Polyurethane artificial leather coloring agent and preparation method thereof

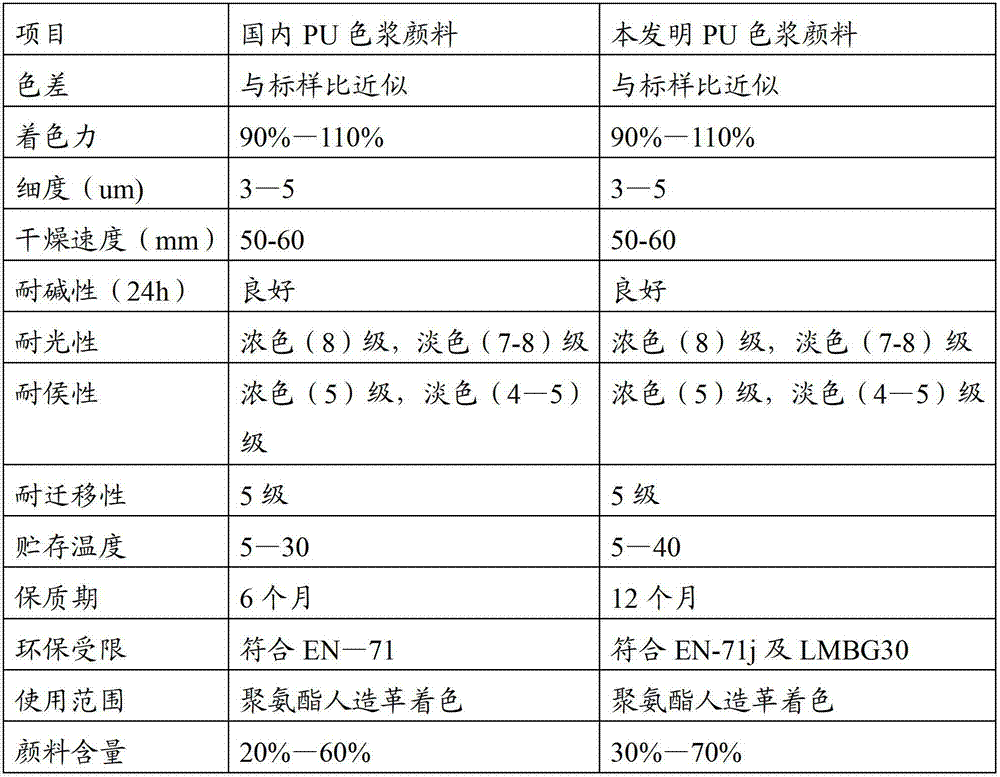

A technology of artificial leather and colorant, applied in the direction of pigment slurry, etc., can solve the problems of infringement and restriction on the development of raw materials for PU artificial leather coloring, and achieve the effect of low cost, weak volatility and high coloring power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The technical solution of the present invention is to provide a coloring agent for polyurethane artificial leather, the coloring agent comprises the following raw materials in different parts by weight: 10-30 parts of propylene glycol methyl ether acetate, 15-45 parts of diacetone alcohol, 5- 15 parts of PU anti-yellowing resin, 3-9 parts of bentonite, 10-60 parts of toner, 0.5-1.5 parts of dispersant, 0.1-0.3 parts of leveling agent, 0.1-0.3 parts of defoamer.

[0036] Preferably, the above-mentioned colorant comprises the following raw materials by weight: 11.2 parts of propylene glycol methyl ether acetate, 18 parts of diacetone alcohol, 8 parts of anti-yellowing resin, 3.6 parts of bentonite, 58 parts of toner, 0.8 part of dispersant, 0.2 parts of leveling agent, 0.2 parts of defoamer.

[0037] Specifically enumerate the embodiment of the coloring agent of the polyurethane artificial leather of following three color systems:

[0038] White Paste Pigment:

[0039] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com