Water-based acrylate pressure-sensitive adhesive and preparation method thereof

A water-based acrylate and acrylate technology, used in adhesives, ester copolymer adhesives, adhesive types, etc., can solve the problem that acrylic pressure-sensitive adhesives are difficult to achieve high temperature retention, and achieve good adhesion. , High retention force, high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

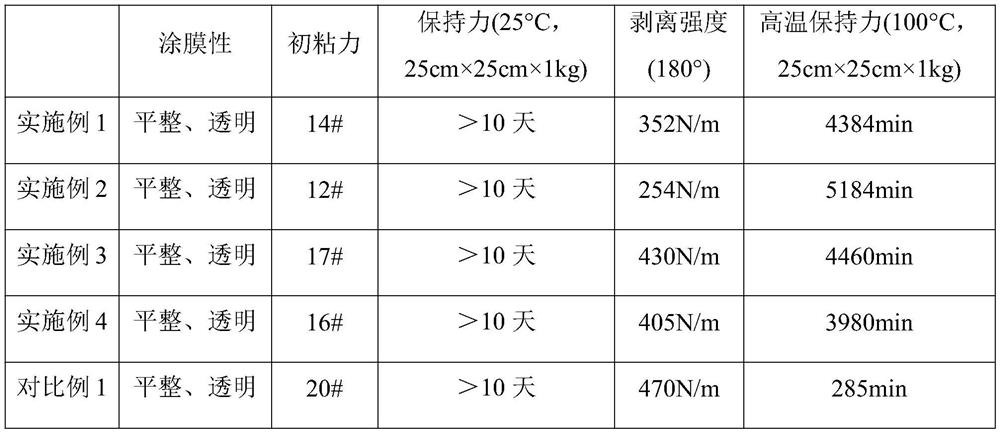

Examples

Embodiment 1

[0043] (1) Preparation of pre-emulsion and initiator

[0044] Weigh 1.8g of sodium alkyl succinate sulfonate emulsifier, 0.4g of fatty alcohol polyether emulsifier, 45.3g of butyl acrylate, 6.8g of isooctyl acrylate, 1.7g of ethyl acrylate, 1.8g of acrylic acid, acetoacetate 1 g of ethyl methacrylate, 0.05 g of tert-dodecyl mercaptan, and 8.95 g of deionized water were mixed with mechanical stirring to obtain pre-emulsified component A, and stirred for at least 30 minutes to prevent delamination;

[0045] Weigh 0.1 g of ammonium persulfate and 2.5 g of deionized water, mix and dissolve to obtain component B;

[0046] Weigh 0.15 g of ammonium persulfate and 2.5 g of deionized water, mix and dissolve to obtain component C.

[0047] (2) Emulsion polymerization

[0048] Add 0.05 g of sodium bicarbonate and 19 g of deionized water into a four-necked reaction flask equipped with a mechanical stirrer, a reflux condenser, a thermometer, and a constant pressure funnel, turn on the me...

Embodiment 2

[0053] (1) Preparation of pre-emulsion and initiator

[0054] Weigh 1.6g of sodium alkyl succinate sulfonate emulsifier, 0.6g of fatty alcohol polyether emulsifier, 44.3g of butyl acrylate, 6.8g of isooctyl acrylate, 1.7g of acrylic acid, ethylene urea methacrylate 2 g of base ester, 0.05 g of tert-dodecyl mercaptan, and 8.95 g of deionized water were mixed with mechanical stirring to obtain pre-emulsified component A, and stirred for at least 30 minutes to prevent delamination;

[0055] Weigh 0.12 g of ammonium persulfate and 2.5 g of deionized water, mix and dissolve to obtain component B;

[0056] Weigh 0.13 g of ammonium persulfate and 2.5 g of deionized water, mix and dissolve to obtain component C.

[0057] (2) Emulsion polymerization

[0058] Add 0.05 g of sodium bicarbonate and 19 g of deionized water into a four-necked reaction flask equipped with a mechanical stirrer, a reflux condenser, a thermometer, and a constant pressure funnel, start stirring at a stirring sp...

Embodiment 3

[0063] (1) Preparation of pre-emulsion and initiator

[0064] Weigh 1.6g of dioctyl sodium sulfosuccinate emulsifier, 0.4g of fatty alcohol polyether emulsifier, 45g of butyl acrylate, 6.8g of isooctyl acrylate, 1.7g of acrylic acid, 1g of ethyl acetoacetate methacrylate, 0.5 g of β-carboxyethyl acrylate, 0.05 g of tert-dodecyl mercaptan, and 8.95 g of deionized water, and mechanically stirred to obtain pre-emulsified component A. Stir for at least 30 minutes to prevent delamination;

[0065] Weigh 0.1 g of ammonium persulfate and 2.5 g of deionized water, mix and dissolve to obtain component B;

[0066] Weigh 0.15 g of ammonium persulfate and 2.5 g of deionized water, mix and dissolve to obtain component C.

[0067] (2) Emulsion polymerization

[0068] Add 0.05 g of sodium bicarbonate and 19 g of deionized water into a four-necked reaction flask equipped with a mechanical stirrer, a reflux condenser, a thermometer, and a constant pressure funnel, start stirring at a stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com