Dynamic covalent bond cross-linked oil displacement polymer and preparation method thereof

A technology of dynamic covalent bond and oil-displacement polymer, which is applied in the fields of oil extraction, transportation and chemical industry, and can solve the problems of high industrialization level, poor applicability of medium and low permeability reservoirs, salt resistance, shear resistance and increasing Problems such as poor stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

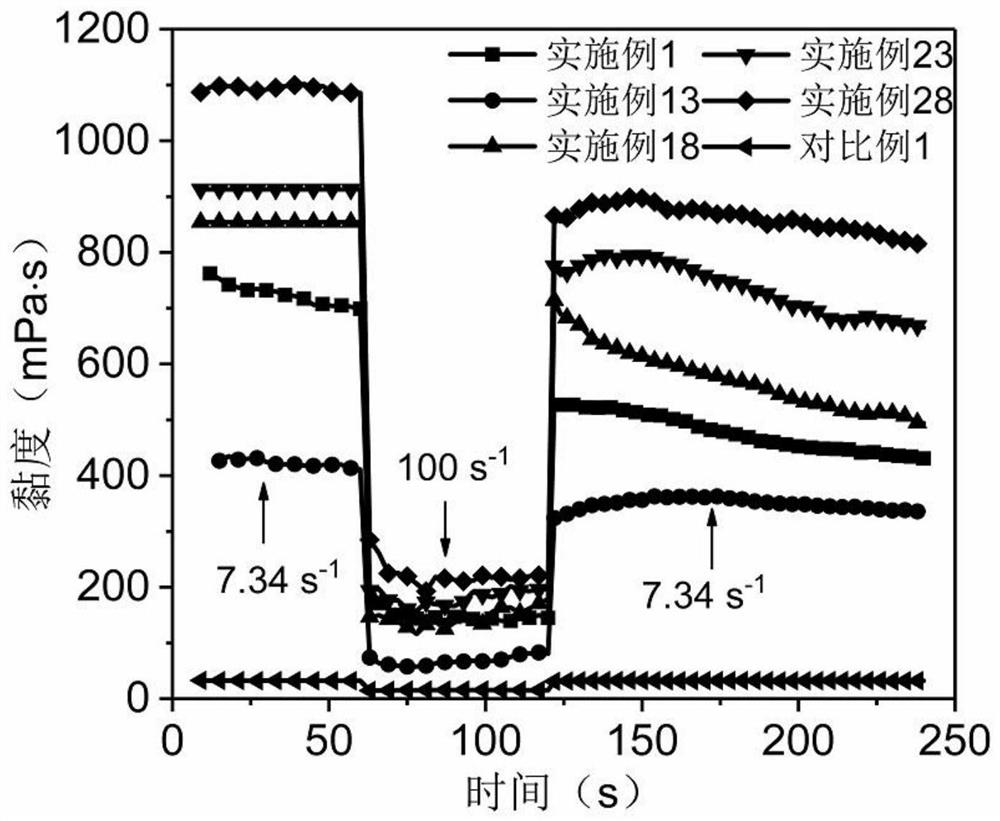

Examples

Embodiment 1

[0042] The preparation method of the oil-displacement polymer cross-linked by dynamic covalent bond comprises the following steps:

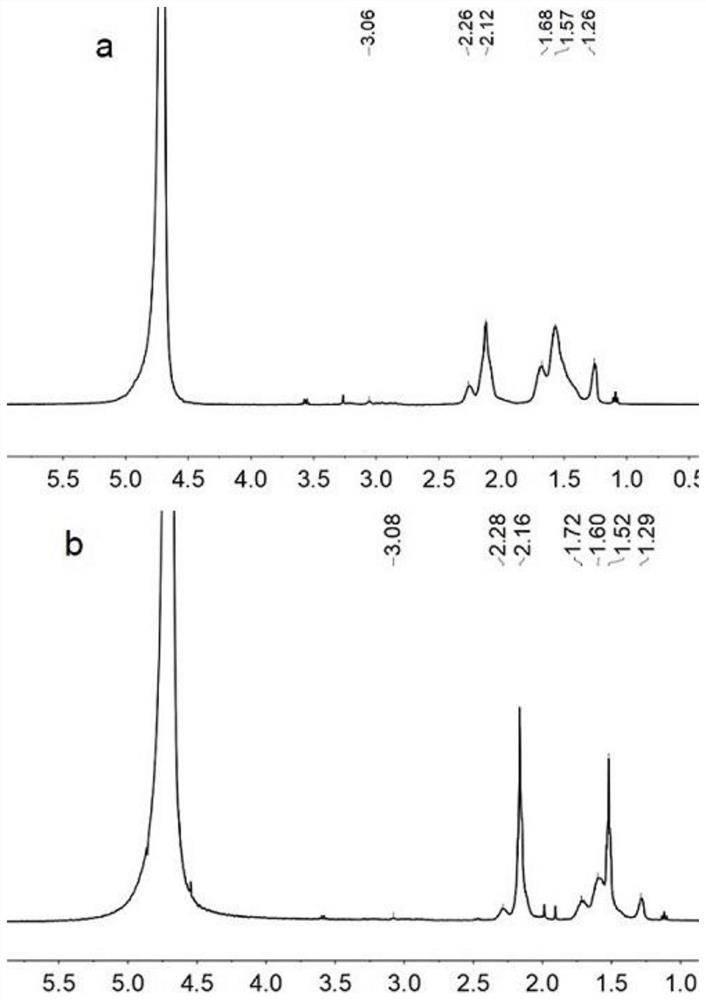

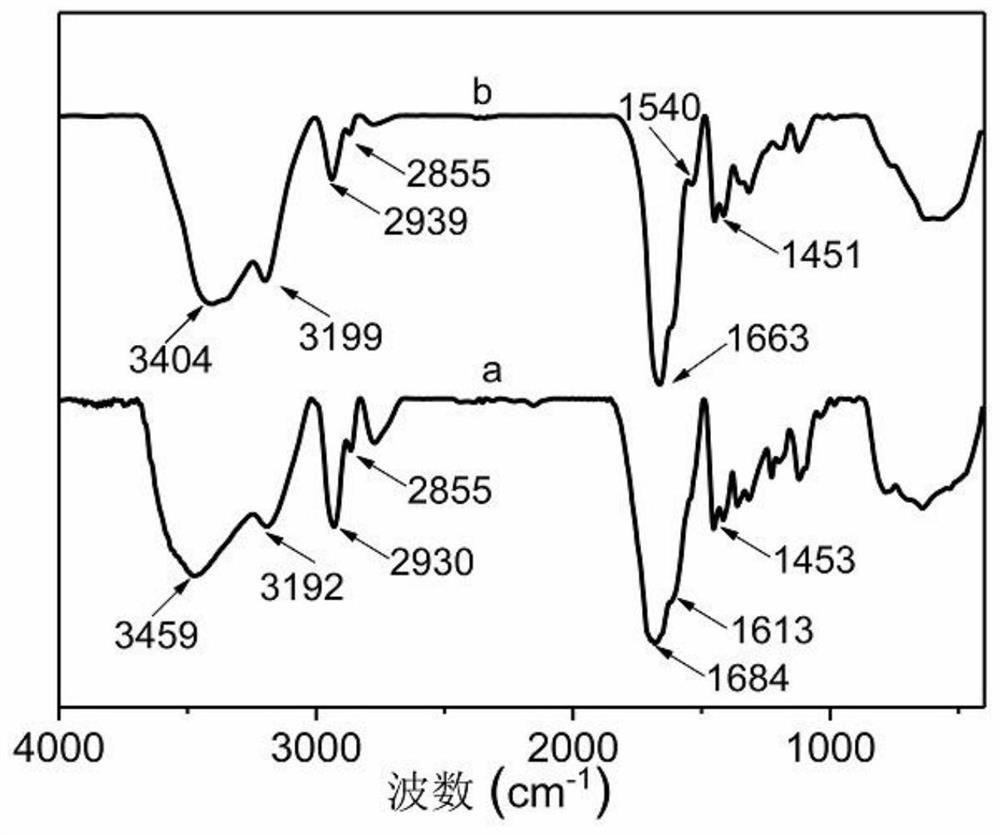

[0043] (1) Synthesis of acrylamide-diacetone acrylamide copolymer

[0044] Add 4.00g of acrylamide to 30g of deionized water, fully dissolve under magnetic stirring, then add 0.50g of diacetone acrylamide to dissolve completely and pass nitrogen gas for 30min, during which time the temperature is raised to 50°C, and 6.75mg of ammonium persulfate (APS) is added. Keep the reaction at 50°C for 8h, precipitate and wash with acetone, dry and pulverize to obtain about 4.31g of white solid.

[0045] (2) Synthesis of acrylamide-diacetone acrylamide copolymer crosslinked by dynamic covalent bonds

[0046] Add 0.06 g of the acrylamide-diacetone acrylamide copolymer obtained in step (1) to 20 mL of deionized water, place it in a horizontal constant temperature shaker at 25 ° C, and dissolve it at a speed of 170 r / min for 12 to 24 hours to obtain a uniform ...

Embodiment 2

[0048] The method for preparing the oil-displacing polymer cross-linked by dynamic covalent bonds is the same as that described in Example 1, except that the amount of adipic hydrazide used in step (2) is 17.5 μL.

Embodiment 3

[0050] The method for preparing the oil-displacing polymer cross-linked by dynamic covalent bonds is the same as that described in Example 1, except that the amount of adipic hydrazide used in step (2) is 26.3 μL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com