Nanometer-reflection thermal insulation coating and preparation method thereof

A technology of reflective heat-insulating paint and heat-insulating paint, applied in reflective/signal paints, coatings, etc., can solve the problems of difficult characterization of reflective and heat-insulating properties, large filler particles, fine cracks, etc., and achieve excellent reflective heat-radiation performance, The effect of low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

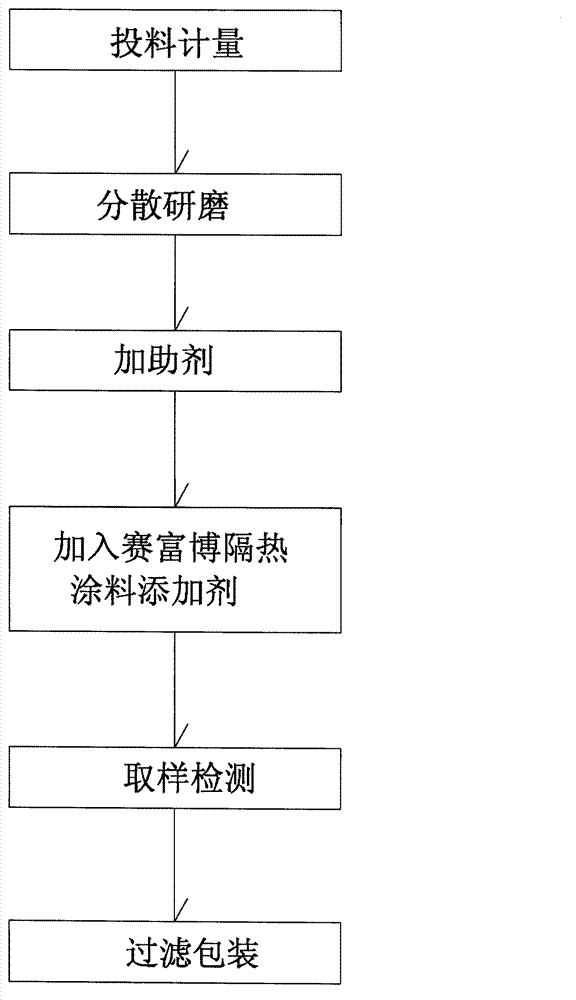

Image

Examples

Embodiment Construction

[0031] The present invention is a nano-reflective heat-insulating coating, which is mixed with the following materials in mass percentage:

[0032] SAFEBO thermal insulation coating additive: 15-25%; wherein, the SAFEBO thermal insulation coating additive contains nano-scale hollow coating ceramic microspheres, nano-scale titanium dioxide and water-based silicone emulsion, with a pH value of 7.1 and a density of 0.55g / cm3, the content (mass ratio) of hollow microspheres is 25%, the size of nanoscale glass microspheres is an average of 2 microns, and the VOC content is less than 4g / L;

[0033] Pure acrylic emulsion: 30-60%;

[0034] Water: 5-15%;

[0035] Filler: 3-8%; wherein, the filler is specifically calcium carbonate;

[0036] Thickener: 1.20%; wherein, the thickener is Rohm and Haas thickener;

[0037] Wetting agent: 1.03%; wherein, the wetting agent is sodium hexametaphosphate;

[0038] Defoamer: 0.84%; wherein, the defoamer is Nopco defoamer;

[0039] Dispersant: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com