Pixel defining layer, display substrate, display device, and inkjet printing method

A pixel-defining layer and inkjet printing technology, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems such as uneven shape, uneven brightness of pixel areas, affecting the display effect of organic light-emitting display devices, etc., and achieve drying speed Consistent, uniform film effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

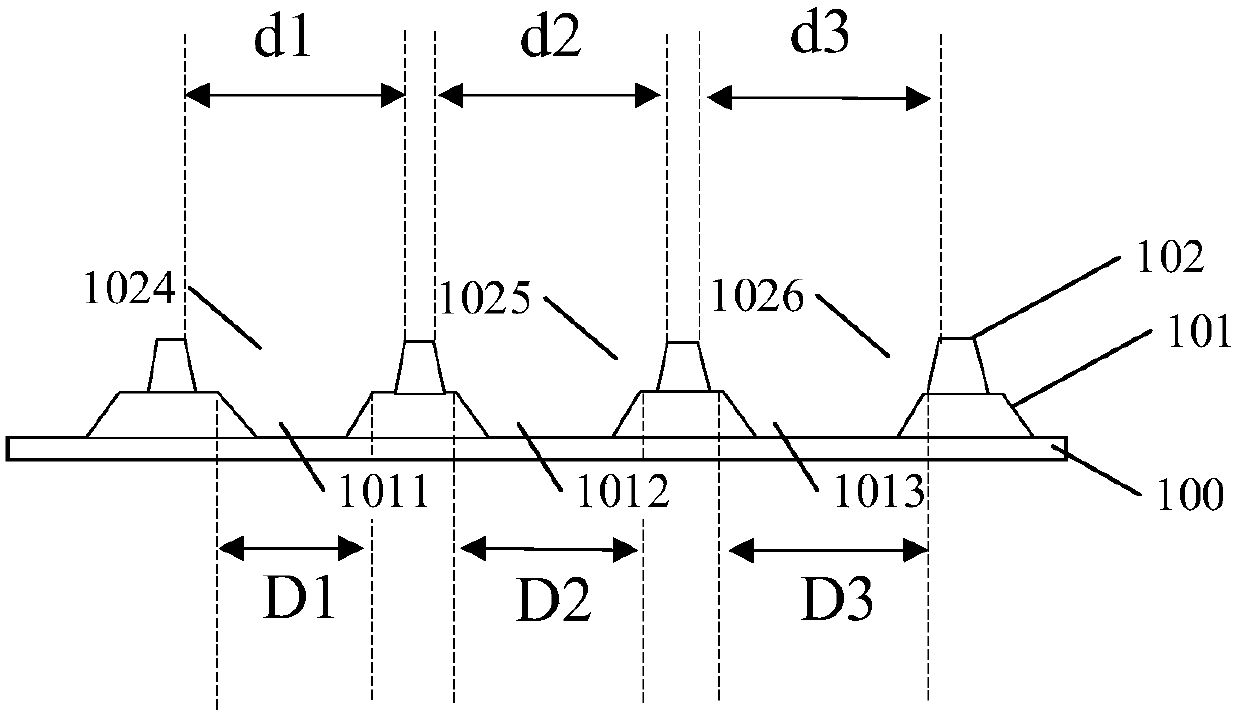

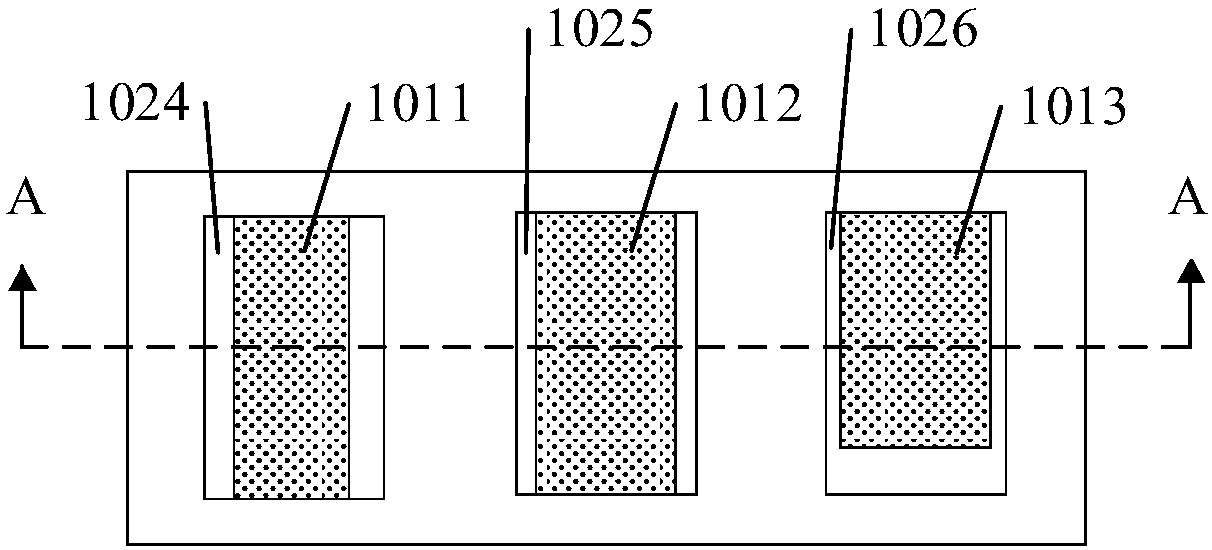

[0042] This embodiment provides a pixel definition layer, figure 1 A schematic cross-sectional view of the pixel defining layer provided in this embodiment, figure 2 A schematic plan view of the pixel defining layer provided in this embodiment, wherein, figure 1 for figure 2 A cross-sectional view of the middle pixel defining layer along the line A-A. Such as figure 1 with figure 2 As shown, the pixel defining layer includes: a first pixel defining layer 101 and a second pixel defining layer 102, the first pixel defining layer 101 has a plurality of first openings with different sizes corresponding to different sub-pixels; the second pixel defining layer 102 is located on the first pixel defining layer 101, and the second pixel defining layer 102 has a plurality of second openings corresponding to different sub-pixels, and the plurality of first openings communicate with the plurality of second openings in one-to-one correspondence, thereby forming corresponding sub-pix...

Embodiment 2

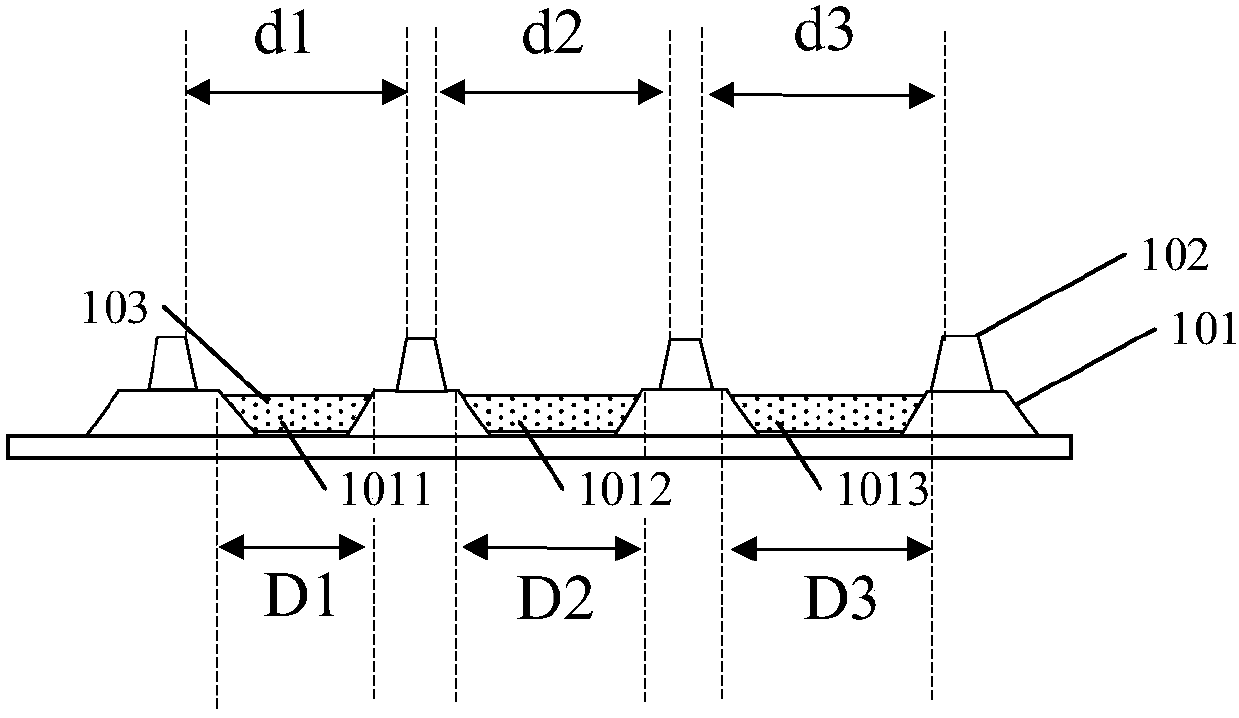

[0063] This embodiment provides an inkjet printing method using any of the above-mentioned pixel defining layers. The pixel defining layer is formed on a base substrate. For example, other structural layers or functional layers are formed on the base substrate. The structural layer is, for example, Including a buffer layer, a passivation layer, etc., the functional layer includes, for example, a driving circuit, etc., and the driving circuit includes devices such as gate lines, data lines, transistors, and capacitors. The pixel defining layer is formed on the above structural layer or functional layer. Such as Figure 3A with Figure 3B As shown, the inkjet printing method includes: performing inkjet printing in the openings provided by the first pixel defining layer 101 and the second pixel defining layer 102 , for example to form the organic functional layer 103 . For example, the height of the ink jet printed in the pixel defining layer is higher than that of the first pi...

Embodiment 3

[0070] This embodiment provides a display substrate, such as Figure 4 As shown, the display substrate includes any one of the above-mentioned pixel defining layers. The pixel defining layer is formed on the base substrate. For example, other structural layers or functional layers are formed on the base substrate. The structural layers include, for example, buffer layers, Passivation layer, etc., the functional layer includes, for example, a driving circuit, etc., and the driving circuit includes gate lines, data lines, transistors, capacitors, and other devices. The pixel defining layer is formed on the above structural layer or functional layer. The display substrate also includes an organic functional layer formed in a plurality of sub-pixel regions obtained by one-to-one communication between the plurality of first openings and the plurality of second openings of the pixel defining layer. The organic functional layer includes a light emitting layer, an electron injection l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com