One-step coated film-formed high-gloss automobile metal wheel hub paint and preparation method thereof

A high-gloss, automotive technology, used in coatings, anti-corrosion coatings, etc., can solve problems such as high cost and complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

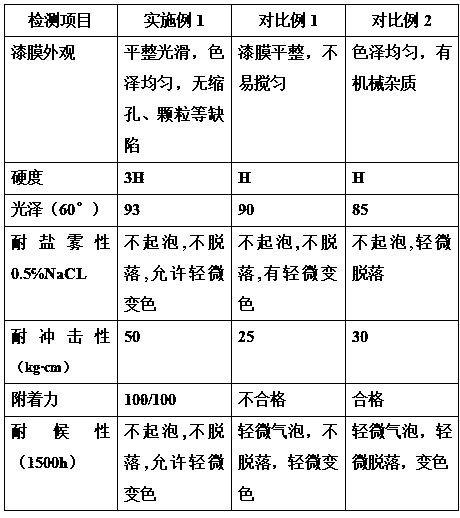

Examples

Embodiment 1

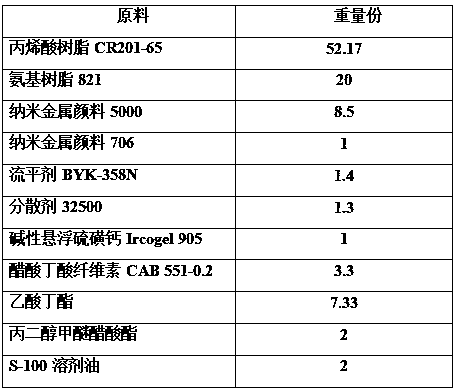

[0046] Table 1 Embodiment 1 Raw material parts by weight

[0047]

[0048] The preparation of metal wheel paint in the present embodiment may further comprise the steps:

[0049] (1) Premixing: Add 2 parts of propylene glycol methyl ether acetate into the stirring tank for stirring; then slowly add 30 parts by weight of CR201-65, 1.3 parts of dispersant 32500, and stir at a speed of 700-800r / min (rev / min) 5-10min, adjust the premixed viscosity to 90-95KU / 25℃ with an appropriate amount of diluent;

[0050] (2) Soaking silver: Add 7.33 parts of butyl acetate into the stirring tank, then slowly add 8.5 parts of nano-metallic pigment 5000 and 1 part of nano-metallic pigment 706, stir evenly for 5-10 minutes (400 rpm), until uniform After soaking, add to the premix and stir well;

[0051] (3) Paint making: Add the remaining 22.7 parts of CR201-65, 20 parts of 821 amino resin, 1.4 parts of BYK-358N leveling agent, 3.3 parts of CAB 551-0.2, and 2 parts of S-100 solvent into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com