Layered graphene and preparation method thereof

A technology of layered graphite and crystalline graphite, applied in the field of graphene, can solve the problems of simple preparation process and few layers, and achieve the effects of high conductivity, small particle size and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The embodiment of the present invention provides a preparation method of layered graphene. The method comprises the steps of:

[0021] S01. Provide crystalline graphite, and perform the first mixing treatment with the crystalline graphite, the reaction solution and the dispersant to obtain the first mixture;

[0022] S02. Performing a second mixing treatment on the first mixture and an activator to obtain a second mixture; post-processing the second mixture to obtain layered graphene;

[0023] Wherein, the reaction liquid is selected from at least one of chlorosulfonic acid, perchloric acid, and sodium perchlorate, and the activator is selected from at least one of hydrogen peroxide, sodium bicarbonate, and sodium peroxide.

[0024] The preparation method of layered graphene in the embodiment of the present invention, the preparation method is to use crystalline graphite as a raw material, and add at least one of chlorosulfonic acid, perchloric acid, and sodium perchlo...

Embodiment 1

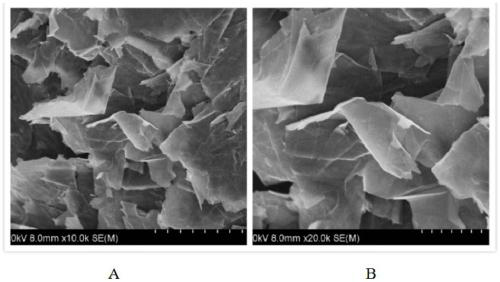

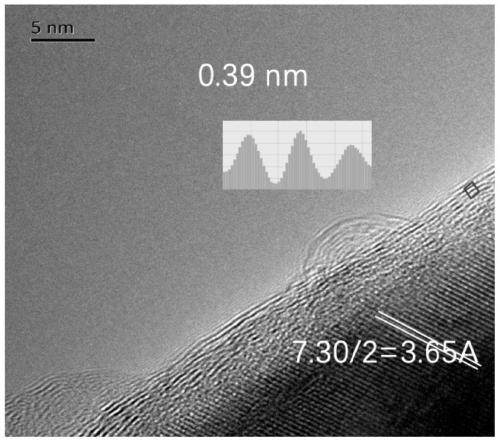

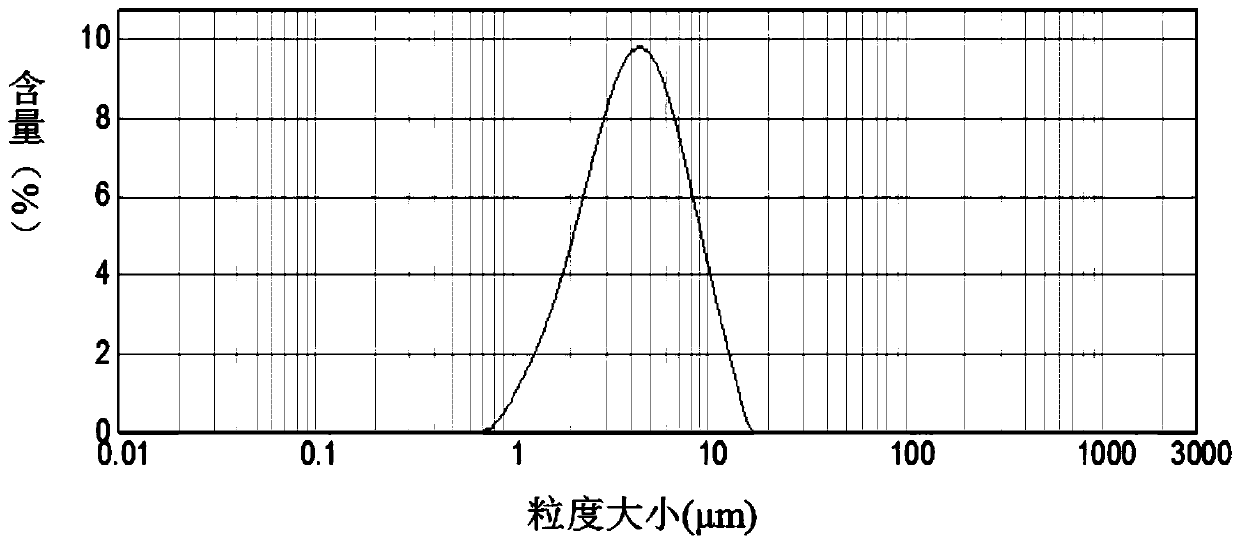

[0051] Layered graphene and its preparation method

[0052] The preparation method comprises the steps of: providing large flake crystalline graphite, mixing the crystalline graphite with chlorosulfonic acid solution (reaction solution) and sodium lauryl sulfate (dispersant), and stirring and mixing for 10 hours with a mechanical stirrer to obtain The first mixture; wherein, the weight ratio of crystalline graphite, reaction liquid and dispersant is 1:50:0.01;

[0053] Stir the first mixture with hydrogen peroxide (activator) with a volume concentration of 50%, wherein the weight ratio of crystalline graphite to the activator is 1:50; and continue to stir rapidly for 30 minutes to obtain the second mixture, add distilled water to mix and Filtration is carried out to obtain aggregates, wherein the weight ratio of the second mixture to distilled water is 1:500; the aggregates are dispersed in distilled water and ultrasonicated for 40 minutes, and the dispersion is freeze-dried t...

Embodiment 2

[0055] Layered graphene and its preparation method

[0056] The preparation method comprises the following steps: providing large scale crystalline graphite, mixing the crystalline graphite with perchloric acid (reaction solution) and polyethylene glycol (dispersant), and stirring and mixing for 20 hours with a mechanical stirrer to obtain the first mixture ; Wherein, the weight ratio of crystalline graphite, reaction liquid and dispersant is 1:150:0.01;

[0057] Stir the first mixture with sodium bicarbonate powder (activator), wherein the weight ratio of crystalline graphite to activator is 1:100; and continue to stir rapidly for 50 minutes to obtain the second mixture, add distilled water to mix and filter Agglomerates are obtained, wherein the weight ratio of the second mixture to distilled water is 1:1000; the agglomerates are dispersed in an ethanol solution and ultrasonicated for 30 minutes to obtain a layered graphene dispersion. Wherein, the layered graphene is a lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com