4% lignosulfonate, 5% alkylphenol polyoxyethylene ether, at rotating speed is 1500rpm, and grinding ball adopts the zirconium pearl that diameter is 1.4mm, and ball-to-material ratio is After grinding for 3 hours in a 2:1 ball mill, add a surplus of deionized water to form a pre-grinding dye system, and add 1.5% polyurethane type hyperbranched dispersant (shown in chemical structural formula (IIa)) to the system. Continue to grind for 2 hours in a ball mill with a rotating speed of 2000rpm, and then filter through a 1μm filter to obtain a filtrate. Add 3% sodium polyacrylate and 0.6% 1,2-benzisothiazol-3-one to the filtrate, and shear at a high speed After emulsification, nano liquid disperse dyes with high color fixation rate can be obtained. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com