Self-crosslinking acrylic emulsion and preparation method thereof

A technology of self-crosslinking acrylic acid and acrylic acid, which is applied in the coating and other directions, can solve the problems of insufficient environmental protection, safety, high VOC content, damage to printed products, etc., and achieve the effect of low VOC content, simple preparation method and outstanding characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

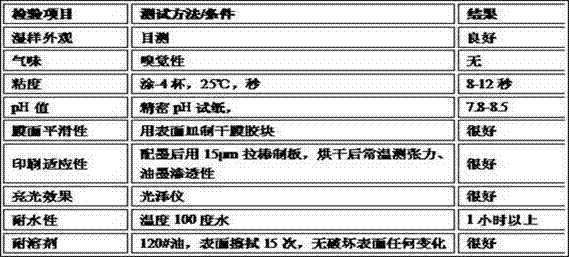

Image

Examples

Embodiment 1

[0060]A self-crosslinking acrylic emulsion, which includes the following raw materials in parts by weight: component A: 130-150 parts of acrylic solid resin, 350-450 parts of water, 40-60 parts of ammonia or monoethanolamine or triethanolamine; component B: 5-12 parts of emulsifier, 15-25 parts of water; Component C: 1-3 parts of persulfate, 5-12 parts of water; Component D1: 85-95 parts of methyl methacrylate, 70- 80 parts; Component D2: 85-95 parts of methyl methacrylate, 70-80 parts of ethyl acrylate; Component E: 0.8-1.5 parts of persulfate, 5-15 parts of water; Component F: diacetone propylene 5-12 parts of amide, 25-35 parts of water; component G: 2-5 parts of adipic acid dihydrazide, 25-35 parts of water. The unit of parts by weight described in this embodiment is kg.

[0061] A preparation method of self-crosslinking acrylic acid emulsion, it comprises the following preparation steps:

[0062] a. In parts by weight, add component A to the reactor: first add water, st...

Embodiment 2

[0068] A self-crosslinking acrylic emulsion, which includes the following raw materials in parts by weight: Component A: 130 parts of acrylic solid resin, 400 parts of water, 40 parts of ammonia water; Component B: 8 parts of emulsifier, 15 parts of water; Component C : 2 parts of ammonium persulfate, 5 parts of water; component D1: 90 parts of methyl methacrylate, 70 parts of ethyl acrylate; component D2: 90 parts of methyl methacrylate, 70 parts of ethyl acrylate; component E : 1 part of ammonium persulfate, 5 parts of water; component F: 9 parts of diacetone acrylamide, 25 parts of water; component G: 3 parts of adipic acid dihydrazide, 25 parts of water. The unit of parts by weight described in this embodiment is kg.

[0069] A preparation method of self-crosslinking acrylic acid emulsion, it comprises the following preparation steps:

[0070] a. Add component A to the reaction kettle in parts by weight: first add water, stir, slowly add acrylic solid resin, then add ammo...

Embodiment 3

[0076] A self-crosslinking acrylic emulsion, which includes the following raw materials in parts by weight: component A: 140 parts of acrylic solid resin, 350 parts of water, 50 parts of monoethanolamine; component B: 5 parts of emulsifier, 20 parts of water; component C: 1 part of ammonium persulfate, 8 parts of water; component D1: 85 parts of methyl methacrylate, 75 parts of ethyl acrylate; component D2: 85 parts of methyl methacrylate, 75 parts of ethyl acrylate; component E: 0.8 parts of ammonium persulfate, 8 parts of water; Component F: 5 parts of diacetone acrylamide, 30 parts of water; Component G: 2 parts of adipic acid dihydrazide, 30 parts of water; Component H: anti-corrosion 0.5 parts of mold agent, 7 parts of water. The unit of parts by weight described in this embodiment is kg.

[0077] A preparation method of self-crosslinking acrylic acid emulsion, it comprises the following preparation steps:

[0078] a. Add component A to the reactor by weight: first add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com