Synchronous feeding structure of lower traction wheel

A tugboat and coaxial technology, which is applied in the field of sewing machines, can solve problems affecting product quality, sewing material movement, sewing material misalignment, etc., and achieve the effect of compact structure, convenient connection and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

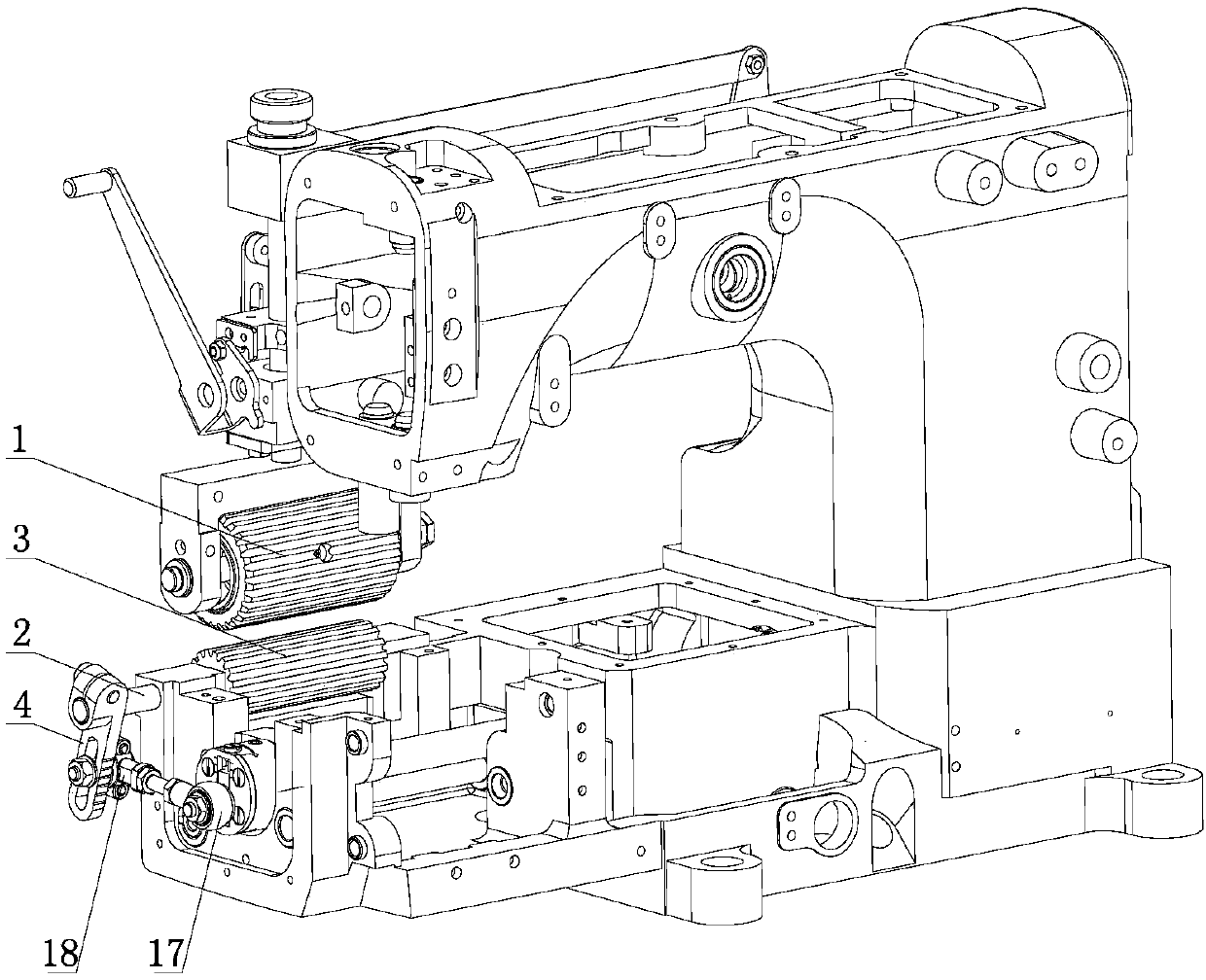

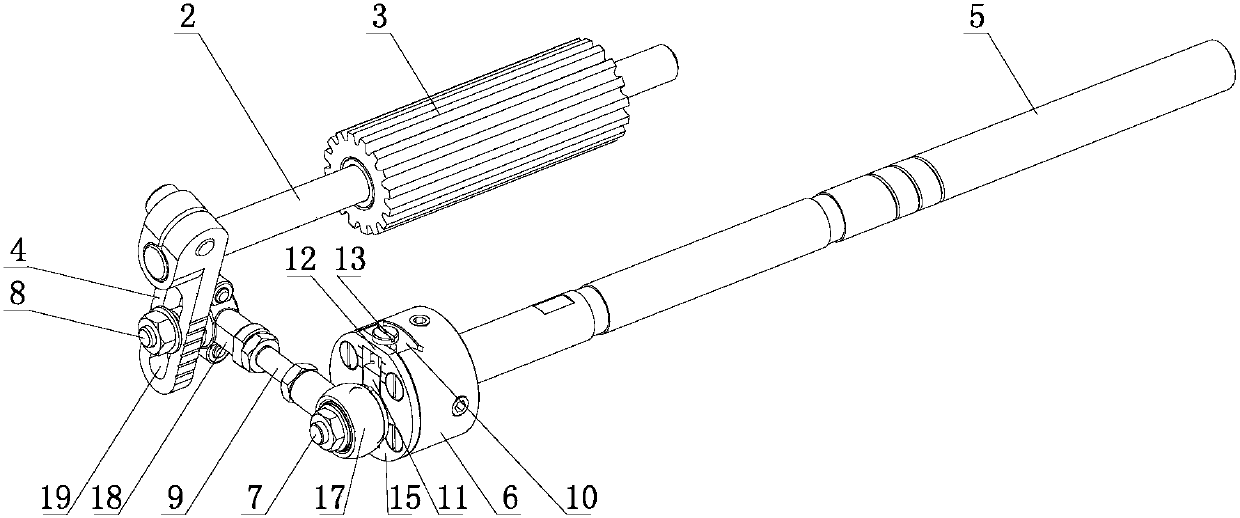

Embodiment 1

[0029] like figure 1 and figure 2 The synchronous feeding structure of the lower tugboat shown includes a rotating shaft 2 parallel to the upper tugboat 1 and a lower tugboat 3 coaxially sleeved on the rotating shaft 2. The lower tugboat 3 is located directly below the upper tugboat 1. and set opposite to the upper tugboat 1, such as figure 1 As shown, the lower tug wheel 3 is placed horizontally, and its highest point is not lower than the upper surface of the workbench. When feeding is required, the lower tug wheel 3 rotates in one direction under the action of the transmission assembly. like figure 1 and figure 2 As shown, a swing rod 4 is fixed on the rotating shaft 2, and a transmission assembly for driving the swing rod 4 to swing when the spindle 5 rotates is provided between the swing rod 4 and the main shaft 5 of the sewing machine. The one-way assembly used to limit the lower tugboat 3 to rotate in one direction all the time when the fork 4 swings.

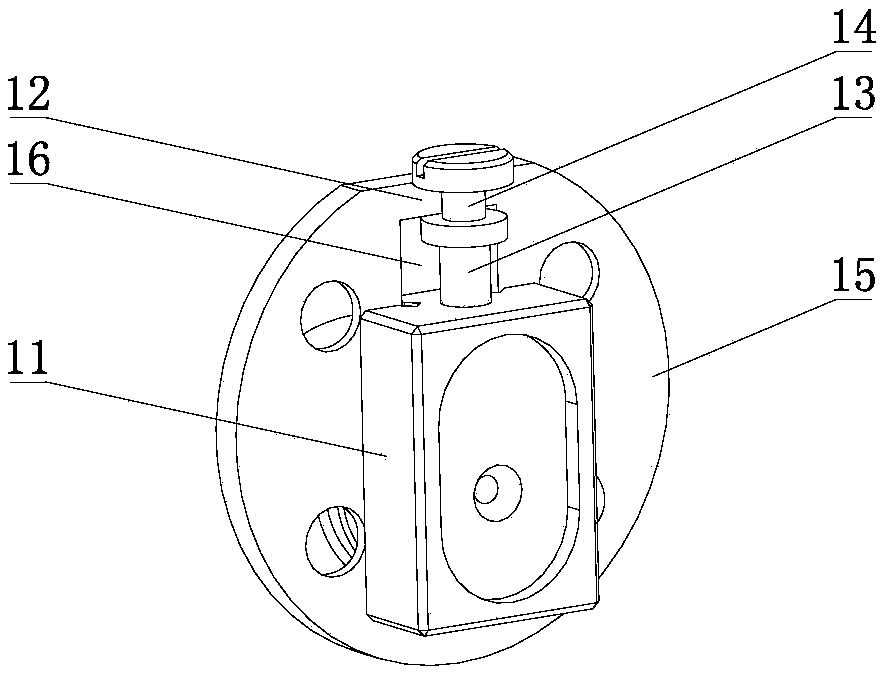

[0030] li...

Embodiment 2

[0040] The structural principle of this embodiment is basically the same as that of Embodiment 1, the difference is that the adjustment limit unit includes a threaded hole arranged in the connecting sleeve 6 and a bolt threaded in the threaded hole, and the threaded hole and the slide The sides of the slot 10 are vertical and the inner end of the threaded hole communicates with the sliding slot 10 , and the inner end of the bolt abuts against the sliding block 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com