A kind of delustering satin film and its production process

A production process and satin technology, which is applied in the field of matte satin film and its production process, can solve the problems of lack of competitiveness and affect the development of CPP film, etc., and achieve the effect of noble visual experience, good hand feeling and excellent barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add the main materials in each layer of A, B, C, and D to the extruder respectively, and then add the auxiliary materials in each layer of A, B, C, and D after the main materials in each layer are melted Melt in the extruder, then extrude the molten material of the main material and auxiliary material onto the casting roll, and then pass through the cooling roll for cooling treatment, and finally the layers of A, B, C, and D are combined to form the matte satin film , and corona treatment is carried out on both sides of the matte satin film; the melt processing temperature in the extruder and the die head processing temperature are both 215°C; the temperature of the casting roll is 28°C, and the cooling The temperature of the rolls was 35°C.

[0021] The A layer includes 44wt% homopolypropylene, 44wt% high density polyethylene, and 9wt% block copolymerized polypropylene resin, and the B and C layers both include 49wt% homopolypropylene, 44wt% high Density polyethylene,...

Embodiment 2

[0023] This embodiment is identical with embodiment 1 process, only process parameter has been adjusted, specifically:

[0024] The A layer includes 46wt% homopolypropylene, 46wt% high density polyethylene, and 11wt% block copolymerized polypropylene resin, and the B and C layers both include 51wt% homopolypropylene, 46wt% high Density polyethylene, 2wt% spherical opening agent, and 4wt% nanoscale additives, the D layer includes 90wt% homopolypropylene, 15wt% polyolefin elastomer; the A layer, B layer, C The thickness ratio of layer and D layer is 61:16:16:11.

Embodiment 3

[0026] This embodiment is identical with embodiment 1 process, only process parameter has been adjusted, specifically:

[0027] The A layer includes 45wt% homopolypropylene, 45wt% high density polyethylene, and 10wt% block copolymerized polypropylene resin, and the B and C layers both include 50wt% homopolypropylene, 45wt% high Density polyethylene, 1.5wt% spherical opening agent, and 3.5wt% nanoscale additives, the D layer includes 88wt% homopolypropylene, 12wt% polyolefin elastomer; the A layer, B layer , C layer, D layer thickness ratio is 60:15:15:10.

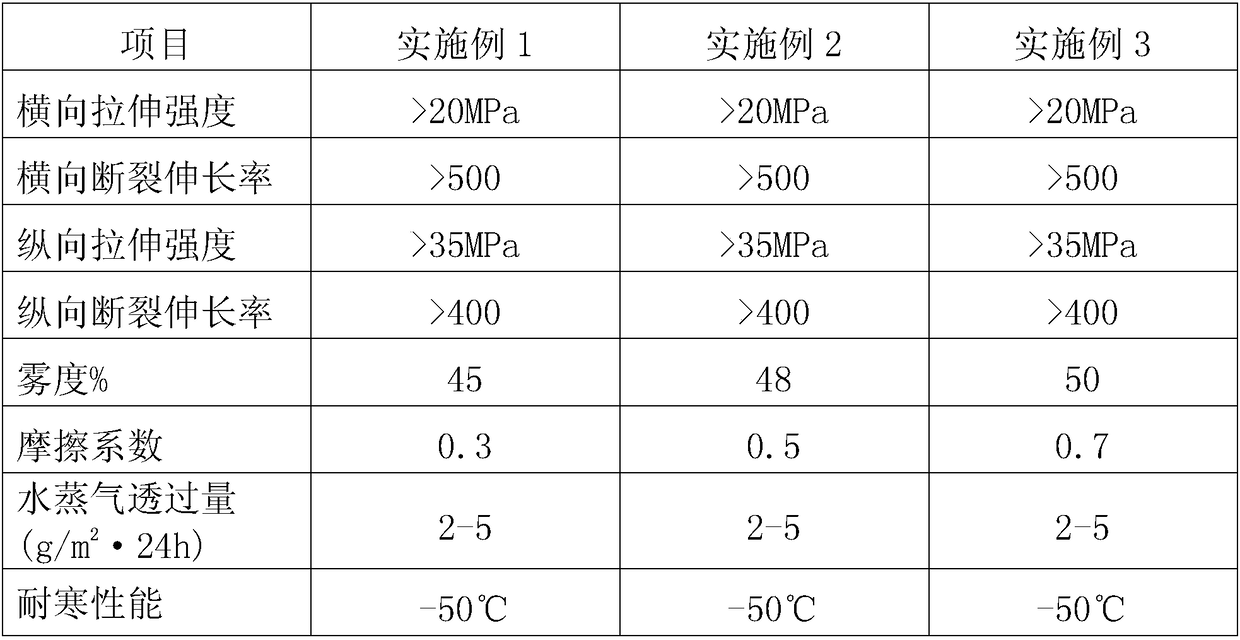

[0028] The main performance parameters of the matting satin film produced according to the foregoing embodiments are shown in the table below:

[0029]

[0030] The above tensile strength parameters show that the film has good toughness and good tensile strength; the elongation at break parameter shows that the film has a good puncture resistance; the haze parameter shows that the film has low gloss, and the appearance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com