Patents

Literature

45results about How to "No chalking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon fluoride super-amphiphobic non-stick coating material

The invention relates to a non-sticking paint containing fluorine-silicon materials, which comprises a coating material portion and a curing agent portion, wherein the amount of the curing agent is 6.5-12% of the coating material portion, the coating material portion mainly comprises fluorocarbon resin, 10-20% of organosilicon resin, 3-30% of color filler, 1-5% of silicon micronized quartz powder and 3-10% of fluorine micronized powder, the curing agent is at least one of biuret, HDI trimer and organotin, the fluorocarbon resin is prepared from perfluoroethylene monomer, alkyl vinyl ester and functional monomers through copolymerization, wherein the fluorine content is greater than 35wt%, the solid content is greater than 50%, the organosilicon resin is end monohydric organosilicon resin.

Owner:ZIBO YINGQIANG CHEM TECH

Normal temperature curing fluorocarbon resin coating and preparation method thereof

The invention discloses a normal temperature curing fluorocarbon resin coating. The coating comprises the following components in percentage by weight: 38 to 60 percent of chlorotrifluoroethylene-vinyl ester polymer, 5 to 10 percent of coupling agent, 1 to 6 percent of pigment, 1 to 5 percent of nanoparticles, 0.05 to 2 percent of aid, 20 to 45 percent of solvent, 5 to 15 percent of curing agent and 0.003 to 0.05 percent of drier, wherein the coupling agent is fluorosilane with -CF3 and -CF2 groups; the aid is a defoamer or a surfactant; the solvent is xylene and methyl isobutyl ketone or butyl acetate and the methyl isobutyl ketone; and the drier is dibutyltin dilaurate. By adopting a specific coating formula, the solubility of fluorocarbon resin in the solvent is improved, the added aid, pigment and the like are soluble, various components are easy to disperse in various dispersion modes, the coating is convenient to operate on site, the adhesion of the coating can reach level 0 and the coating has high scratch resistance and high acid, alkali and salt resistance.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Method for producing granular potassium sulfate

ActiveCN102690144ARound particlesFlat surfacePotassium fertilisersFertilizer mixturesPolyoxyethylene castor oilPrill

The present invention relates to a method for producing granular potassium sulfate, belonging to the technical field of fertilizer manufacturing. The method includes the specific steps of preparation of an adhesive and granulation of powdery potassium sulfate. The preparation of the adhesive includes the following steps: adding water to a reactor having a jacket so as to dissolve polyvinyl alcohol; adding polyoxyethylene castor oil at a preset temperature; adding polyoxyethylene octyl phenol ether and dibutyl phthalate according to a formula; cooling the mixture after a certain reaction time; adding sodium silicate for a certain time of reaction at a certain temperature to obtain the adhesive. The granulation of the powdery potassium sulfate includes the following steps: adding the powdery potassium sulfate with fineness less than 60 mesh to a disk or a rotary drum granulator; adding the prepared adhesive proportionately to the rotating materials to perform granulation, drying, cooling and screening are performed on the granulated material to produce a product. The granular potassium sulfate produced by the method in the invention is advantaged in round and uniform particle, smooth surface and high particle strength, being capable of being directly applied and being used as raw material of a blending fertilizer.

Owner:HENAN LEEF FERTILIZER

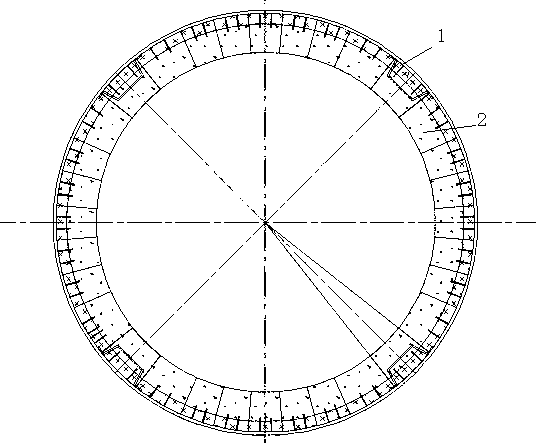

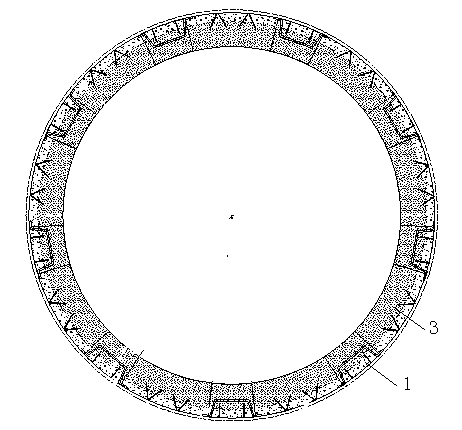

Stable kiln liner of asphalt rotary kiln

InactiveCN102853653AExtended service lifeDelay or prevent damageRotary drum furnacesMulliteEngineering

The invention relates to an asphalt rotary kiln, in particular to a stable kiln liner of an asphalt rotary kiln. The stable kiln liner is divided into a part from a kiln front cover to a transition section and a part from the transition section to a kiln end. A liner of the part from the kiln front cover to the transition section adopts a double-layer precast block brick mode, a heat preservation layer is made of light pouring materials, and a working layer is made of ultra-low cement combined with high-purity corundum-mullite pouring materials. The kiln liner adopts four fixed precast blocks which are distributed at 360 degrees, and a precast block brick is built between every two fixed precast blocks in a welding mode. The part from the transition section to the kiln end adopts a mode combining double-layer precast block bricks and pouring materials, a heat preservation layer is made of light pouring materials, a working layer is made of ultra-low cement combined with high-purity corundum-mullite pouring materials, and the kiln liner adopts a clip flower mode with nine precast blocks and nine pouring materials. By means of the kiln liner, structural stability of brickworks of the kiln liner is ensured, pulverization of the heat preservation layers in the production process is avoided, and accordingly, service life of the kiln liner is prolonged.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

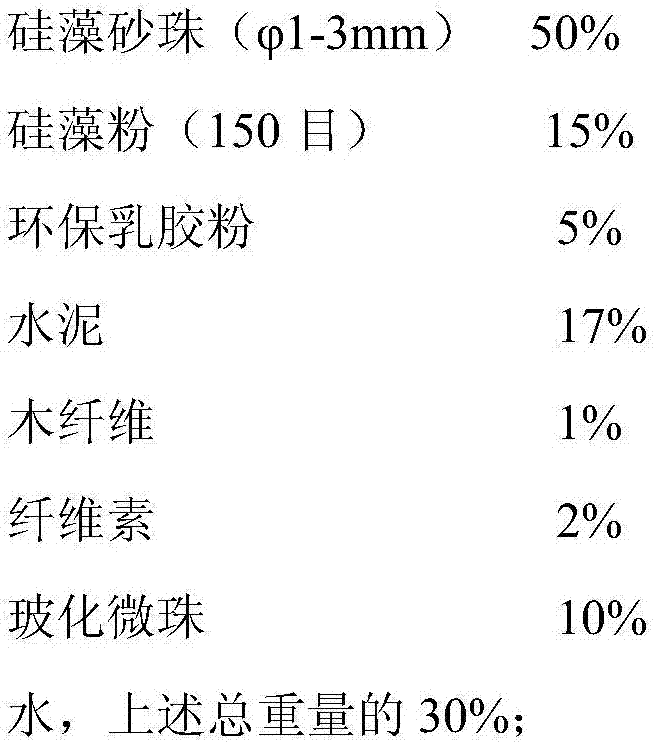

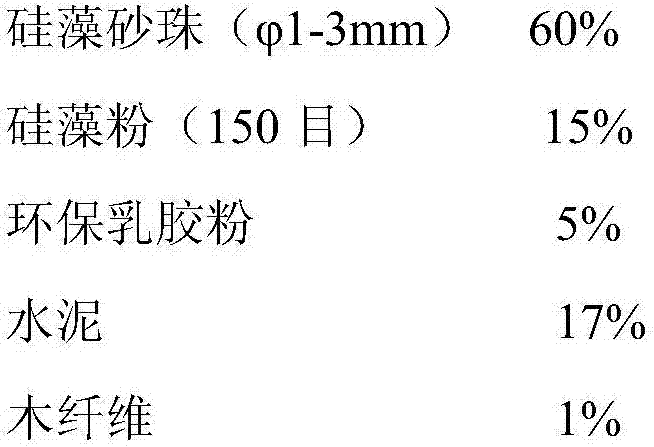

Diatom sand beads and high-strength, environment-friendly and thermal-insulation mortar containing same

The invention relates to diatom sand beads and high-strength, environment-friendly and thermal-insulation mortar containing the same. The diatom sand beads are prepared from second-class and third-class diatomite used as a raw material through four steps including drying, purification, granulation and roasting. The diatom sand beads are light in weight, environment-friendly and high in adsorbability and have the advantages of damp prevention, fire prevention, purification, thermal insulation and the like. The thermal-insulation mortar is prepared from 50%-60% of the diatom sand beads, 10%-20% of diatom powder, 5%-8% of environment-friendly latex powder, 10%-20% of cement, 1% of wood fiber, 2% of cellulose, 0-10% of glass beads and water. The thermal-insulation mortar can replace cement mortar to be directly applied to building wall brick surfaces, when the thermal-insulation mortar is used for an exterior wall, other decoration processes can be performed directly on the thermal-insulation mortar, and when the thermal-insulation mortar is used for an interior wall, the thermal-insulation mortar can well adsorb indoor formaldehyde produced during decoration, is environment-friendly and can purify indoor air; the thermal-insulation mortar has the advantages of being light in weight, low in heat conductivity coefficient, environment-friendly, thermal-insulation, high-temperature-resistant, fireproof, low-temperature-resistant, noise-reducing, damp-proof, mildew-proof, anti-condensation, free of radioactive substances, stable in physical and chemical property and the like.

Owner:长白朝鲜族自治县玉鑫硅藻土有限公司

Nanometer-reflection thermal insulation coating and preparation method thereof

InactiveCN102964961AExcellent reflective heat radiation performanceLow thermal conductivityReflecting/signal paintsEmulsionWeather resistance

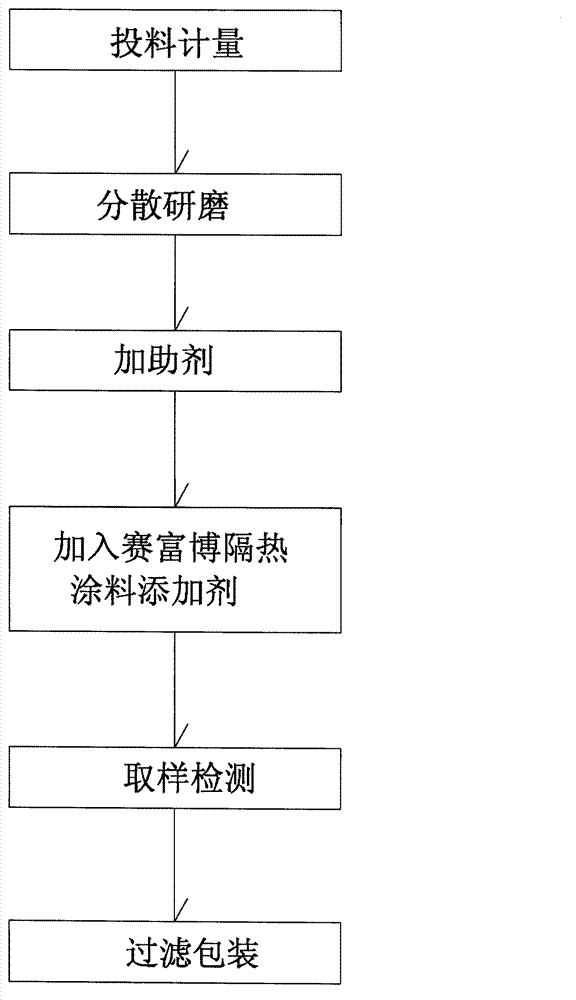

The invention relates to a nanometer-reflection thermal insulation coating and a preparation method thereof. The nanometer-reflection thermal insulation coating is formed by mixing the following materials in percentage by weight: 15-25% of Surfa Pore thermal insulation coating additive, 30-60% of pure acrylic emulsion, 5-15% of water, 3-8% of stuffing, 1.20% of thickener, 1.03% of wetting agent, 0.84% of defoaming agent, 0.65% of dispersing agent and 0.82% of coalescing agent. The nanometer-reflection thermal insulation coating has the advantages of admirable application property, excellent thermal radiation reflection property, relatively low coefficient of heat conductivity, super stain resistance, self-cleaning property and crack resistance, admirable weather resistance and color retention, excellent scrub resistance and the like.

Owner:LIONTRUNK (BEIJING) TECH CO LTD +1

Hydrated alumina molded matter and preparation method thereof, alumina molded matter and applications of hydrated alumina molded matter and alumina molded matter

ActiveCN103480326AGood strength retentionHigh strengthCatalyst carriersMolecular sieve catalystsCelluloseMolecular sieve

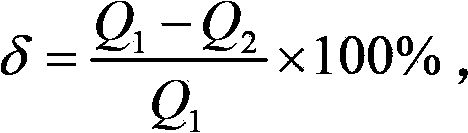

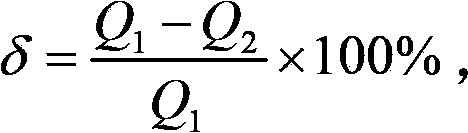

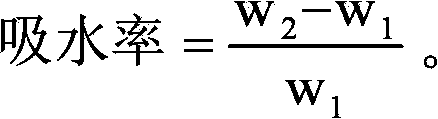

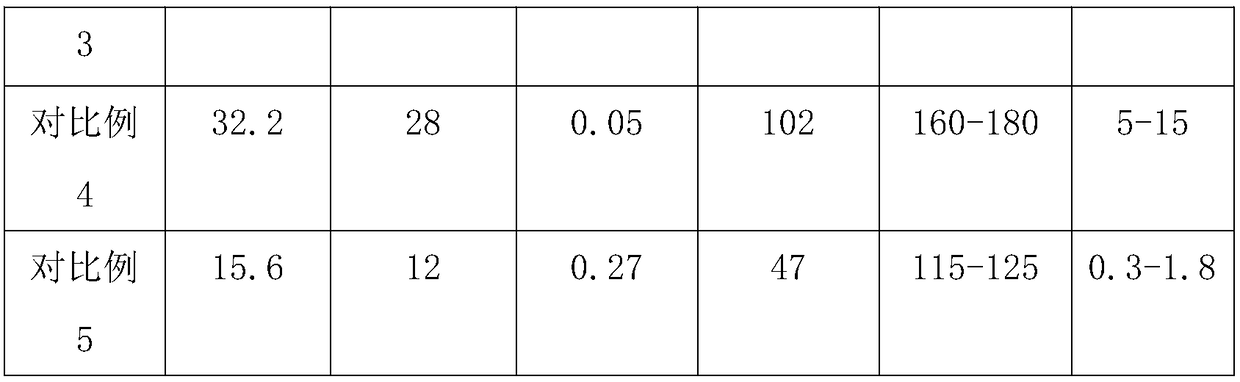

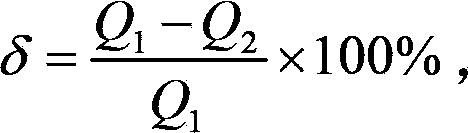

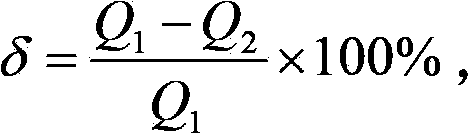

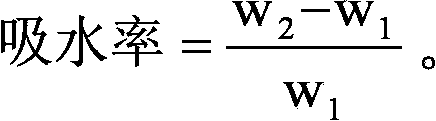

The invention provides a hydrated alumina molded matter, and a preparation method and an application thereof. The hydrated alumina molded matter is prepared by molding raw materials comprising at least one hydrated alumina, at least one Y molecular sieve and at least one cellulose ether. The water absorption rate of the hydrated alumina molded matter is 0.4-1.5, the delta value is 10% or less, and the Q1 is 12 N / mm or more. The invention also provides an alumina molded matter and an application thereof, wherein the alumina molded matter is prepared by calcination of the hydrated alumina molded matter. The molded matters provided by the invention have high strength and good strength retention rate. According to the method of the invention, a peptizing agent is not used during the molding process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Energy saving heat preserving tile

The invention relates to an energy saving heat preserving tile. The semis of the energy saving heat preserving tile comprises the following raw materials: 30 to 40 percent of kaolin, 15 to 25 percent of calcite powder, 8 to 15 percent of talcum powder, 10 to 20 percent of hollow microspheres, 5 to 15 percent of titanium white, 10 to 15 percent of fluoro-silicon resin, and 10 to 15 percent of water. The thickness of the tile is 8 to 12 mm. The tile is also added with sodium nitrate accounting for 0.5 to 0.7 percent. The energy saving heat preserving tile provided by the invention can endure long time exposing to the weather of complex environment without pulverization, delaminating and changing of color, is resistant to abrasion and water, and has excellent performance of heat insulating, temperature maintaining and energy saving.

Owner:QINGDAO BAOLIKANG NEW MATERIALS

Water paint with pearl matt effect for glass door and preparation method thereof

InactiveCN104449131AFast dryingGood film formingAntifouling/underwater paintsPaints with biocidesDiethylene glycol monobutyl etherPolymer science

The invention discloses a water paint with pearl matt effect for a glass door. The water paint with pearl matt effect for the glass door is characterized by being prepared from the following raw materials in parts by weight: 40-47 parts of a water-based acrylic resin, 28-34 parts of a vac-veova emulsion, 1-3 parts of diethylene glycol monobutyl ether, 0.3-0.6 part of titanium di(dioctyl pyrophosphoryl) oxygen-containing acetate, 0.2-0.4 part of fluoroalkyl polyether modified polysiloxane, 0.3-0.5 part of ethylene glycol distearate, 0.2-0.4 part of lauramidopropyl betaine, 0.5-0.8 part of glass frosting powder, 0.2-0.4 part of polyglycerol ester, 0.3-0.5 part of sodium alkyl naphthalene sulfonate, 0.1-0.3 part of ethylene glycol, 3-5 parts of modified nano titanium dioxide photocatalyst, 1-2 parts of a pigment and 10-15 parts of deionized water. The paint provided by the invention has high drying speed, excellent film-forming property, good luster and good adhesion and is not easy to peel; the added ethylene glycol distearate and glass frosting powder have well pearl decoration effect and anti-wear effect on a paint film; the added modified nano titanium dioxide photocatalyst can increase the functions, such as bacterial resisting, mildew resisting, air purifying, odour removing, pollution preventing and self-cleaning properties and the like of the paint.

Owner:安徽省实防新型玻璃科技有限公司

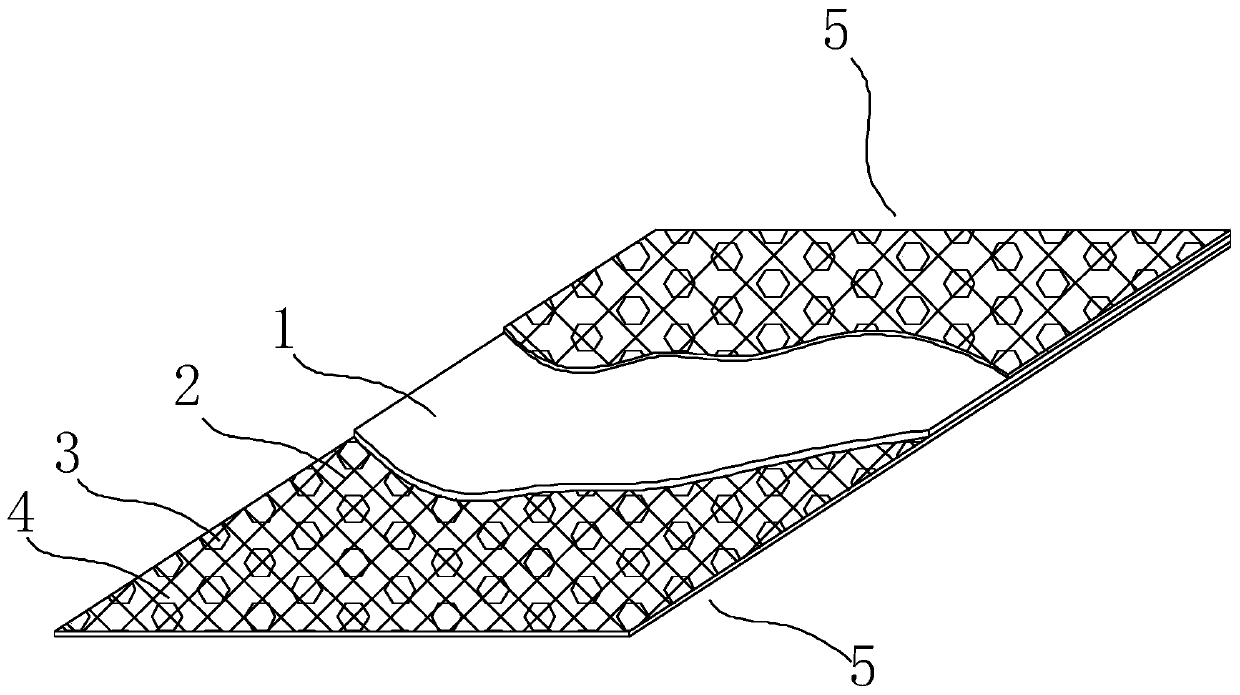

Novel composite refractory mica tape and manufacturing method thereof

InactiveCN110421908AMeet integrity test requirementsImprove fire resistanceLamination ancillary operationsLaminationGlass fiberAdhesive

The invention discloses a novel composite refractory mica tape. The mica tape comprises a synthetic mica paper layer, high silica glass fiber meshes, ceramization silicon rubber particles and refractory adhesive layers, the ceramization silicon rubber particles are pasted through each refractory adhesive layer and evenly dispersed on each high silica glass fiber mesh to form a composite layer, andthe synthetic mica paper layer is pasted between two composite layers through the refractory adhesive layers. The mica tape has good fire resistance, and meets the British refractory cable standard BS, especially no pulverization appears at conditions of a temperature of 800 DEG C, fire-resistant and insulation effects are still reliable, the performance is better than a traditional mica tape, and thus the mica tape meets line integrity test requirements with a flame temperature of 800-1000 DEG C and a duration time of 120 min.

Owner:CHONGQING TAISHAN CABLE

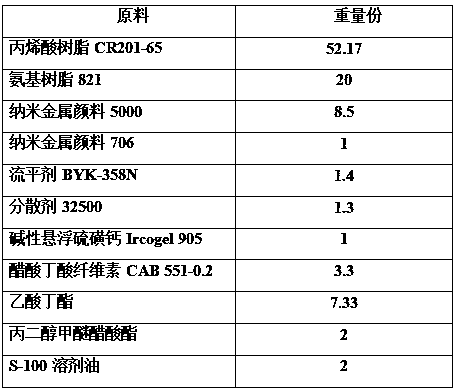

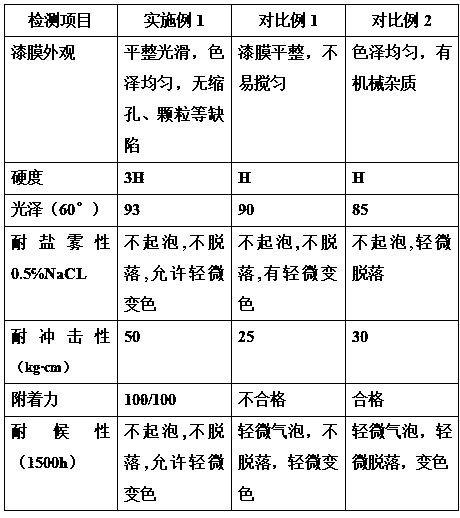

One-step coated film-formed high-gloss automobile metal wheel hub paint and preparation method thereof

ActiveCN109486306AMeet the requirements of one-time coating processHigh hardnessAnti-corrosive paintsAcrylic resinDiluent

The invention belongs to the technical field of coatings, and particularly relates to one-step coated film-formed high-gloss automobile metal wheel hub paint and a preparation method thereof. The paincomprises 40-55 parts of acrylic resin, 20-26 parts of amino resin, 8.0-13 parts of nano-metal pigments, 4.0-7.0 parts of auxiliaries and 10-15 parts of diluents. The acrylic resin reacts with the butyl ether amino resin, and the one-step coated film-formed high-gloss automobile metal wheel hub paint with high-temperature resistance, good adhesive force and high additional values can be obtainedby the aid of the metal pigments. Moreover, an original triple-coating triple-baking or triple-coating one-baking preparation process is changed into a one-coating one-baking paint preparation process, and the paint has better performances such as high gloss and salt fog resistance. The method is simple in preparation process and suitable for industrial production.

Owner:ZHANGZHOU XIN ZHAN WANG CHEM IND

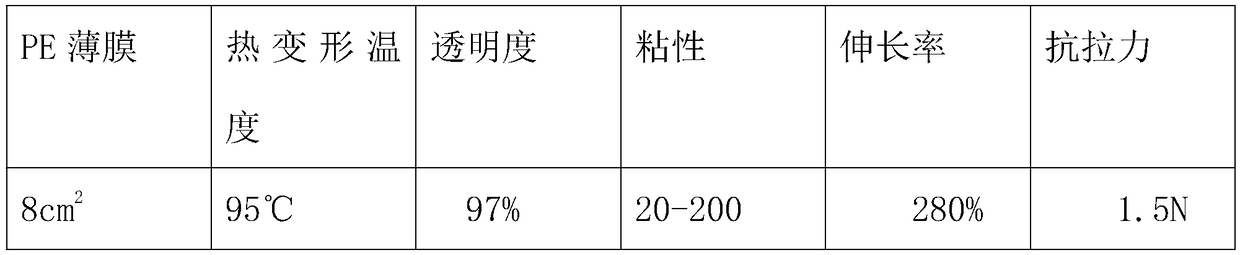

PE (poly ethylene) film for wire and cable and preparation method of PE film

The invention discloses a PE (poly ethylene) film for a wire and a cable and a preparation method of the PE film. The PE film is prepared from the following concrete materials in parts: 15-25 parts ofcrosslinked polyethylene, 8-16 parts of low-density polyethylene, 6-14 parts of medium-density polyethylene, 7-14 parts of polyisobutene, 4-8 parts of modified polyester fiber, 0.5-1 part of aluminumoxide, 0.8-3 parts of cellulose acetate, 2-6 parts of silica gel, 1-5 parts of dimethyl formamide, 1-5 parts of hydroxypropyl methyl cellulose, 2-6 parts of polyethylene terephthalate, 1.2-2.5 partsof nanoscale titanium oxide, 0.5-1.4 parts of nanoscale aluminum oxide, 0.6-1.5 parts of tetrabutyl titanate, 1.4-3 parts of methylphenol, 0.6-1.8 parts of magnesium stearate, 0.8-1.5 parts of an antioxidant and 1.5-3 parts of a plasticizer. The PE film prepared by the invention does not become aged, allochroic, cracked, brittle or pulverized under the action of atmosphere, sunlight and oxygen, the PE film has a relatively stable mechanical property and strong chemical stability simultaneously, and the PE film is simple in processing technology and low in raw material cost, thereby being suitable for production in quantity.

Owner:深圳市双源包装材料有限公司

Optical radiation resistant exterior wall paint

InactiveCN1800277AReduce absorptionImprove water resistanceChloropene polymer coatingsReflecting/signal paintsOptical radiationEmulsion

The invention discloses a radiation reactant exterior wall paint in the field of exterior wall paint producing technology. It is formed by toluene, 120# petrol, alkyd resin, VAE, DBP, chloroprene rubber and painting; it has the following preparing steps: adding the toluene and the 120# petrol into the autoclave sterilizer to mix them, adding the alkyd resin, VAE, DBP and chloroprene rubber and using high speed cutting emulsion machine to do cutting emulsion, adding the painting after 1-2h and emulsion erasing until the material purity achieves to below 60mu m, then filter charging the product.

Owner:邹文和

Preparation method of phosphogypsum fireproof door core board

The invention discloses a preparation method of a phosphogypsum fireproof door core board and relates to the technical field of fireproof building materials. The method includes: alkali-washing livistona chinensis leaf fibers and performing ionization surface modification; mixing raw materials in batches to prepare a thick material; pouring the thick material in a mold, allowing the material to stand, and maintaining, cutting and shaping the material. The fireproof door core board is improved significantly in aspects of mechanical strength, fireproof and waterproof properties, heat resistanceand anti-freeze effect, and oil resistance, etc., has better overall performance, is better in applicability, and is guaranteed in service life well.

Owner:HEFEI YIZHI DOORS & WINDOWS CO LTD

Waterborne seam beautifying agent and preparation method thereof

ActiveCN109355051AGood adhesionLow shrinkageNon-macromolecular adhesive additivesEpoxy resin adhesivesMass ratioHardness

The invention provides a waterborne seam beautifying agent. The agent is composed of an A component and a component B according to the mass ratio of 1:1, the A component comprises preparation raw materials of 78-92 parts of bisphenol A type epoxy resin, 8-22 parts of polyether monoamine and 2-8 parts of hydrophilic gaseous phase silicon dioxide; the B component comprises preparation raw materialsof 20-25 parts of isophoronediamine, 18-28 parts of the bisphenol A type epoxy resin, 6-12 parts of emulsifiers and 4-8 parts of the hydrophilic gaseous phase silicon dioxide. The invention relates tothe technical field of environmental materials, the waterborne seam beautifying agent has the advantages that the formula is simple, the durability is high, a water erasable function is achieved to help to perform cleaning processing after construction, the agent has no toxin and harm after curing is conducted, there exists no VOC emission, the surface hardness is high, the scratching resisting performance is high, the agent has excellent flexibility and bonding performance, powdering, mildewing and the like are prevented, and the appearance is good.

Owner:广州市连拓新材料有限公司

Silicon fluoride super-amphiphobic non-stick coating material

Owner:ZIBO YINGQIANG CHEM TECH

Production method of potassium sulfate fertilizer granules

ActiveCN109956823ARound particlesUniform particle sizeSolid/semi-solid fertilisersPotassium fertilisersPotassium sulfateUltimate tensile strength

The invention relates to a production method of potassium sulfate fertilizer granules. The production method comprises the following steps: crushing potassium sulfate and iron oxide red, mixing potassium sulfate and iron oxide red, preparing a binder, and performing granulation. The potassium sulfate granulated fertilizer product produced by the method is uniform in particle size, round and tidy in particles and smooth in surface, and the particle strength reaches the national fertilizer requirement standard. The potassium sulfate fertilizer particles cannot be pulverized in the transportationand application processes, and can be used as a raw material of a compound fertilizer.

Owner:ZHENGZHOU UNIV +1

Washable putty powder for interior wall latex paint

ActiveCN103497561BGood wash resistanceHigh bonding strengthFilling pastesMaterials scienceMilk paint

The invention discloses a water washing resistant putty powder for interior wall emulsion paint, and the water washing resistant putty powder comprises the following raw materials: by weight, 40-50 parts of calcium carbonate powder, 50-60 parts of modified talcum powder, 20-30 parts of ash calcium powder, 10-15 parts of white cement, 2.5-3.5 parts of hydroxypropyl methylcellulose, 3-5 parts of hydroxypropyl starch ether, 0.5-1 part of HS-2 moisturizing lubricant and 2-3 parts of NSJF-6 A emulsion powder. The putty powder has excellent water washing resistance and high bonding strength, when the putty powder meets water and is affected with damp, the putty powder may not fall off powder, pulverize, hollow and crack, is excellent in construction property, non-material-throwing and non curling, and has the advantages of being high in hardness, fast in film forming, moisturizing, mildew and damp proof, aging resistant, long in storage time, convenient to use, stable in performance and the like.

Owner:广东瓦科新材料有限公司

Hot-melt pressure-sensitive adhesive for manufacturing tire label coating and preparation method thereof

InactiveCN111320956AGuaranteed uptimeNo chalkingStampsPressure sensitive film/foil adhesivesElastomerHot melt

The invention provides a hot-melt pressure-sensitive adhesive for manufacturing tire label coating and a preparation method thereof, and relates to the field of hot-melt pressure-sensitive adhesives.The hot-melt pressure-sensitive adhesive for manufacturing the tire label coating is prepared from the following components in parts by mass: 32 to 45 parts of an organic polymer elastomer, 10 to 26 parts of a viscosity regulator, 10 to 30 parts of a tackifier and 0.3 to 1 part of other auxiliary agents, by selecting a plurality of high-quality organic polymer new materials which have specific functions and are produced abroad, the selection material and the proportion of the conventional hot-melt pressure-sensitive adhesive are broken through. The method is characterized in that a self-ownednew process and an equipment process parameter method are adopted. The four technical requirements that the product quality of numerous hot melt adhesive production enterprises cannot stably meet thehigh-end tire label due to high product quality requirement and high production difficulty of the hot melt pressure-sensitive adhesive for coating the high-end tire label are solved.

Owner:厦门鼎宏热熔胶有限公司

Method of preparing molten steel refining agent by using industrial solid waste FCC catalyst

The invention discloses a method of preparing a molten steel refining agent by using an industrial solid waste FCC catalyst. The molten steel refining agent is prepared by mixing the industrial solidwaste FCC catalyst with lime powder as a primary raw material, handling difficulty of the industrial solid waste FCC catalyst and polluting problem caused by the industrial solid waste FCC catalyst can be solved effectively, recycling of the solid waste is achieved fully, waste is turned into wealth, the production cost is lowered greatly, and the additional value of a product is improved. The prepared refining agent is low in melting point, high in melting speed, large in sulfur capacity, short in smelting time and good in desulfurizing, deoxidizing and inclusion-removing effects. Meanwhile,reduced rare earth oxides in the FCC waste catalyst also can play a role of enhancing properties of steel. The method is simple in preparation process, environmental-friendly and favorable to popularize, and has a relatively large application potential.

Owner:WUHAN UNIV OF SCI & TECH

Green coating for buildings

The invention discloses a green coating for buildings. The green coating is characterized by comprising the following substances in parts by weight: 25-29 parts of furfuryl alcohol resin, 18-23 parts of isocyanate, 1-9 parts of fillers, 6-9 parts of clamshell powder, 3-5 parts of scapharca subcrenata shell powder, 2-6 parts of mactra veneriformis shell powder, 1-3 parts of perlite, 12-15 parts of cedrus saw dust, 13-16 parts of silver birch saw dust, 16-18 parts of oak saw dust, 3-4 parts of prunus padus saw dust, 9-14 parts of organosilicone modified epoxy resin, 10-15 parts of mixed solvent and 1-9 parts of toughening agent. The green coating has the characteristics of high wet-dry curing speed, high bonding strength, waterproof and moistureproof properties and the like. After the green coating is used, the phenomena such as dusting, cracking, hollowing, shedding, frosting and the like can not appear on walls.

Owner:QINGDAO UWELL INFORMATION TECH

Environment-friendly titanium-based polymer alloy anti-corrosion daub

PendingCN112961601AStrong adhesionNo chalkingFireproof paintsAnti-corrosive paintsGlass fiberPolymer alloy

The invention provides environment-friendly titanium-based polymer alloy anti-corrosion daub. The daub comprises solvent-free titanium-based polymer alloy anti-corrosion daub and water-soluble titanium-based polymer alloy anti-corrosion daub, belonging to the technical field of novel anti-corrosion materials. The environment-friendly titanium-based polymer alloy anti-corrosion daub consists of a titanium-based polymer alloy copolymer, an auxiliary film-forming matter, an anti-corrosion and wear-resistant filler, a chemical additive, a reactive diluent or purified water and an independent curing agent, and has the characteristics of strong adhesive force, temperature change resistance, wear resistance, corrosion resistance, no pulverization, no cracking and no shedding; construction is easy and convenient, no toxicity or odor exists, flammable and explosive risks do not exist, and safety and environment friendliness are achieved; compared with glass fiber reinforced plastics, layer-by-layer cloth sticking is not needed for the daub; and compared with a vitrified brick, seamless connection and overall protection are achieved, and particularly, acid corrosion in a high-temperature-resistant environment is achieved, and the economic life exceeds 5 years.

Owner:兰州星河石化防腐有限公司

Polysiloxane heat-reflective topcoat and preparation method thereof

InactiveCN104946129AOutstanding resistance to atmospheric agingOutstanding resistance to UV degradationAnti-corrosive paintsReflecting/signal paintsWeather resistanceThermal insulation

The invention provides a polysiloxane heat-reflective topcoat and a preparation method thereof. The polysiloxane heat-reflective topcoat comprises a component A and a component B, and the weight ratio of the component A to the component B is 8:(1-1.5); the component A comprises the following ingredients by weight: 30-40 parts of polysiloxane resin, 3-8 parts of a thermal insulation material, 0.6-0.9 part of a stabilizer, 25-48 parts of a mixed solvent, 0.2-0.5 part of a dispersant, 17-33 parts of an anti-aging pigment and an anti-aging filler, and 0.2-0.5 part of an anti-settling agent; the component B comprises the following ingredients by weight: 60-70 parts of a curing agent and 18-35 parts of a curing agent solvent. The polysiloxane heat-reflective topcoat is high in ageing-resistant performance, weather resistance and chemical resistance, has a heat reflection function, can be suitable for various construction methods, and is good in recoatability and excellent in cost performance; besides, external corrosion protection of the surface of coated steel is achieved, a lot of coating expenditures can be reduced, and the service life is prolonged.

Owner:上海海悦涂料有限公司

Production method of refractory mud blank

The invention belongs to the technical field of refractory raw material production, in particular relates to a production method of a refractory mud blank. When the refractory mud blank is produced, lignocellulose is added into the raw material. In the invention, the lignocellulose is used as a refractory mud blank additive so as to ensure that the refractory mud blank is not pulverized and cracked in the process of drying, and is not burst and chipped in the process of sintering, thereby ensuring that the sintering is even, and the operation of a kiln car is safe.

Owner:SANMENXIA XINYANGSHAO SYNTHETIC MATERIALS

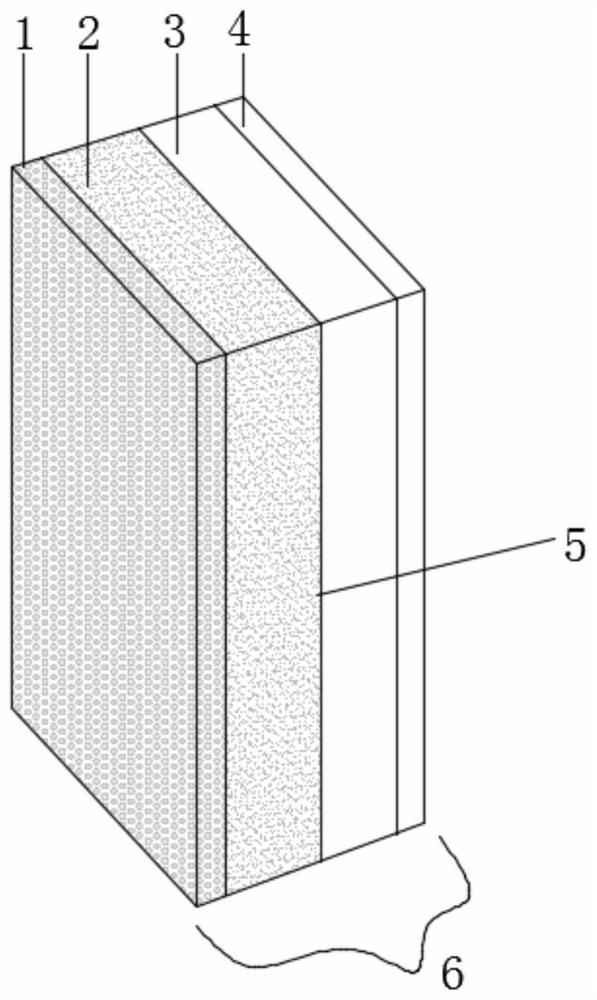

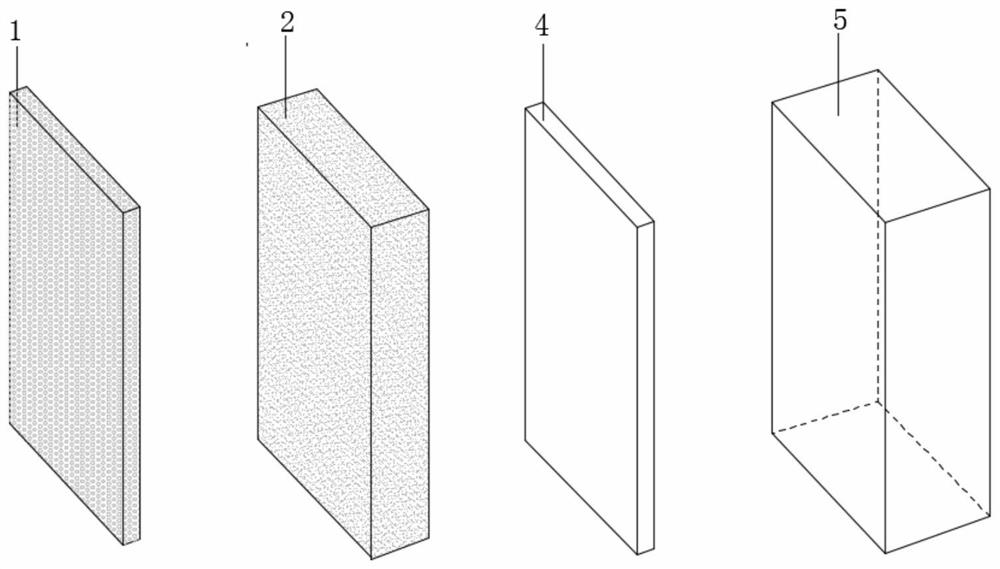

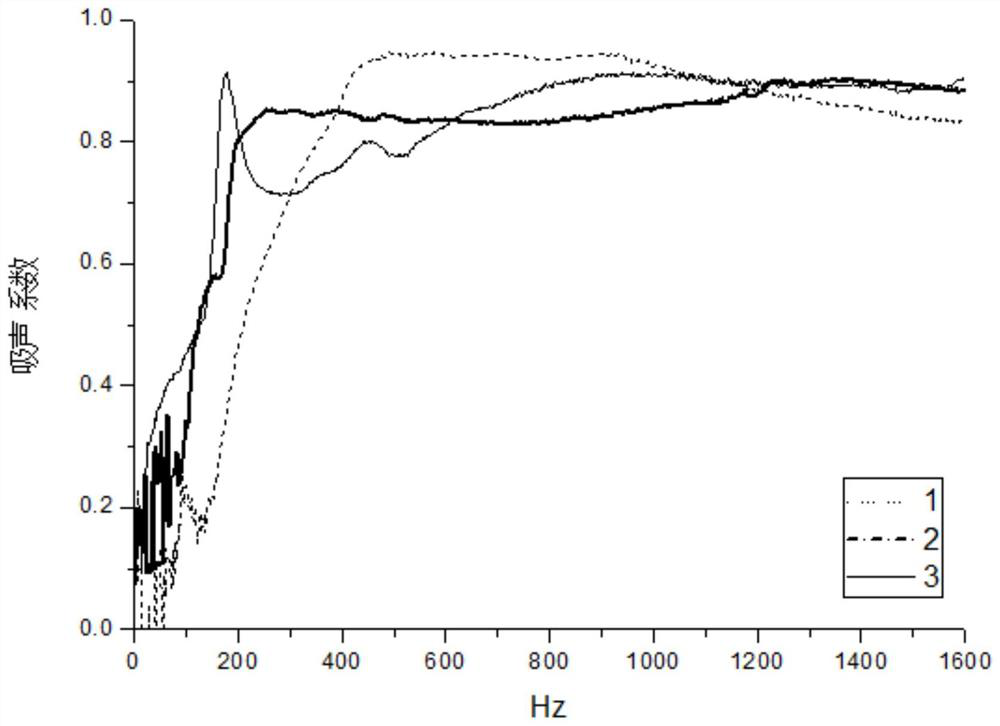

Ceramic fiber sound absorption component

PendingCN111653259AAdjustable acoustic performanceSound absorption coefficient is stableSound producing devicesMicro perforated plateFiber

The invention relates to a ceramic fiber sound absorption component. The ceramic fiber sound absorption component comprises a micro-perforated plate, a ceramic fiber plate, a back plate and side plates, the micro-perforated plate, the ceramic fiber plate and the back plate are sequentially arranged in the horizontal direction and are the same in section size, the micro-perforated plate is tightlyattached to the ceramic fiber plate, the side plates are arranged between the ceramic fiber plate and the back plate, and the ceramic fiber plate and the back plate are tightly attached to the side plates. The side plates are of a frame structure, so that a closed cavity is formed between the ceramic fiber plate and the back plate; the micro-perforated plate, the ceramic fiber plate, the back plate and the side plates can be fixedly connected through angle steel to form an integral sound absorption component. The sound absorption component has excellent fireproof performance and acoustic performance, the flame retardance can reach the A level, the 100 Hz sound absorption coefficient can reach 0.3 or above, suppression of different noise frequency bands can be achieved through adjustment ofmaterial parameters and structural parameters, and the sound absorption component adapts to the frequency spectrum characteristics of different noise sources.

Owner:YUNNAN POWER GRID

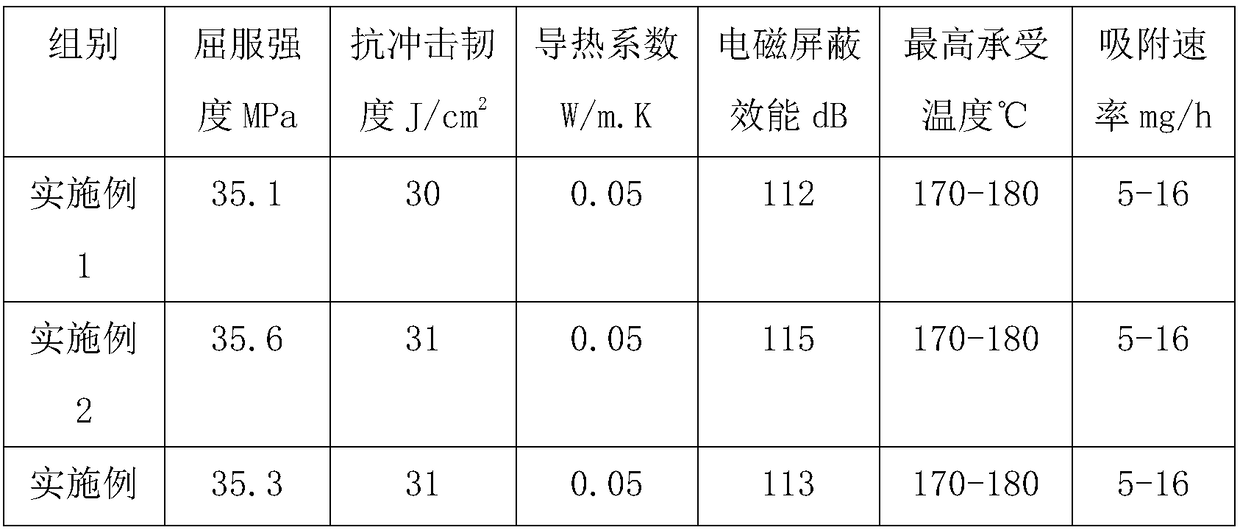

Palygorskite powder-added wood-plastic door and window material and preparation method thereof

The invention discloses a palygorskite powder-added wood-plastic door and window material and a preparation method thereof, and relates to the technical field of door and window materials. The wood-plastic door and window material comprises the following raw materials: a PVC waste material, a PE waste material, fly ash, palygorskite powder, chabazite powder, diatomite, porous SiO2, coconut charcoal fiber, broussonetia papyrifera wood chip powder, borax, calcium lignosulfonate, low-molecular weight polyethylene wax, sucrose fatty acid ester, a curing agent, a foaming agent, a foam stabilizing agent and a coupling agent. The preparation method comprises the following steps: mixing and extruding the raw materials and the like to obtain the wood-plastic door and window material. The wood-plastic door and window material has excellent comprehensive performance, not only can achieve the purposes of noise reduction and energy saving relatively well, but also can effectively purify air and shield electromagnetic waves, so that the wood-plastic door and window material improves the quality of indoor working and living environments, and is durable, practical and wide in application field.

Owner:合肥市旺友门窗有限公司

Iron-containing hydrated alumina molded matter and preparation method thereof, and iron-containing alumina molded matter and applications of iron-containing hydrated alumina molded matter and iron-containing alumina molded matter

ActiveCN103480327AGood strength retentionPromote absorptionCatalyst carriersOther chemical processesCelluloseHydration reaction

The invention provides an iron-containing hydrated alumina molded matter, and a preparation method and an application thereof. The iron-containing hydrated alumina molded matter is prepared from raw materials comprising at least one hydrated alumina, at least one iron-containing compound and at least one cellulose ether. The water absorption rate of the iron-containing hydrated alumina molded matter is 0.4-1.5, the delta value is 10% or less, and the Q1 is 12 N / mm or more. The invention also provides an iron-containing alumina molded matter prepared by calcination of the iron-containing hydrated alumina molded matter. The invention also provides an application of the molded matters as a drying agent or as a carrier of a supported catalyst. The iron-containing hydrated alumina molded matter contains no peptizing agent, has good strength retention rate, and cannot or basically cannot generate phenomena of dissolving, powdering or pore collapsing even being immersed in an impregnating solution for a long time. The method of the invention does not adopt the peptizing agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Optical radiation resistant exterior wall paint

InactiveCN100351329CReduce absorptionImprove water resistanceChloropene polymer coatingsReflecting/signal paintsOptical radiationEmulsion

The invention discloses a radiation reactant exterior wall paint in the field of exterior wall paint producing technology. It is formed by toluene, 120# petrol, alkyd resin, VAE, DBP, chloroprene rubber and painting; it has the following preparing steps: adding the toluene and the 120# petrol into the autoclave sterilizer to mix them, adding the alkyd resin, VAE, DBP and chloroprene rubber and using high speed cutting emulsion machine to do cutting emulsion, adding the painting after 1-2h and emulsion erasing until the material purity achieves to below 60mu m, then filter charging the product.

Owner:邹文和

Roasting inserts of carbon elements for aluminium

The invention discloses a roasting inserts used in roasting process of carbon elements for aluminium, Including ecorundum brown corundum and / or white corundum of more than 50% in mass percentage. The invention provided roasting inserts has high coefficient of heat conduction, Which can reducing time of heat conducting from a fire channel to the carbon elements producing area, Improving heat efficiency, Saving application amount of roasting raw material, Shorting cooling time of roasting finished product; And low burning loss rate, And cases of bonding together, adsorbing onto surface of the carbon elements are not easily appeared.

Owner:SNTO TECH GRP

Oil-resistant anti-freeze-thawing fireproof door core board

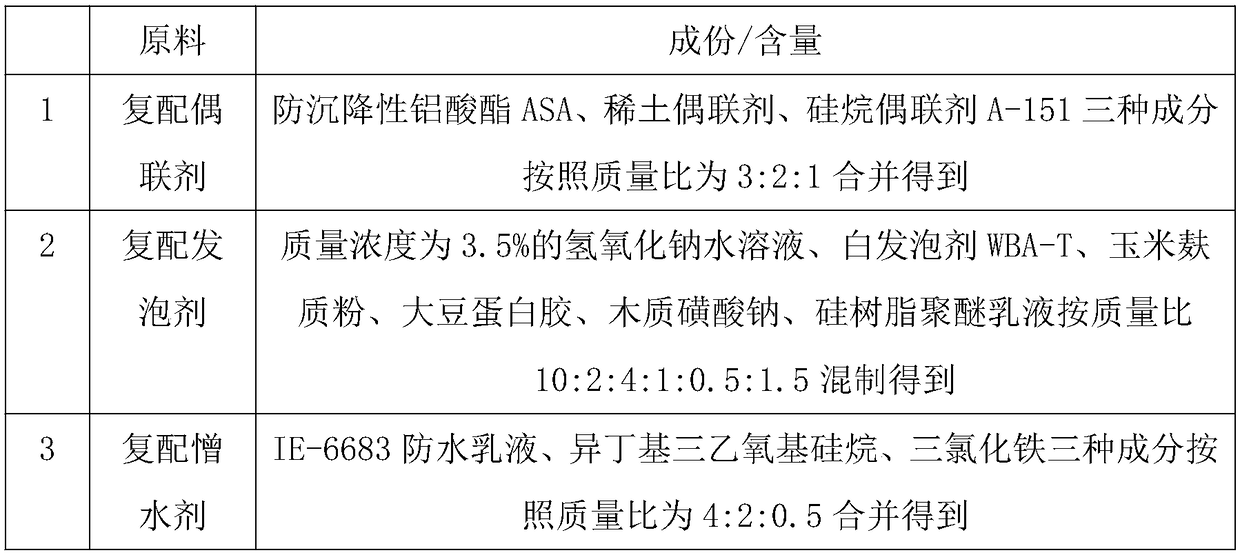

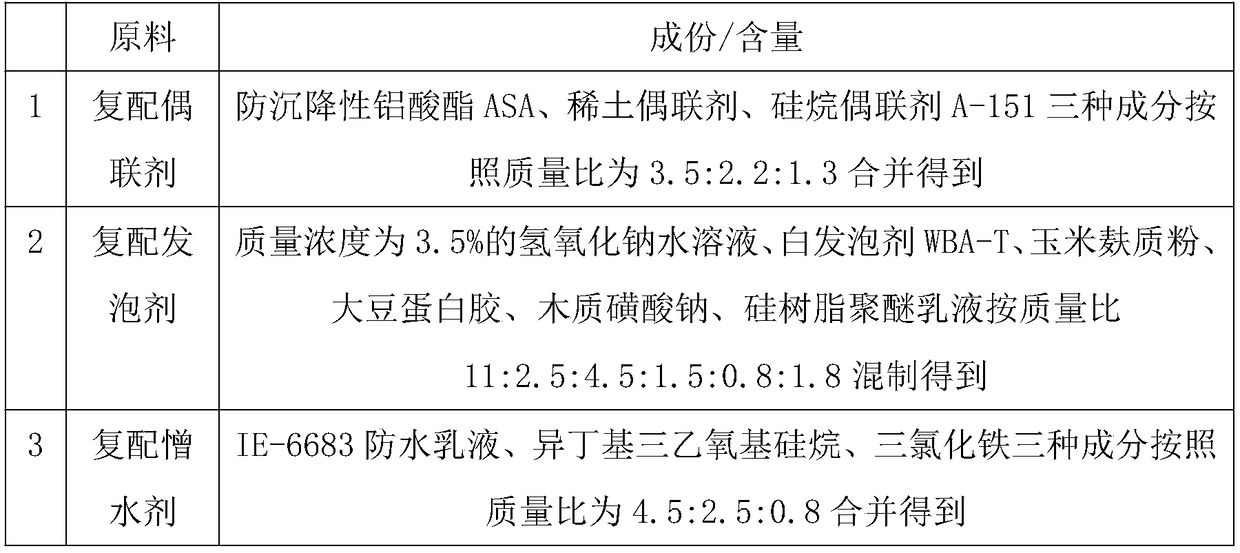

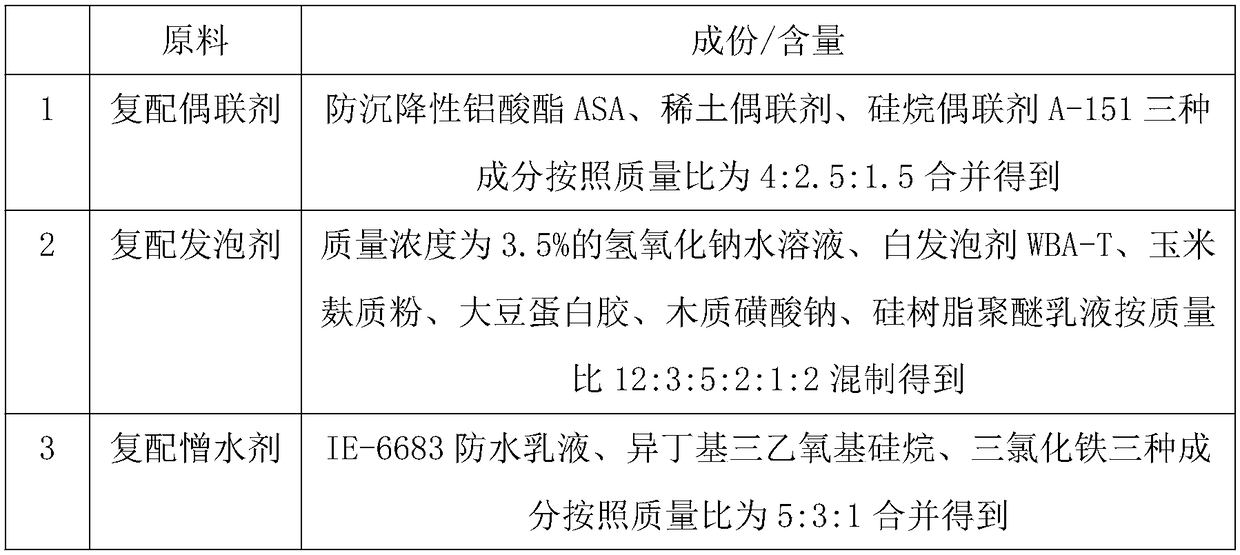

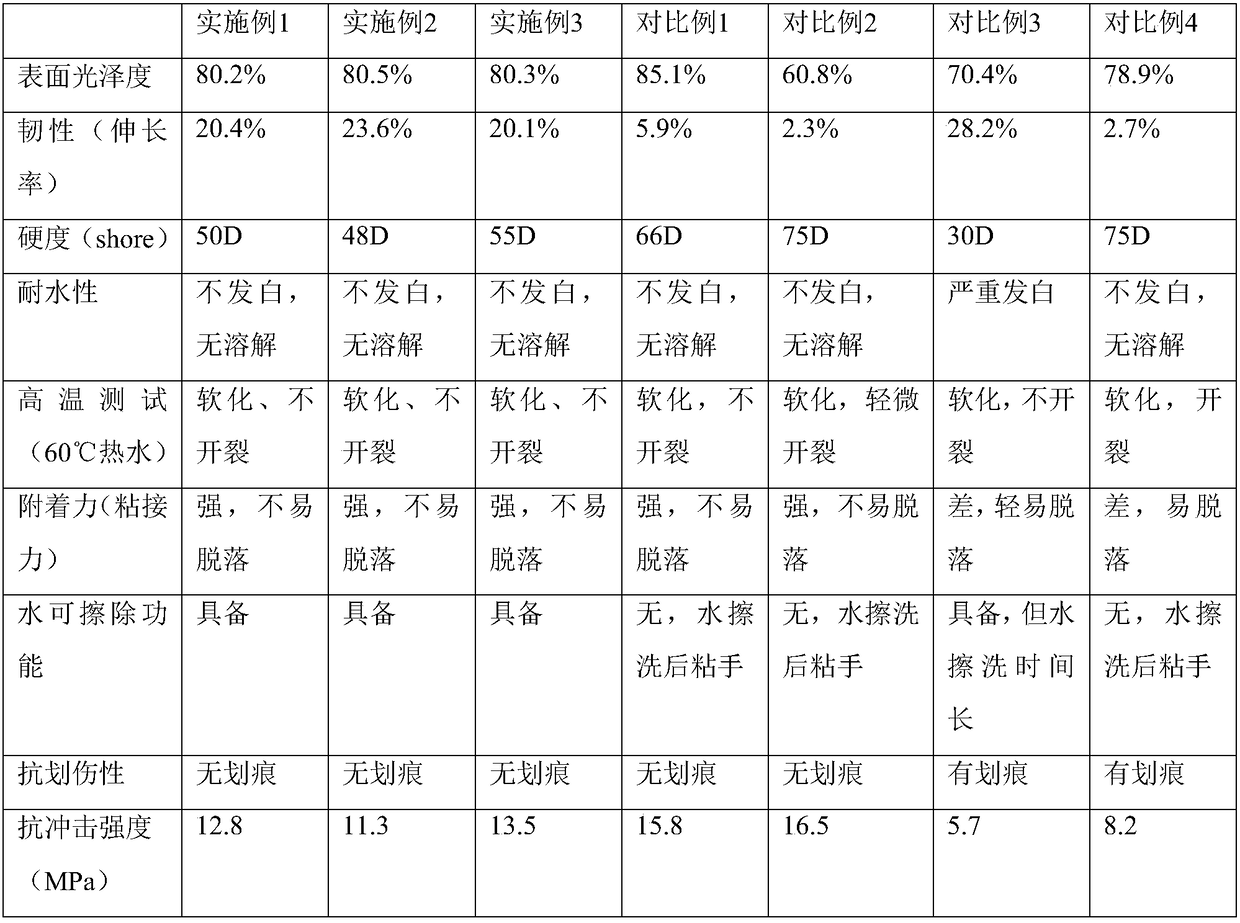

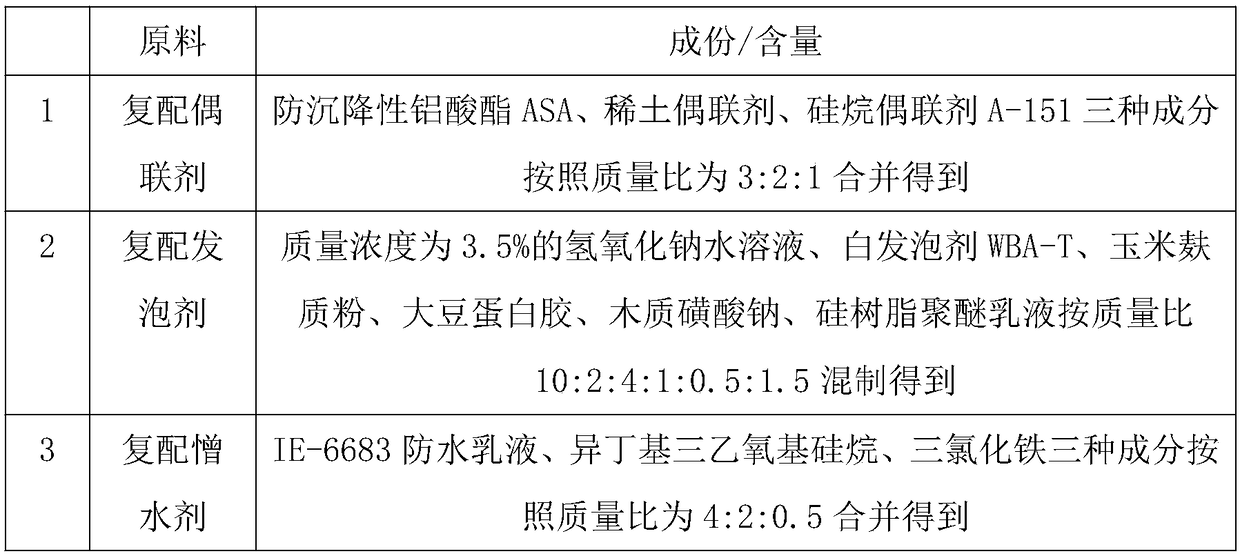

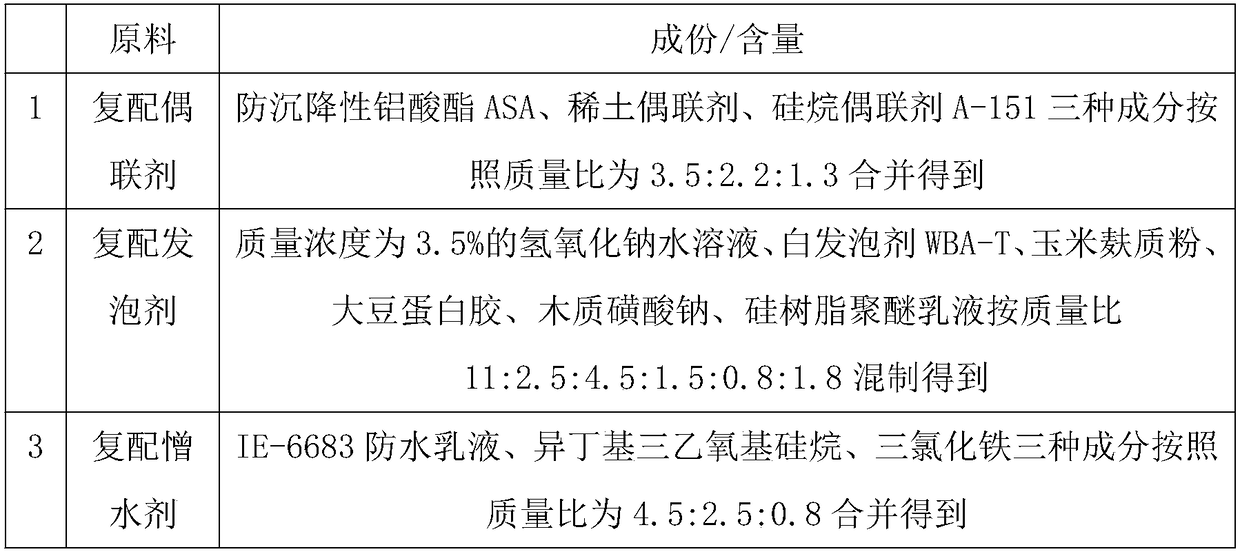

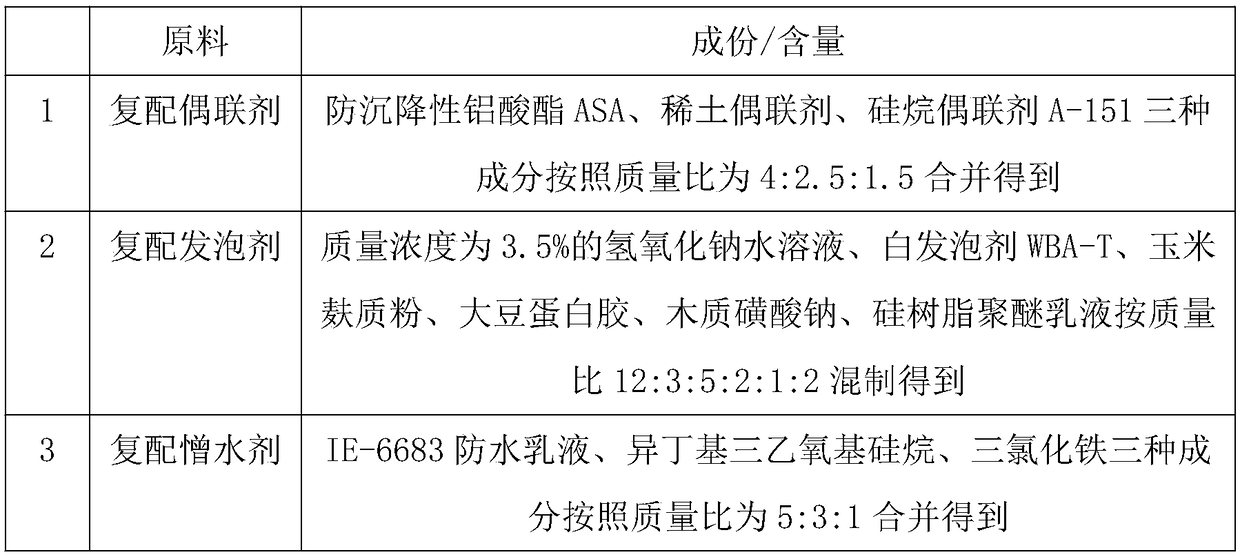

The invention discloses an oil-resistant anti-freeze-thawing fireproof door core board and relates to the technical field of fireproof building material. The door core board includes: niobium / yttriumtailing powder, phosphogypsum powder, pyrophyllite powder, livistona chinensis leaf fibers, volcanic ash Portland cement, maleic anhydride grafted polypropylene, ZK-9 rubber powder, a dispersant FT-78, a compound coupling agent, a compound foaming agent, and a compound water repellent. The fireproof door core board is significantly improved in mechanical strength, fireproof and waterproof effect,heat resistant and anti-freeze performance, and oil resistance, is better in overall performance and applicability, and is guaranteed in service life better.

Owner:HEFEI YIZHI DOORS & WINDOWS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com