Dyeing method of reactive dye with high color fixation rate

A technology of reactive dyes and dyeing methods, applied in the field of reactive dyeing with high fixation rate, can solve the problems of high equipment requirements, reduced wet rubbing fastness, decreased tear strength, etc., so as to reduce environmental pollution and improve dyeing rate. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

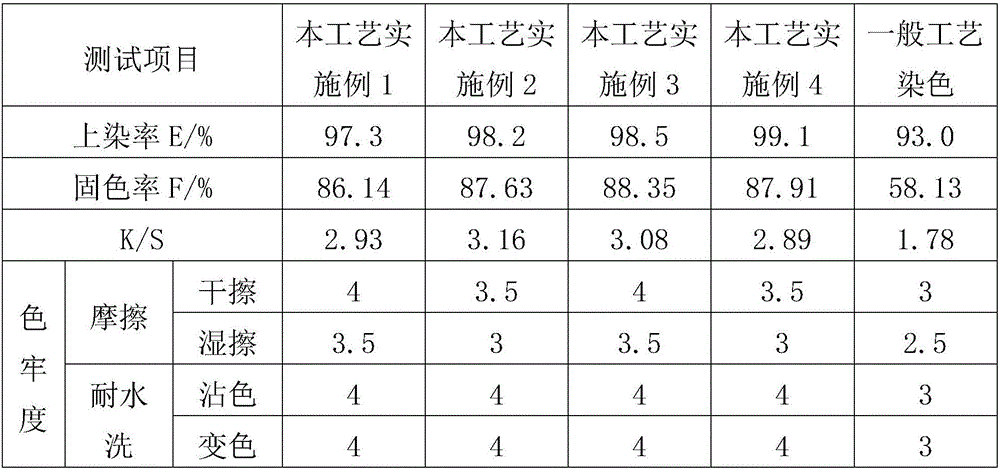

Examples

Embodiment 1

[0020] In the present embodiment, a kind of reactive dye dyeing method of high fixation rate comprises the steps:

[0021] S1, pretreatment, padding the fabric to be dyed in the finishing solution containing chitosan quaternary ammonium salt, two dipping and two padding, the temperature of the padding tank is 30 ° C, the excess rate is 100%, pre-baked at 80 ° C for 3 minutes , then baked at 110°C for 10min, washed in cold water, and dried at 60°C; wherein the finishing liquid containing chitosan quaternary ammonium salts includes: chitosan quaternary ammonium salt 5g / L, triethanolamine 5g / L, Polycarboxylic acid 0.5g / L, sodium hypophosphite 1g / L, the balance is water, wherein the preparation method of chitosan quaternary ammonium salt comprises: chitosan is added in isopropanol, adding content is 25wt% The sodium hydroxide solution was stirred evenly, then etherifying agent CTA was added, stirred and reacted in a water bath at 60°C for 2 hours, added hydrochloric acid to adjust...

Embodiment 2

[0025] In the present embodiment, a kind of reactive dye dyeing method of high fixation rate comprises the steps:

[0026]S1, pretreatment, padding the fabric to be dyed in the finishing solution containing chitosan quaternary ammonium salt, two dipping and two padding, the temperature of the padding tank is 50 ° C, the excess rate is 90%, pre-baked at 100 ° C for 1 min , and then baked at 130°C for 5 minutes, washed in cold water, and dried at 80°C; wherein the finishing liquid containing chitosan quaternary ammonium salt includes: chitosan quaternary ammonium salt 15g / L, N-methyldiethanolamine 1g / L, polycarboxylic acid 2g / L, sodium hypophosphite 0.1g / L, and the balance is water, wherein the preparation method of chitosan quaternary ammonium salt comprises: adding chitosan in isopropanol, adding The sodium hydroxide solution with a content of 35wt% was stirred evenly, then etherification agent CTA was added, stirred and reacted in a water bath at 40° C. for 4 hours, and hydro...

Embodiment 3

[0030] In the present embodiment, a kind of reactive dye dyeing method of high fixation rate comprises the steps:

[0031] S1, pretreatment, padding the fabric to be dyed in the finishing solution containing chitosan quaternary ammonium salt, two dipping and two padding, the temperature of the padding tank is 40°C, the excess rate is 95%, pre-baked at 90°C for 2min , then baked at 120°C for 7 minutes, washed in cold water, and dried at 70°C; wherein the finishing liquid containing chitosan quaternary ammonium salts includes: chitosan quaternary ammonium salts 10g / L, organic amine compounds 3g / L L, polycarboxylic acid 1g / L, sodium hypophosphite 0.5g / L, surplus are water, wherein the preparation method of chitosan quaternary ammonium salt comprises: chitosan is added in isopropanol, adding content is 30wt% sodium hydroxide solution was stirred evenly, then etherification agent CTA was added, stirred and reacted in a water bath at 50° C. for 3 hours, hydrochloric acid was added t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com