Preparation method of zinc oxide with core-shell structure and obtained zinc oxide

A core-shell structure, zinc oxide technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of polluting zinc oxide activity, low effective utilization rate, large carbon emission, etc., and achieves low carbon emission and high effective utilization rate. , the effect of improving the degree of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

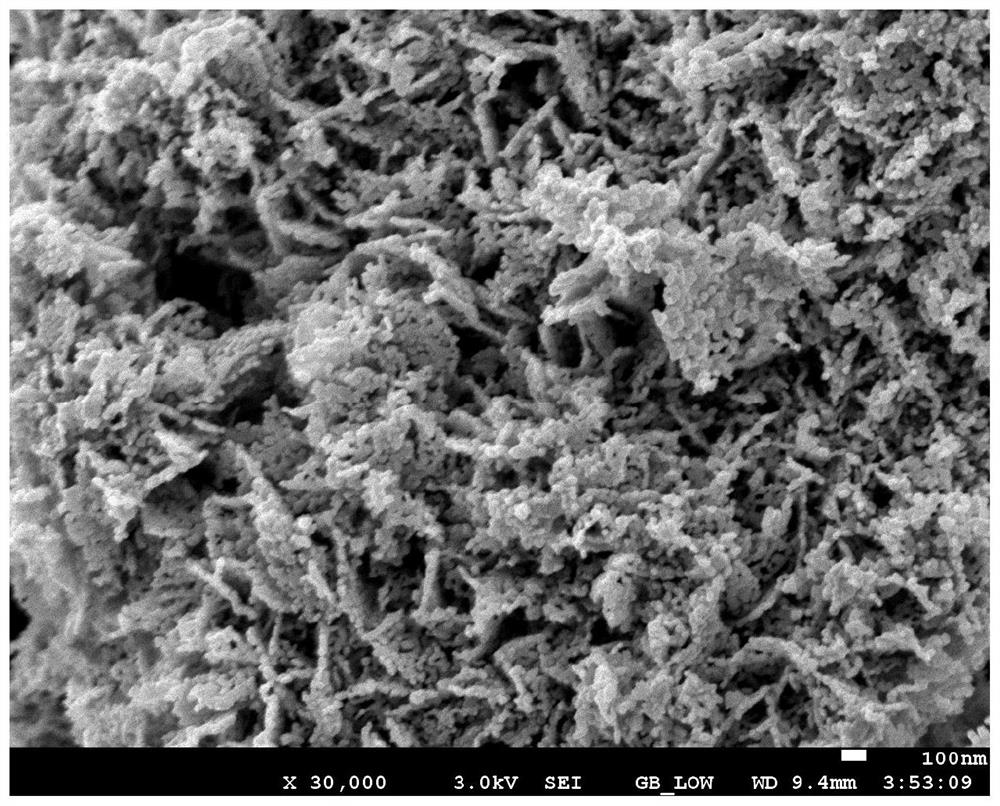

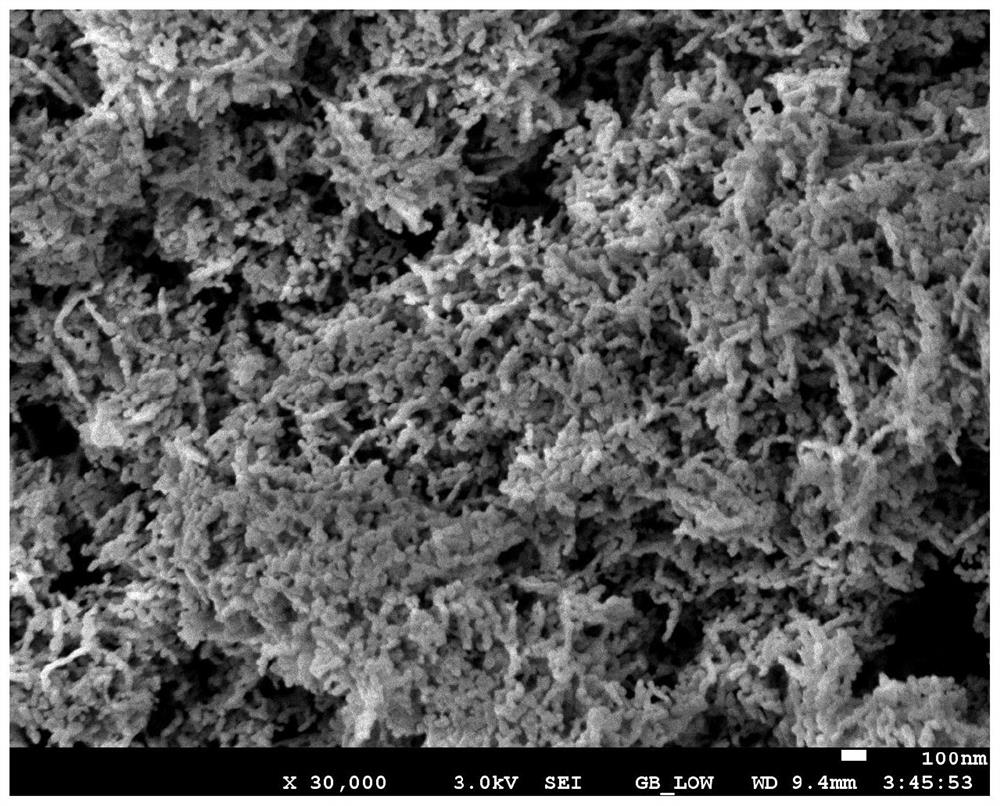

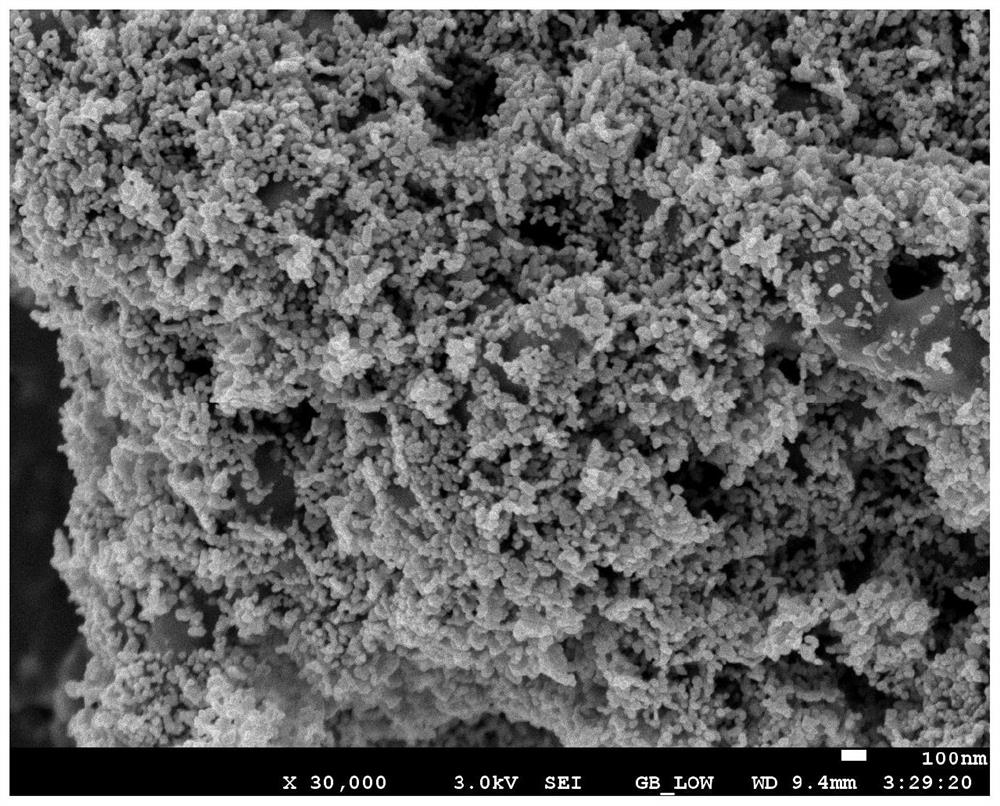

Image

Examples

preparation example Construction

[0022] A kind of preparation method of core-shell structure zinc oxide of the present invention comprises the following steps:

[0023] 1) get nuclear material, add dispersant and sepiolite, the addition of dispersant is 5-10% of nuclear material quality, the addition of sepiolite is 1-3% of nuclear material quality, and dispersant is made of hard Fatty acid, cetyltrimethylammonium bromide, sodium dodecylbenzenesulfonate and KH550 are composed of a composite dispersant according to the mass ratio of 1-2:0.1-0.3:0.05-0.10:0.5-1.0, stirring , to get the primary mixture;

[0024] 2) Take the zinc-containing solution, add the initial mixture obtained in step 1) into the zinc-containing solution, the mass ratio of the nuclear material in the initial mixture to the zinc in the zinc-containing solution is 1:2-3:1, stir to obtain a reaction liquid;

[0025] 3) Take the alkaline solution and add it to the reaction solution obtained in step 2), the molar ratio of the solute in the alk...

Embodiment 1

[0037] A kind of preparation method of core-shell structure zinc oxide of the present invention comprises the following steps:

[0038] 1) Take calcium carbonate as the core material 50g, add 2g of dispersant and 1g of sepiolite, the dispersant is made of stearic acid, cetyltrimethylammonium bromide, sodium dodecylbenzenesulfonate and KH550 according to A composite dispersant with a mass ratio of 1:0.1:0.05:0.5 is stirred to obtain an initial mixture;

[0039] 2) Get 1500mL of zinc chloride as the zinc-containing solution, the molar concentration of zinc chloride is 1mol / L, the initial mixture obtained in step 1) is added to the zinc-containing solution, the nuclear material in the initial mixture and the zinc in the zinc-containing solution The mass ratio of the mixture is 1:2, stirred to obtain the reaction solution;

[0040] 3) get 3000mL sodium carbonate solution to be alkaline solution, the molar concentration of sodium carbonate solution is 1mol / L, joins in step 2) in t...

Embodiment 2

[0044] A kind of preparation method of core-shell structure zinc oxide of the present invention comprises the following steps:

[0045] 1) Take calcium carbonate as the core material 100g, add 5g of dispersant and 1g of sepiolite, the dispersant is made of stearic acid, cetyltrimethylammonium bromide, sodium dodecylbenzenesulfonate and KH550 according to A composite dispersant with a mass ratio of 2:0.3:0.10:1.0 is stirred to obtain an initial mixture;

[0046] 2) Get 770mL of zinc nitrate as the zinc-containing solution, the molar concentration of zinc nitrate is 2mol / L, the initial mixture obtained in step 1) is added to the zinc-containing solution, the mass of the nuclear material in the initial mixture and the zinc in the zinc-containing solution The ratio is 1:1, stir to obtain the reaction solution;

[0047] 3) get 2300mL sodium hydroxide solution to be alkaline solution, the molar concentration of sodium hydroxide solution is 2mol / L, join in the reaction solution of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com