Soap-free self-crosslinking nano acrylic emulsion as well as preparation method and application thereof

An acrylic emulsion and self-crosslinking technology, applied in the direction of coating, can solve the problem of not increasing the hardness of the coating film, and achieve the effect of reducing the film forming temperature, fast film forming speed, and bright appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with examples, which are only preferred implementations of the present invention, and are not limitations of the present invention.

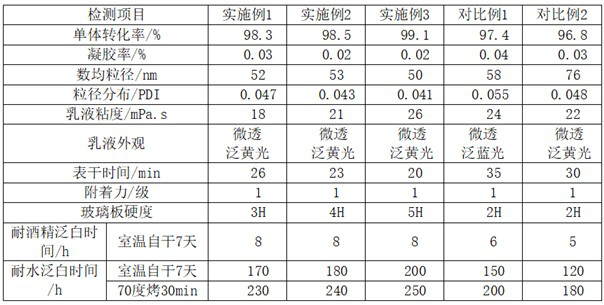

[0021] The following table is the formula table (unit: %) of 3 examples and 2 comparative examples of soap-free self-crosslinking nanoacrylic emulsion of the present invention.

[0022]

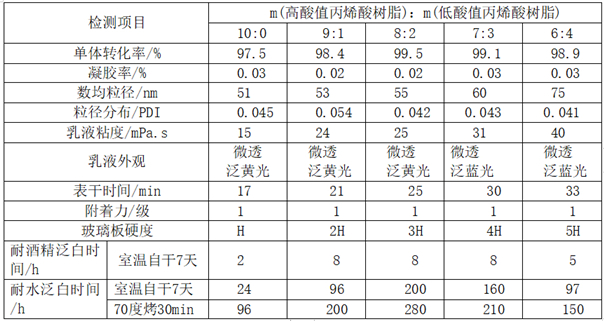

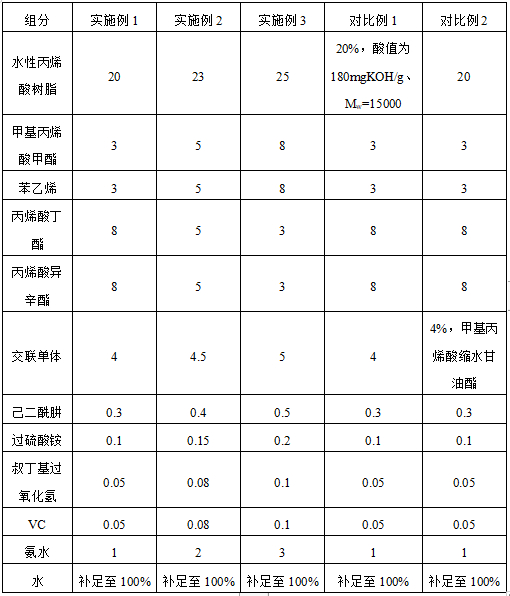

[0023] Wherein, the cross-linking monomer is diacetone acrylamide and butyl acrylamide, and the mass ratio of the diacetone acrylamide and butyl acrylamide is 3:1; the water-based acrylic resin includes high acid value acrylic resin and Low acid value acrylic resin, the acid value of the high acid value acrylic resin is 220mgKOH / g, M w =20000, the acid value of the low acid value acrylic resin is 80mgKOH / g, M w =5500, the mass ratio of the high acid value acrylic resin to the low acid value acrylic resin is 8:2. The following table is the formula table of the water-based acrylic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com