Environment-friendly tire rubber material and preparation method thereof

A technology for rubber materials and tires, which is applied in the field of environmentally friendly tire rubber materials and its preparation, can solve the problems of poor environmental protection performance, further improvement of rubber performance stability, and many types and quantities of additives, etc., to achieve airtight performance and Good performance stability, good fatigue resistance, high production efficiency and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

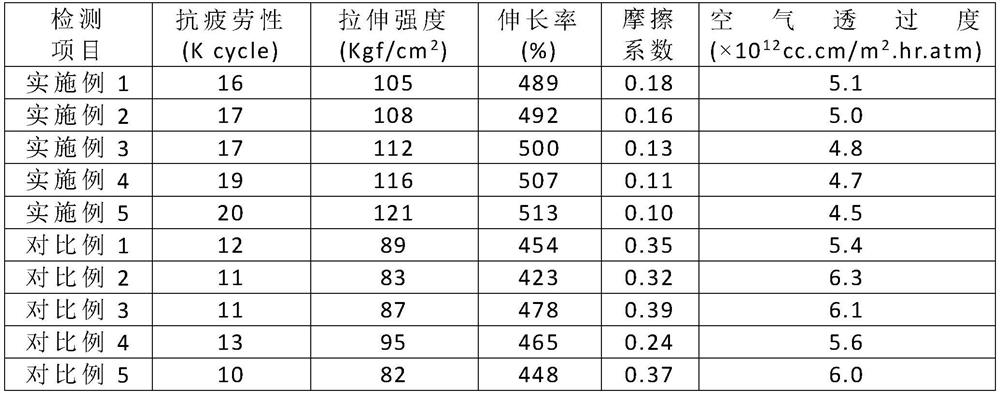

Examples

Embodiment 1

[0031] An environment-friendly tire rubber material is characterized in that it comprises the following components in parts by weight: 30 parts of sulfonamide / carboxyl-terminated liquid fluorine rubber condensation polymer, 10 parts of castor oil-based hyperbranched epoxy resin, diacetone 40 parts of acrylamide / N-(4-cyano-3-trifluoromethylphenyl)methacrylamide / 2-(ethyleneoxy)ethylamine / 4-acyl-18-crown ether-6 copolymer, 15 parts of fly ash, 4 parts of graphene hollow nanofibers, 3 parts of vulcanizing agent, 1 part of vulcanization accelerator, and 1 part of coupling agent.

[0032] Described coupling agent is silane coupling agent KH550; Described vulcanizing agent is dibenzoyl peroxide; Described vulcanization accelerator is zinc dibutyldithiocarbamate; The particle diameter of described fly ash is 800 mesh.

[0033] The diacetone acrylamide / N-(4-cyano-3-trifluoromethylphenyl)methacrylamide / 2-(ethyleneoxy)ethylamine / 4-acyl-18-crown ether-6 copolymerization The preparation ...

Embodiment 2

[0038] An environment-friendly tire rubber material is characterized in that it comprises the following components by weight: 33 parts of sulfonamide / carboxyl-terminated liquid fluorine rubber polycondensate, 12 parts of castor oil-based hyperbranched epoxy resin, diacetone 45 parts of acrylamide / N-(4-cyano-3-trifluoromethylphenyl)methacrylamide / 2-(ethyleneoxy)ethylamine / 4-acyl-18-crown ether-6 copolymer, 17 parts of fly ash, 5 parts of graphene hollow nanofibers, 3.5 parts of vulcanizing agent, 1.5 parts of vulcanization accelerator, and 1.2 parts of coupling agent.

[0039] Described coupling agent is silane coupling agent KH560; Described vulcanizing agent is tetramethylthiuram disulfide; Described vulcanization accelerator is hexamethylene diamine carbamate; Described fly ash The particle size is 900 mesh.

[0040] The diacetone acrylamide / N-(4-cyano-3-trifluoromethylphenyl)methacrylamide / 2-(ethyleneoxy)ethylamine / 4-acyl-18-crown ether-6 copolymerization The preparation ...

Embodiment 3

[0046] An environment-friendly tire rubber material is characterized in that it comprises the following components in parts by weight: 35 parts of sulfonamide / carboxyl-terminated liquid fluorine rubber condensation polymer, 13 parts of castor oil-based hyperbranched epoxy resin, diacetone 50 parts of acrylamide / N-(4-cyano-3-trifluoromethylphenyl)methacrylamide / 2-(ethyleneoxy)ethylamine / 4-acyl-18-crown ether-6 copolymer, 20 parts of fly ash, 6 parts of graphene hollow nanofibers, 4 parts of vulcanizing agent, 2 parts of vulcanization accelerator, 1.5 parts of coupling agent; the coupling agent is silane coupling agent KH570; the vulcanizing agent is peroxide barium; the vulcanization accelerator is ethylene dicarbamate; the particle size of the fly ash is 1000 mesh.

[0047] The diacetone acrylamide / N-(4-cyano-3-trifluoromethylphenyl)methacrylamide / 2-(ethyleneoxy)ethylamine / 4-acyl-18-crown ether-6 copolymerization The preparation method of the compound comprises the following ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com