Polyester-cotton blended yarn dyeing process

A yarn dyeing and polyester-cotton blending technology is applied in the field of yarn dyeing and finishing, which can solve the problems of low dyeing uniformity of polyester-cotton blended yarns, improve dyeing quality and dyeing effect, save production water consumption, and reduce dyeing. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

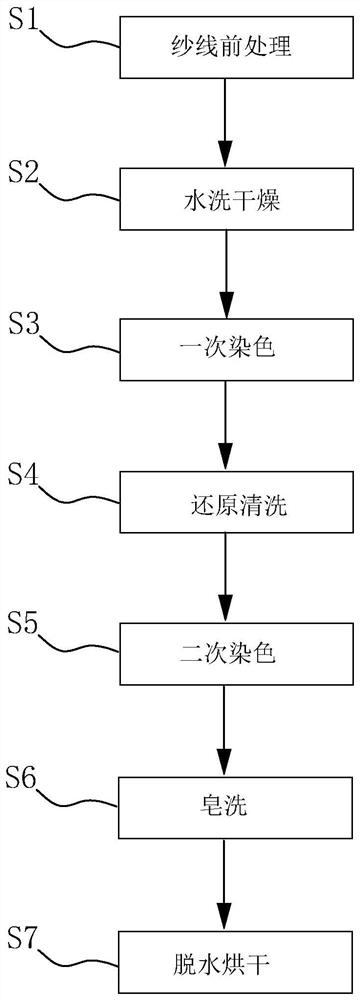

[0040] refer to figure 1

[0041] A kind of polyester-cotton blended yarn dyeing process comprises the steps:

[0042] S1. Yarn pretreatment, the yarn is transported through the unwinding mechanism to the pretreatment solution for soaking. The pretreatment solution includes 3 parts of pectinase, 4 parts of α-amylase, 4 parts of hydrogen peroxide, 0.5 parts of sodium silicate, 1 Parts of anionic penetrant OEP-98, 0.5 part of cocamidopropyl hydroxy sultaine, 65 parts of deionized water, pH is 7, temperature of pretreatment solution is 75°C, treatment time is 30min; Use ultrasonic waves to continuously ultrasonically vibrate the yarn;

[0043] S2, washing and drying, cleaning the yarn that has completed the pretreatment of step S1, and drying the yarn to a moisture content of 2%;

[0044]S3, one-time dyeing, add 1.5g / L disperse dye leveling agent in the primary dyeing bathtub, the disperse dye leveling agent includes anionic disperse leveling agent and non-ionic disperse level...

Embodiment 2

[0050] refer to figure 1

[0051] A kind of polyester-cotton blended yarn dyeing process comprises the steps:

[0052] S1. Yarn pretreatment, the yarn is transported through the unwinding mechanism to the pretreatment solution for soaking. The pretreatment solution includes 4 parts of pectinase, 6 parts of α-amylase, 5 parts of hydrogen peroxide, 0.7 part of sodium silicate, 1.5 1 part of anionic penetrant OEP-98, 0.7 part of cocamidopropyl hydroxy sultaine, 70 parts of deionized water, pH 7.5, pretreatment liquid temperature 80 ℃, treatment time 35 minutes; yarn soaking process Use ultrasonic waves to continuously ultrasonically vibrate the yarn;

[0053] S2, washing and drying, the yarn that has completed the pretreatment of step S1 is cleaned, and the yarn is dried to a moisture content of 2.5%;

[0054] S3, one-time dyeing, add 2g / L disperse dye leveling agent in the primary dyeing bathtub, the disperse dye leveling agent includes anionic disperse leveling agent and non...

Embodiment 3

[0060] refer to figure 1

[0061] A kind of polyester-cotton blended yarn dyeing process comprises the steps:

[0062] S1. Yarn pretreatment, the yarn is transported through the unwinding mechanism to the pretreatment solution for soaking. The pretreatment solution includes 5 parts of pectinase, 7 parts of α-amylase, 6 parts of hydrogen peroxide, 0.9 parts of sodium silicate, 2 parts of 1 part of anionic penetrant OEP-98, 0.9 part of cocamidopropyl hydroxysulfobetaine, 80 parts of deionized water, pH 8, pretreatment liquid temperature 80 ℃, treatment time 45 minutes; yarn soaking process Use ultrasonic waves to continuously ultrasonically vibrate the yarn;

[0063] S2, washing and drying, cleaning the yarn that has completed the pretreatment of step S1, and drying the yarn to a moisture content of 3%;

[0064] S3, one-time dyeing, add 2.5g / L disperse dye leveling agent in the primary dyeing bathtub, the disperse dye leveling agent includes anionic disperse leveling agent an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com