Palygorskite powder-added wood-plastic door and window material and preparation method thereof

A palygorskite powder and wood-plastic technology, which is applied in the field of door and window materials, can solve the problems of insufficient functionality and achieve the effects of low density, energy saving, good heat insulation and sound insulation performance, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

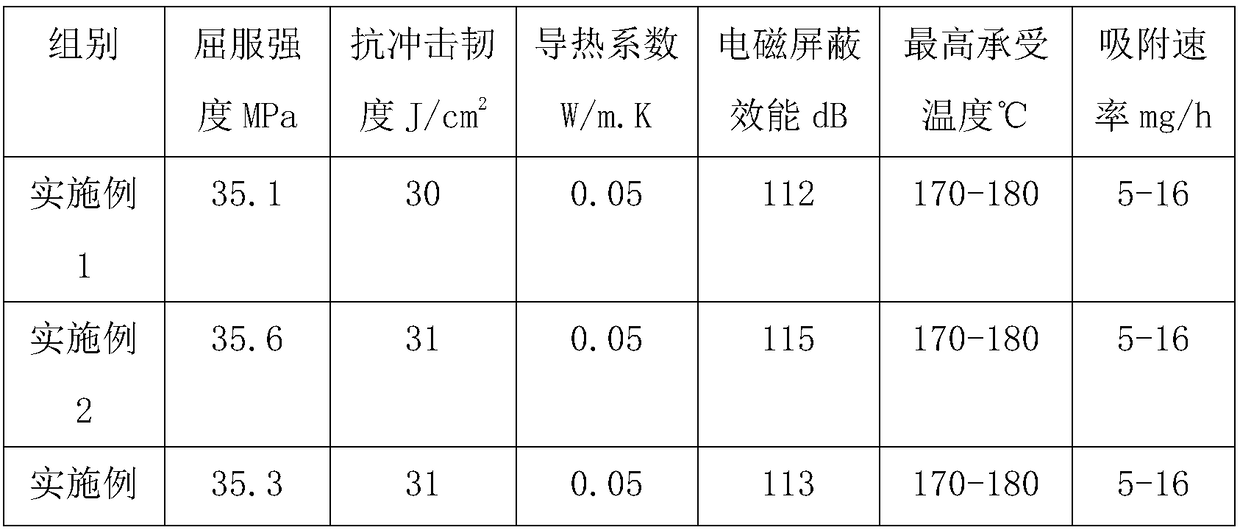

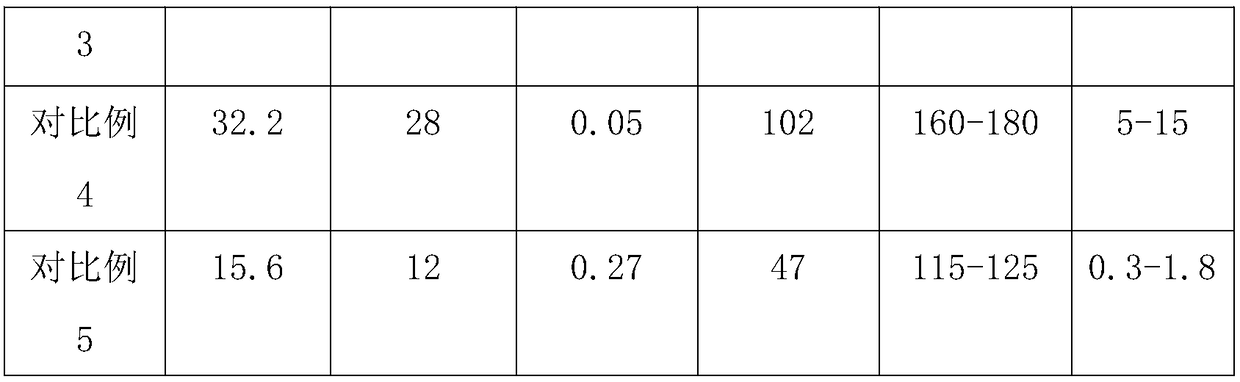

Examples

Embodiment 1

[0028] A wood-plastic door and window material added with palygorskite powder, the following raw materials are weighed: 30kg of waste PVC material, 15kg of waste PE material, 20kg of wood chip powder, 4kg of fly ash, 3kg of palygorskite powder, 2kg of chabazite powder, diatom Soil 3kg, porous SiO 2 1kg, coconut charcoal fiber 1kg, borax 3kg, calcium lignosulfonate 0.8kg, low molecular weight polyethylene wax 1kg, sucrose fatty acid ester 1kg, curing agent 2kg, foaming agent 3kg, foam stabilizer 1kg and coupling agent 2g;

[0029] The preparation and selection of present embodiment raw material are as follows:

[0030] (1) Structural sawdust powder: Take 23kg of tree structural sawdust and grind it to 100 mesh to obtain sawdust powder. Soak the sawdust powder in hot water at a temperature of 70°C for 6 hours, take it out and dry it with a mass concentration of 10%. Soak in hydrogen peroxide for 2.5 hours, filter, wash with deionized water, and then dry; then soak in 10% sodium...

Embodiment 2

[0043] A wood-plastic door and window material added with palygorskite powder, the following raw materials are weighed: 35kg of waste PVC material, 20kg of waste PE material, 25kg of wood chip powder, 5kg of fly ash, 4kg of palygorskite powder, 2.5kg of chabazite powder, silicon Alite 4kg, Porous SiO 2 1.5kg, coconut charcoal fiber 1.5kg, borax 3.5kg, calcium lignosulfonate 1kg, low molecular weight polyethylene wax 1.25kg, sucrose fatty acid ester 1.5kg, curing agent 2.5kg, foaming agent 4kg, foam stabilizer 1.5kg And coupling agent 2.5kg;

[0044] The preparation and selection of present embodiment raw material are as follows:

[0045](1) Structural sawdust powder: Take 28 kg of tree structural sawdust and grind it to 110 mesh to obtain sawdust powder. Soak the sawdust powder in hot water with a temperature of 80°C for 5.5 hours, take it out and dry it with a mass concentration of 11 Soak in % hydrogen peroxide for 2.2 hours, filter, wash with deionized water, and then dry...

Embodiment 3

[0058] A wood-plastic door and window material added with palygorskite powder, the following raw materials are weighed: 40kg of waste PVC material, 25kg of waste PE material, 0kg of wood chip powder, 6kg of fly ash, 5kg of palygorskite powder, 3kg of chabazite powder, diatom Soil 5kg, porous SiO 2 2kg, coconut charcoal fiber 2kg, borax 4kg, calcium lignosulfonate 1.2kg, low molecular weight polyethylene wax 1.5kg, sucrose fatty acid ester 2kg, curing agent 3kg, foaming agent 5kg, foam stabilizer 2kg and coupling agent 3kg ;

[0059] The preparation and selection of present embodiment raw material are as follows:

[0060] (1) Structural sawdust powder: Take 33kg of tree structural sawdust and grind it to 120 mesh to obtain sawdust powder. Soak the sawdust powder in hot water at a temperature of 90°C for 5 hours, take it out and dry it with a mass concentration of 12%. Soak in hydrogen peroxide for 2 hours, filter, wash with deionized water, and then dry; then soak in 12% sodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com