A road milling machine

A milling machine and milling technology, which is applied in the field of road milling machines, can solve the problems of inability to adjust and the limited variation range of the milling drum speed, and achieve the effect of improving milling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

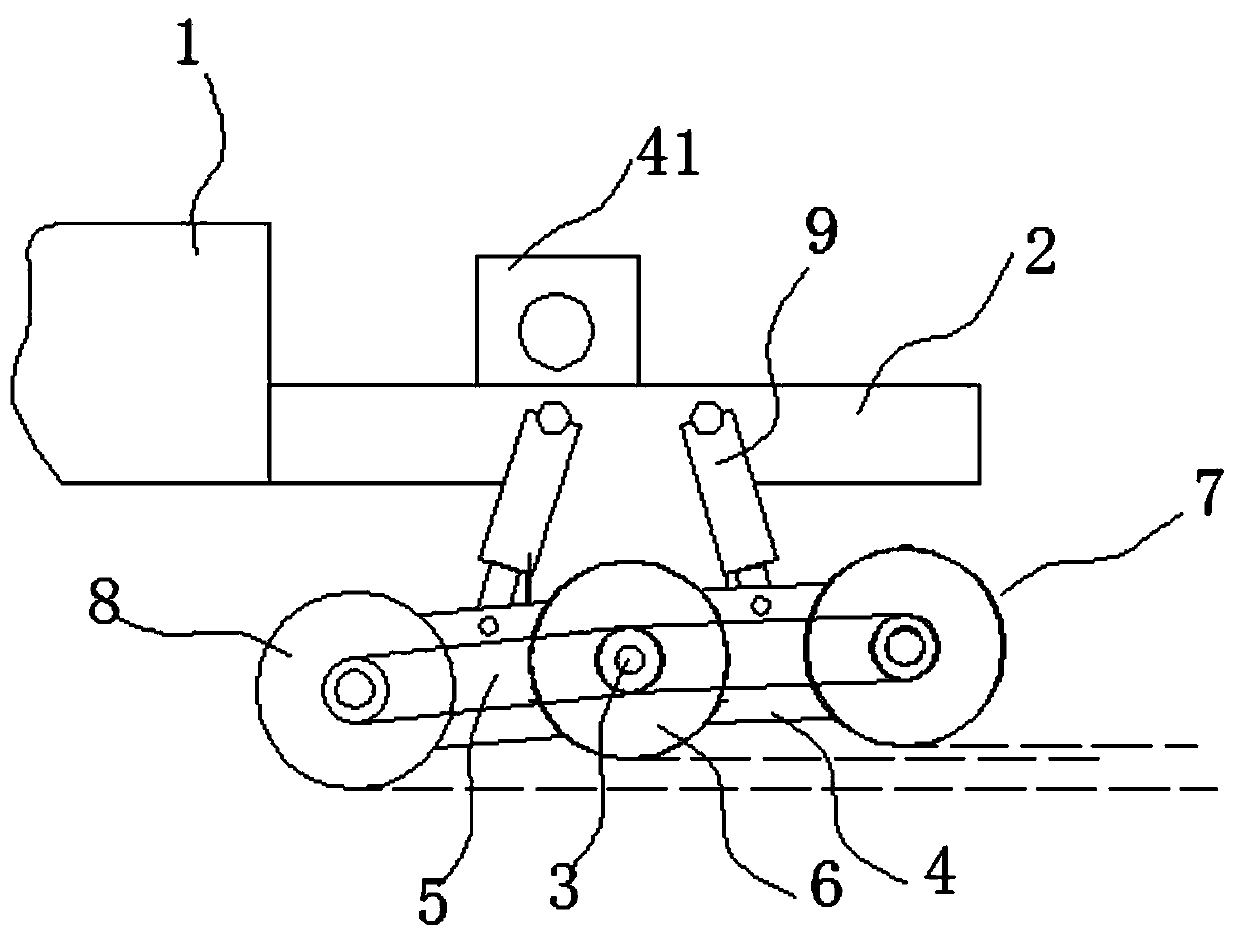

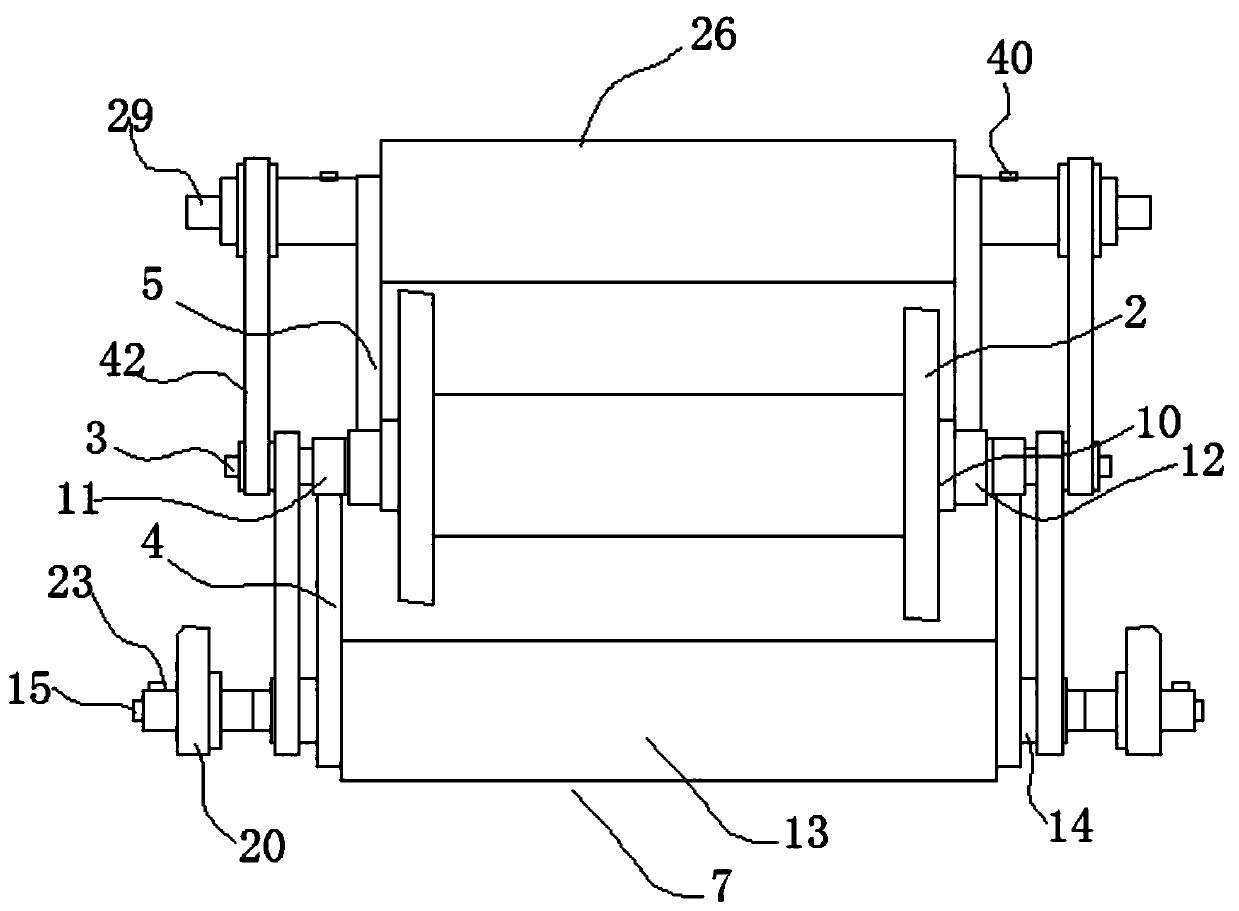

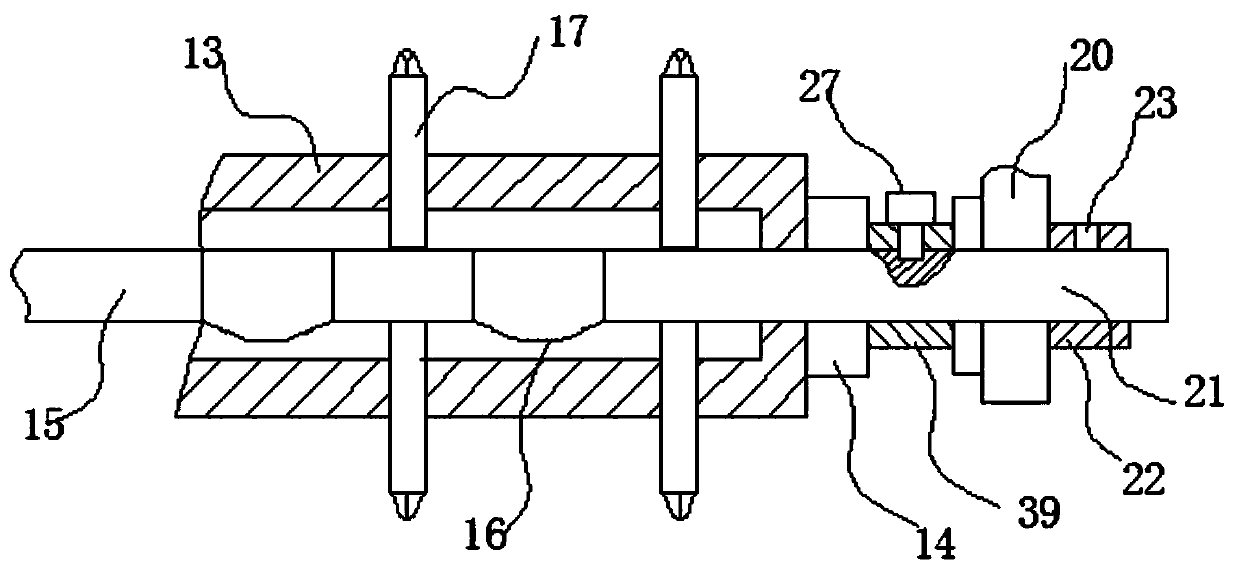

[0028] Such as figure 1 , figure 2 As shown, a road milling machine includes a frame 1 and a lifting seat 2, and a lifting drive mechanism is arranged between the frame 1 and the lifting seat 2. The lifting drive mechanism can adopt a hydraulic lifting mechanism, and the hydraulic The cylinder is fixedly installed on the frame, the piston rod of the hydraulic cylinder is fixedly installed on the lifting seat, and a guide column can also be fixedly installed on the frame, and a guide sleeve cooperating with the guide column is installed on the lifting seat , the lifting base 2 is rotatably mounted with a rotating shaft 3, and the lifting base 2 is also coaxially rotatably mounted with a first swing housing 4 and a second swing housing 5, and the first swing housing 4 and the The rotation axes of the second swing housing 5 are coincident, the rotation axes of the first swing housing 4 and the second swing housing 5 are coincident with the axis of the rotation shaft, and the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com