Aqueous binder emulsion for pre-coating and thermally laminating PET film and preparation method thereof

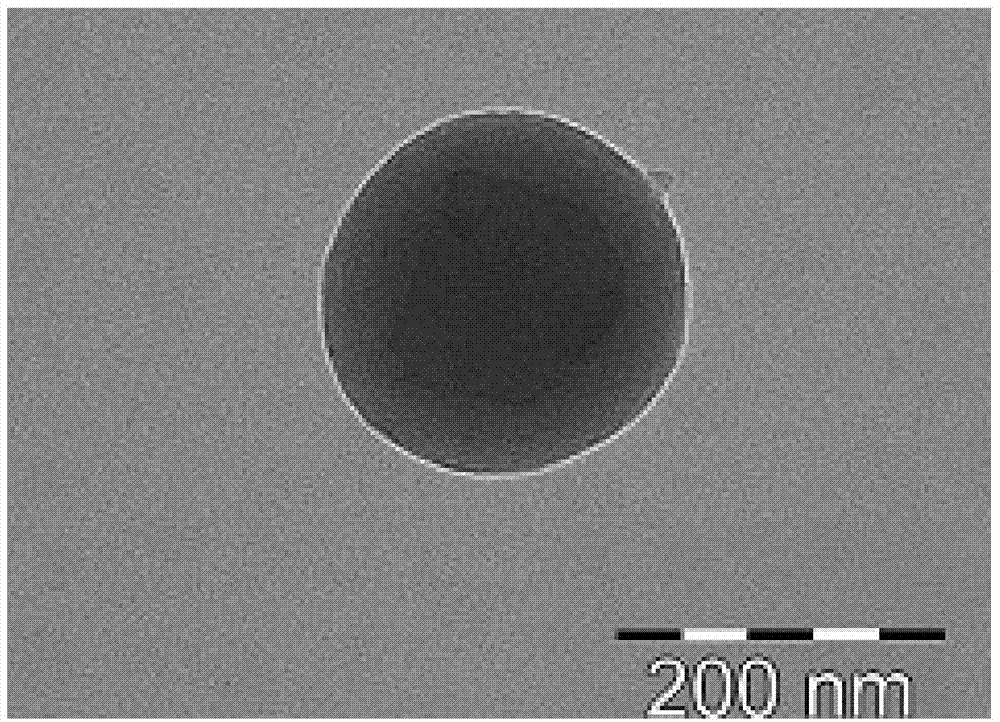

A water-based adhesive and adhesive technology, applied in the direction of film/sheet adhesive, adhesive type, ester copolymer adhesive, etc., can solve the problem of low bond strength and difficulty in obtaining gloss Transparency crystal album products and other issues, to achieve the effect of small particle size, solve the difficult balance between stain resistance and low temperature flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

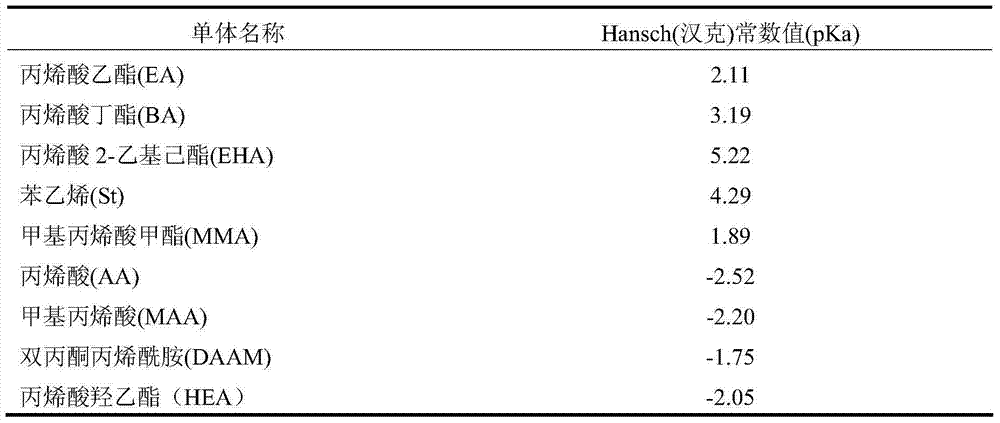

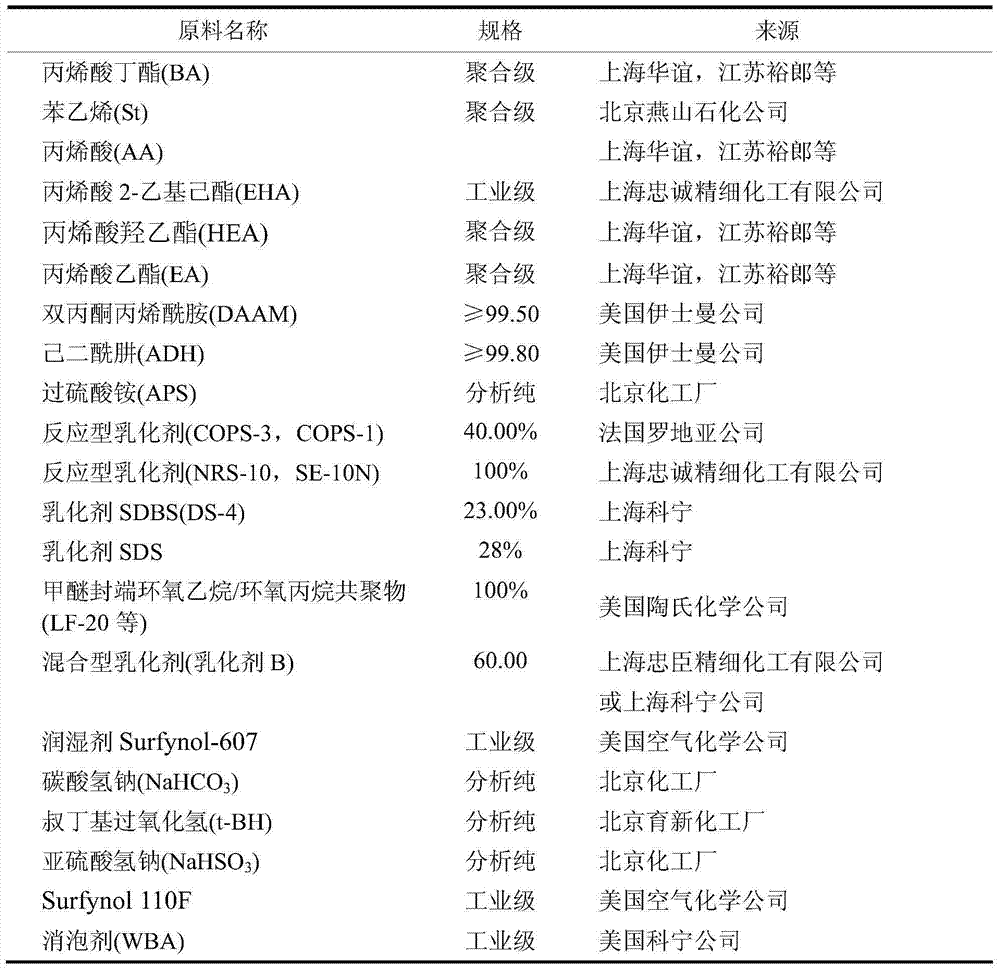

Method used

Image

Examples

Embodiment

[0100] Ⅰ Preparation of seed emulsion

[0101] (1) Pre-emulsification Add metered deionized water into a 5000ml three-neck flask, start stirring, add metered emulsifier, start adding metered monomer after 15 minutes, continue high-speed stirring and emulsification for about 1 hour;

[0102] (2) Polymerization Add deionized water to a 1000ml four-neck flask equipped with stirring, reflux condenser, thermometer and constant pressure dropping funnel, start stirring, and when the temperature rises to 82°C, add the measured bottom emulsifier for 5 minutes Then add the measured initiator aqueous solution, and after the temperature reaches the highest and stabilize for 2 minutes, start to add the pre-emulsion solution and the initiator aqueous solution dropwise. During the dropping, the temperature is controlled at 86-88°C, and the total dropping time is controlled at 90°C. ~100 minutes; keep warm for 1h after the dropwise addition;

[0103] (3) Cool down to below 40°C and add measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com