Alkaline silica sol color fixing agent and preparation method thereof

A technology of silica sol and color-fixing agent, which is applied in the direction of manufacturing tools, wood treatment, wood processing equipment, etc., can solve the problem of color fixing rate, color fastness improvement, hindering dye molecule adsorption and diffusion, increasing water consumption and Environmental pollution and other issues, to achieve the effect of improving color fastness to washing, easy operation, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of alkaline silica sol of the present invention specifically comprises the following steps:

[0026] (1) Mix 21.2g tetraethyl orthosilicate and 92g absolute ethanol, stir evenly, and make A solution.

[0027] (2) 76g of distilled water and 7mL of concentrated ammonia water with a mass fraction of 28% were mixed to obtain solution B.

[0028] (3) Get 38g of A solution and put it into the reactor, heat up to 40°C at a heating rate of 2°C / min, start the stirrer in the reactor, and control the stirring speed at 500 rpm; Add solution B and the remaining solution A dropwise, condense and reflux at 40°C, react for 30 minutes, then add 0.1g of KH550 (γ-aminopropylethoxysilane) dropwise, continue to stir and react for 1.5 hours, and let it stand for aging After 12 hours, a milky white alkaline silica sol color fixing agent was obtained.

[0029] The alkali silica sol color-fixing agent has a viscosity of 25 mPa·S, a solid content of 12%, and an average p...

Embodiment 2

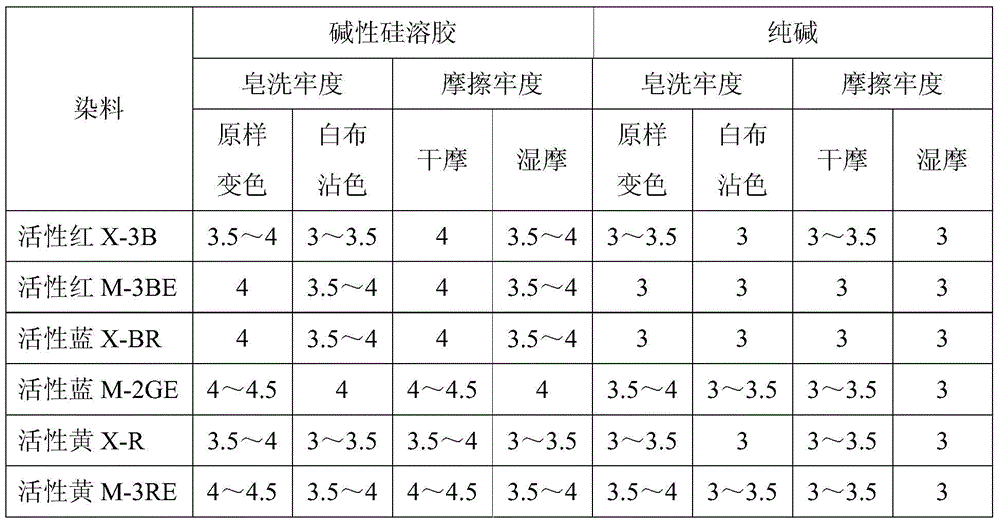

[0034] The alkaline silica sol color-fixing agent of embodiment 1 is compared with soda ash, investigates the color-fixing effect of reactive dyestuff to wood staining:

[0035] Respectively prepare reactive red X-3B dyeing solution, reactive red M-3BE dyeing solution, reactive blue X-BR dyeing solution, reactive blue M-2GE dyeing solution, reactive yellow X-R dyeing solution, reactive Yellow M-3RE dyeing solution; add 40g / L sodium sulfate to each dyeing solution, and dye poplar veneer (specification 100×50×2mm) for 3 hours at a bath ratio of 1:20 at a constant temperature of 80°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com