Waterborne seam beautifying agent and preparation method thereof

A kind of beautifying agent and water-based technology, which is applied in the field of water-based beautifying agent and its preparation, can solve problems such as difficulty in taking into account adhesion, durability and environmental performance, lack of water erasable function, unfavorable cleaning treatment, etc., to achieve Good anti-sag property, good constructability, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

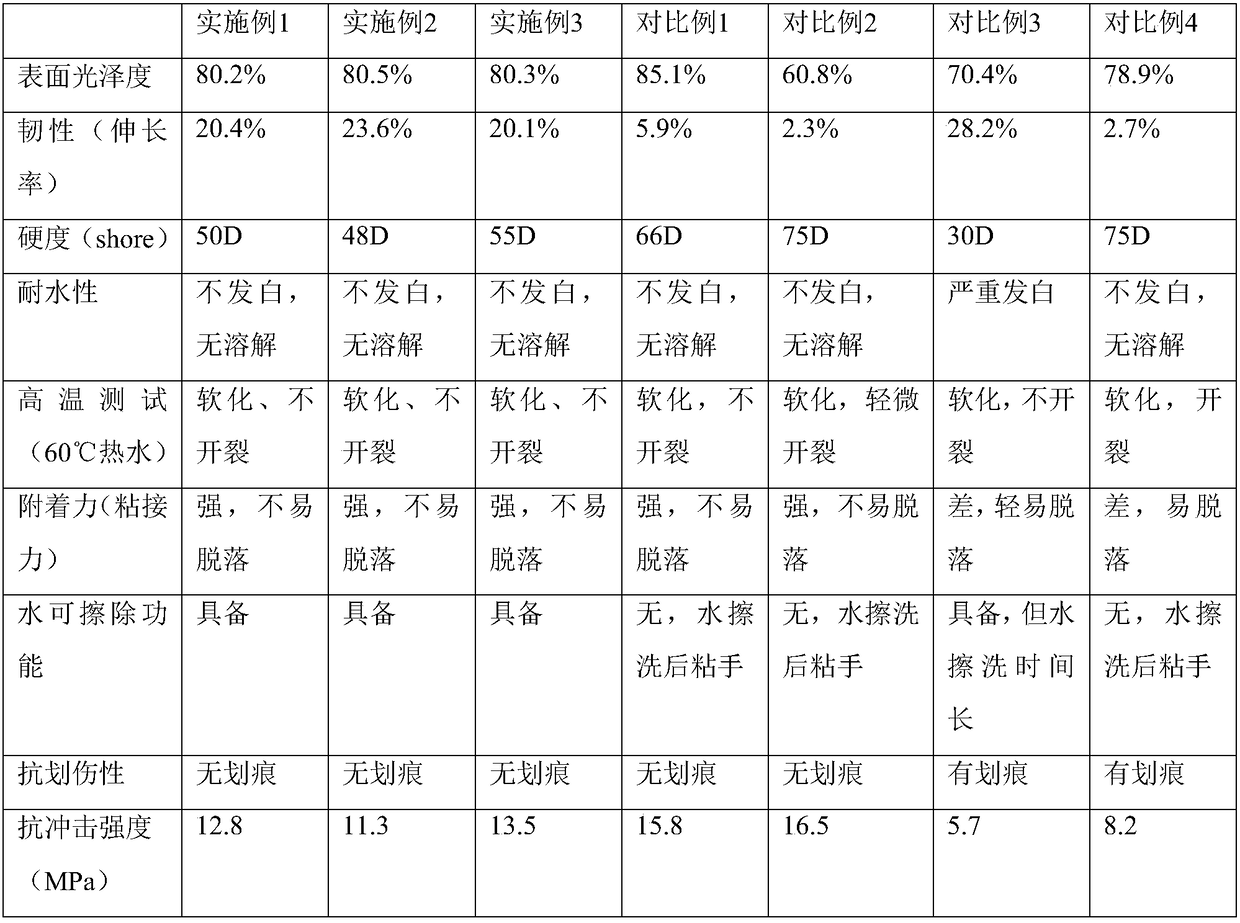

Examples

Embodiment 1

[0026] Example 1 Water-based beauty joint agent

[0027] The water-based beautifying agent is composed of component A and component B in a mass ratio of 1:1; the component A includes the following raw materials in parts by mass: 90 parts of bisphenol A epoxy resin, polyether monoamine 10 parts, 5 parts of hydrophilic fumed silica; the B component includes the following preparation raw materials in parts by mass: 40 parts of isophorone diamine, 22 parts of bisphenol A epoxy resin, 25 parts of benzyl alcohol , 8 parts of emulsifier, 5 parts of hydrophilic fumed silica.

[0028] The polyether monoamine is M-2070; the molecular formula of the emulsifier is C 19 h 38 o 2 , whose structure is

[0029] The preparation method of water-based beautifying agent comprises the steps:

[0030]1) Preparation of component A: Weigh bisphenol A epoxy resin and put it into the first reaction container, raise the temperature to 125°C, add polyether monoamine dropwise at a stirring speed of...

Embodiment 2

[0033] Example 2 Water-based beauty joint agent

[0034] The water-based beautifying agent is composed of component A and component B in a mass ratio of 1:1; the component A includes the following raw materials in parts by mass: 85 parts of bisphenol A epoxy resin, polyether monoamine 15 parts, 4 parts of hydrophilic fumed silica; the B component includes the following preparation raw materials in parts by mass: 42 parts of isophorone diamine, 20 parts of bisphenol A epoxy resin, 23 parts of benzyl alcohol , 10 parts of emulsifier, 5 parts of hydrophilic fumed silica.

[0035] The polyether monoamine is M-2070; the molecular formula of the emulsifier is C 19 h 38 o 2 , whose structure is

[0036] The preparation method of water-based beautifying agent comprises the steps:

[0037] 1) Preparation of component A: Weigh bisphenol A epoxy resin and put it into the first reaction container, raise the temperature to 125°C, add polyether monoamine dropwise at a stirring speed ...

Embodiment 3

[0040] Example 3 Water-based beauty joint agent

[0041] The water-based beautifying agent is composed of component A and component B in a mass ratio of 1:1; the component A includes the following raw materials in parts by mass: 80 parts of bisphenol A epoxy resin, polyether monoamine 20 parts, 4 parts of hydrophilic fumed silica; the B component includes the following preparation raw materials in parts by mass: 45 parts of isophorone diamine, 20 parts of bisphenol A epoxy resin, 20 parts of benzyl alcohol , 9 parts of emulsifier, 6 parts of hydrophilic fumed silica.

[0042] The polyether monoamine is M-2070; the molecular formula of the emulsifier is C 19 h 38 o 2 , whose structure is

[0043] The preparation method of water-based beautifying agent comprises the steps:

[0044] 1) Preparation of component A: Weigh bisphenol A epoxy resin and put it into the first reaction container, raise the temperature to 125°C, add polyether monoamine dropwise at a stirring speed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com