A solvent-free polyurethane adhesive for semi-high temperature resistant and high temperature cooking flexible packaging

A solvent-free polyurethane, high-temperature cooking technology, used in polyurea/polyurethane adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the phenomenon of delamination, glue leakage, composite structure bubbles or white Points and other problems, to achieve good bonding effect, reduce the effect of air bubbles or white spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

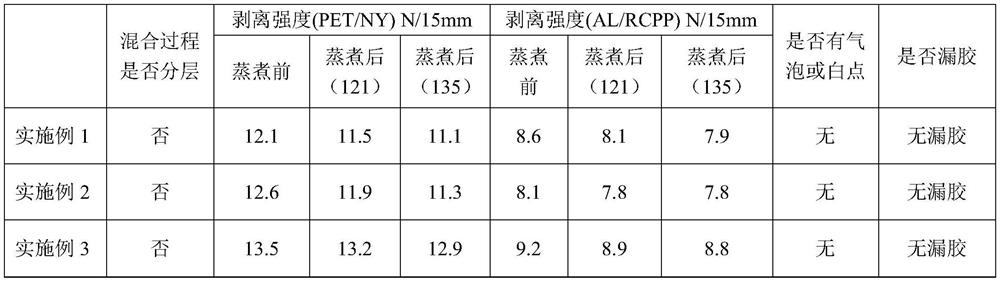

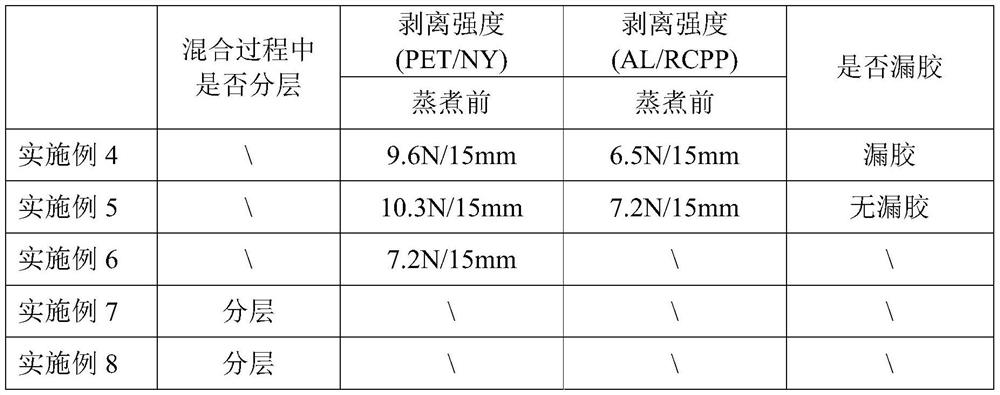

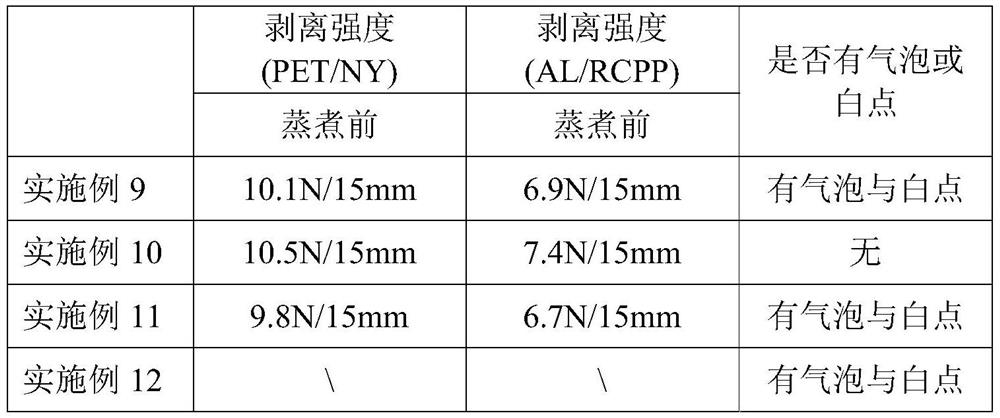

Examples

preparation example Construction

[0048] The second aspect of the present invention provides a method for preparing the solvent-free polyurethane adhesive for semi-high temperature resistant and high temperature cooking flexible packaging, comprising the following steps:

[0049](1) Add the first component of polyester polyol, the first component of polyether polyol and isocyanate into the reactor, heat and reduce pressure, dehydrate, feed nitrogen, and then react at 110-130°C for 3- 6h, get A component;

[0050] (2) Put component A into roller 1, put component B into roller 2 and mix well, set aside.

Embodiment 1

[0052] Embodiment 1 of the present invention provides a solvent-free polyurethane adhesive for flexible packaging, its preparation raw materials include A component and B component, A component includes the first component polyester polyol, the first component polyether polyol Alcohol and isocyanate; B component includes the second component polyester polyol and the second component polyether polyol; the weight ratio of A component to B component is 1:0.3;

[0053] The weight ratio of the first component polyester polyol, the first component polyether polyol and isocyanate in component A is 1:2.2:2.1; the second component polyester polyol and the second component in B component The weight ratio of the component polyether polyol is 1:3.2;

[0054] The first component polyether polyol is VORANOL 400LM and VORANOL T5001; the weight ratio of VORANOL 400LM and VORANOL T5001 is 1:0.08; the second component polyether polyol is VORANOL 2110TB and VORANOLT5001; the weight ratio of VORA...

Embodiment 2

[0068] Embodiment 2 of the present invention provides a solvent-free polyurethane adhesive for flexible packaging, its preparation raw materials include A component and B component, A component includes the first component polyester polyol, the first component polyether polyol Alcohol and isocyanate; B component includes the second component polyester polyol and the second component polyether polyol; the weight ratio of A component to B component is 1:0.9;

[0069] The weight ratio of the first component polyester polyol in component A, the first component polyether polyol and isocyanate is 1:3.9:3; the second component polyester polyol in component B and the second The weight ratio of the component polyether polyol is 1:4.8;

[0070] The first component polyether polyol is VORANOL 400LM and VORANOL T5001; the weight ratio of VORANOL 400LM and VORANOL T5001 is 1:0.17; the second component polyether polyol is VORANOL 2110TB and VORANOLT5001; the weight ratio of VORANOL 2110TB a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com