Printing and dyeing technology with high dyeing automation degree

A technology of printing and dyeing technology, applied in the processing of textile materials, textile processing machine accessories, extrusion liquid/gas/vapor removal other than drums, etc., can solve the problem of reducing dyeing efficiency, high labor intensity and low desizing efficiency. and other problems, to achieve the effect of high degree of dyeing automation, reducing labor intensity and improving dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

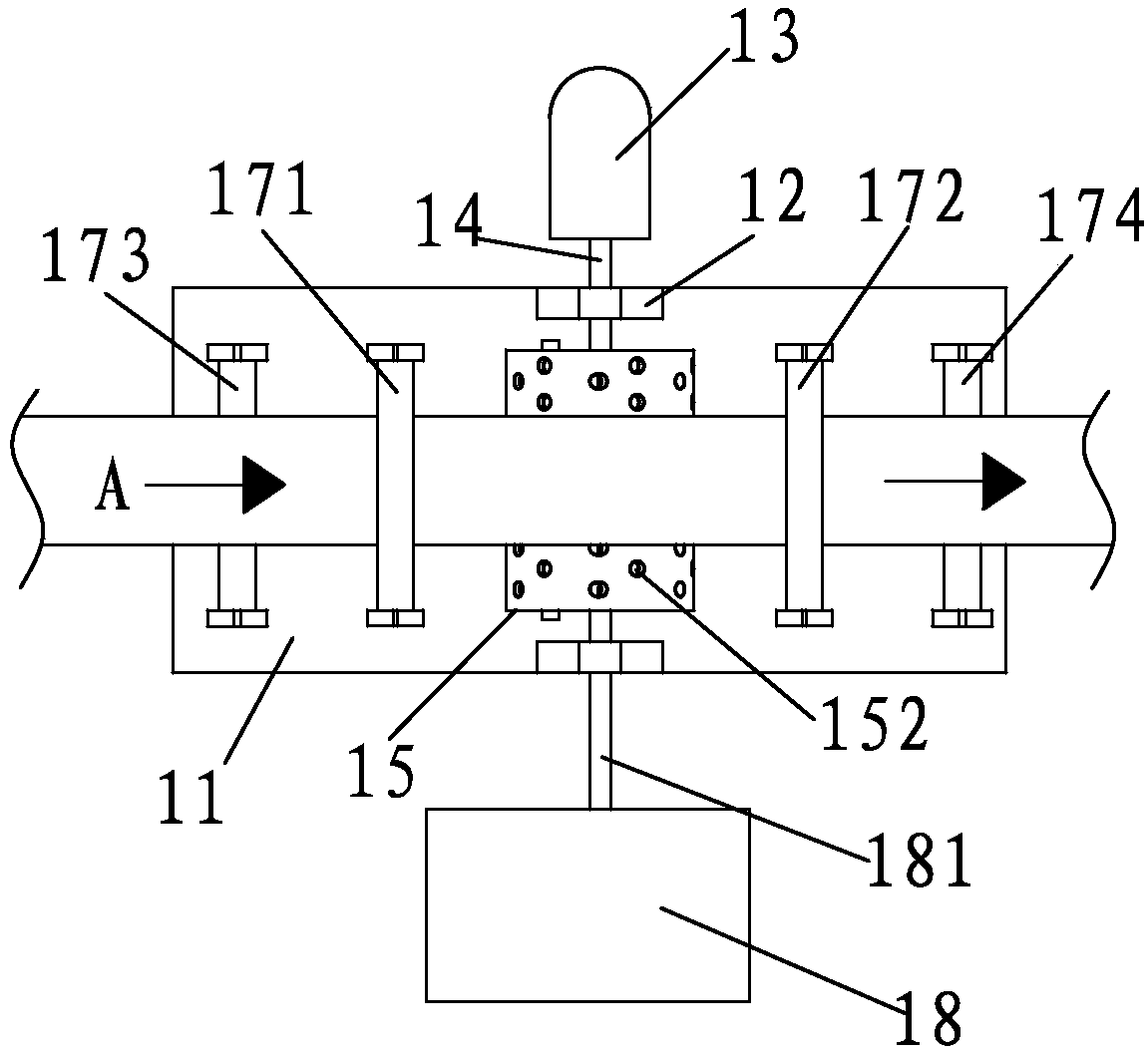

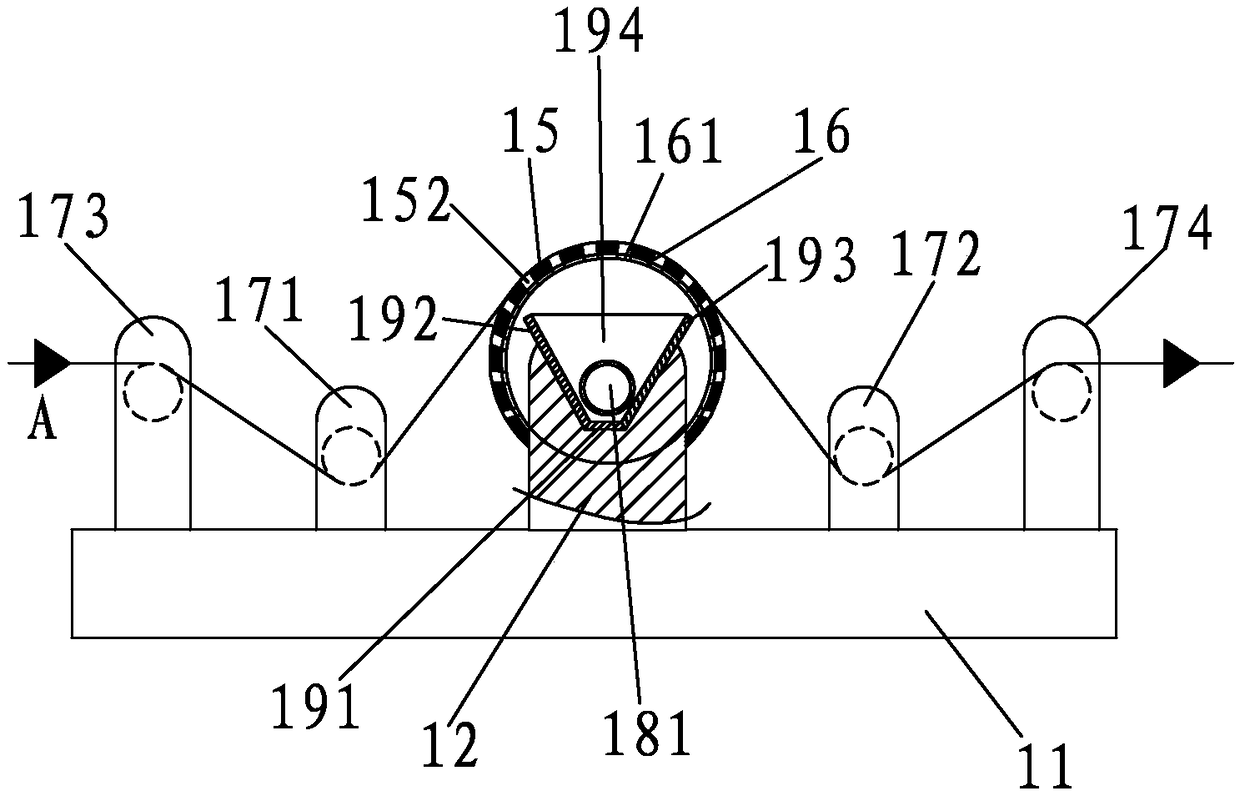

[0053] The direction of arrow A in the figure is the advancing direction of the cloth, and the direction of arrow B is the advancing direction of the impurity removal conveyor belt.

[0054] Such as Figure 1-13 As shown, a printing and dyeing process with a high degree of dyeing automation, wherein the printing and dyeing process with a high degree of dyeing automation includes the following steps:

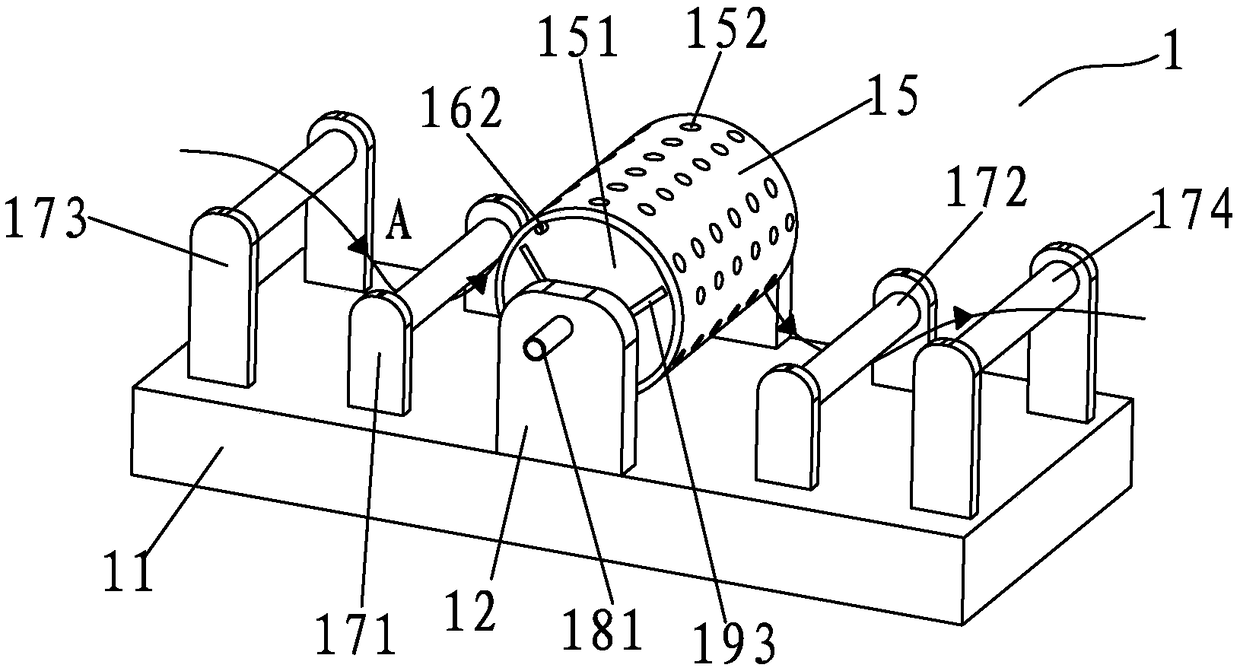

[0055]1. Place the cloth on the conveyor belt, and transport it to the singeing machine 1 through the conveyor belt, and the singeing machine 1 burns the fluff on the cloth; the singeing machine 1 includes a first base 11, a support frame 12, a first motor 13. The first rotating shaft 14, the annular electric heating metal cylinder 15, the annular cylindrical bag 16, the regional negative pressure device, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com