A kind of disperse dye polyester dyeing method using siloxane as medium

A technology of disperse dyes and dyeing methods, applied in the field of textile ecological dyeing and finishing, can solve the problems of difficult wastewater treatment, large water consumption, and high equipment dependence, and achieve the effect of reducing dependence and requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 30g of disperse red dye and 200g of siloxane medium to prepare a dye solution for later use. Get 6kg of polyester fiber and put it into siloxane medium, liquor ratio 1:4.5, add dyeing solution and 500g ethyl acetate, keep 7 o C / min heating up to 80 o C, keep 2 o C / min heating up to 140 o C, keep warm for 60min, quickly cool down and remove the liquid, then add siloxane medium, with 7 o C / min heating up 80 o C to keep warm for 10 minutes, wash twice in total, and finally deliquify and dry to obtain the finished dyed product.

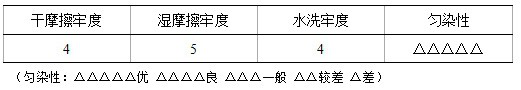

[0024]

Embodiment 2

[0026] Take 10g of disperse orange dye and 200g of siloxane medium to prepare a dye solution for later use. Take 1.5kg of polyester fiber and put it into siloxane medium, bath ratio 1:5, add dye solution and 50% ethanol, keep 5 o C / min heating up to 80 o C, keep 3 o C / min heating up to 140 o C, keep warm for 50min, quickly cool down and remove the liquid, then add siloxane medium, with 8 o C / min heating up to 90 o C to keep warm for 10 minutes, wash twice in total, and finally deliquify and dry to obtain the finished dyed product.

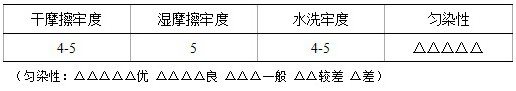

[0027]

Embodiment 3

[0029] Take 0.1g of disperse blue dye and 1g of siloxane medium to prepare a dye solution for later use. Take 10g of polyester fiber and put it into siloxane medium, the bath ratio is 1:10, add dyeing solution, keep 7 o C / min heating up to 80 o C insulation for 30min, the insulation process is divided into four equal parts, the first three parts are three times to add dye solution, the last part is to add 1g acetic acid, keep 2 o C / min heating up to 140 o C, keep warm for 60min, quickly cool down and remove the liquid, then add siloxane medium, with 7 o C / min heating up 80 o C to keep warm for 10 minutes, wash twice in total, and finally deliquify and dry to obtain the finished dyed product.

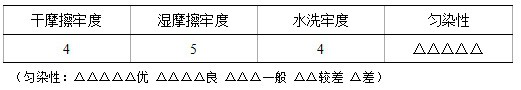

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com