Room-temperature multi-self-crosslinked core-shell type copolymer emulsion as well as preparation method and application thereof

A polymer emulsion and self-crosslinking technology, which is applied in coatings, anti-corrosion coatings, etc., can solve problems such as poor anti-corrosion performance and poor compactness of coating films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

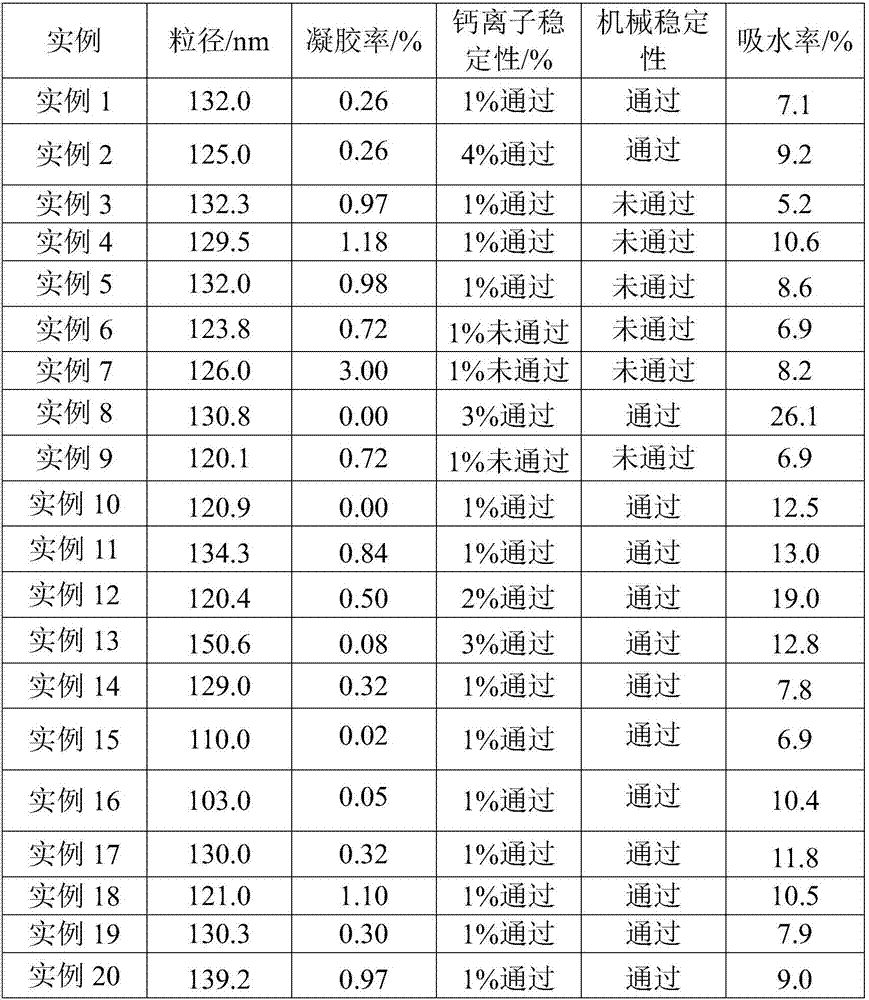

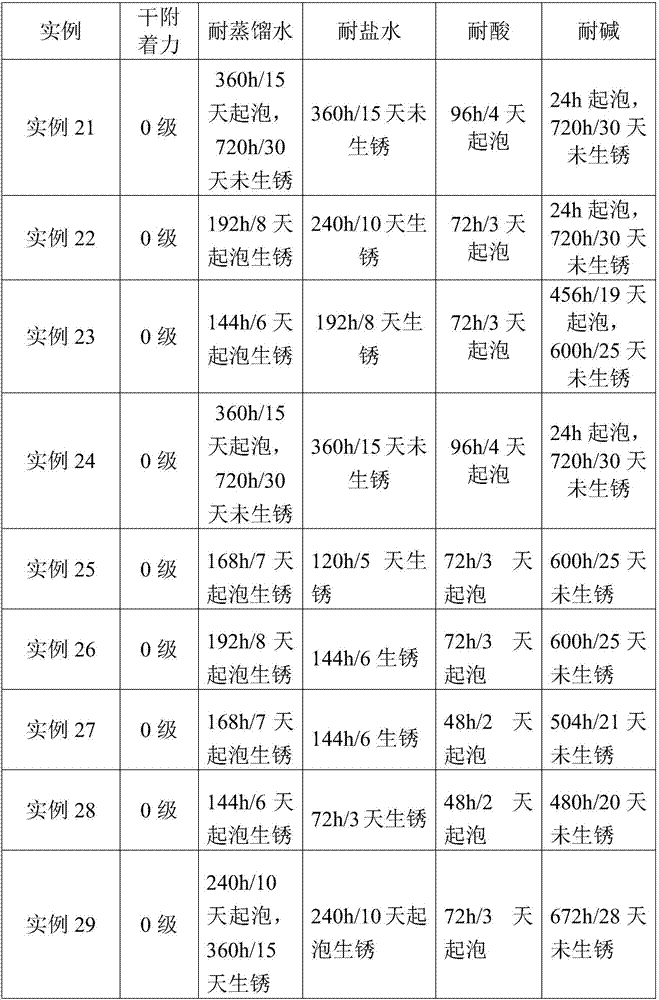

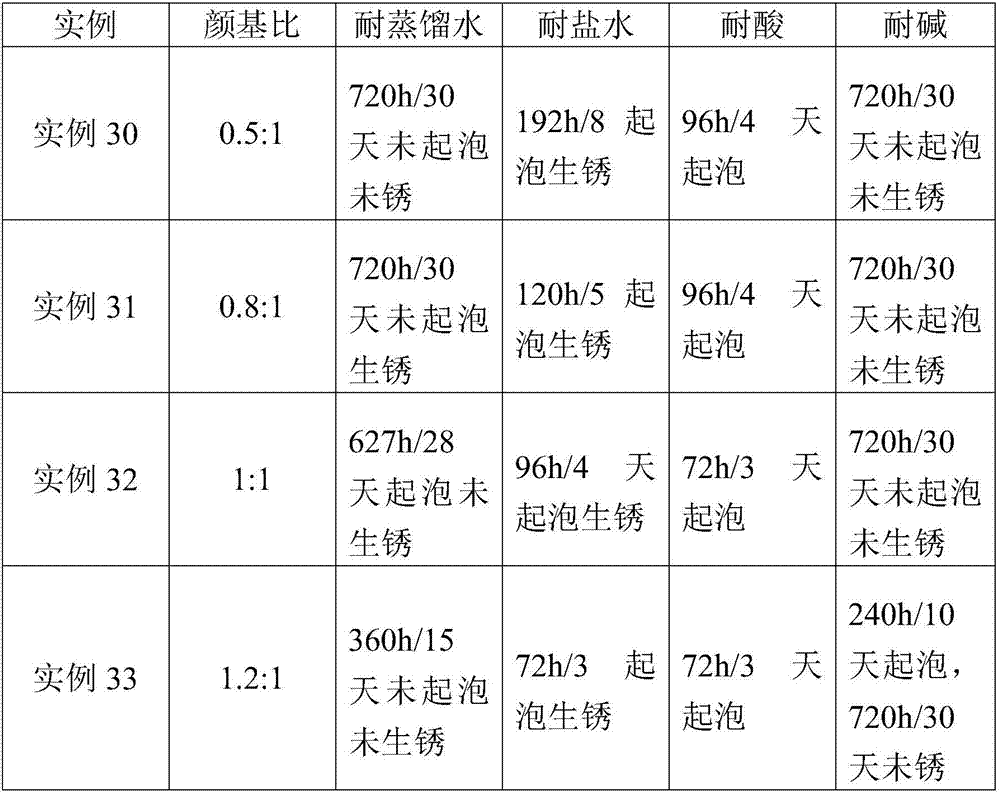

Examples

example 1

[0026] nuclear reaction:

[0027] (1) Add 31kg of deionized water, 0.21kg of emulsifier SE-10N, and 0.105kg of emulsifier TX-30 into the reaction kettle. After stirring and dissolving, add 1kg of styrene, 1kg of butyl acrylate, and 0.08kg of diacetone acrylamide, Mechanical stirring was used to obtain a pre-emulsion. Dissolve 63g of initiator ammonium persulfate in 1kg of deionized water to obtain 1063g of initiator aqueous solution for later use, adjust the temperature to 80°C, add 106.3g of initiator aqueous solution to the reaction kettle dropwise within 15min, and wait for the system to turn blue, keep it warm for 30min, as Seed lotion.

[0028] (2) Mix 4kg styrene, 4kg butyl acrylate, and 0.32kg diacetone acrylamide to obtain a monomer mixture, and simultaneously add 425.2g of initiator aqueous solution and monomer mixture to the seed emulsion of step (1) reactor In the middle, control the dropwise addition in 1-2h, and keep warm for 1h after the addition.

[0029] She...

example 2

[0032] In this embodiment, the emulsifier 0.21kg SE-10N and 0.105kg TX-30 in step (1) of Example 1 are replaced by 0.252kg SE-10N and 0.126kg TX-30. The rest are the same as Example 1.

example 3

[0034] In this embodiment, SE-10N is replaced by SR-10, and the rest is the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com