Patents

Literature

35results about How to "Reduce white point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laminate and filter of display using the same laminate

InactiveCN1576886AImprove conductivityIncrease reflectionOptical filtersCoatingsVisibilityDisplay device

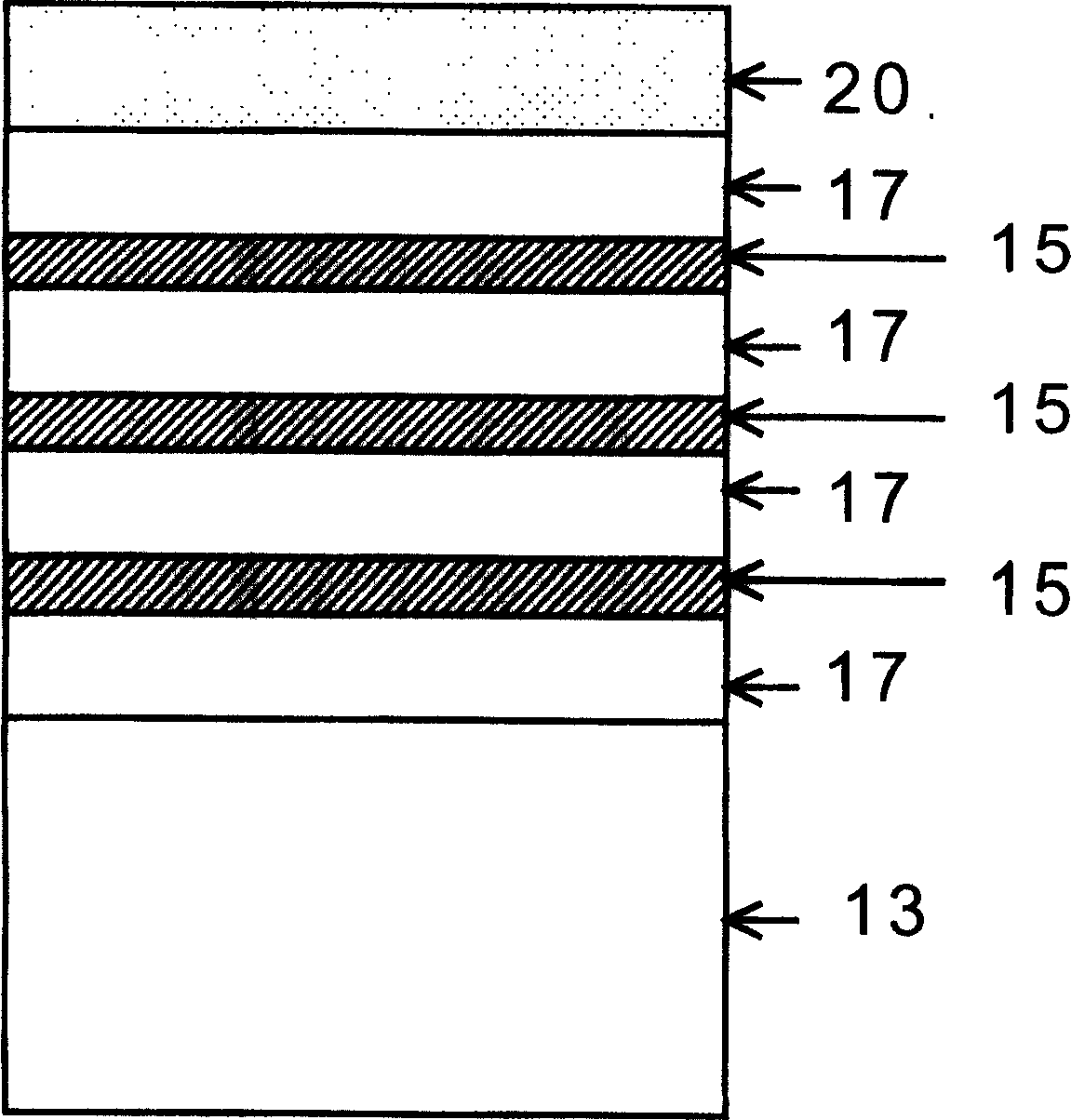

A transparent and conductive laminate that is substantially decreased in reactive defects, and a display filter, a heat-ray reflecting film and an electromagnetic wave-shielding film comprising the laminate are provided. The laminate includes a transparent substrate, a transparent conductive thin-film layer containing silver, and a protective layer containing a binder material and inorganic fine particles, wherein the transparent conductive thin-film layer is in contact with the protective layer. The generation of reflective defects can be outstandingly reduced. Therefore, a laminate superior in electromagnetic wave-shielding ability, heat-ray reflecting ability and visibility for a long period of time and products comprising the laminate can be obtained.

Owner:YAMAMOTO CHEM INC

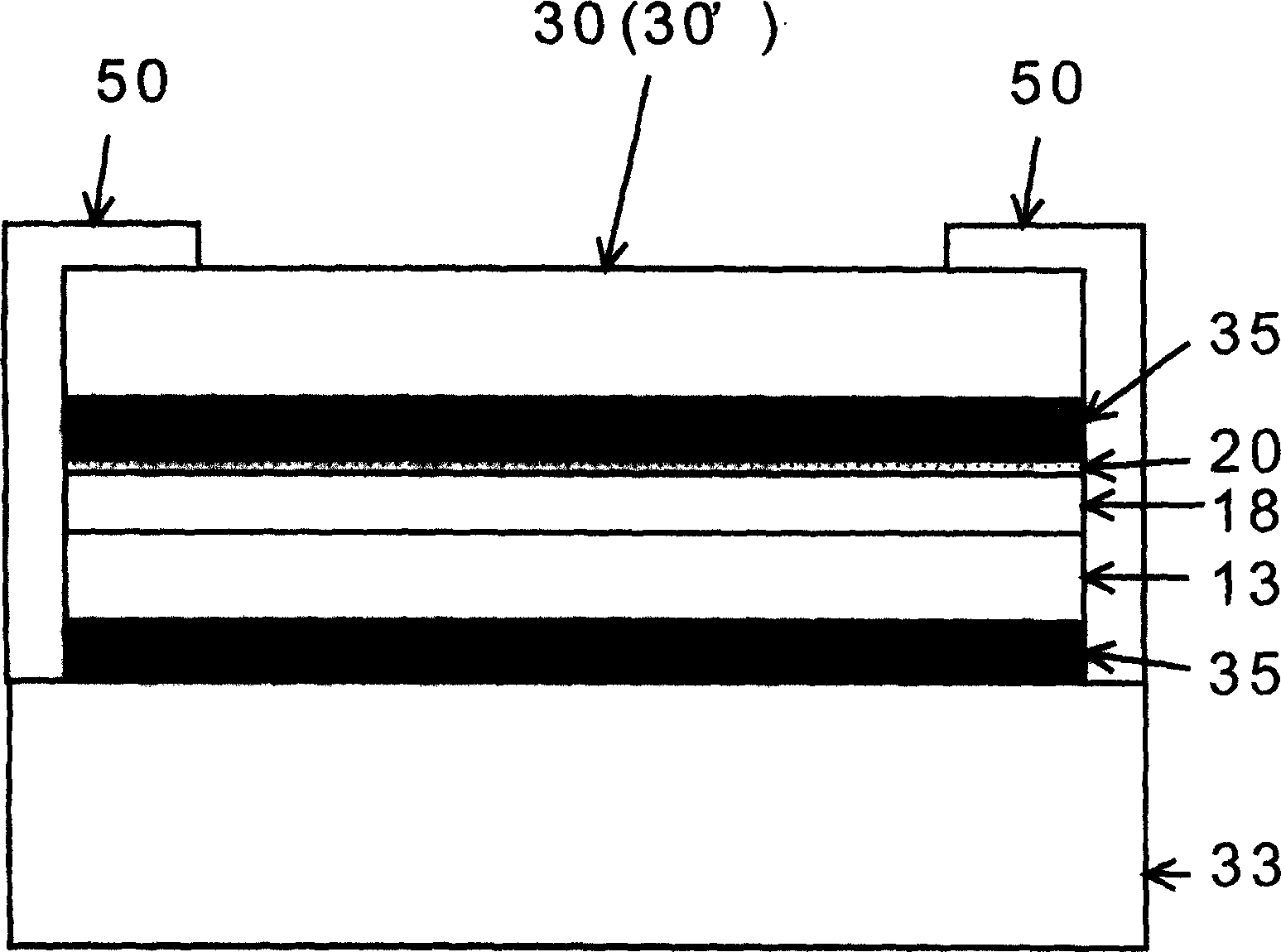

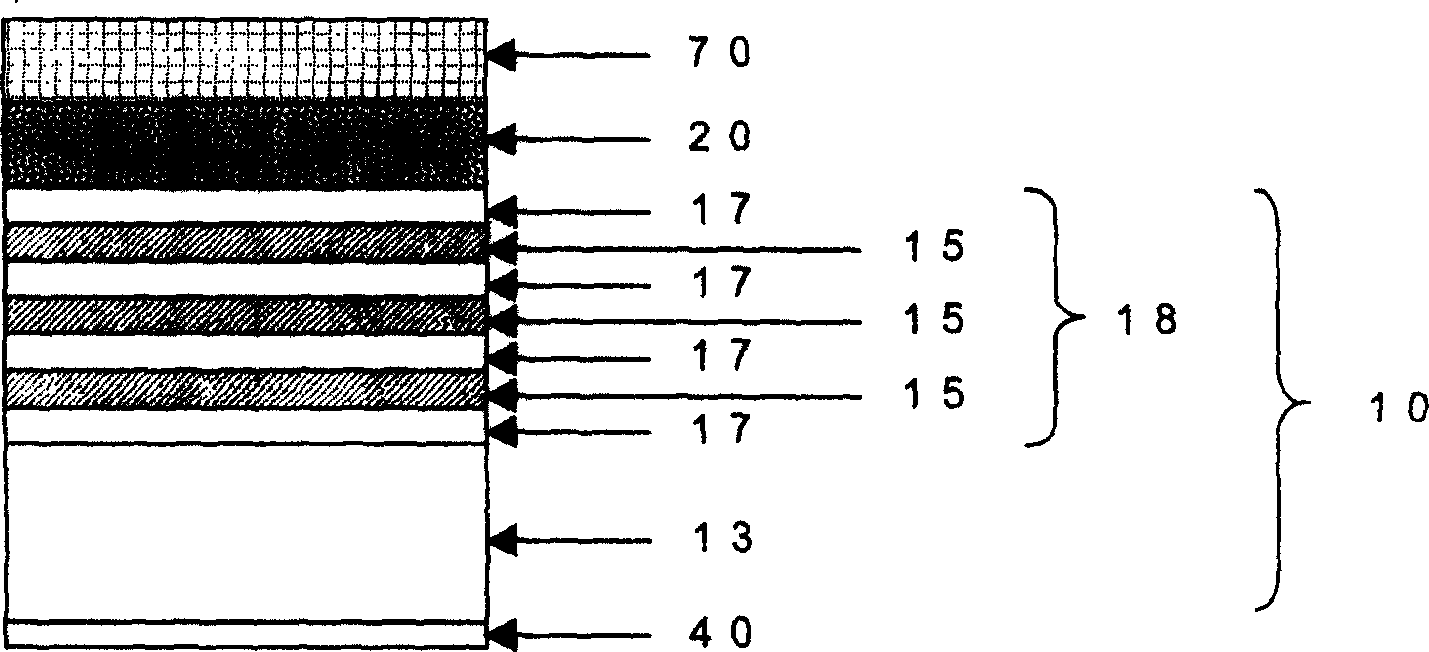

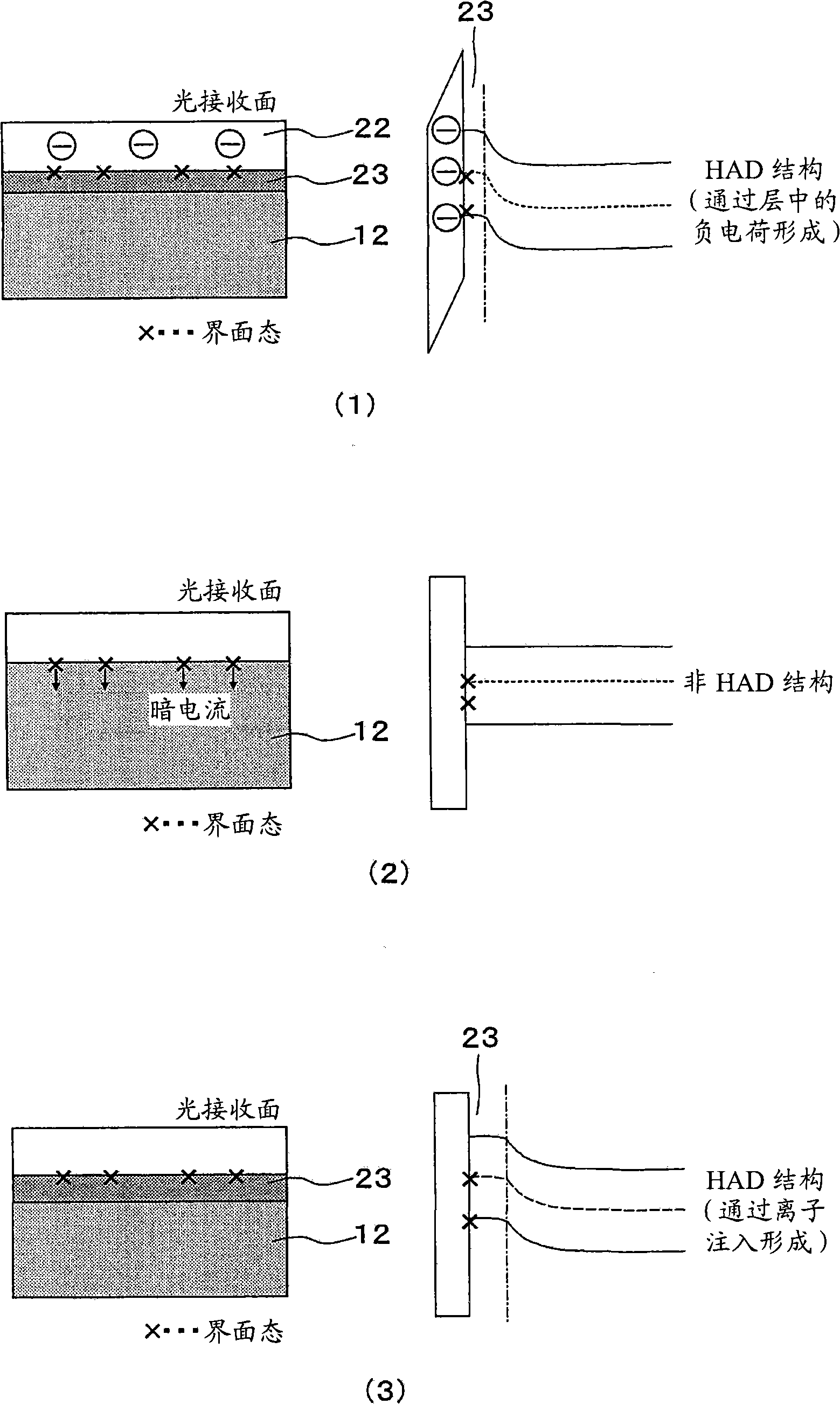

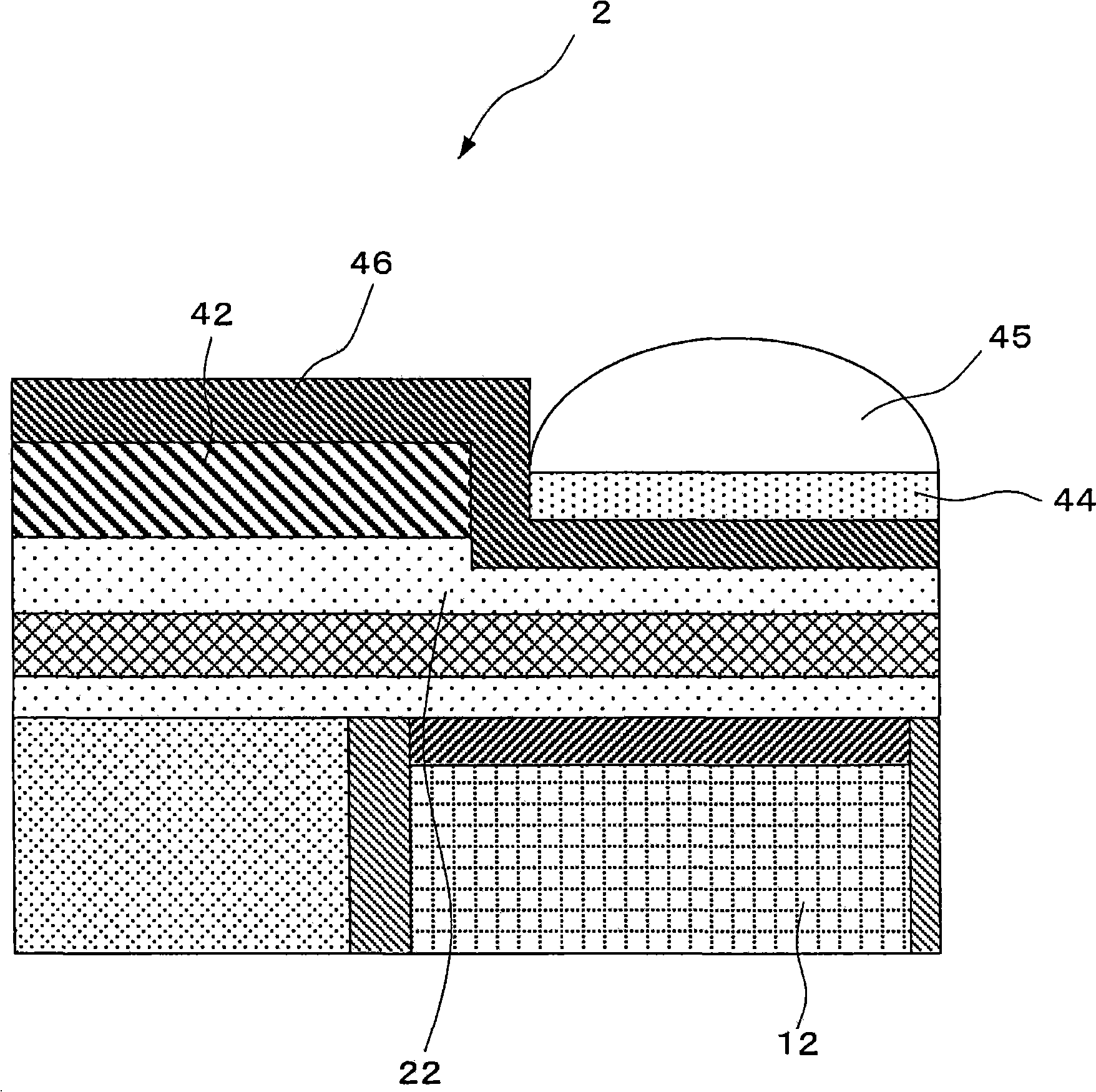

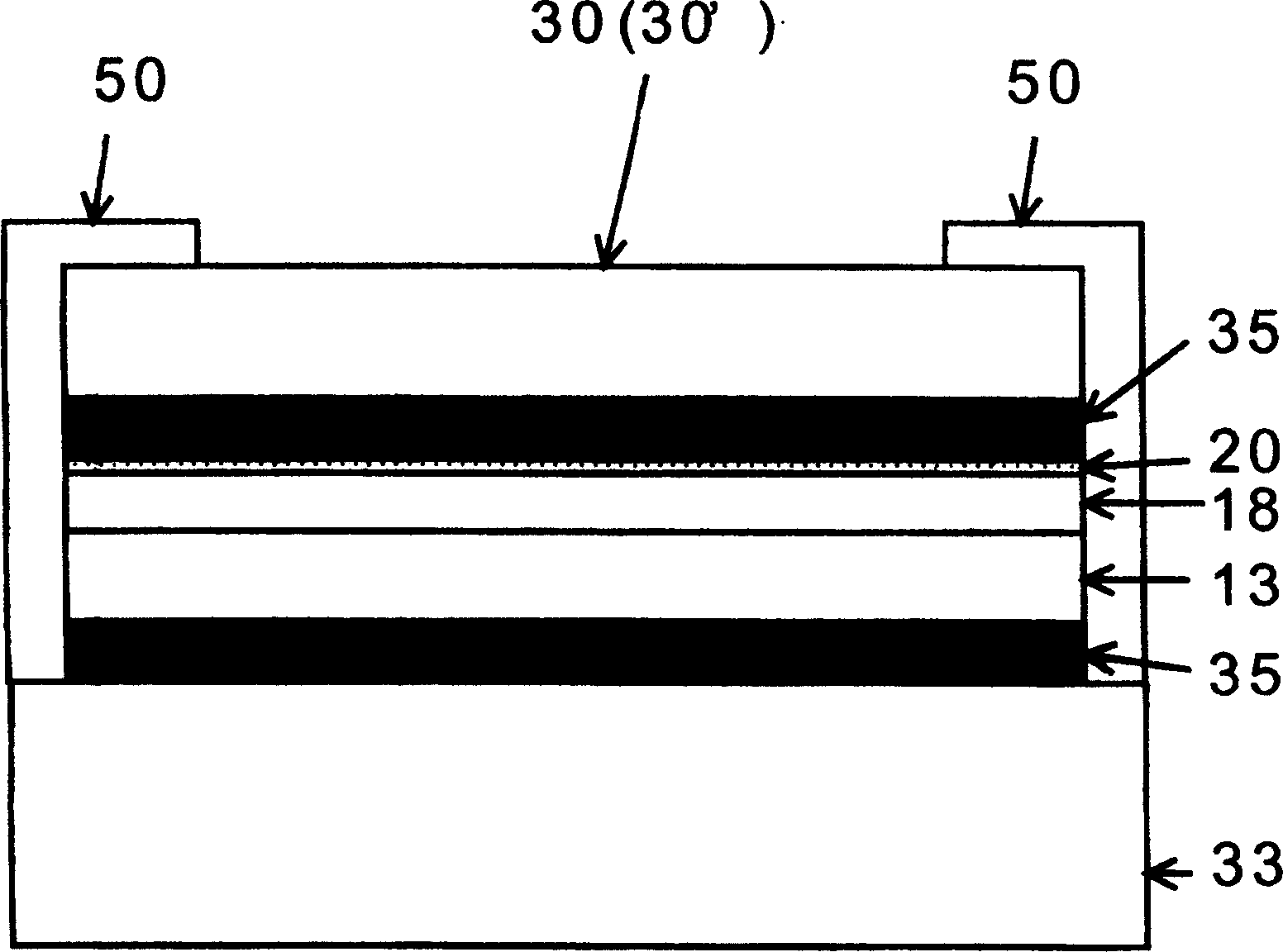

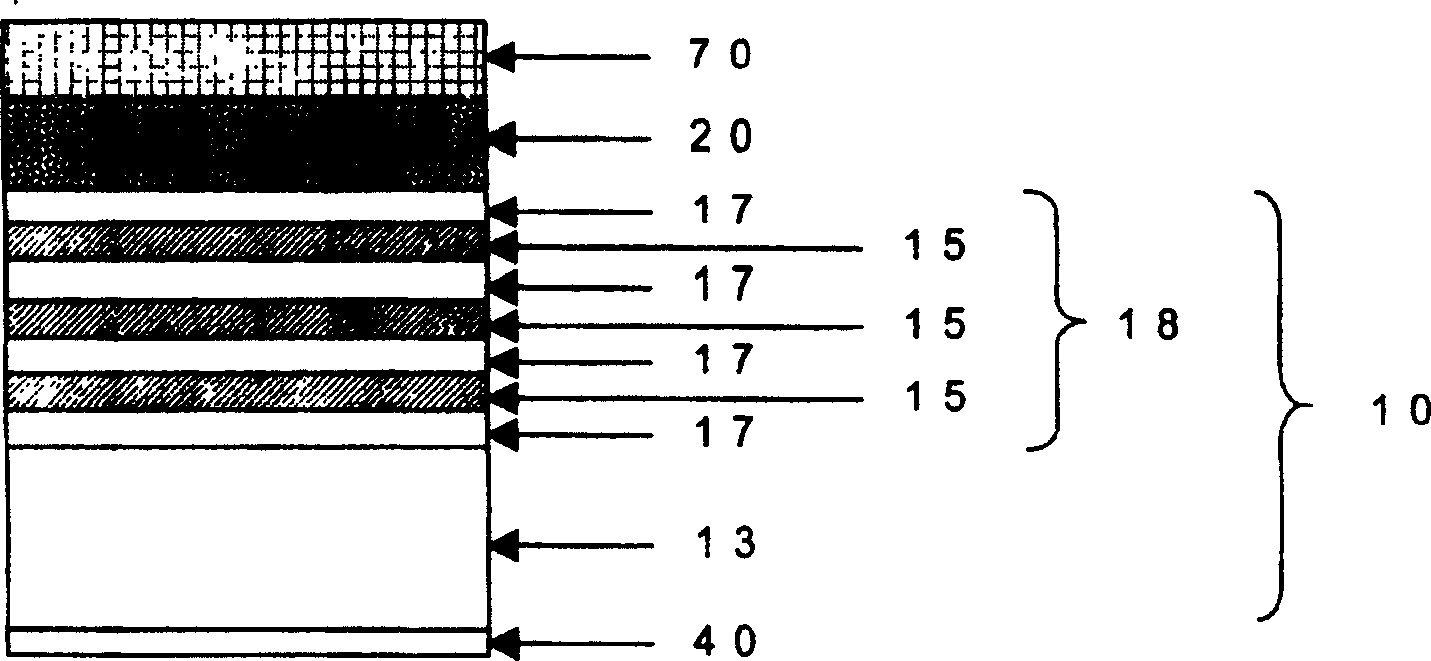

Solid state imaging device, its manufacturing method, and imaging device

ActiveCN101409301AReduce noiseReduce white pointTelevision system detailsSolid-state devicesSolid-stateNegative charge

The invention discloses a solid state imaging device having a light sensing section that performs photoelectric conversion of incident light and an imaging device, including: an insulating layer formed on a light receiving surface of the light sensing section; a layer having negative electric charges formed on the insulating layer; and a hole accumulation layer formed on the light receiving surface of the light sensing section. According to the solid image device of the invention, dark current is reduced, noises in the images are reduced, as a result, the invention has the advantages of high image.

Owner:SONY CORP

Polyamide resin composition

A polyamide resin composition comprising: a polyamide (X) having a diamine constituent unit which mainly comprises a metaxylylenediamine unit and a dicarboxylate constituent unit which mainly comprises an adipate constituent unit; and specific amounts of a phosphate-type antioxidant and alkaline component. The polyamide (X) is characterized by a specific terminal group concentration balance and a specific amino group reaction rate. By using the polyamide resin composition, both of the prevention of yellow discoloration and the reduction of gelatinization or fisheye formation can be achieved.

Owner:MITSUBISHI GAS CHEM CO INC

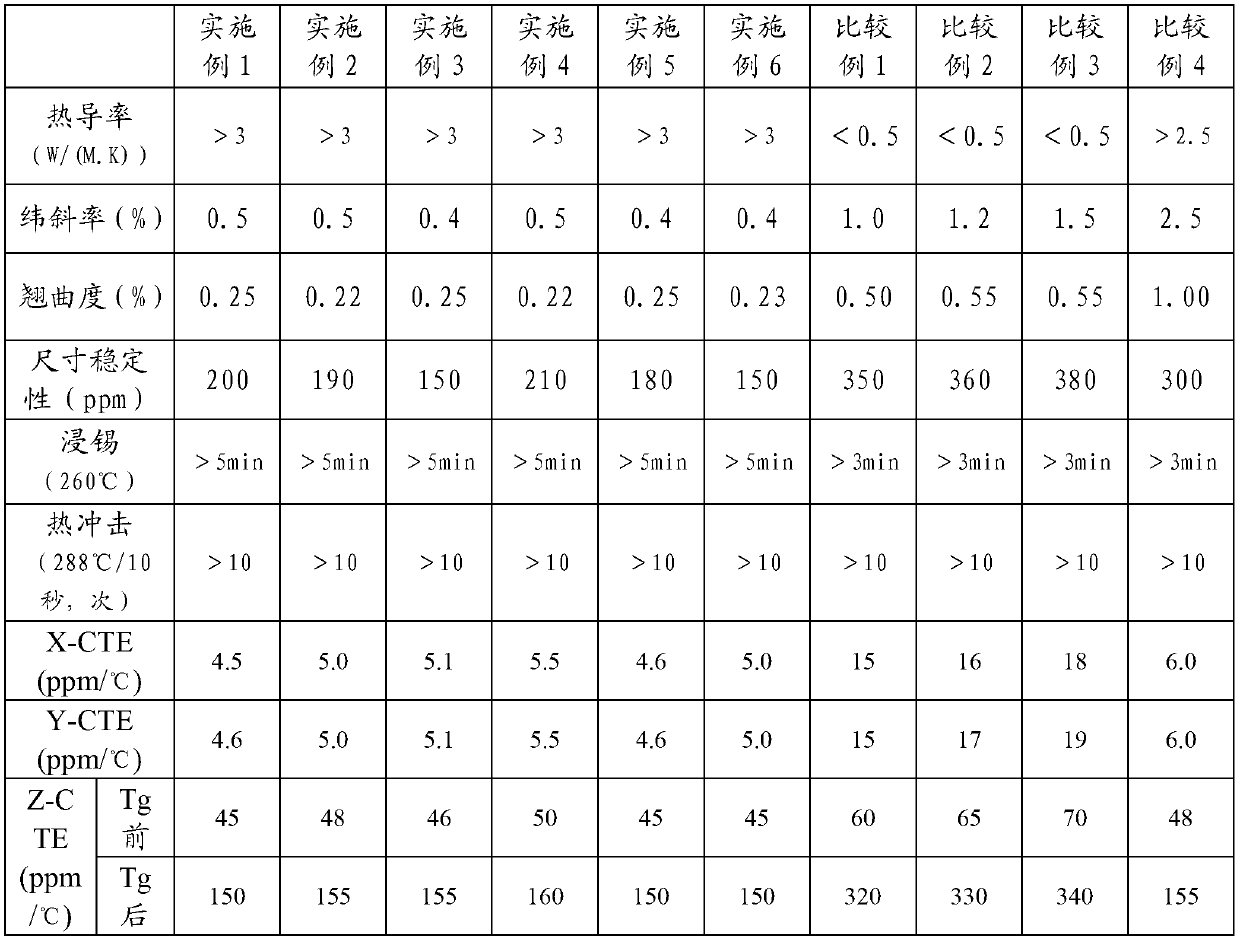

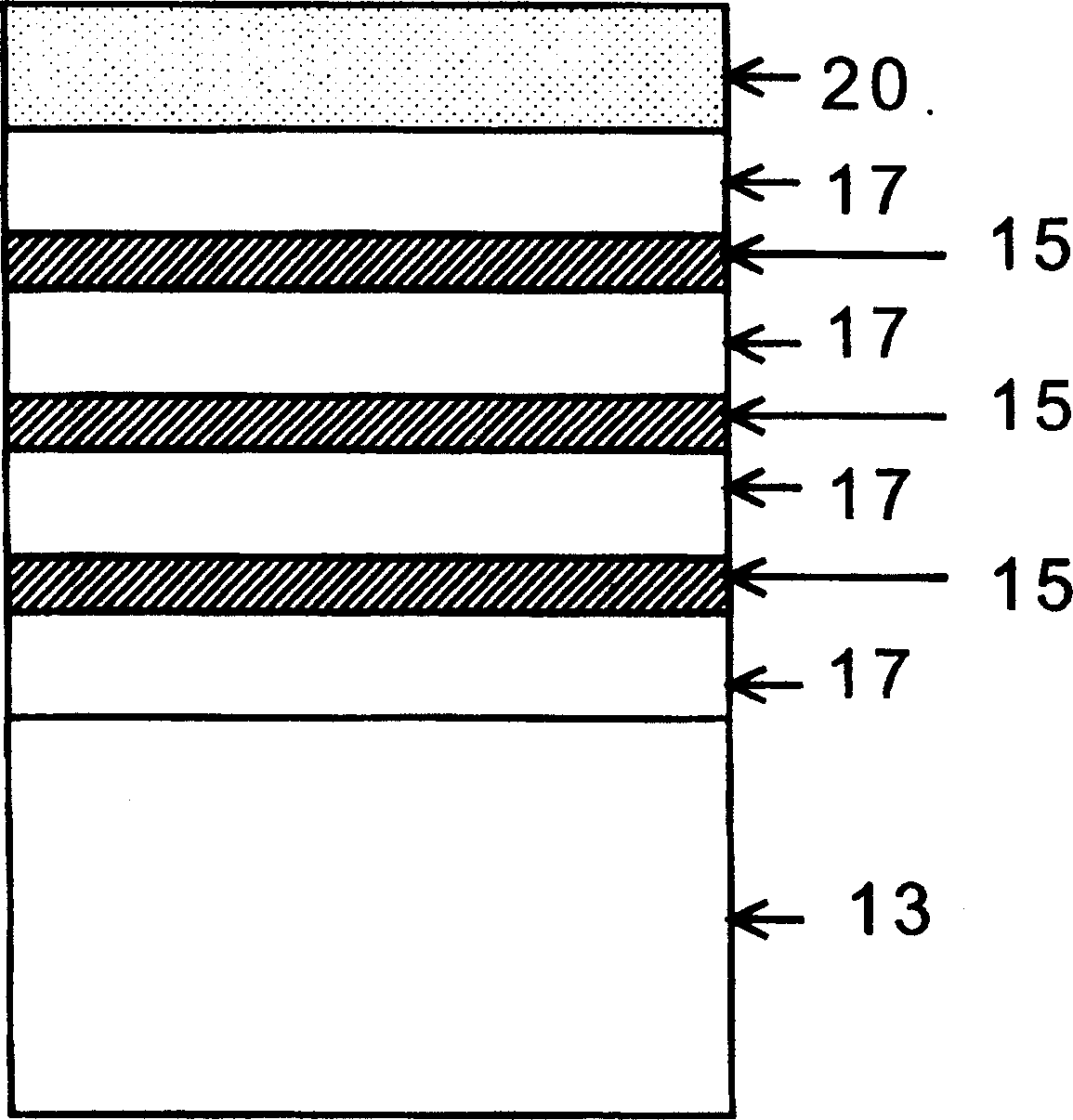

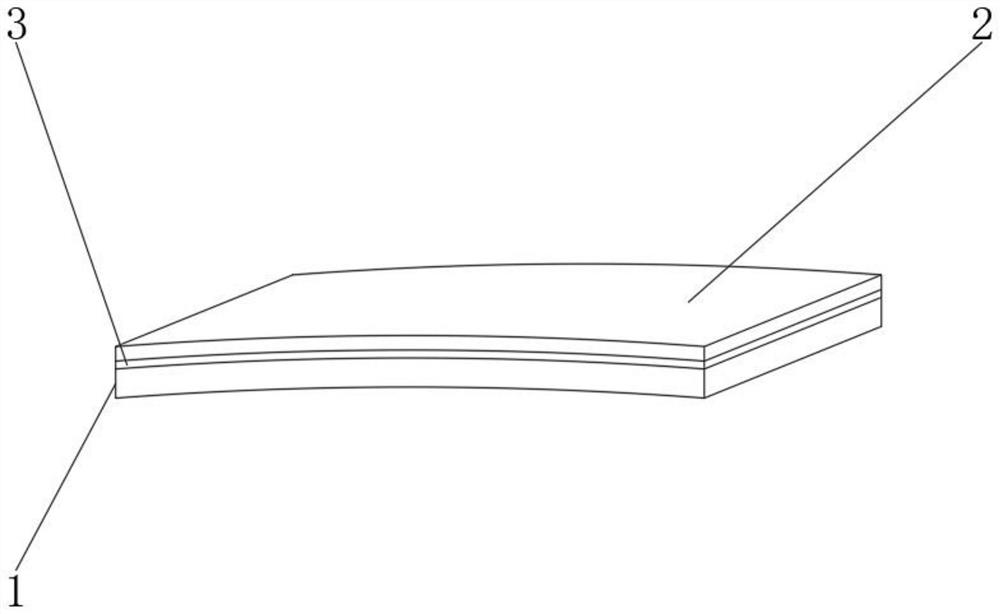

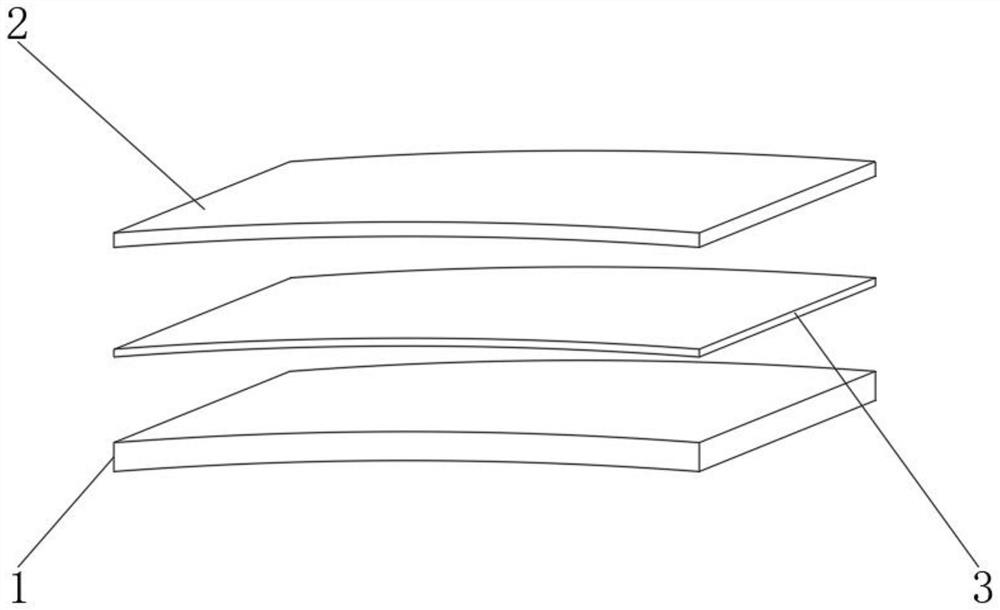

Carbon fiber base fabric composite material and preparation method and application thereof

ActiveCN103129042AAvoid problems such as falling apart or even breakingMeet needsLaminationLamination apparatusFiberCarbon fibers

The invention relates to the technical field of printed circuit boards, in particular to a carbon fiber base fabric composite material. The carbon fiber base fabric composite material comprises at least one layer of carbon fiber base fabric and adhesive layers. The adhesive layers are one layer more than the carbon fiber base fabric. The composite material is formed by the carbon fiber base fabric and the adhesive layers through alternately laminating in a press fit mode. The carbon fiber base fabric is made of carbon fiber through knitting in the warp and weft direction. Compared with a glass fabric base fabric bonding sheet, the carbon fiber base fabric composite material has better thermal conductivity, overcomes the defects that weft skewing can easily happen to a carbon fiber sheet and production operations of the carbon fiber sheet is hard, greatly improves warping of products, and particularly improves the stability of the sizes of the products.

Owner:GUANGDONG SHENGYI SCI TECH

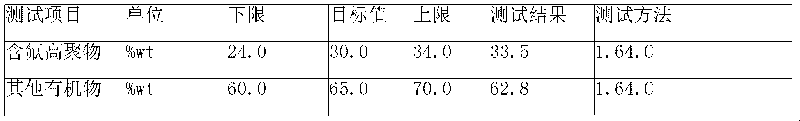

Linear metallocene PE modified compound additive

The invention relates to a linear metallocene PE modified compound additive, which consists of the following components in parts by weight: 10-20 parts of hindered phenol antioxidant, 45-60 parts of phosphate auxiliary antioxidant and 20-30 parts of plastic processing aid (PPA). The linear metallocene PE modified compound additive in the invention is applied in linear low-density PE devices and has the advantages of satisfying production requirement of metallocene PE, overcoming the problem of pipeline blocking in current devices and realizing continuous and stable production of devices.

Owner:李庆民

Polarization membrane and manufacturing method thereof, polarizer and optical laminate

Provided is a polarizing film which has few voids and is free of wrinkles and a method for manufacturing the same, and to provide a polarizing plate and an optical laminate. The polarizing film is obtained by treating a polyvinyl alcohol film in order of swelling treatment, dyeing treatment, boric acid treatment and rinse treatment, subjecting the film to uniaxial stretching in a boric acid treatment step and / or a step before the same and further alleviating the stretching of the film by 1 to 5% in the stretching direction in the at least one step after the stretching treatment. The polarizing plate is obtained by pasting a protective film to the at least one surface of the polarizing film. The optical laminate is obtained by pasting at least one kind selected from a retardation plate, a viewing angle improving film and a translucent reflection plate to the polarizing plate pasted with the protective film on the at least one surface.

Owner:SUMITOMO CHEM CO LTD

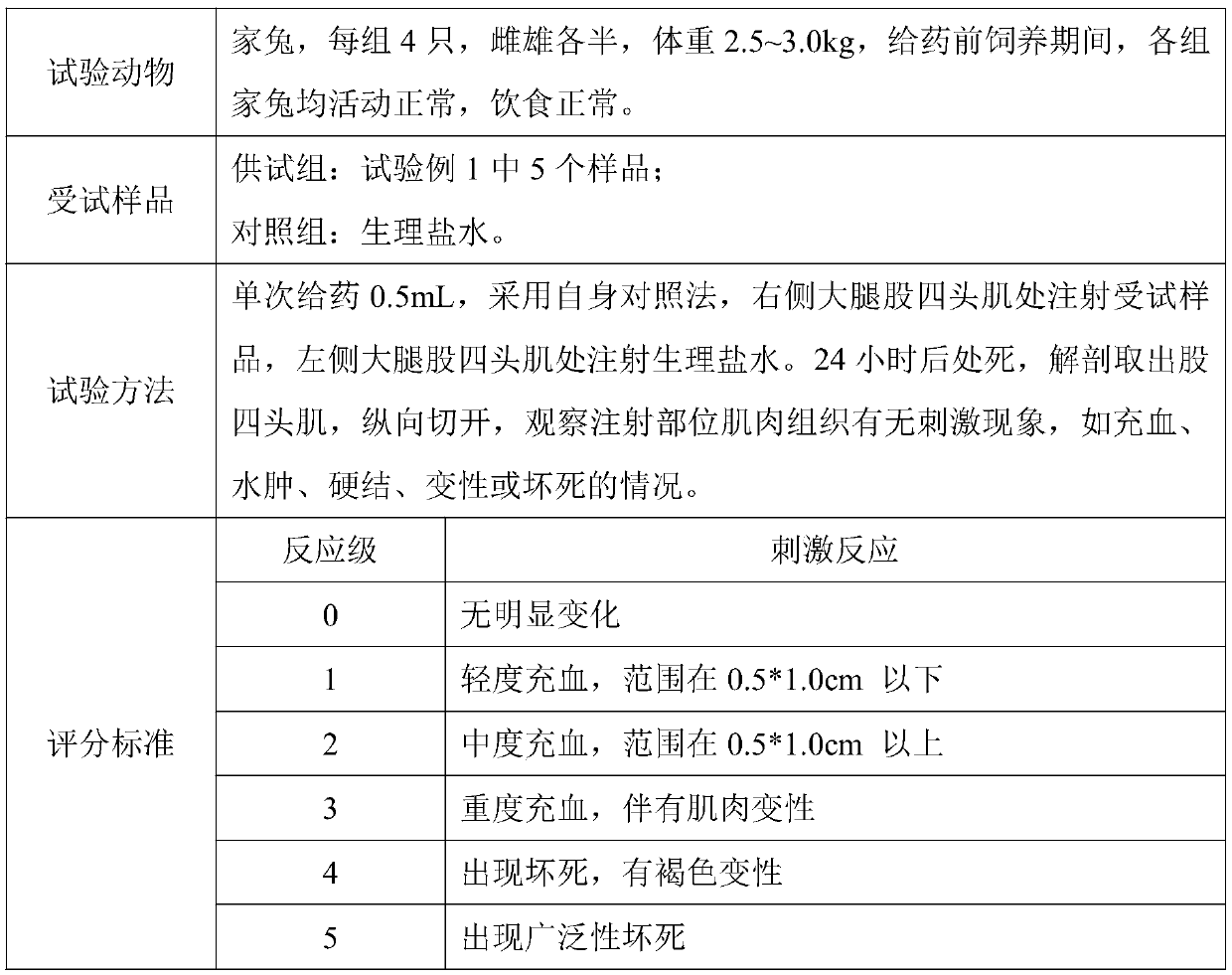

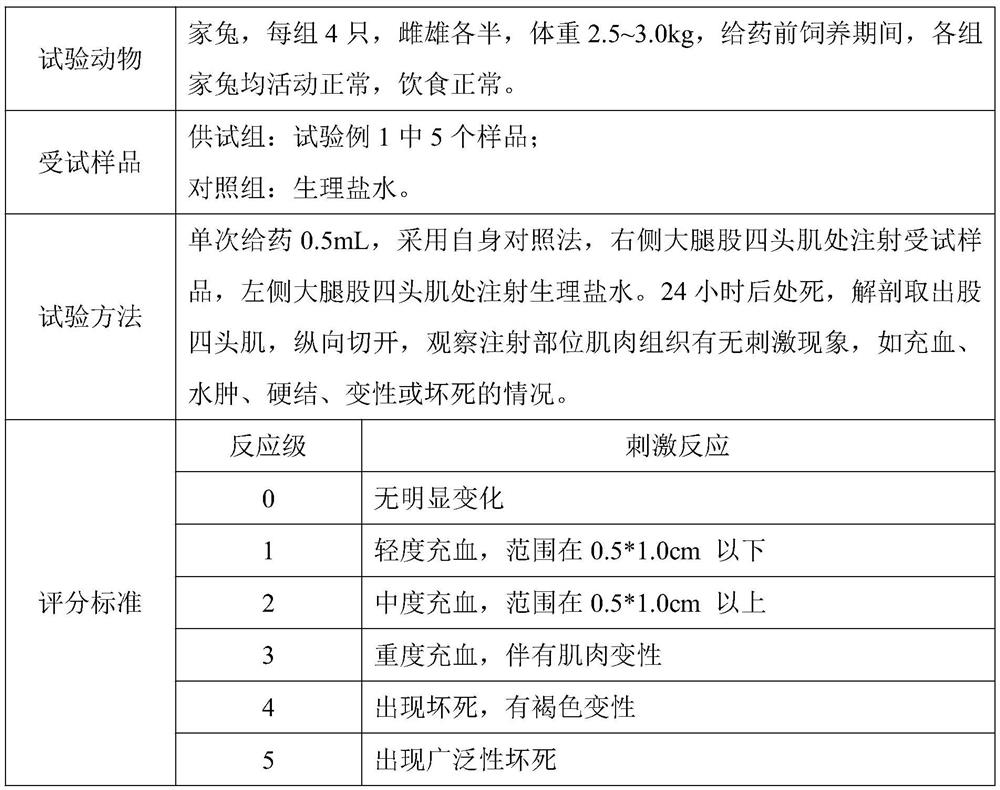

Ketorolac tromethamine injection capable of reducing irritation and free of organic solvent

ActiveCN111481501ASuppress generationLess irritatingOrganic active ingredientsAntipyreticIrritationOrganosolv

The invention provides a ketorolac tromethamine injection capable of reducing irritation and free of an organic solvent. By using a tromethamine-acidifying agent buffer system is used as a protectiveagent, adverse effects of ethanol and monopotassium phosphate on a packing material and severe irritation at an injection part in the prior art are avoided. The production process is simple and controllable, the physicochemical property of the liquid medicine is stable, and the medication safety and compliance of patients can be improved.

Owner:南京锐志生物医药有限公司

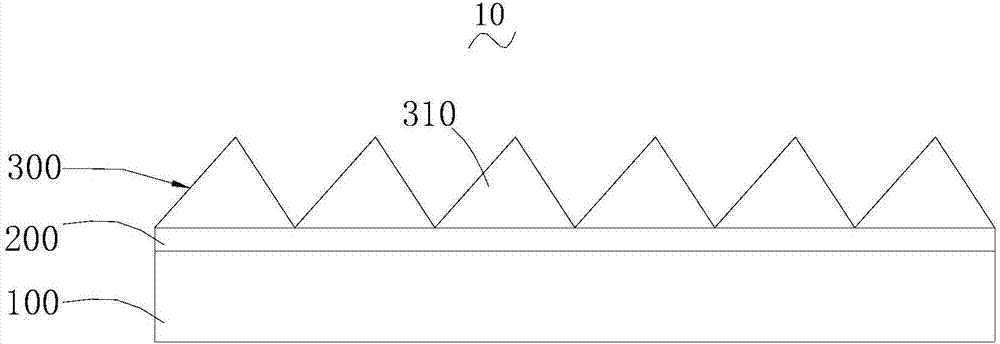

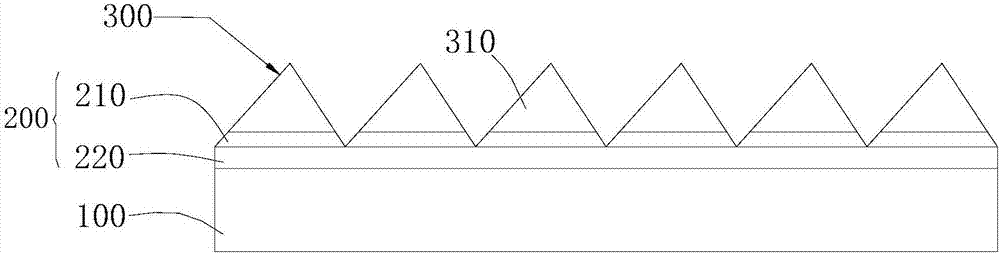

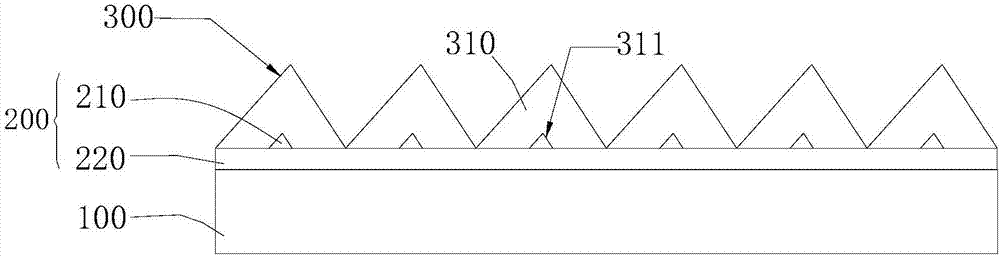

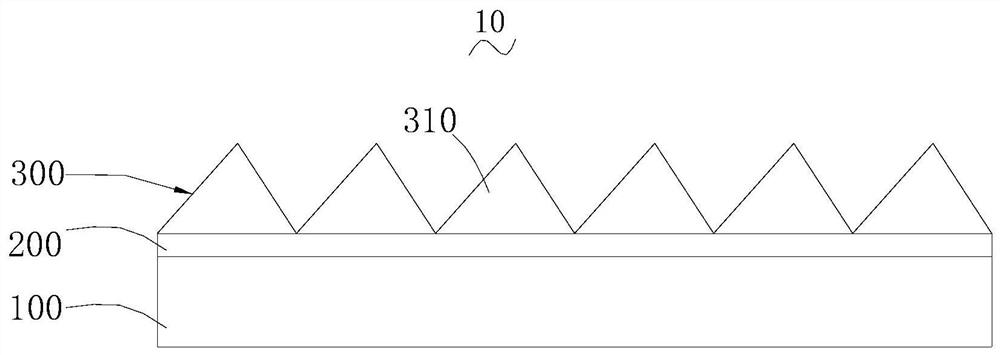

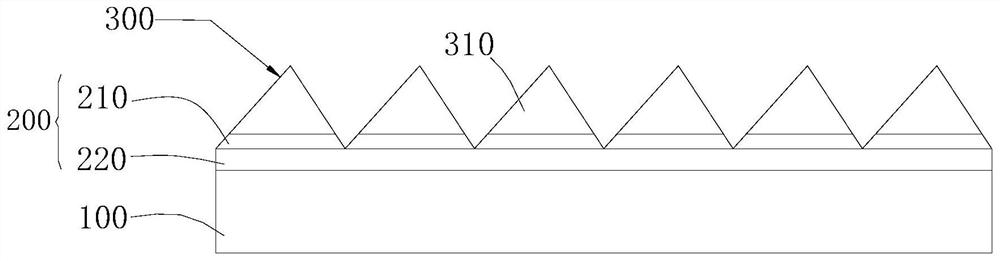

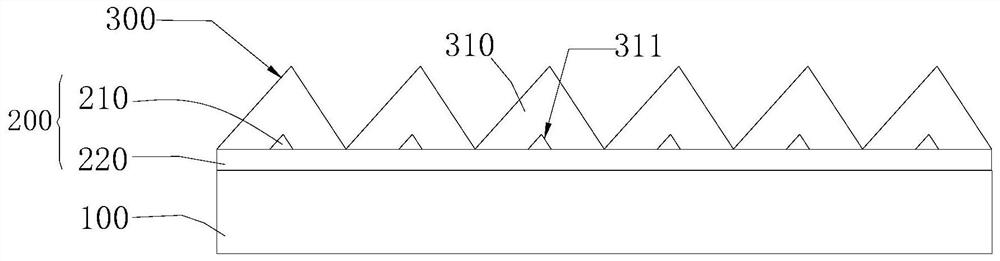

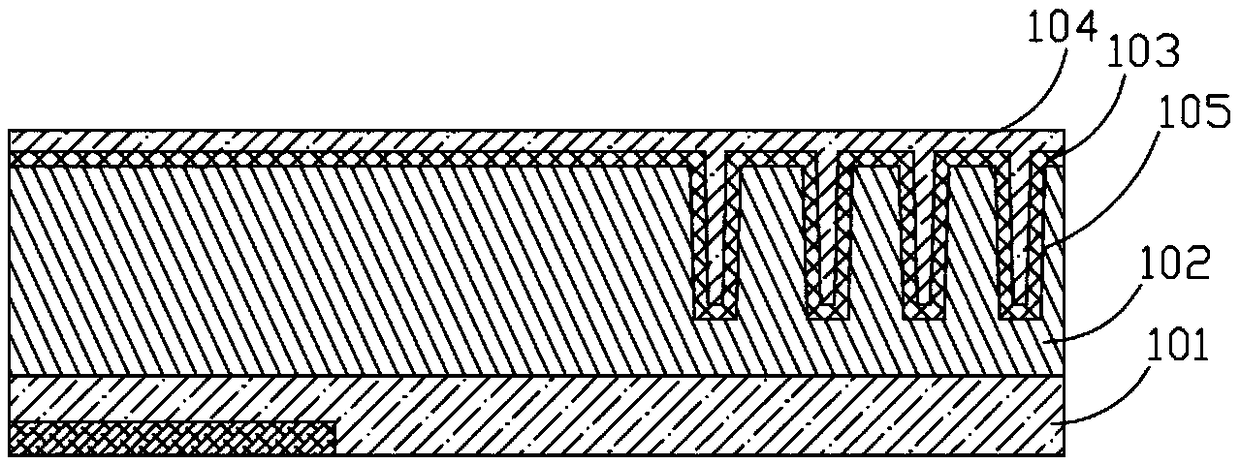

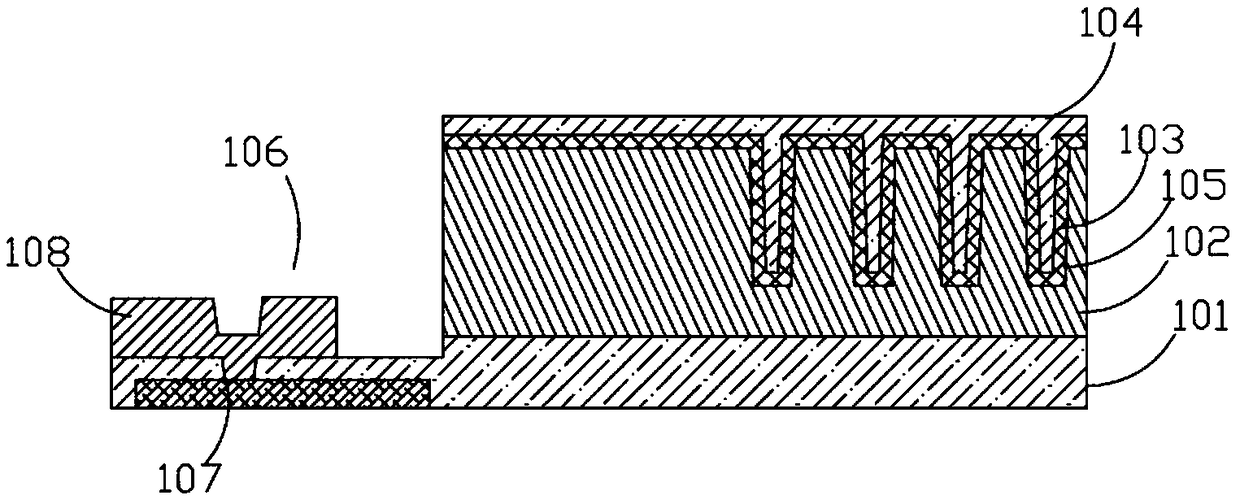

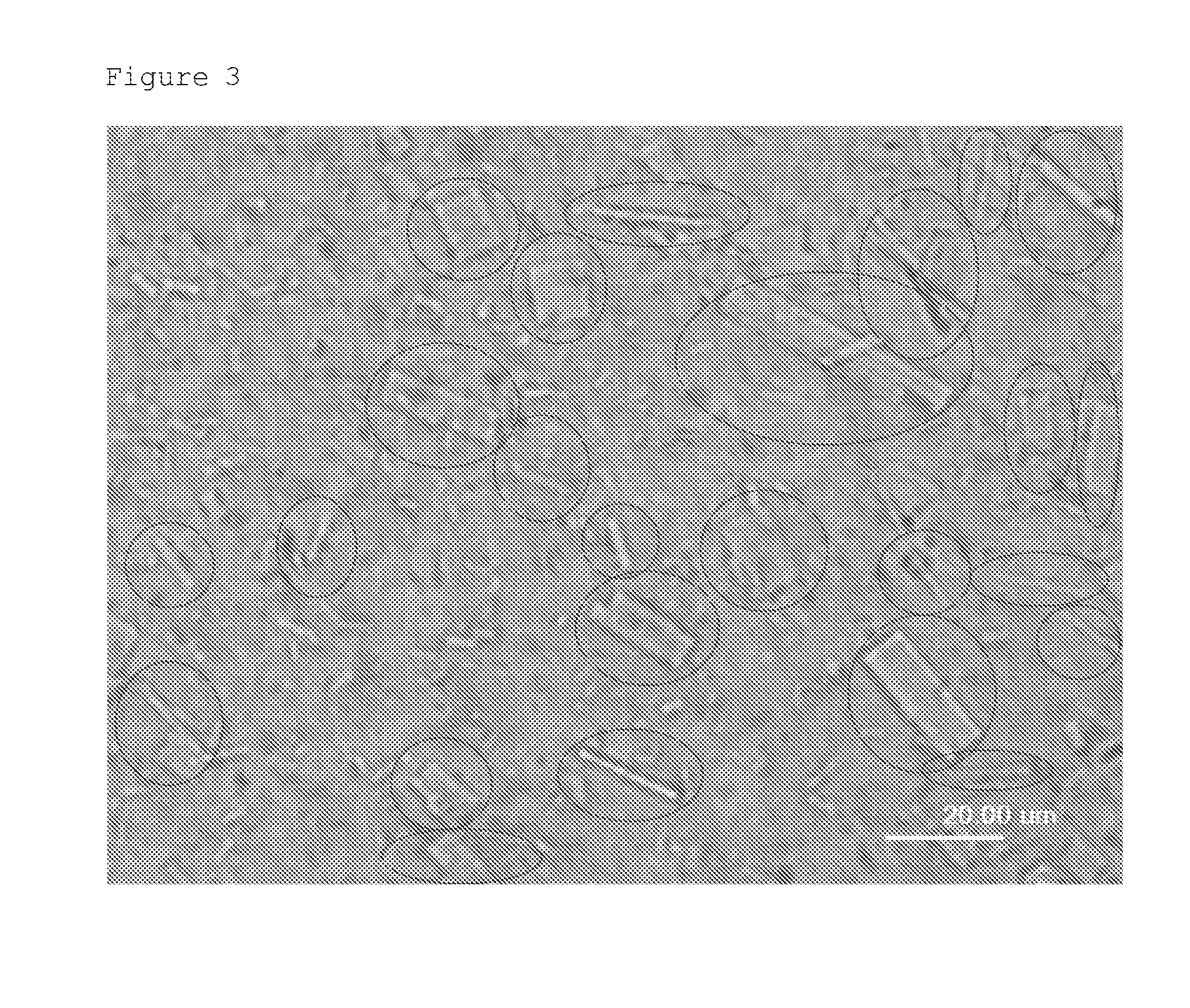

Bright enhancement film, manufacturing method therefor, backlight module group, and display equipment

ActiveCN106970435AReduce white pointReduce the impact of the display effectDiffusing elementsNon-linear opticsCompression moldingDisplay device

The invention discloses a bright enhancement film, a manufacturing method therefor, a backlight module group, and display equipment. The bright enhancement film comprises a base material, a soft glue layer, and a prism structure layer. The manufacturing method comprises the steps: coating the surface of the base material with a soft resin layer; solidifying the soft resin, and forming the soft glue layer; coating the surface of the soft glue layer with a hard resin layer; carrying out the compression molding of the hard resin layer through a die which has a complementary structure with the prism structure layer, and enabling the hard resin layer to form a structure which has a plurality of preset prism shapes; solidifying the structure with the plurality of preset prism shapes to form a plurality of first prisms, wherein the plurality of first prisms form a prism structure layer. The backlight module group comprises any one prism structure above. The display equipment comprises any one backlight module group above. According to the invention, the damage to the bright enhancement film is reduced, and the white points or white spots generated during the use of the backlight module group are reduced. Moreover, the possibility that the display equipment of a display is affected is reduced.

Owner:TCL DISPLAY TECH HUIZHOU

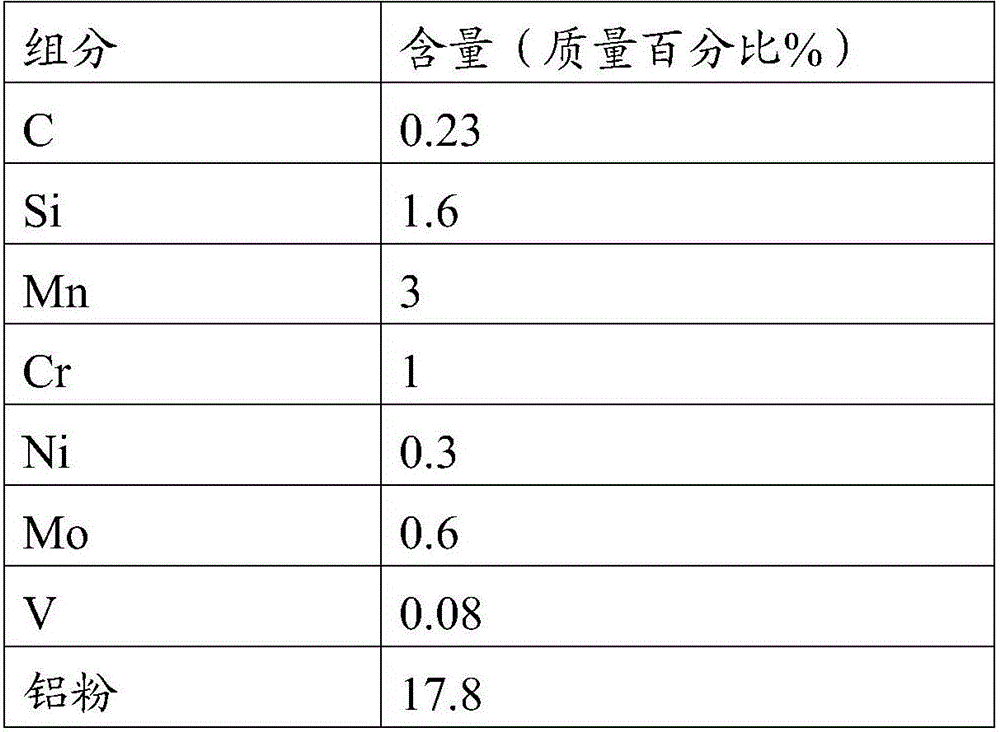

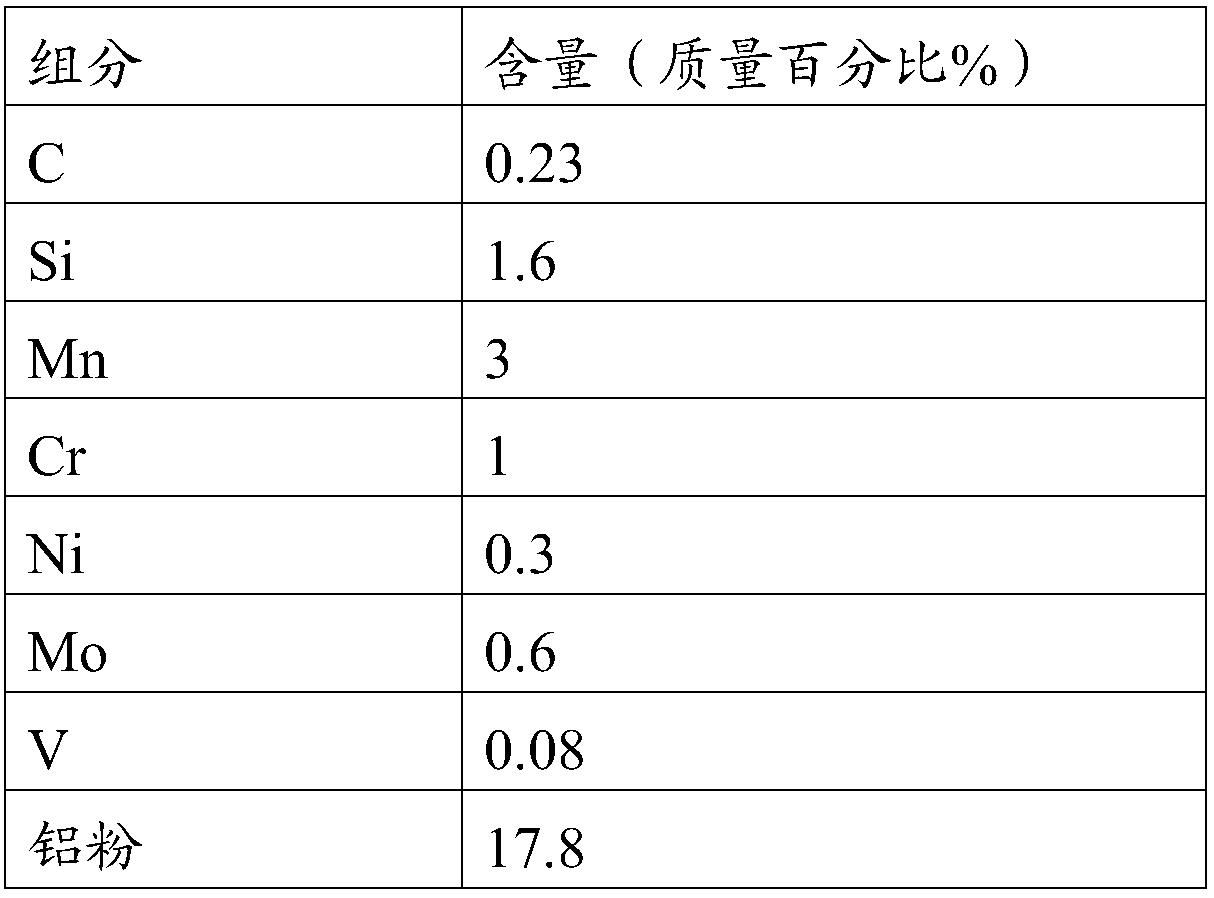

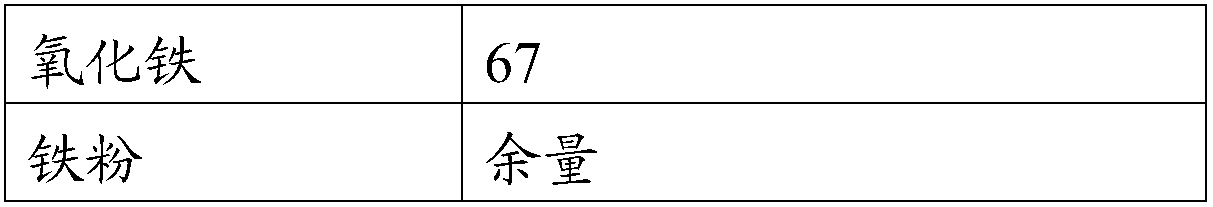

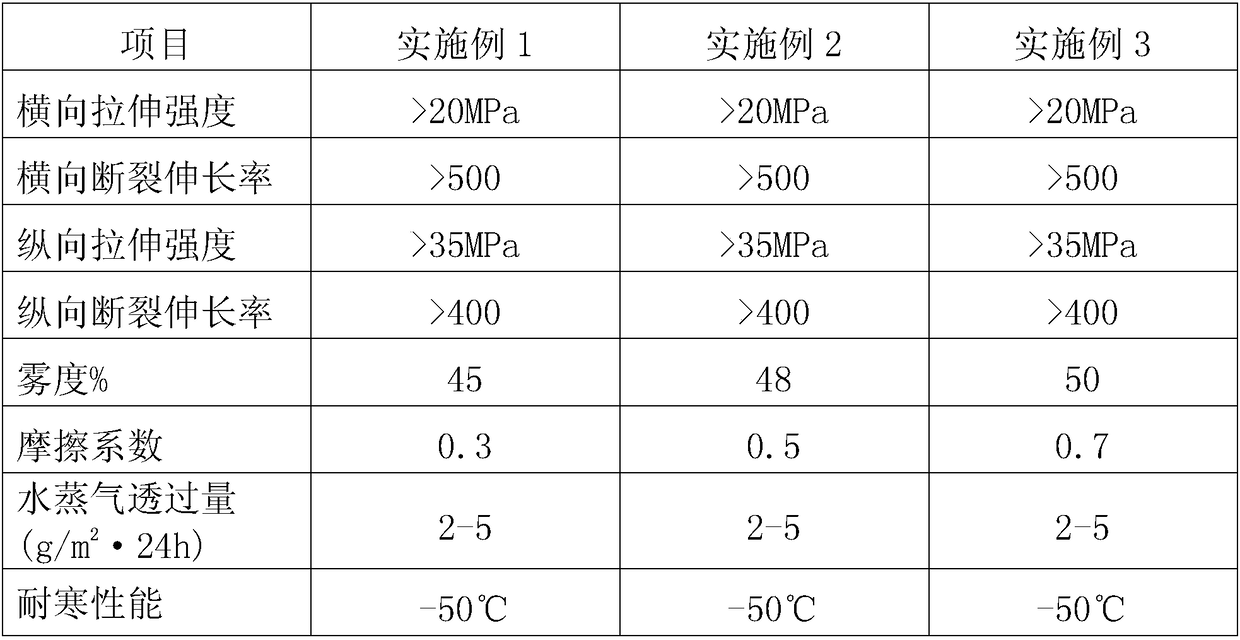

Exothermic welding flux and application thereof

ActiveCN105921881AImprove qualityReduce white pointWelding/cutting media/materialsAlumino-thermic welding apparatusExothermic weldingIron powder

The invention discloses exothermic welding flux. The exothermic welding flux comprises iron powder, iron oxide and an alloy additive. The alloy additive comprises C, Si, Mn, Cr, Ni, Mo, V and aluminum powder. The exothermic welding flux comprises, by mass percent, 0.10%-0.25% of C, 1.0%-1.6% of Si, 1.8%-3% of Mn, 0.5%-1.0% of Cr, 0.3%-1.2% of Ni, 0.2%-0.6% of Mo, 0.03%-0.1% of V, 17.8%-19.2% of aluminum powder, 60%-67% of iron oxide and the balance iron powder. The invention further provides application of the exothermic welding flux to steel rail welding.

Owner:张绵胜 +3

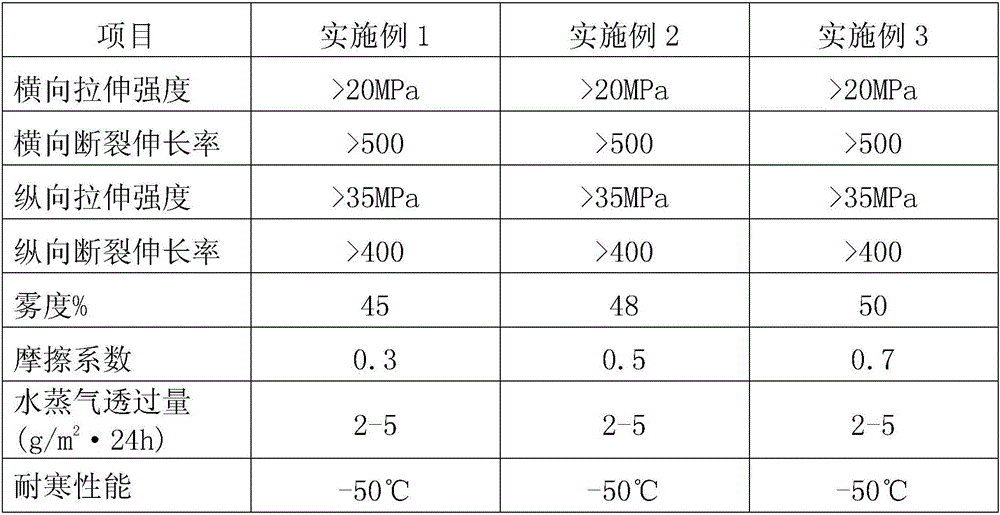

Antistatic matt film and preparation method thereof

InactiveCN111267443ASmooth and delicateBeautiful white matte finishSynthetic resin layered productsPolymer scienceAntistatic agent

The invention discloses an antistatic matt film and a preparation method thereof. The antistatic matt film is of a three-layer structure and sequentially comprises an anti-adhesion layer, a core layerand a matt layer from top to bottom; the anti-adhesion layer is prepared from the following raw materials in parts by weight: 80 to 90 parts of polypropylene and 1 to 3 parts of an anti-adhesion agent; the core layer is prepared from the following raw materials in parts by weight: 80 to 90 parts of polypropylene and 2 to 4 parts of antistatic agent; the matt layer is prepared from the following raw materials in parts by weight: 90 to 96 parts of matt master batch and 2 to 3 parts of slipping agent; the three-layer structure of the antistatic matt film is formed by melt co-extrusion and two-way stretching. The matt film prepared by the invention has the advantages of few crystal points and white points on the film surface, higher haze and lower glossiness, smooth and fine hand feeling of the matt layer and more attractive white matte effect, can be used for protecting the surface of an electronic product, plays a role in preventing dust and scratching the electronic product in the production process, and is also suitable for being used as an outer package of a high-end commodity.

Owner:GETTEL GRP TONGCHENG PLASTIC IND

Laminate and filter of display using the same laminate

InactiveCN1278136CImprove conductivityIncrease reflectionOptical filtersCoatingsPolymer scienceDisplay device

Owner:YAMAMOTO CHEM INC

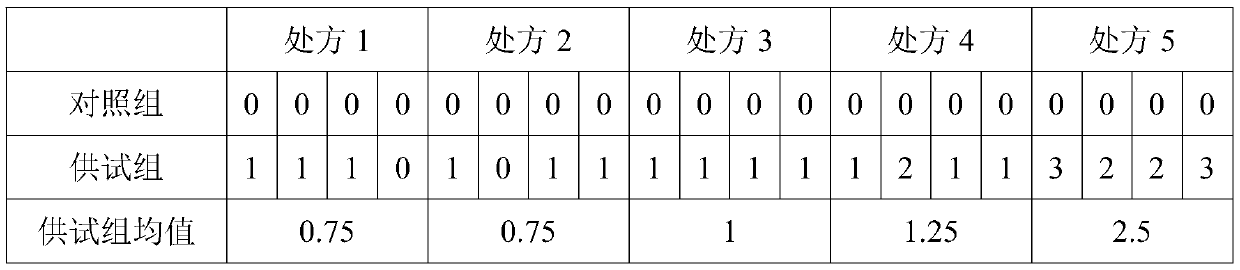

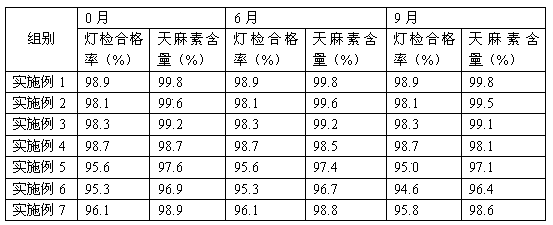

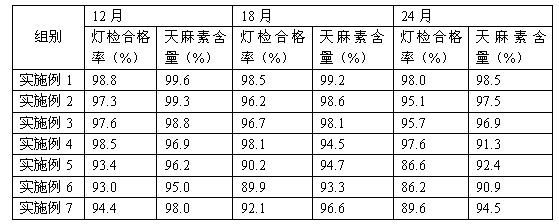

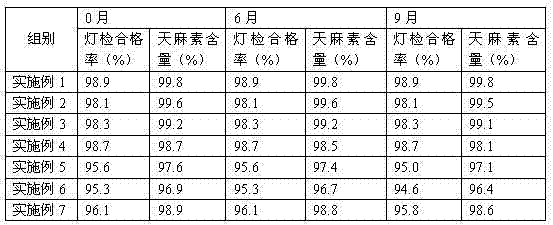

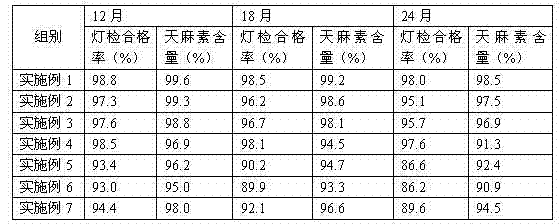

Gastrodin injection and preparation process thereof

ActiveCN103520095ALess prone to white spotsHigh clarityOrganic active ingredientsNervous disorderGlycineCLARITY

The invention provides a gastrodin injection and a preparation process thereof, and the gastrodin injection can be used for reducing white spots and white blocks occurring during storage, improving the clarity, guaranteeing the safety of medication and meanwhile guaranteeing better stability. According to the gastrodin injection and the preparation process thereof, lactose, procaine hydrochloride, sodium hyposulfite, niacinamide and glycine are used as auxiliary materials; the white spots and the white blocks occurring during storage can be reduced, the clarity can be improved and the safety of medication can be guaranteed after proportioning; but meanwhile, we found that the gastrodine content is obviously reduced after the gastrodin injection is stored for a period of time after the auxiliary materials are added; after the addition sequence of the auxiliary material is adjusted by using the special technology, the content of the gastrodine in the gastrodin injection is still stable after long-time storage, so that the validity of the clinical medication is guaranteed.

Owner:JIANGXI GUOYAO PHARMA LLC

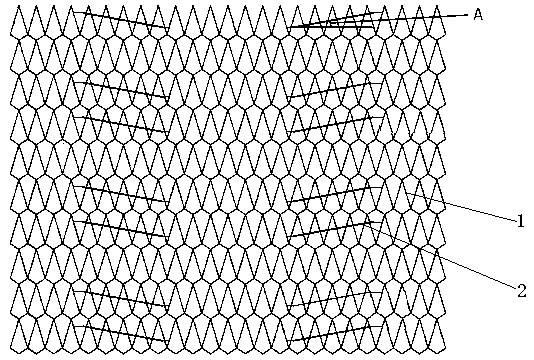

Double-rail sintering furnace mesh belt

PendingCN108955246AReduce contact areaReduce back electric field white pointCharge treatment typeFurnace typesEngineeringSolar cell

The invention relates to the technical field of solar cell piece production, and particularly provides a double-rail sintering furnace mesh belt. A double-rail sintering furnace is provided with a first rail and a second rail, the mesh belt is arranged on each of the first rail and the second rail, wherein each mesh belt comprises a mesh belt body, a plurality of ejector pins are arranged on eachmesh belt body, every two ejector pins form an ejector pin pair, the ejector pin pairs are arranged in the length directions of the mesh belt bodies in a left-right symmetry mode, and an included angle is formed between the bottom surface of each ejector pin and the horizontal direction of the corresponding mesh belt body. The probability that the chamfer of a cell piece is inserted into each ejector pin is reduced, the probability of clamping breaking and corner missing caused by the mesh belt ejector pins is reduced, meanwhile, the contact area between the cell piece and the corresponding ejector pin is reduced, and finally, the white points of the back electric field after the cell piece is sintered are reduced.

Owner:SUZHOU RUNYANG PHOTOVOLTAIC TECH

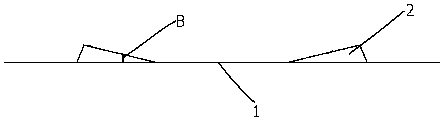

Glass plate manufacturing method

ActiveCN101855182BReduce white pointImprove visibilityPhotomechanical apparatusOriginals for photomechanical treatmentAbsorptanceDisplay device

Owner:ASAHI GLASS CO LTD

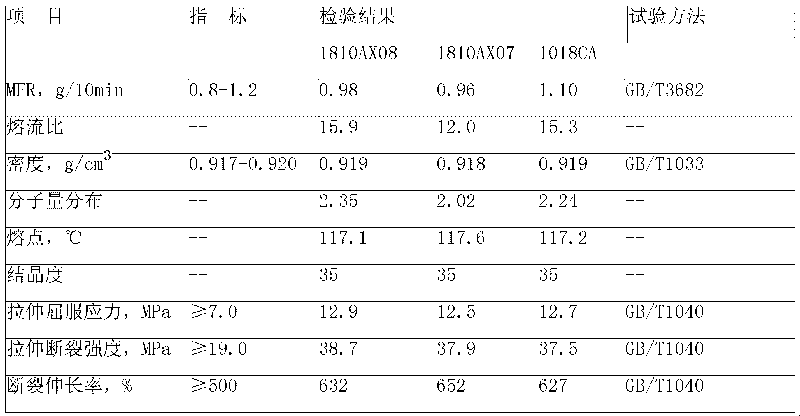

Polyethylenic resin laminated film

InactiveCN101213077BReduce white pointLess thick spotsFlexible coversWrappersPolymer scienceThin membrane

The present invention provides a polyethylene resin laminate film, more specifically a polyethylene resin film having a good balance of heat-sealing property and stiffness of the film, having less fish-eyes, having little fisheyes and also having less unevenness in thickness. [MEANS FOR SOLVING PROBLEMS] A polyethylene resin laminate film having at least a laminate layer (A) and a seal layer (B),the laminate layer (A) comprising at least two polyethylene resins each having a density of 900 to 970 kg / m<3> and a molecular weight distribution (Mw / Mn) of 2.0 to 3.5, the densities of the at leasttwo polyethylene resins being different from each other, the average density of the laminate layer being 920 to 945 kg / m<3>, the seal layer (B) comprising a polyethylene resin having a density of 900to 930 kg / m<3>, and the average density of the laminate layer (A) being larger than that of the seal layer (B).

Owner:TOYOBO CO LTD

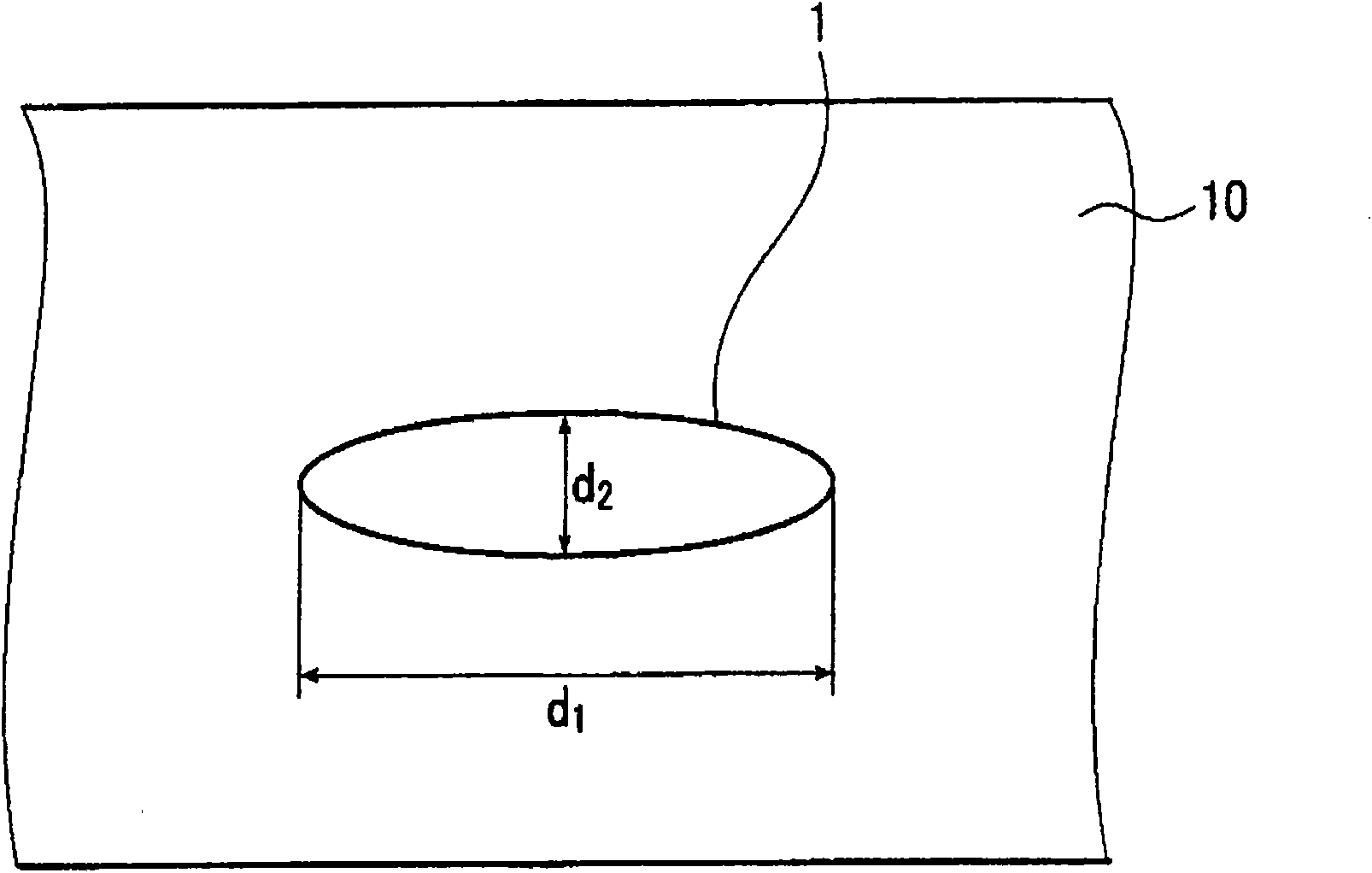

Novel composite white reflective film

The invention discloses a novel composite white reflective film which comprises a white reflective film. An adhesive layer is arranged on the outer surface of the upper end of the white reflective film. A transparent film is arranged on the outer surface of the upper end of the adhesive layer. The outer surface of the upper end of the white reflective film is fixedly connected with the outer surface of the lower end of the adhesive layer. The outer surface of the upper end of the adhesive layer is fixedly connected with the outer surface of the lower end of the transparent film. The thickness of the white reflective film is 55 microns, and the thickness of the transparent film is 25 microns. According to the novel composite white reflective film, generation of white points and black points can be reduced, the situation that white balls are formed after an LCM is lightened due to extrusion deformation of the white reflective film can be prevented, foreign matter defects in the production process of backlight source products are avoided, the two needed main materials and processes can be independently completed by domestic manufacturers, the industrial cost can be reduced, the domestic selling price of a silver-plated specular reflective film can be further reduced, and a better use prospect is brought.

Owner:尧志萍

Brightening film and its manufacturing method, backlight module and display device

ActiveCN106970435BReduce white pointReduce the impact of the display effectDiffusing elementsNon-linear opticsDisplay deviceEngineering

Owner:TCL DISPLAY TECH HUIZHOU

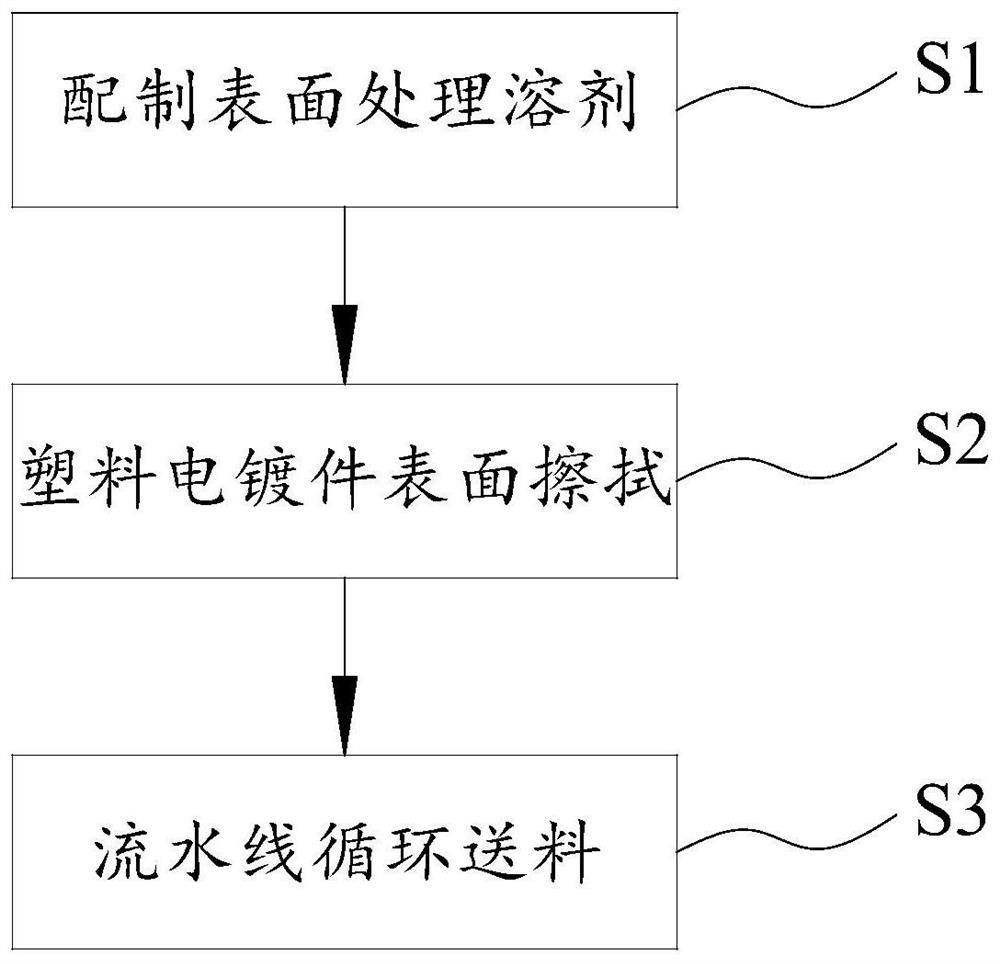

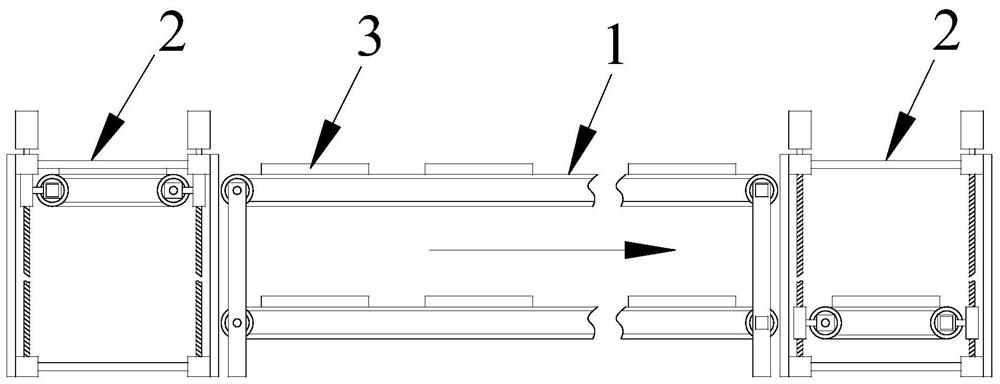

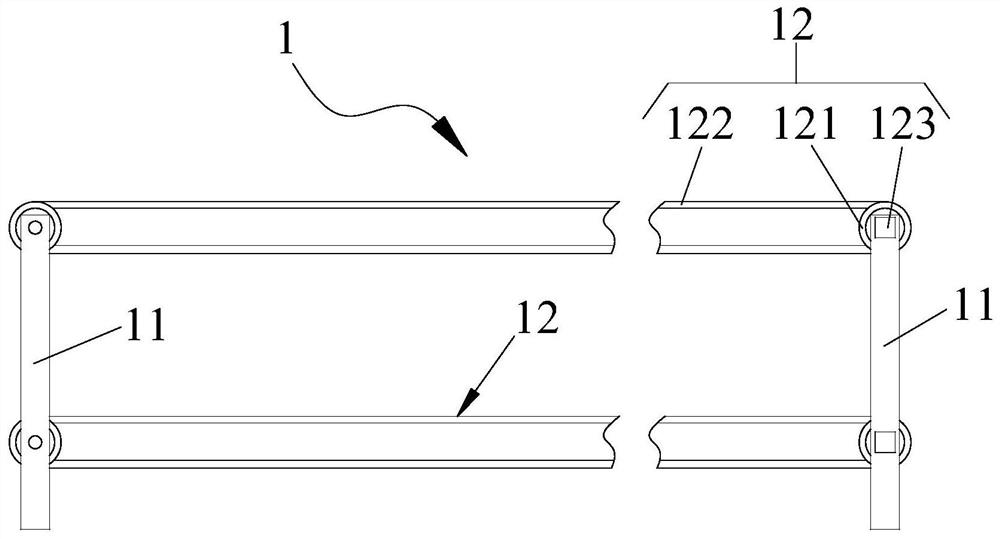

Surface treatment solvent for plastic electroplated part and treatment method

The invention discloses a surface treatment solvent for a plastic electroplated part. The solvent comprises the following raw materials of, in percentage by mass, 80% of an anionic surfactant, 2% of formaldehyde and 18% of deionized water. The surface treatment solvent for the plastic electroplated part is stable in structure, has good solubility in water, is good in wetting and dispersing performance, and can well reduce white spots on a surface of the plastic electroplated part.

Owner:宣城托新精密科技有限公司

Light extinction silk and satin film and protection process thereof

ActiveCN106364102AImprove barrier propertiesImprove moisture resistanceFlexible coversWrappersElastomerLight extinction

The invention relates to a light extinction silk and satin film and a protection process thereof. The light extinction silk and satin film comprises a layer A, a layer B, a layer C and a layer D which are sequentially compounded. The layer A is prepared from 44 wt% to 46 wt% of homo-polypropylene, 44 wt% to 46 wt% of high density polyethylene and 9 wt% to 11 wt% of block co-polypropylene resin, and the layer B and the layer C are both prepared from 49 wt% to 51 wt% of homo-polypropylene, 44 wt% to 46 wt% of high density polyethylene, 1 wt% to 2 wt% of spherical anti-block agent and 3 wt% to 4 wt% of nanoscale aid, and the layer D is prepared from 85 wt% to 90 wt% of homo-polypropylene and 10 wt% to 15 wt% of polytolefin elastomers. The thickness ratio of the layer A to the layer B to the layer C to the layer D is 60:15:15:10. During production, the main materials of all the layers are added into an extruder, after the main materials are melted, the auxiliary materials of all the layers are added into the extruder for fusion, then melt is extruded to a curtain coating roll, finally, all the layers are compounded into the light extinction silk and satin film, and the both sides of the light extinction silk and satin film are subjected to corona treatment. The light extinction silk and satin film is outstanding in moisture stopping performance, excellent in cold resisting performance, good in heat resisting performance, good in hand feeling and low in gloss, and gives people a noble visual feeling and the effect close to silks and satins.

Owner:永新股份(黄山)包装有限公司

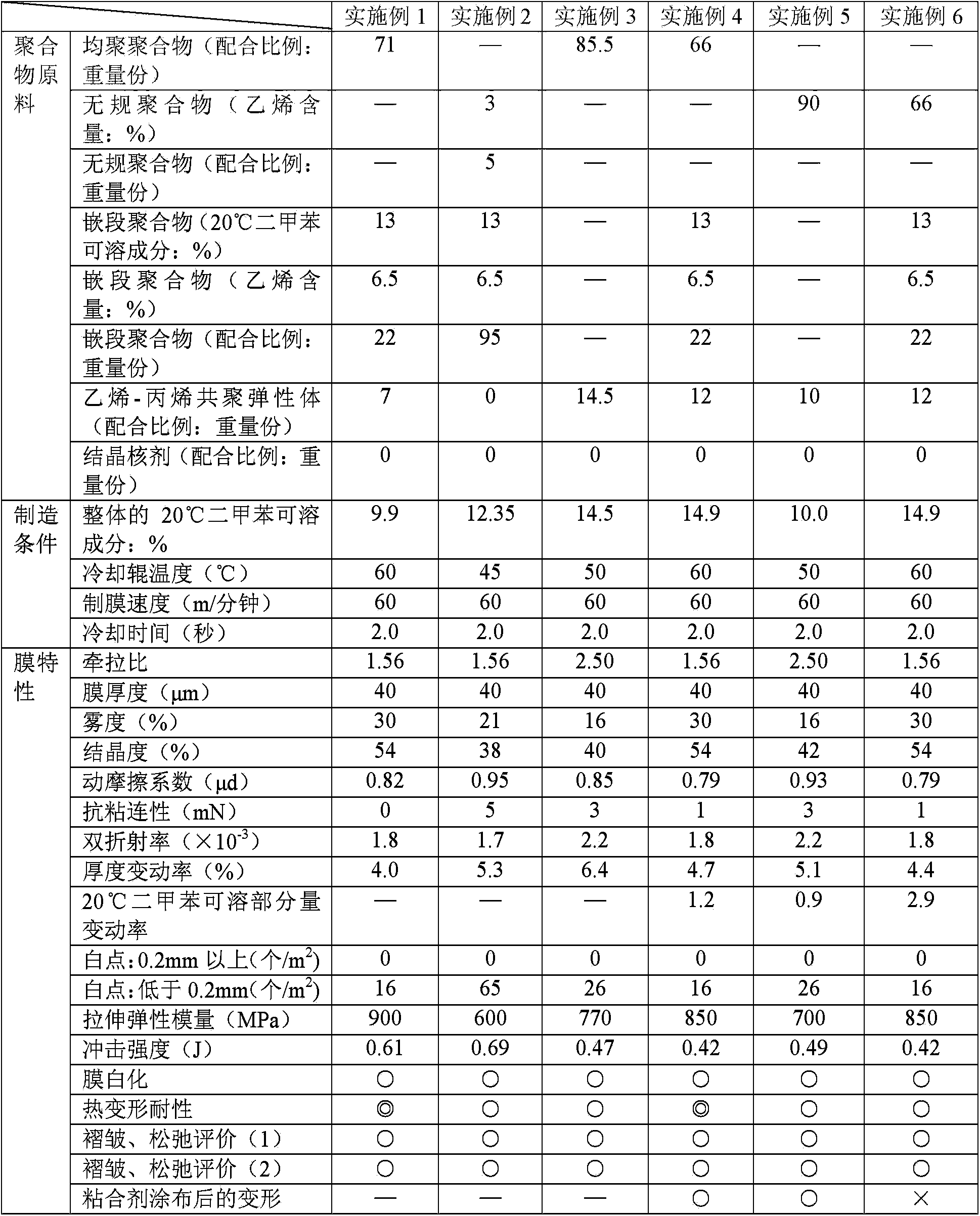

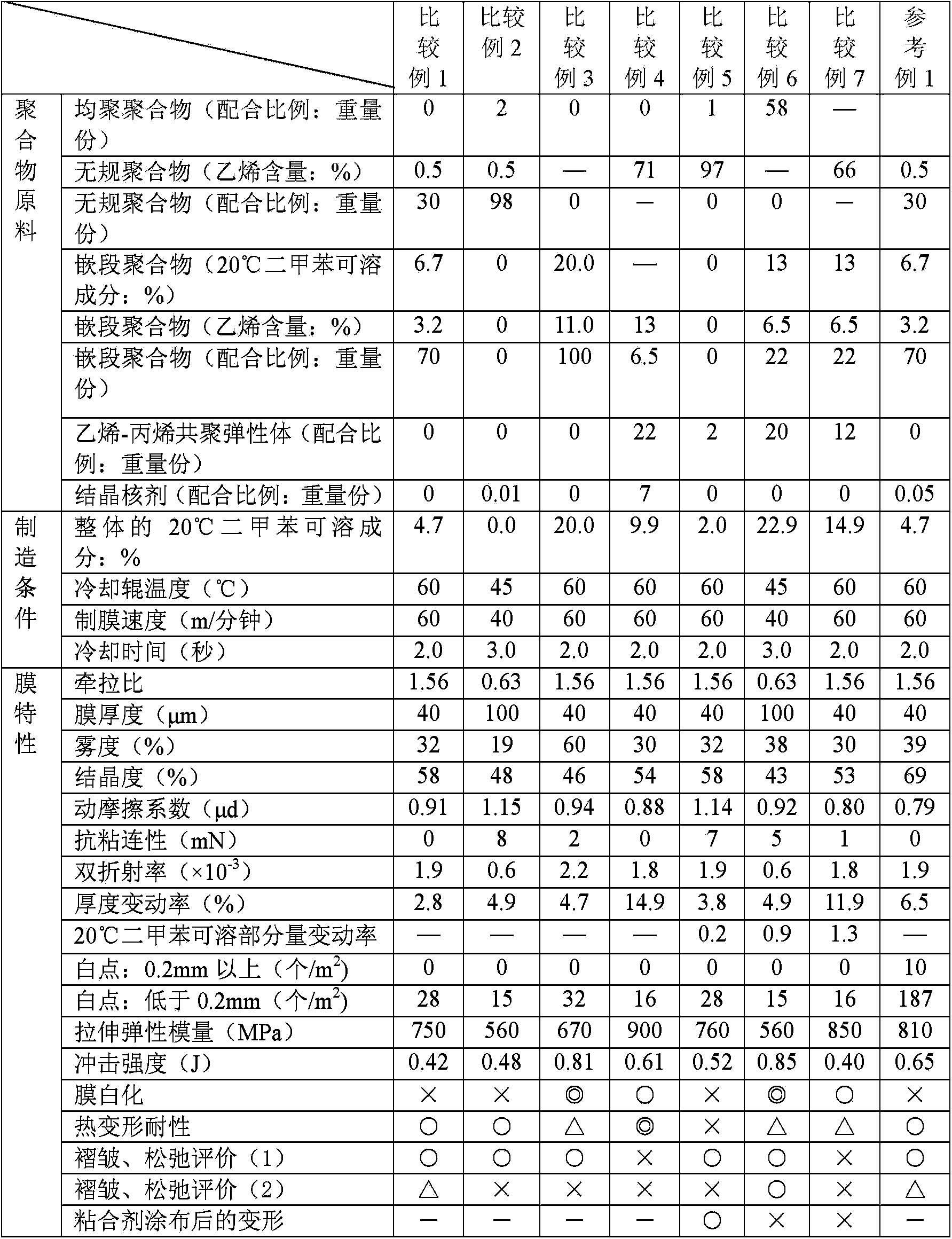

Polypropylene resin film for surface protection, and surface protective film

ActiveCN102369235BImprove stabilityGood planarityFilm/foil adhesivesSynthetic resin layered productsTectorial membraneWrinkle skin

Disclosed is a polypropylene resin film for surface protection, which has excellent thermal dimensional stability, planarity, impact resistance and bonding workability, while being reduced in fish eyes. The polypropylene resin film for surface protection is free from wrinkles or sags when the film is rolled into a roll. The polypropylene resin film is suitable, for example, for a base film of a protective film. Also disclosed is a protective film which is obtained by providing the polypropylene resin film for surface protection with an adhesive layer. Specifically disclosed is a polypropylene resin film for surface protection, which is substantially composed of a polypropylene resin and is characterized by having a xylene-soluble content at 20°C of more than 9% but less than 15%, a crystal nucleator content of not more than 100 ppm, a film thickness variation in the width direction of not less than 1% but not more than 10%, a coefficient of kinetic friction of not more than 1.0, and a tensile modulus of elasticity of not less than 500 MPa but not more than 900 MPa.

Owner:TOYOBO CO LTD

Gastrodin injection and preparation process thereof

ActiveCN103520095BGuaranteed validityReduce contentOrganic active ingredientsNervous disorderGlycineCLARITY

Owner:JIANGXI GUOYAO PHARMA LLC

A kind of thermite welding flux and its application

ActiveCN105921881BImprove qualityReduce white pointWelding/cutting media/materialsSoldering mediaExothermic weldingIron powder

The invention discloses exothermic welding flux. The exothermic welding flux comprises iron powder, iron oxide and an alloy additive. The alloy additive comprises C, Si, Mn, Cr, Ni, Mo, V and aluminum powder. The exothermic welding flux comprises, by mass percent, 0.10%-0.25% of C, 1.0%-1.6% of Si, 1.8%-3% of Mn, 0.5%-1.0% of Cr, 0.3%-1.2% of Ni, 0.2%-0.6% of Mo, 0.03%-0.1% of V, 17.8%-19.2% of aluminum powder, 60%-67% of iron oxide and the balance iron powder. The invention further provides application of the exothermic welding flux to steel rail welding.

Owner:张绵胜 +3

A kind of delustering satin film and its production process

ActiveCN106364102BImprove barrier propertiesImprove moisture resistanceFlexible coversWrappersElastomerPolyolefin

The invention relates to a light extinction silk and satin film and a protection process thereof. The light extinction silk and satin film comprises a layer A, a layer B, a layer C and a layer D which are sequentially compounded. The layer A is prepared from 44 wt% to 46 wt% of homo-polypropylene, 44 wt% to 46 wt% of high density polyethylene and 9 wt% to 11 wt% of block co-polypropylene resin, and the layer B and the layer C are both prepared from 49 wt% to 51 wt% of homo-polypropylene, 44 wt% to 46 wt% of high density polyethylene, 1 wt% to 2 wt% of spherical anti-block agent and 3 wt% to 4 wt% of nanoscale aid, and the layer D is prepared from 85 wt% to 90 wt% of homo-polypropylene and 10 wt% to 15 wt% of polytolefin elastomers. The thickness ratio of the layer A to the layer B to the layer C to the layer D is 60:15:15:10. During production, the main materials of all the layers are added into an extruder, after the main materials are melted, the auxiliary materials of all the layers are added into the extruder for fusion, then melt is extruded to a curtain coating roll, finally, all the layers are compounded into the light extinction silk and satin film, and the both sides of the light extinction silk and satin film are subjected to corona treatment. The light extinction silk and satin film is outstanding in moisture stopping performance, excellent in cold resisting performance, good in heat resisting performance, good in hand feeling and low in gloss, and gives people a noble visual feeling and the effect close to silks and satins.

Owner:永新股份(黄山)包装有限公司

A kind of ketorolac tromethamine injection that reduces irritation and does not contain organic solvents

ActiveCN111481501BImprove complianceImprove comfortOrganic active ingredientsAntipyreticInjection siteIrritation

The invention provides a ketorolac tromethamine injection that reduces irritation and does not contain organic solvents. By using the tromethamine-acidulant buffer system as a protective agent, the adverse effects of ethanol and potassium dihydrogen phosphate on the packaging material and the serious irritation at the injection site in the prior art are avoided. The production process of the invention is simple and controllable, the physical and chemical properties of the medicinal liquid are relatively stable, and the drug safety and compliance of patients can be improved.

Owner:南京锐志生物医药有限公司

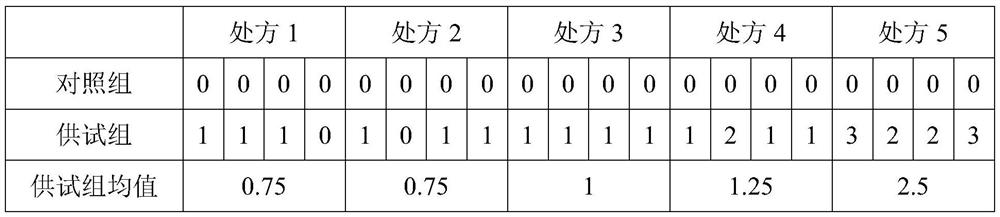

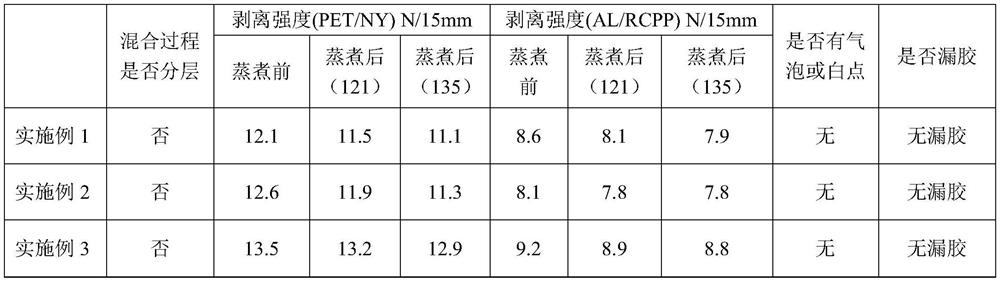

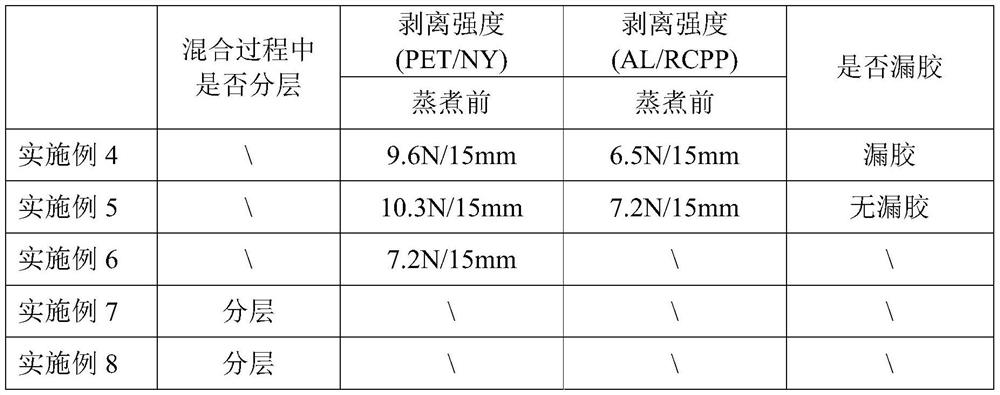

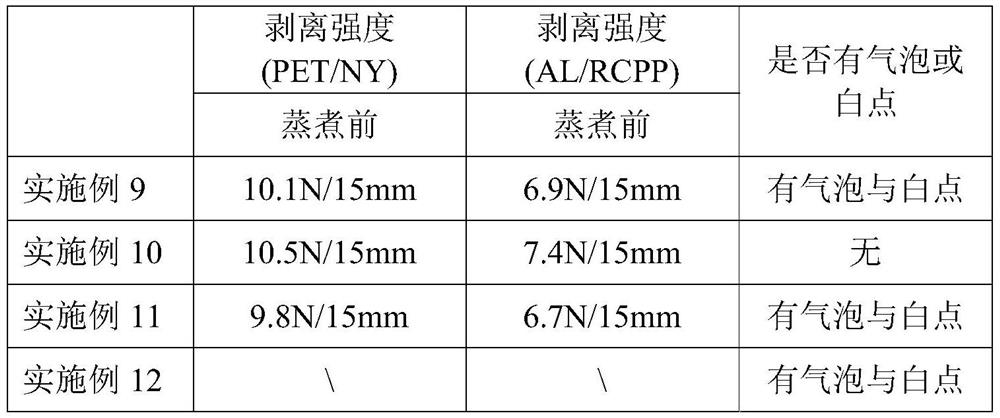

A solvent-free polyurethane adhesive for semi-high temperature resistant and high temperature cooking flexible packaging

ActiveCN111171776BImprove adhesionLow peel strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterEpoxy

The invention relates to the technical field related to polyurethane adhesives. More specifically, the invention provides a solvent-free polyurethane adhesive for semi-high temperature resistant and high-temperature cooking flexible packaging. The preparation raw materials include A component and B component, A component Including the first component polyester polyol, the first component polyether polyol and isocyanate; B component includes the second component polyester polyol and the second component polyether polyol; and the polyol of the first component The number average molecular weight of the ester polyol is greater than that of the polyester polyol of the second component, and the weight ratio of the A component to the B component is 1: (0.3-0.9). The polyurethane adhesive provided by the invention avoids the peeling strength reduction or delamination of the composite material after high-temperature cooking, and can also effectively reduce the presence of bubbles or white spots in the composite structure obtained. During the preparation of aluminum foil composite materials, the problem of glue leakage will occur.

Owner:HUZHOU OCHEM CHEM

A method for transforming and reusing old cotton

InactiveCN102758378BReduce consumptionAcid-base decreaseVegetable materialSecondary cellulose fibresFiberAcid washing

Owner:徐奎元 +1

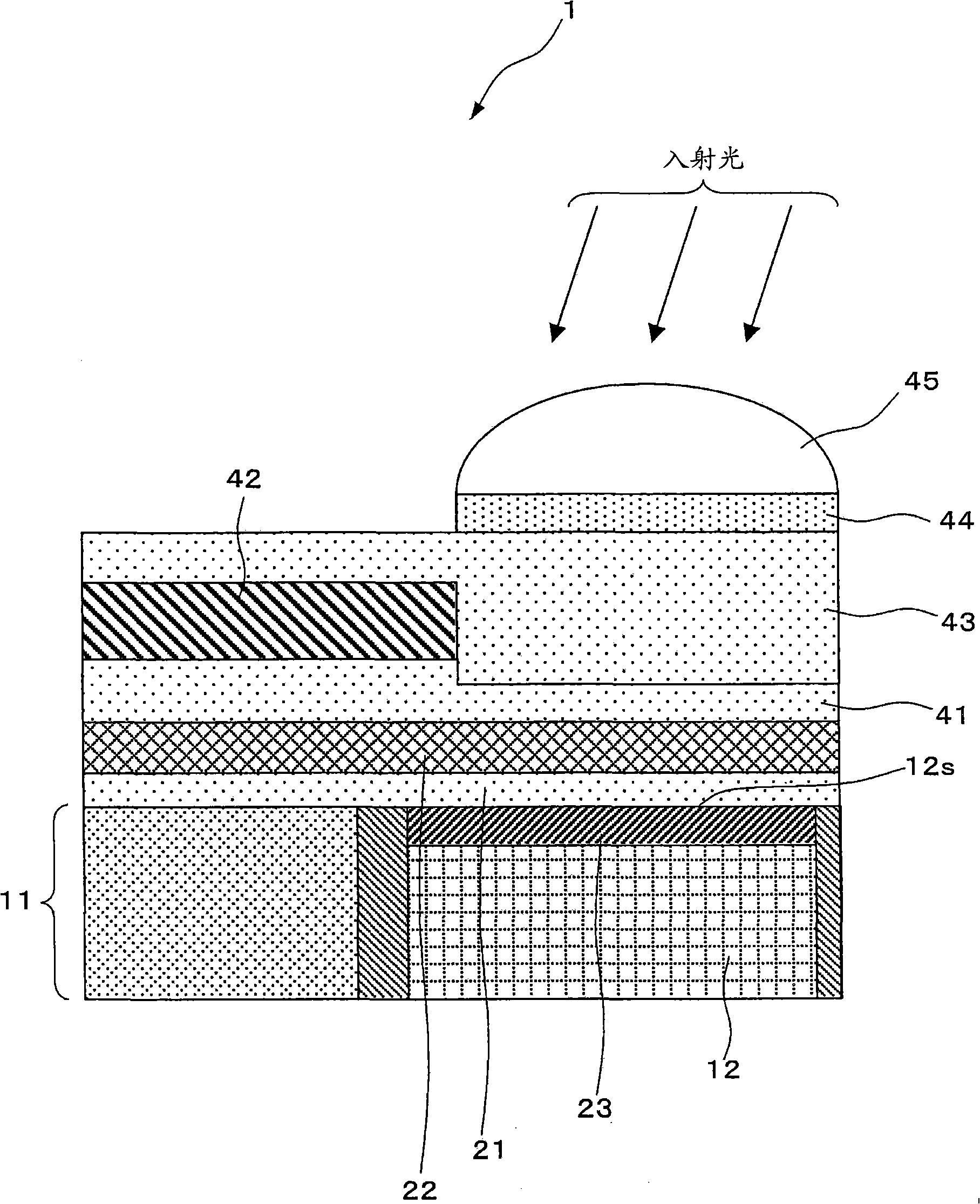

A cmos image sensor and its manufacturing method

The invention provides a CMOS-type image sensor and a manufacturing method therefor. The CMOS-type image sensor comprises a second oxidation layer and a substrate located at one side of the oxidationlayer. A first trench which is recessed downwards to the second oxidation layer is formed at one side of the substrate. The substrate and the first trench are sequentially provided with an HIK layer and a first oxidation layer from the top to the bottom. A wiring groove which passes through the first oxidation layer, a high dielectric film layer and a part of the second oxidation layer is formed on the first trench which is provided with the high dielectric film layer and the first oxidation layer. The first oxidation layer and the interior of the wiring groove are provided with first metal layers. The first metal layer on of the wiring groove is provided with an aluminum wiring board, and the aluminum wiring board is electrically connected with the high dielectric film layer which is exposed by the side wall of the wiring groove through the first metal layer in the wiring groove, so as to provide a voltage for the high dielectric film layer when a voltage is applied to the aluminum wiring board, to generate a bigger potential difference between the high dielectric film layer and the substrate, to enable the substrate to have the stronger capability of electron constraint, and to reduce the white points and dark currents.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

Method for inhibiting crystal growth rate of amide compound and method for producing molded article of polyolefin-based resin

ActiveUS20120035304A1Improve productivitySuppressing increase in pressure of moldingOrganic chemistryPolyolefinCrystal growth rate

A method for inhibiting the crystal growth rate of an amide compound present in a molten polyolefin-based resin and a method for producing a polyolefin-based resin molded article are provided.A phenol compound is incorporated into an amide compound-containing polyolefin-based resin such that a weight ratio, amide compound:phenol compound, is 60:40 to 10:90.

Owner:NEW JAPAN CHEM CO

A voltage control method for an electrochromic device

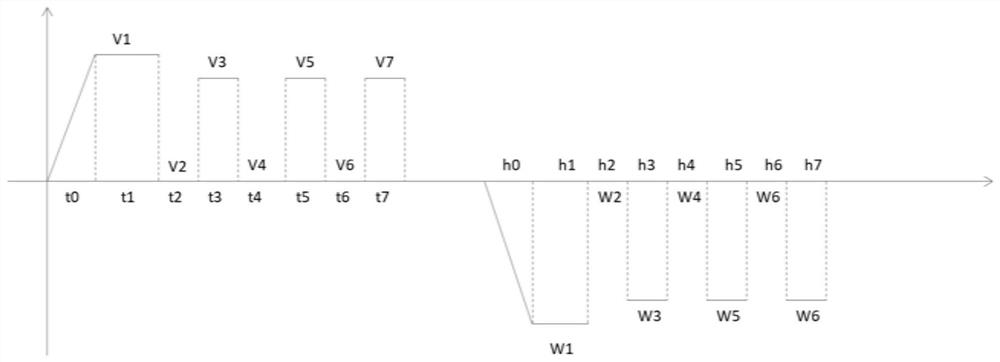

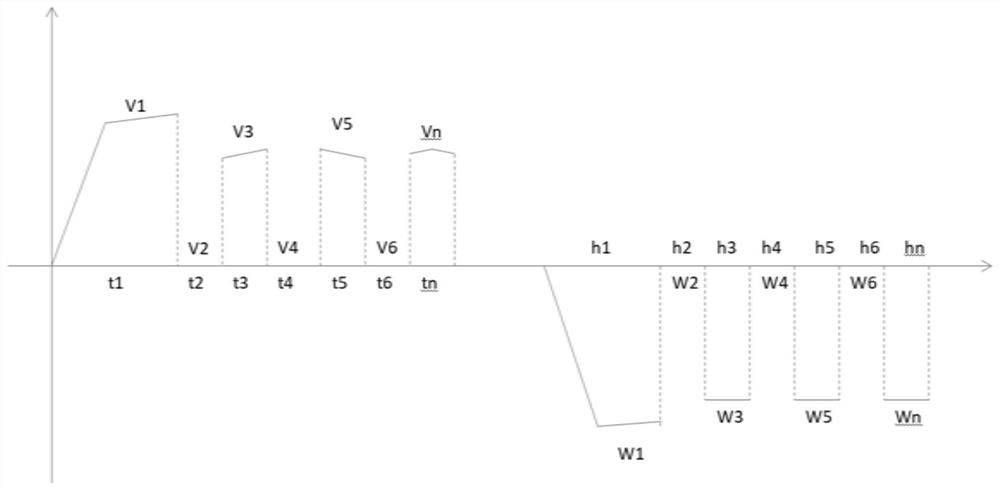

ActiveCN109375446BExtend your lifeEffective use of memory effectsNon-linear opticsMemory effectPulse voltage

The invention provides a voltage control method of an electrochromic device. Both the coloring process and the fading process are driven by a pulse voltage, and the pulse voltage is applied instead of a continuous voltage to maintain the coloring and fading state of the electrochromic device, which can effectively use the electric current. The memory effect of the electrochromic device itself, in the same working time, the device driven by the pulse voltage, the film layer withstand voltage time will be much shorter than the device driven by the continuous voltage, and the life of the electrochromic device is the same as that of the film layer. The time of the voltage is related, so the pulse driving can effectively prolong the life of the device.

Owner:安徽威迪智能玻璃有限公司

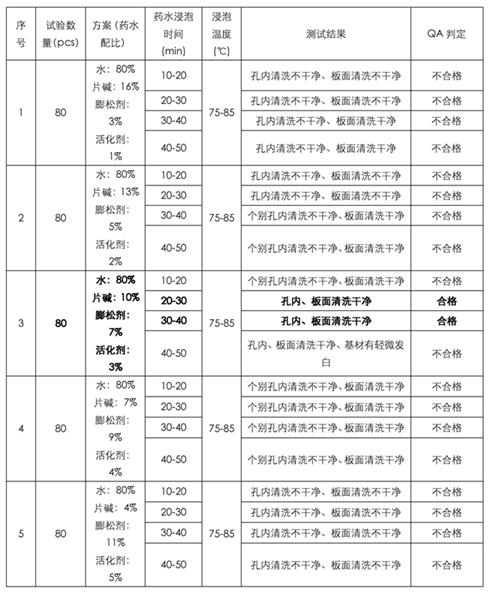

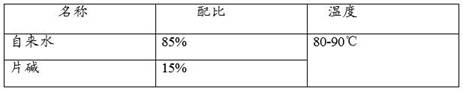

Solder resist film removal method and solder resist film removal solution

ActiveCN113194627BReduce surface tensionEasy accessPrinted circuit liquid treatmentNon-metallic protective coating applicationCold airSolder mask

Owner:TEAN ELECTRONICS DA YA BAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com