Intelligent adjustable formwork drying box suitable for intelligent robot formwork manufacturing line

A technology of intelligent robot manufacturing and drying box, which is applied in the direction of drying solid materials, dry goods handling, and drying gas arrangement, etc., can solve the problems of personalized custom drying conditions, unable to rotate multiple mold shells, etc., and achieves high degree of automation and convenience Loading and unloading, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

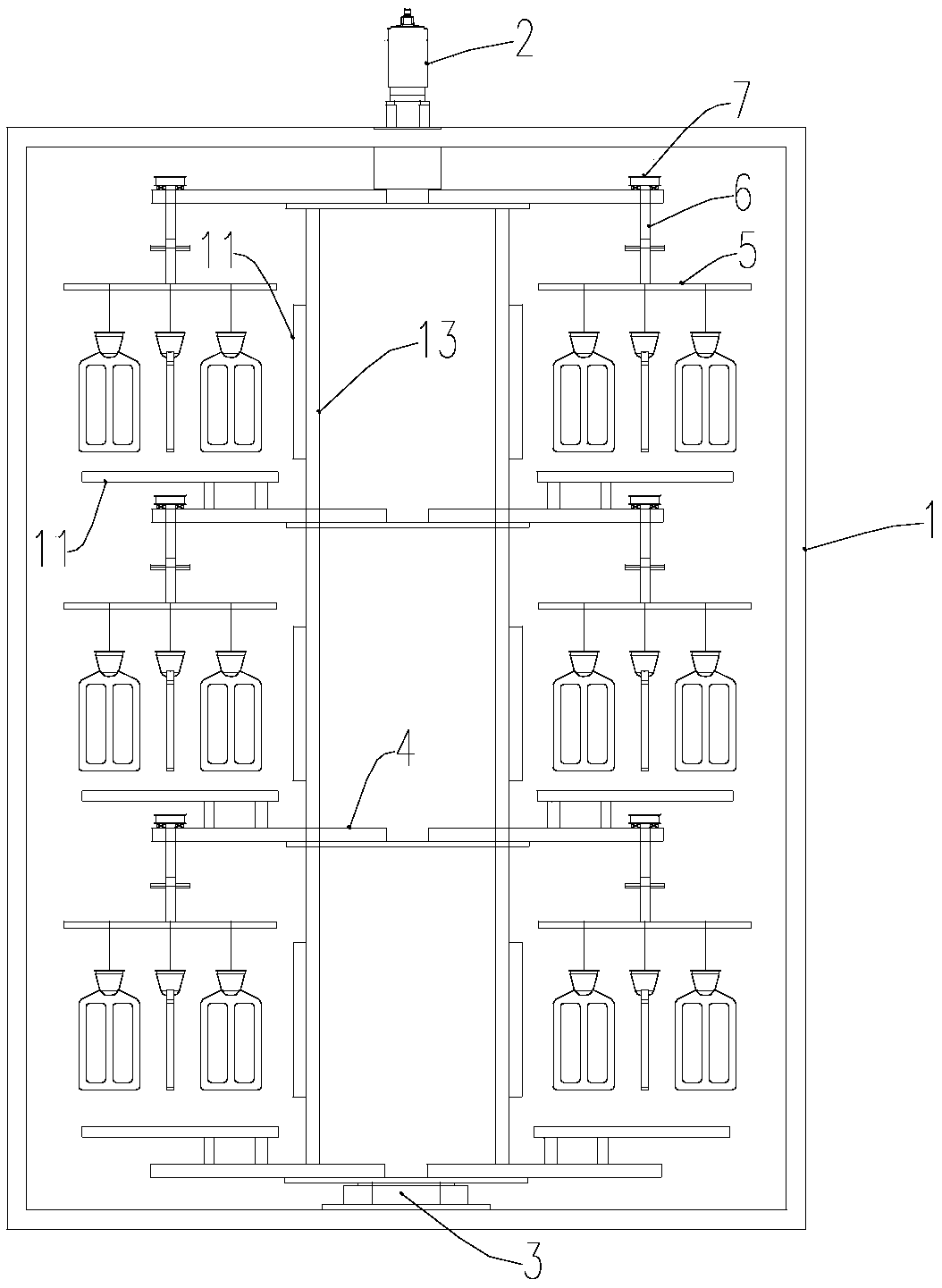

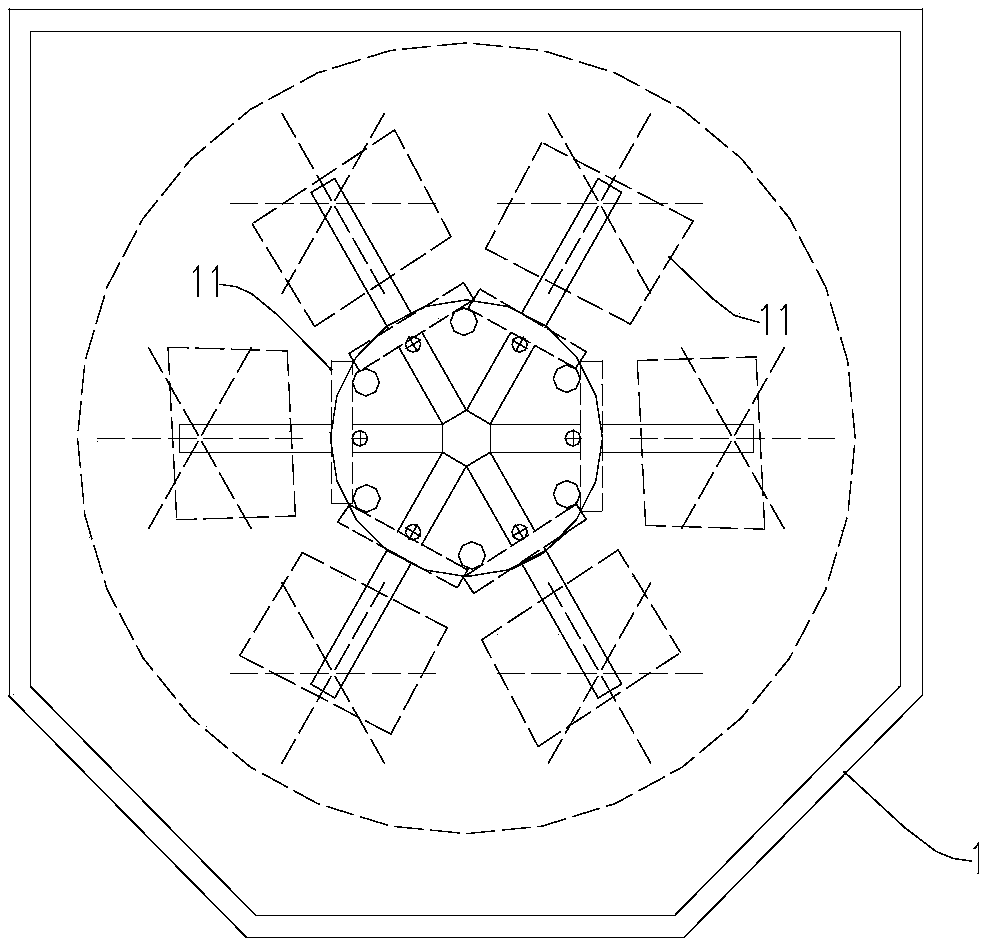

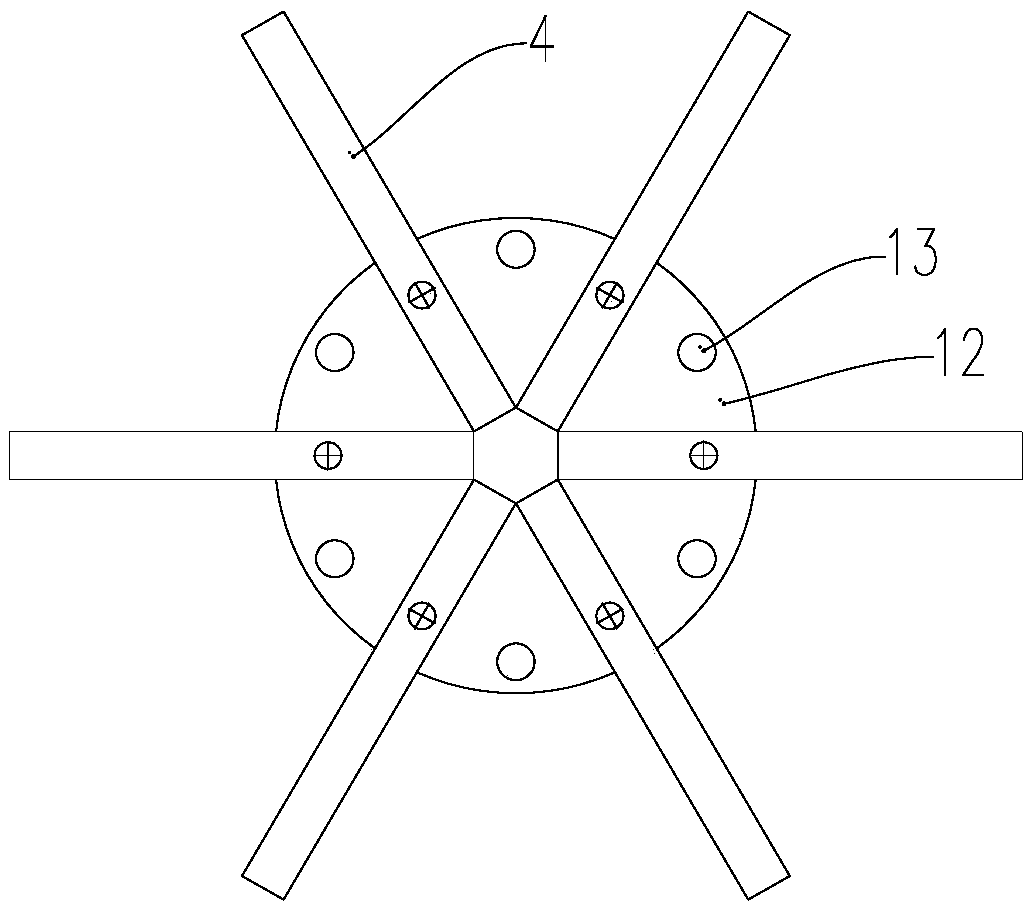

[0035] like Figures 1 to 7 As shown, the present invention provides an intelligent controllable mold shell drying box suitable for intelligent robot shell making lines, which includes a box body 1 and a revolution mechanism and an autorotation mechanism located in the box body 1, and the box body 1 A door body that can be opened and closed is provided on the side wall. The rotation mechanism includes a plurality of rotation units, and each of the rotation units can hold a plurality of mold shells to be dried. The revolution mechanism includes a On the top is the first drive motor 2 that drives the revolution mechanism to rotate. When the revolution mechanism rotates, it can drive the rotation unit to rotate. There a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com