Preparation method of phosphogypsum fireproof door core board

A fire-resistant door core board and phosphogypsum technology, which is applied in ceramic products, applications, household appliances, etc., can solve the problems of insufficient fire resistance and application limitations, and achieve the effects of high fire resistance, wide source of raw materials, and strong water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment relates to a phosphogypsum fireproof door core board and its preparation method. The fireproof door core board is composed of the following raw materials in parts by weight:

[0051] 42 parts of niobium yttrium tailings powder;

[0052] 16 parts of phosphogypsum powder;

[0053] 20 parts of pyrophyllite powder;

[0054] 6 parts palm leaf fiber;

[0055] 11 parts of pozzolan Portland cement;

[0056] 2 parts of maleic anhydride grafted polypropylene;

[0057] 3 parts of ZK-9 rubber powder;

[0058] Parts of dispersant FT-781:

[0059] 2 parts of compound coupling agent;

[0060] 3 parts of compound foaming agent;

[0061] Composite water repellent 1.5 parts.

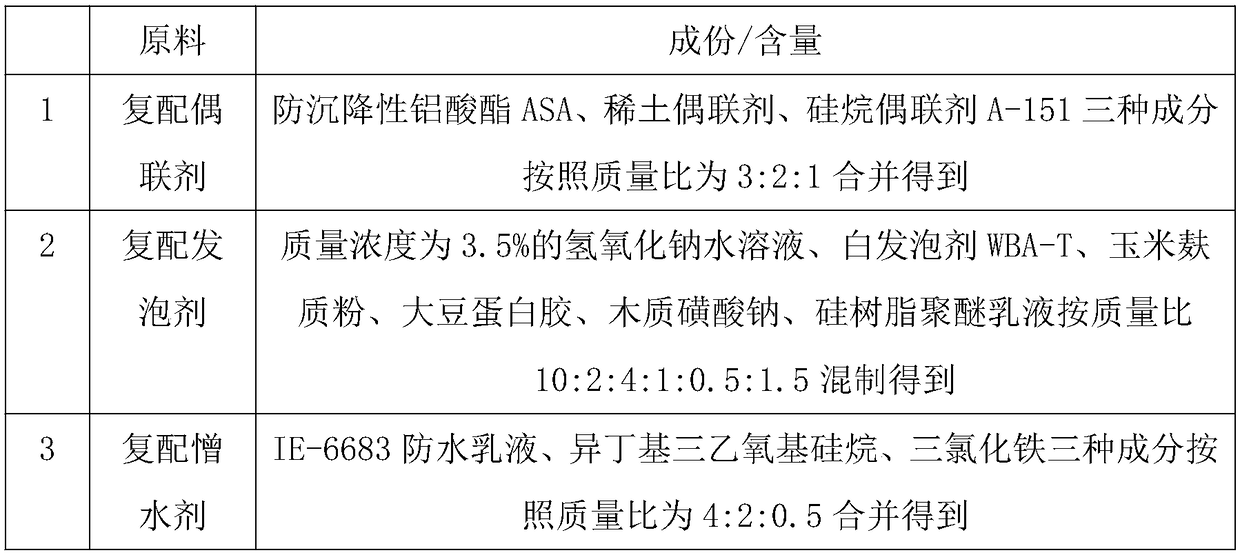

[0062] The selection and preparation of the compound coupling agent, compound foaming agent and compound hydrophobic agent in this embodiment are shown in Table 1 below:

[0063] Table 1

[0064]

[0065] The preparation method of the above-mentioned compound foaming agent is as follows...

Embodiment 2

[0071] This embodiment relates to a phosphogypsum fireproof door core board and its preparation method. The fireproof door core board is composed of the following raw materials in parts by weight:

[0072] 46 parts of niobium yttrium tailings powder;

[0073] Phosphogypsum powder 19 parts;

[0074] 22 parts of pyrophyllite powder;

[0075] 6.5 parts of palm leaf fiber;

[0076] 12 parts of pozzolan Portland cement;

[0077] 2.5 parts of maleic anhydride grafted polypropylene;

[0078] 3.5 parts of ZK-9 rubber powder;

[0079] Dispersant FT-781.3 parts:

[0080] 2.4 parts of compound coupling agent;

[0081] 3.5 parts of compound blowing agent;

[0082] Compound water repellent 1.7 parts.

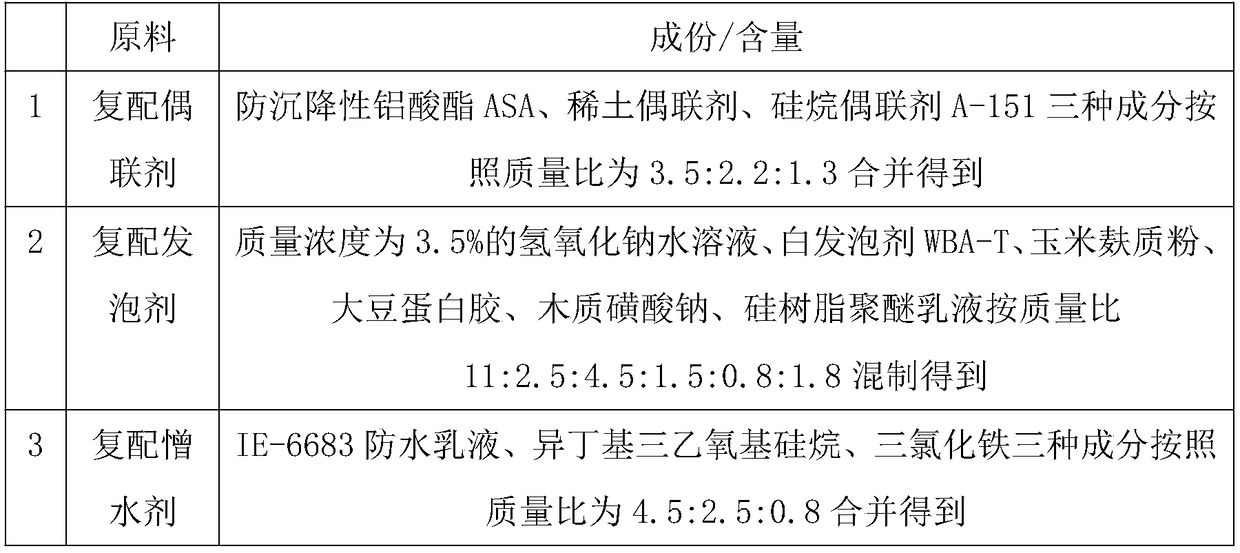

[0083] The selection and preparation of the compound coupling agent, compound blowing agent and compound hydrophobic agent in this embodiment are shown in Table 2 below:

[0084] Table 2

[0085]

[0086] The preparation method of the above-mentioned compound foaming agent is as...

Embodiment 3

[0092] This embodiment relates to a phosphogypsum fireproof door core board and its preparation method. The fireproof door core board is composed of the following raw materials in parts by weight:

[0093] 48 parts of niobium yttrium tailings powder;

[0094] Phosphogypsum powder 20 parts;

[0095] 25 parts of pyrophyllite powder;

[0096] 7 parts palm leaf fiber;

[0097] 13 parts of pozzolan Portland cement;

[0098] 2.8 parts of maleic anhydride grafted polypropylene;

[0099] 4 parts of ZK-9 rubber powder;

[0100] Dispersant FT-781.5 parts:

[0101] 2.5 parts of compound coupling agent;

[0102] 4 parts of compound foaming agent;

[0103] Compound water repellent 2 parts.

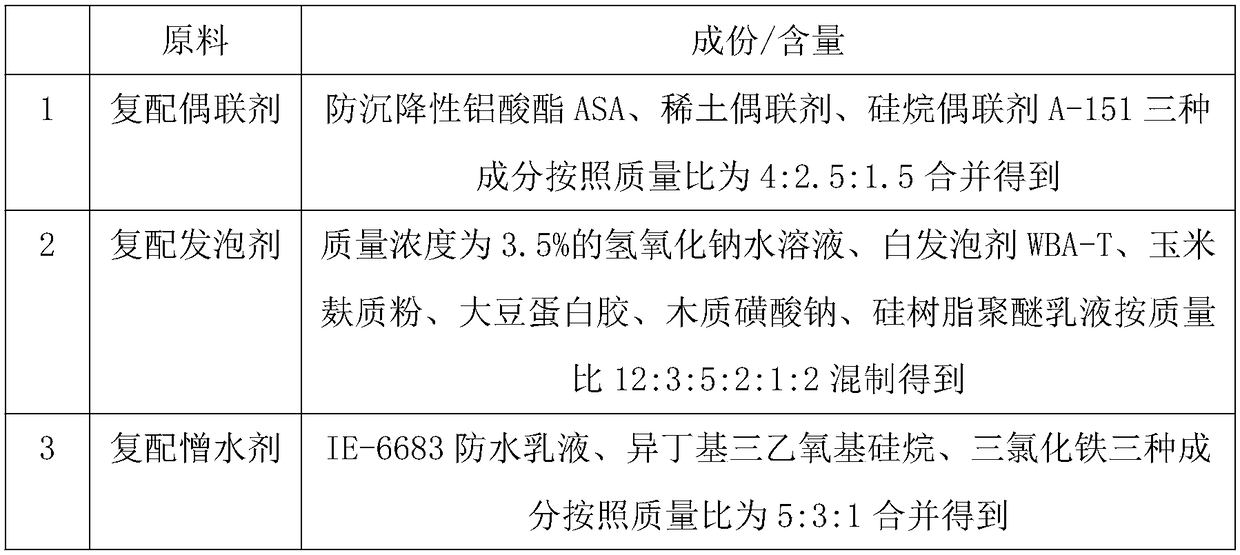

[0104] The selection and preparation of the compound coupling agent, compound foaming agent and compound hydrophobic agent in this embodiment are shown in Table 3 below:

[0105] table 3

[0106]

[0107] The preparation method of the above-mentioned compound foaming agent is as follows: t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com