Linear metallocene PE modified compound additive

A metallocene polyethylene and composite additive technology, applied in the field of linear metallocene polyethylene modified composite additives, can solve the problems of unstable operation of the device, blocked delivery pipeline, low melting point, etc., and achieve the goal of overcoming pipeline blockage and continuous and stable production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

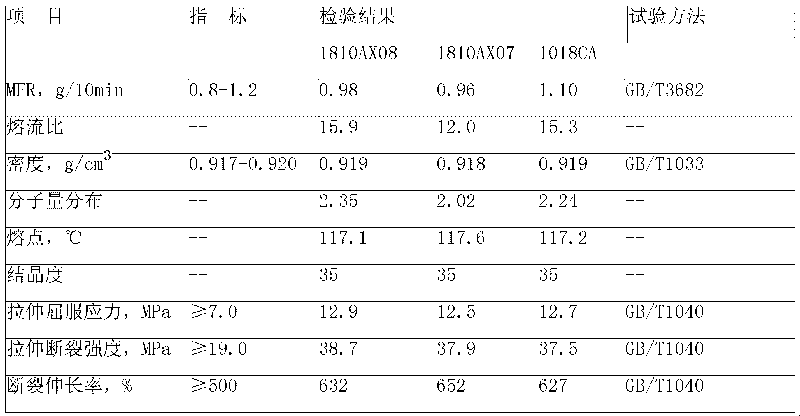

Embodiment 1

[0025] The linear metallocene polyethylene modified composite additive of the present invention is composed of the following components in parts by weight: 10 parts of hindered phenol primary antioxidant CA, 45 parts of phosphate auxiliary antioxidant 626, and plastic processing aid PPA FX -5920 20 copies.

Embodiment 2

[0027] The linear metallocene polyethylene modified composite additive of the present invention is composed of the following components in parts by weight: 20 parts of hindered phenol primary antioxidant 425, 60 parts of phosphate auxiliary antioxidant 618, plastic processing aid FX- 9366 PPA 30 copies.

Embodiment 3

[0029] The linear metallocene polyethylene modified composite additive of the present invention is composed of the following components in parts by weight: 15 parts of hindered phenol primary antioxidant 1076, 45 parts of phosphate auxiliary antioxidant 168, plastic processing aid PPA FX -5911 25 copies.

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com