Sewing machines for threading and string drawing on waist of garment

A sewing machine and waist piercing technology, which is applied in the direction of sewing machine components, sewing equipment, cloth feeding mechanism, etc., can solve the problems of increasing labor intensity of workers, increasing processing time, poor appearance of fabric stitches, etc., and meets the requirements of guaranteed technical standards, The processing process is simple and the stitches are regular

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be discussed in detail below in conjunction with embodiment:

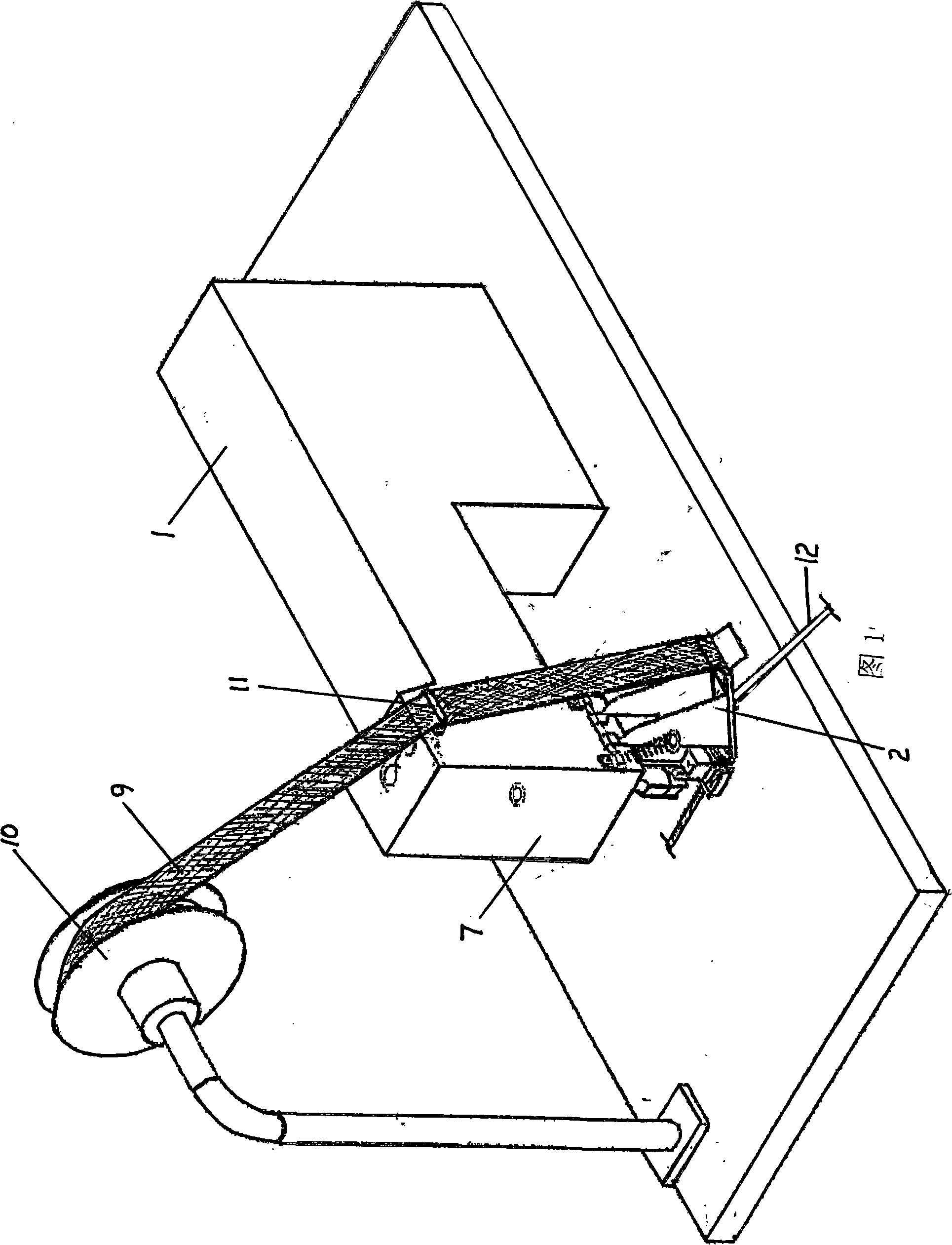

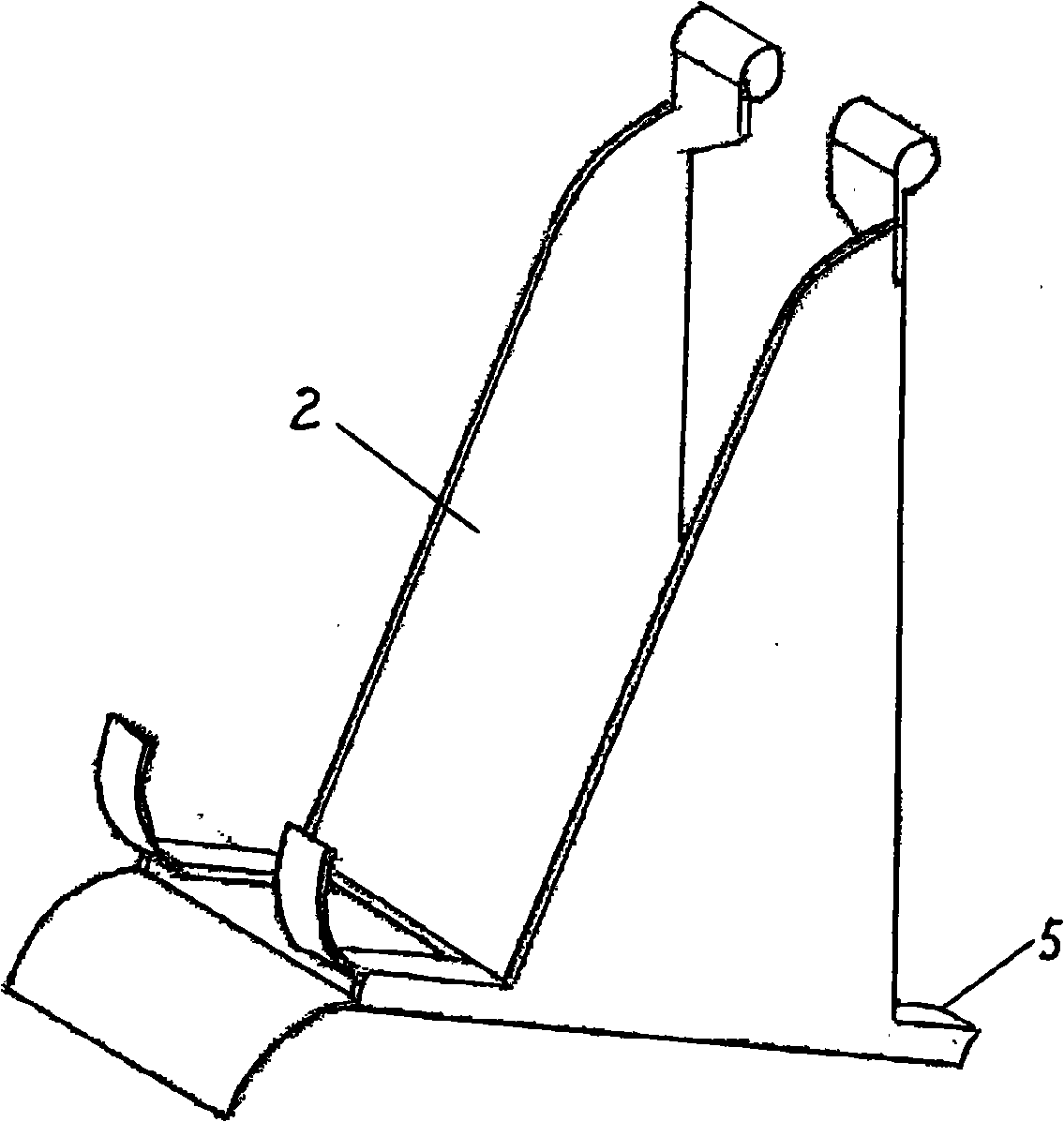

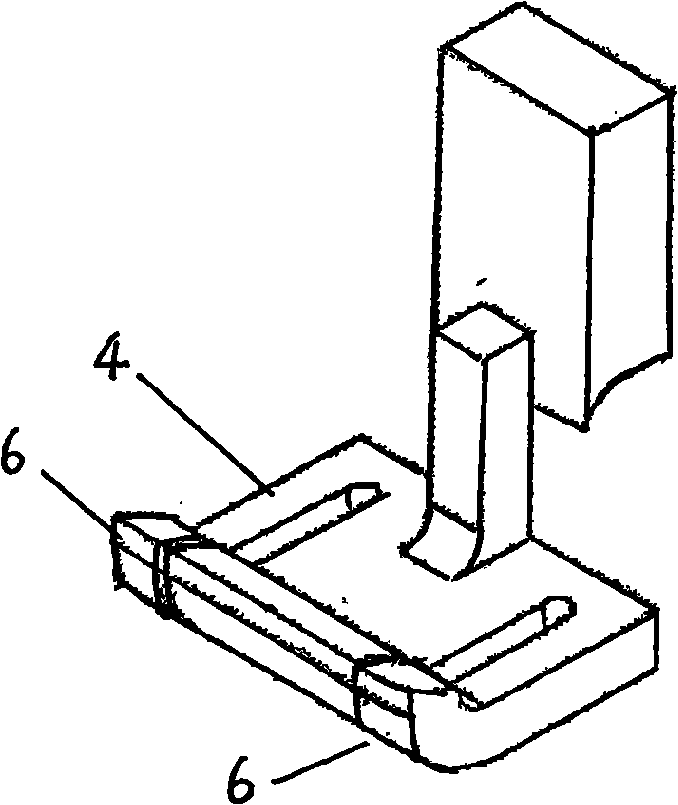

[0016] As shown in accompanying drawing 1,5,6, the present invention comprises double-needle lockstitch machine 1, the threading belt conveyor frame 2 that is connected with the nose 7 of double-needle lockstitch machine 1 and is arranged on threading belt conveyor frame 2 The threading rope 12 at the bottom uses the threading hole 3, and the threading belt conveyor frame 2 and the machine head 7 hinges are provided with a threading tape mouthpiece 5 corresponding to the presser foot 4 of the double-needle lockstitch sewing machine 1 at the threading tape conveyor frame 2 lower end. Even, a spring 8 is arranged between the threading tape conveyor frame 2 and the head 7, and a tape rack 10 winding the tape 9 is provided on the double-needle lockstitch sewing machine 1 .

[0017] As shown in accompanying drawing 1, the present invention adopts double-needle lockstitch sewing machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com