A high pvc latex paint composition with low odor that reduces indoor formaldehyde content

A composition and latex paint technology, applied in latex paint, coating, etc., can solve the problems of slow effect, inconspicuous effect, and unsustainable spraying effect of purifying agent, etc., and achieve the effect of low odor and good general performance of paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0146] Latex paint of the present invention is made by above-mentioned latex paint composition, and preparation method comprises the steps:

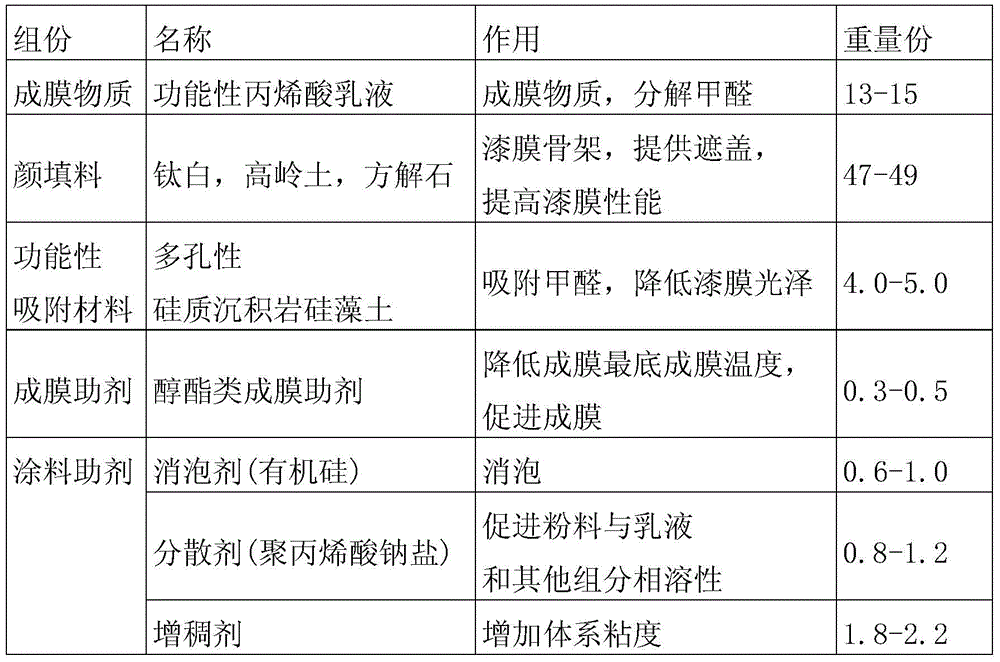

[0147] Mix 13-15 parts by weight of film-forming substances, 47-49 parts by weight of pigments and fillers, 4-5 parts by weight of functional adsorption materials, 3-6 parts by weight of coating aids, and 0.3-0.5 parts by weight of film-forming aids with dilution water , the pigment volume concentration (PVC) ranges from 70 to 75 to obtain the latex paint.

[0148] Therefore, the latex paint of the present invention contains the following components by weight:

[0149] 13-15 parts by weight of film-forming substance;

[0150] 47-49 parts by weight of pigments and fillers;

[0151] 4-5 parts by weight of functional adsorption material;

[0152] 4 to 5 parts by weight of coating additives;

[0153] 0.3-0.5 parts by weight of film-forming aid;

[0154] dilution water,

[0155] Wherein, the film-forming substance is an acrylic acid cop...

Embodiment 1

[0198] Preparation of latex paint

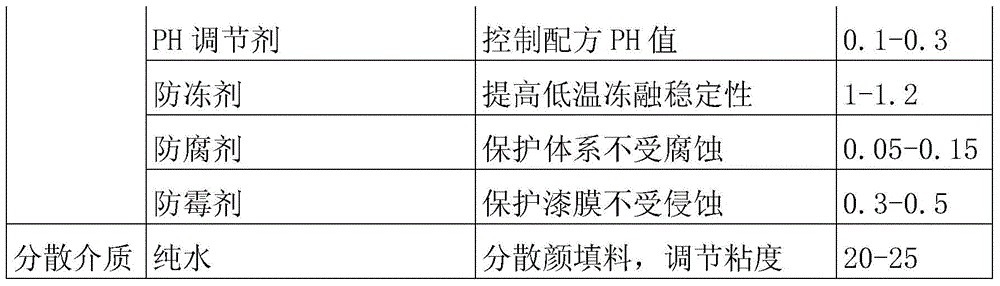

[0199] Prepare raw material according to the weight part in following table 2, adopt the following steps to make latex paint:

[0200] First, put water into the dispersion tank, and control the speed at 700-800 rpm; slowly add the dispersant, wetting agent, defoamer, and thickener into the dispersion tank for 15 minutes; then add various colors in sequence Filler and functional adsorption material; then add pH adjuster and stir for 1 minute; control the speed at 1400-1500 rpm and disperse for 20 minutes; then add a small amount of pure water to cool down; add film-forming substance (emulsion) and stir 1 minute; then add antifreeze propylene glycol, defoamer, antifungal agent, and preservative in turn to disperse for 2 minutes; finally add pure water to adjust the viscosity to a suitable viscosity, the viscosity is 100±2KU, and the finished product is made.

[0201] Table 2 Example 1 formula

[0202]

[0203]

Embodiment 2

[0205] Preparation of latex paint

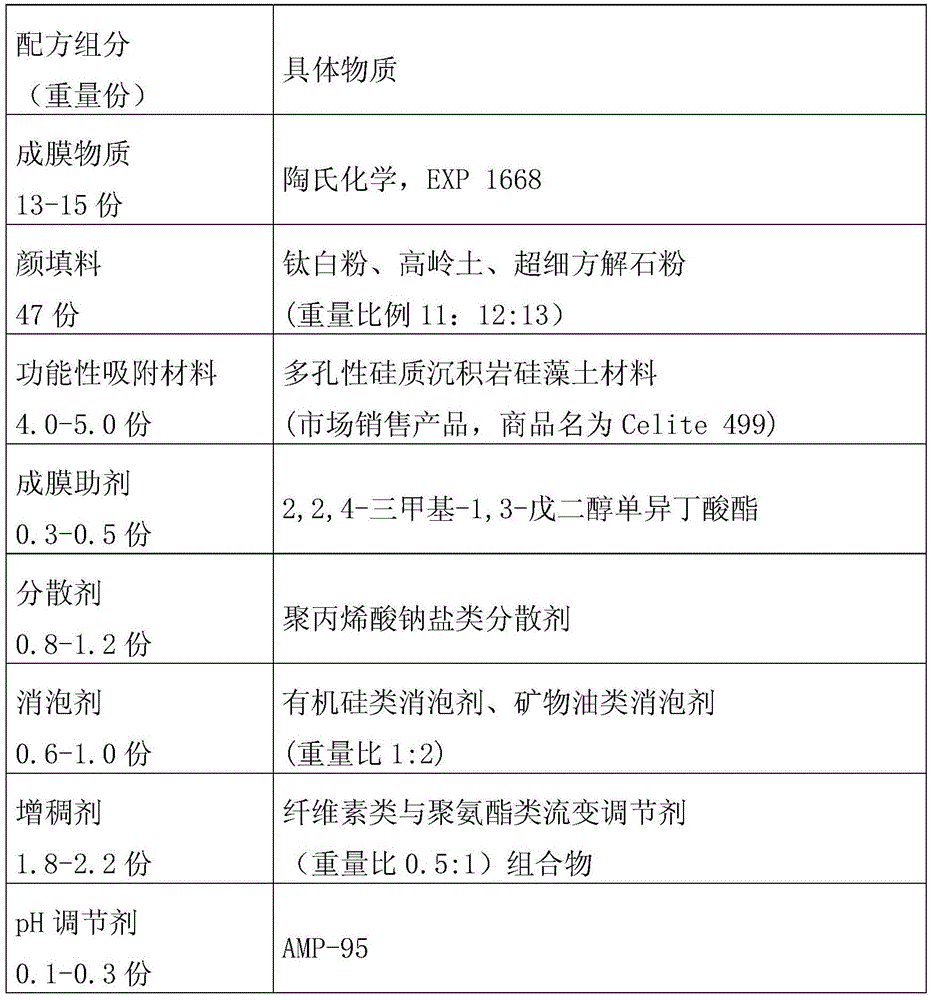

[0206] Prepare raw material according to the weight part in following table 3, adopt the following steps to make latex paint:

[0207] First, put water into the dispersion tank, and control the speed at 700-800 rpm; slowly add the dispersant, wetting agent, defoamer, and thickener into the dispersion tank for 15 minutes; then add various colors in sequence Filler and functional adsorption material; then add pH adjuster and stir for 1 minute; control the speed at 1400-1500 rpm and disperse for 20 minutes; then add a small amount of pure water to cool down; add film-forming substance (emulsion) and stir 1 minute; then add antifreeze propylene glycol, defoamer, antifungal agent, and preservative in turn to disperse for 2 minutes; finally add pure water to adjust the viscosity to a suitable viscosity, the viscosity is 100±2KU, and the finished product is made.

[0208] Table 3 Example 2 formula

[0209]

[0210]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com