Hot-end high-temperature large glass identifying and removing device and removing method

A technology of removing device and bulk, applied in measuring devices, instruments, sorting and other directions, can solve the problems of large gap, increased system investment cost, increased selection of conveying equipment and crushing equipment, etc., to achieve convenient use and reduce investment. , The effect of the overall structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the content of the present invention, the present invention will be described in detail below in conjunction with specific examples.

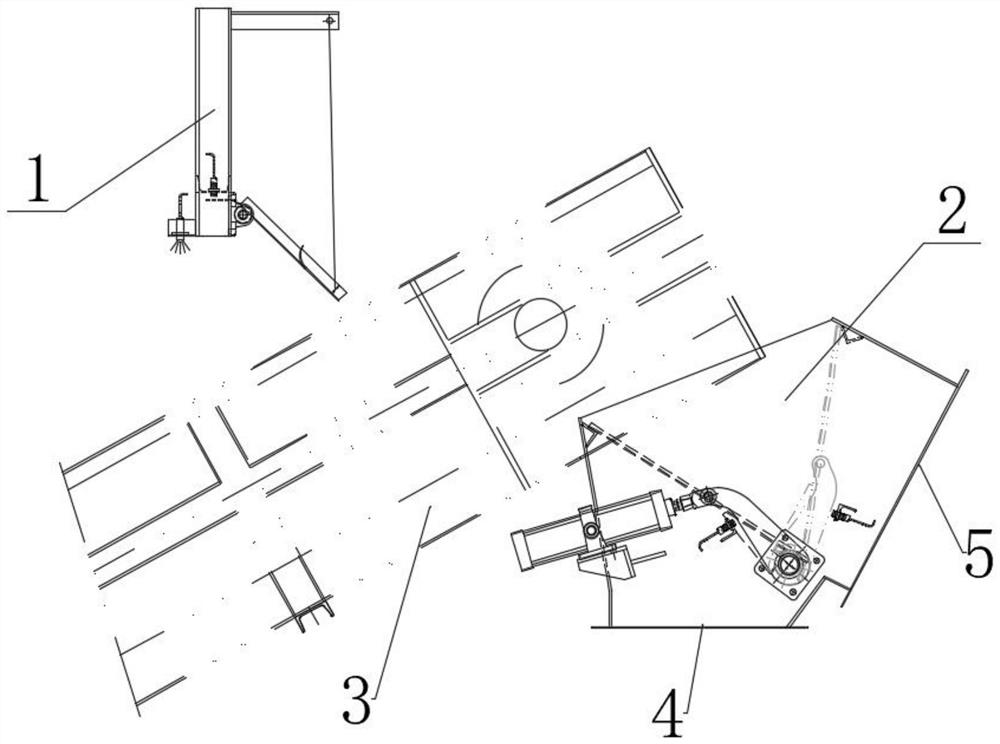

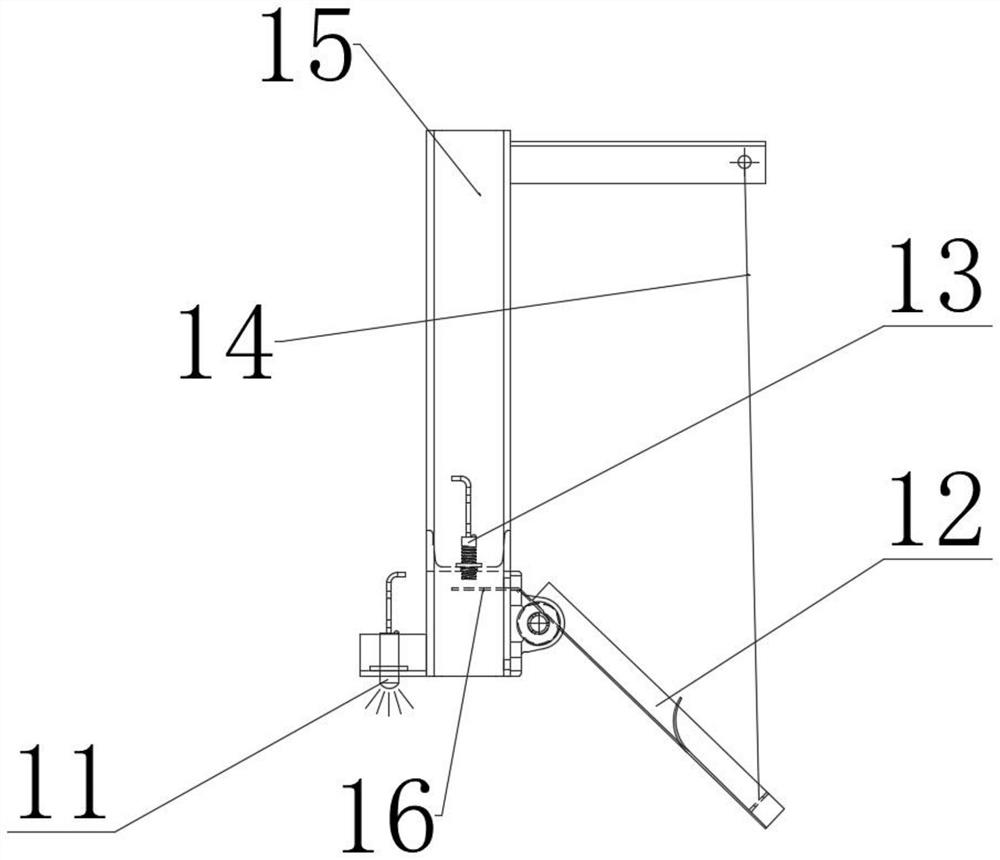

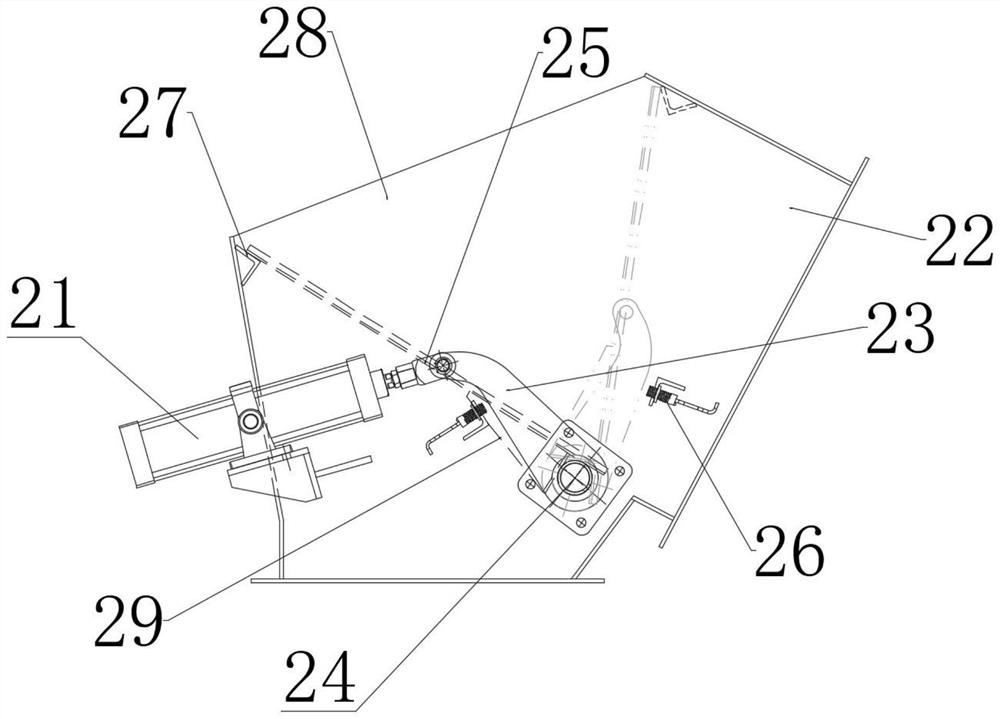

[0029] Such as figure 1 As shown, an embodiment of the device for identifying and rejecting large pieces of hot-end high-temperature glass according to the present invention includes an identification mechanism 1 and a rejection mechanism 2. The identification mechanism 1 is located above the outlet 3 of the scraper to identify the scraper. The material on the outlet 3, the rejecting mechanism 2 is located under one side of the outlet 3 of the fishing machine, so as to screen the materials on the outlet 3 of the fishing machine, the identification mechanism 1 includes a bracket 15, a bracket installed on the bracket 15 A high-temperature detection probe 11 and a bulk detection sensor 13, the high-temperature detection probe 11 identifies the high-temperature material on the outlet 3 of the scraper, and a bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com