Patents

Literature

52results about How to "Reduce gel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spray-dried, mixed metal ziegler catalyst compositions

ActiveUS20070060725A1Improve productivityImproved catalyst homogeneityMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsZiegler–Natta catalystTitanium

A Ziegler-Natta catalyst composition comprising a solid mixture formed by halogenation of: Al) a spray-dried catalyst precursor comprising the reaction product of a magnesium compound, a non-metallocene titanium compound, and at least one non-metallocene compound of a transition metal other than titanium, with A2) an organoaluminium halide halogenating agent, a method of preparing, precursors for use therein, and olefin polymerization processes using the same.

Owner:UNION CARBIDE CORP

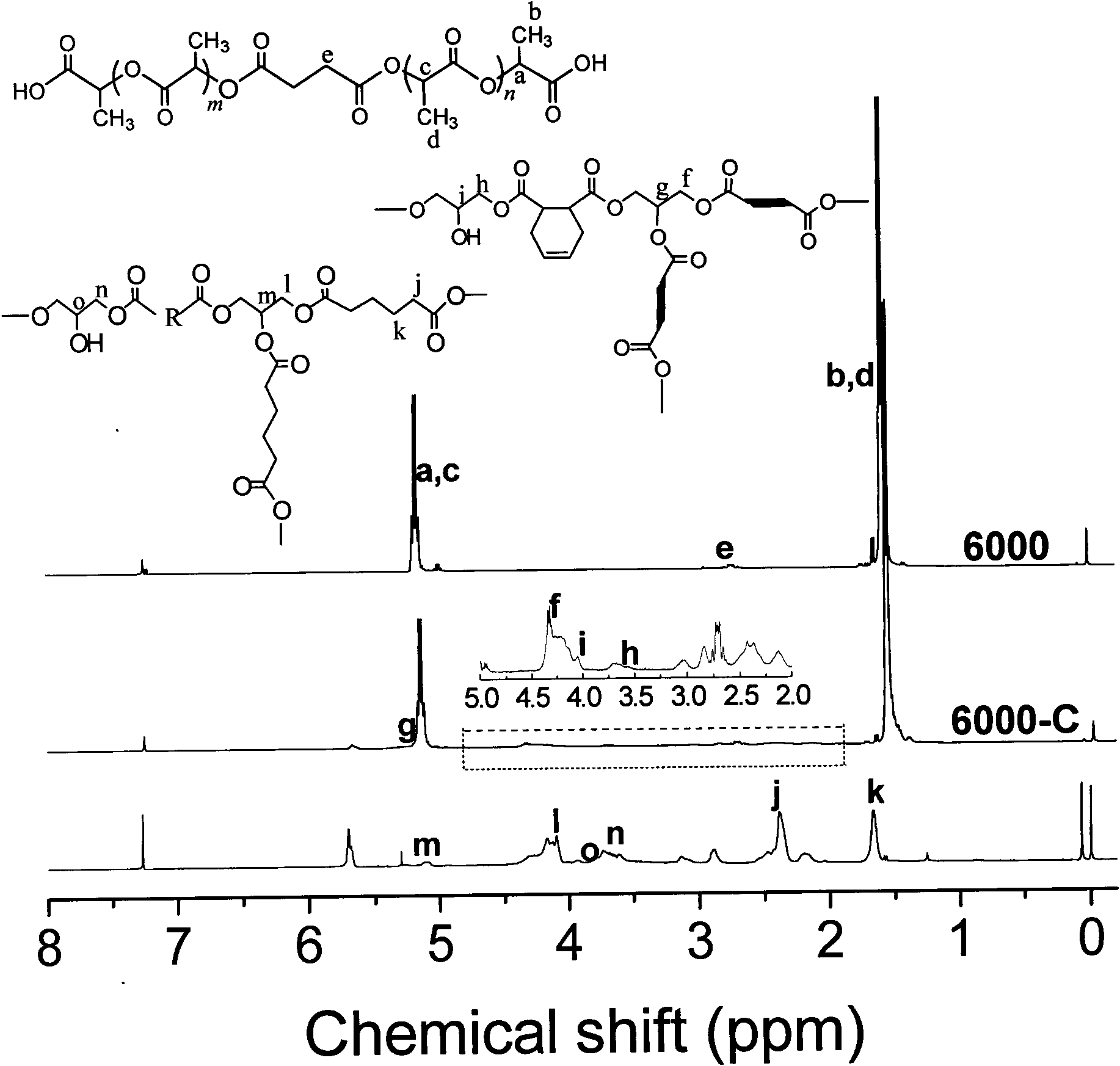

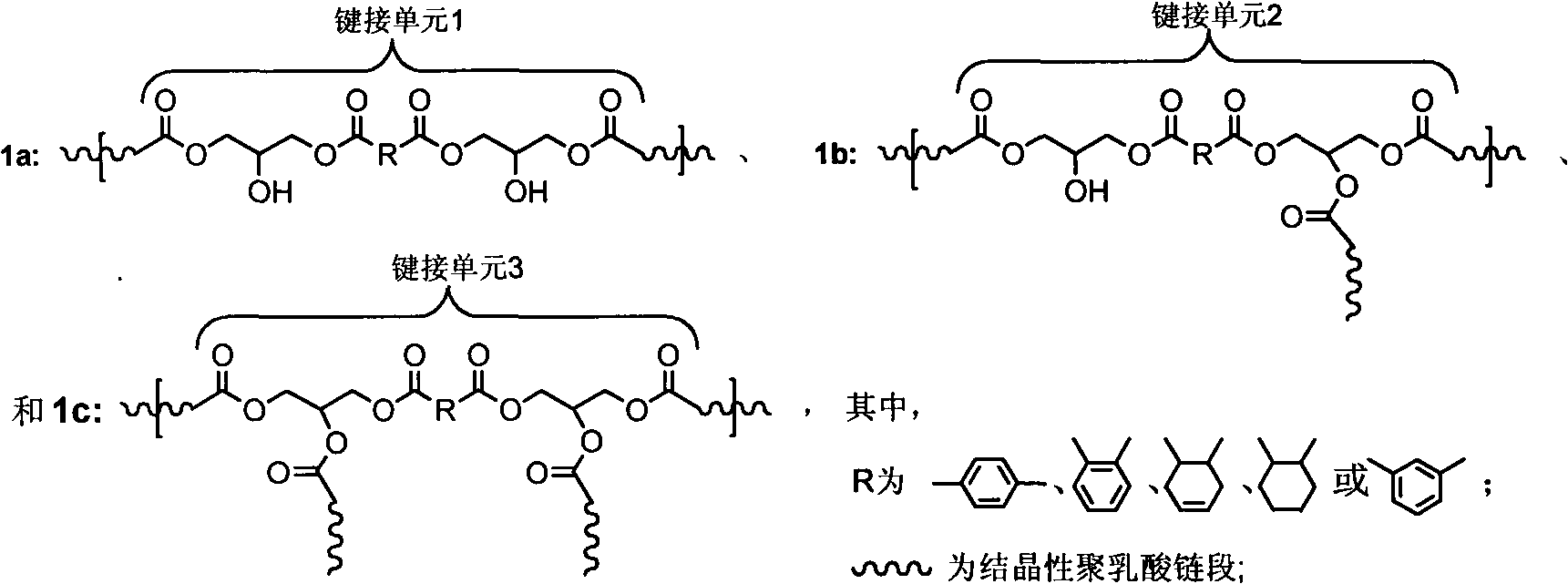

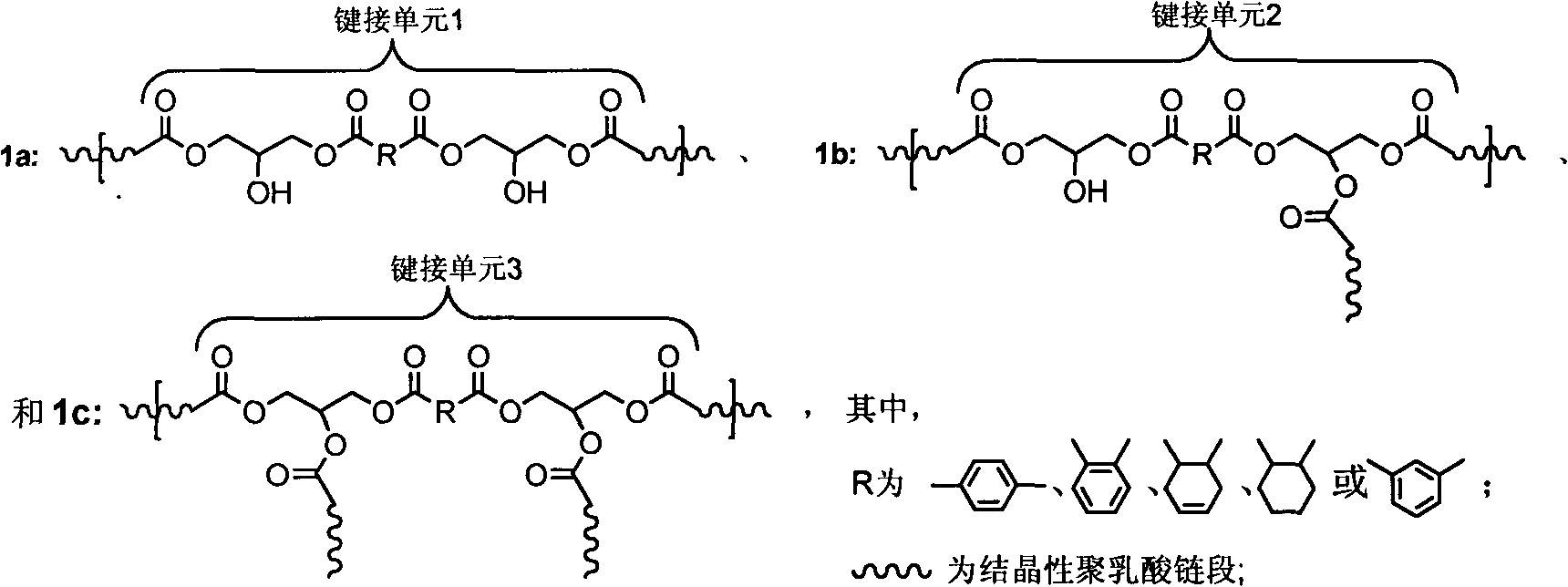

High-molecular weight long-chain branched crystalline polylactic acid material and preparation method thereof

The invention discloses a high-molecular weight long-chain branched crystalline polylactic acid material and a preparation method thereof. The preparation method comprises the following steps of: 1) adding 0.1 to 1 percent of protonic acid catalyst into aqueous solution of lactic acid or mixed solution of the aqueous solution of the lactic acid and silicon dioxide nano particle silica sol containing 0.1 to 10 weight percent of lactic acid, and dehydrating to obtain a product I; 2) adding 0.4 to 2 molar percent of dibasic acid or anhydride into the product I, and reacting to obtain a product II; 3) adding 0.1 to 1 weight percent of lewis acid catalyst into the product II, performing melt polycondensation, and adding 0.1 to 5 weight percent of crystallization accelerator to obtain terminal carboxyl group crystalline polylactic acid prepolymers; and 4) reacting diglycidyl ester and the terminal carboxyl group crystalline polylactic acid prepolymers in a molar ratio of 0.8:1-1.2:1 to obtain the high-molecular weight long-chain branched crystalline polylactic acid material. The preparation method has the advantages of simplicity, short reaction time, high efficiency, low cost and environmental friendliness and capability of contributing to realizing commercialization.

Owner:ZHEJIANG UNIV

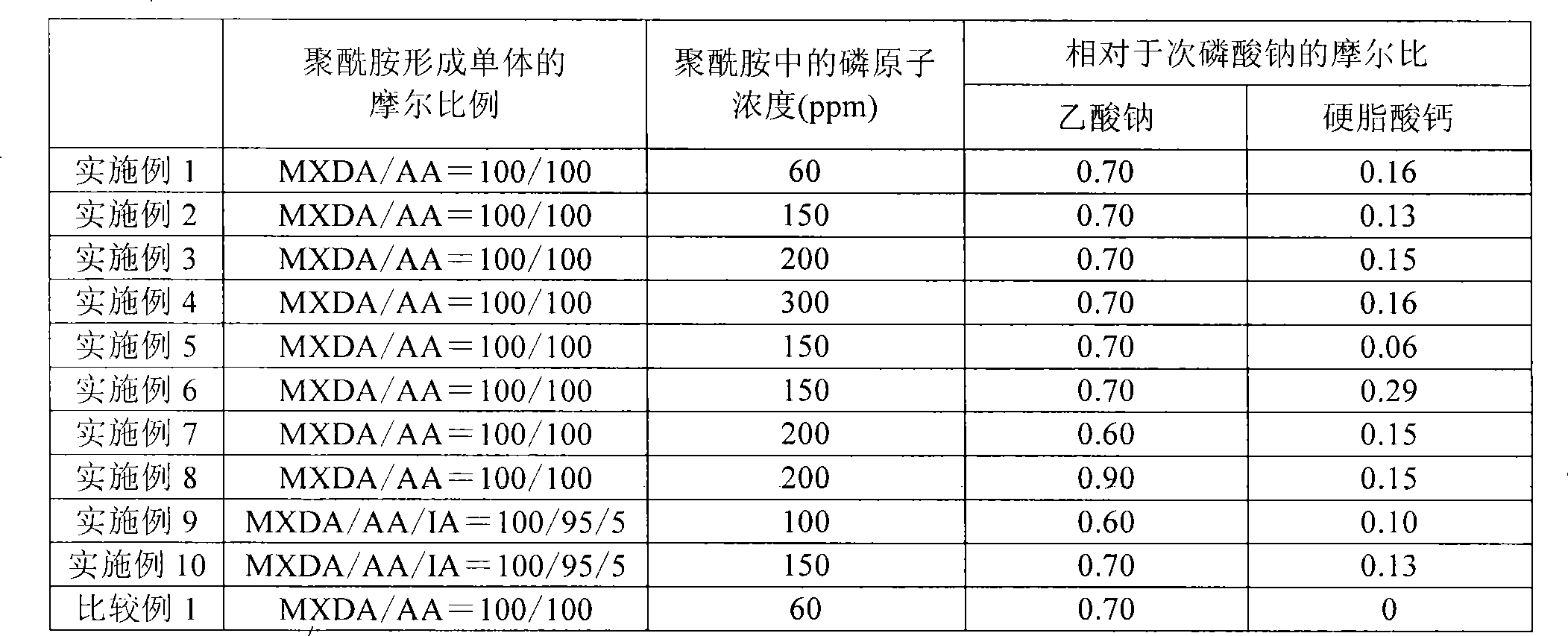

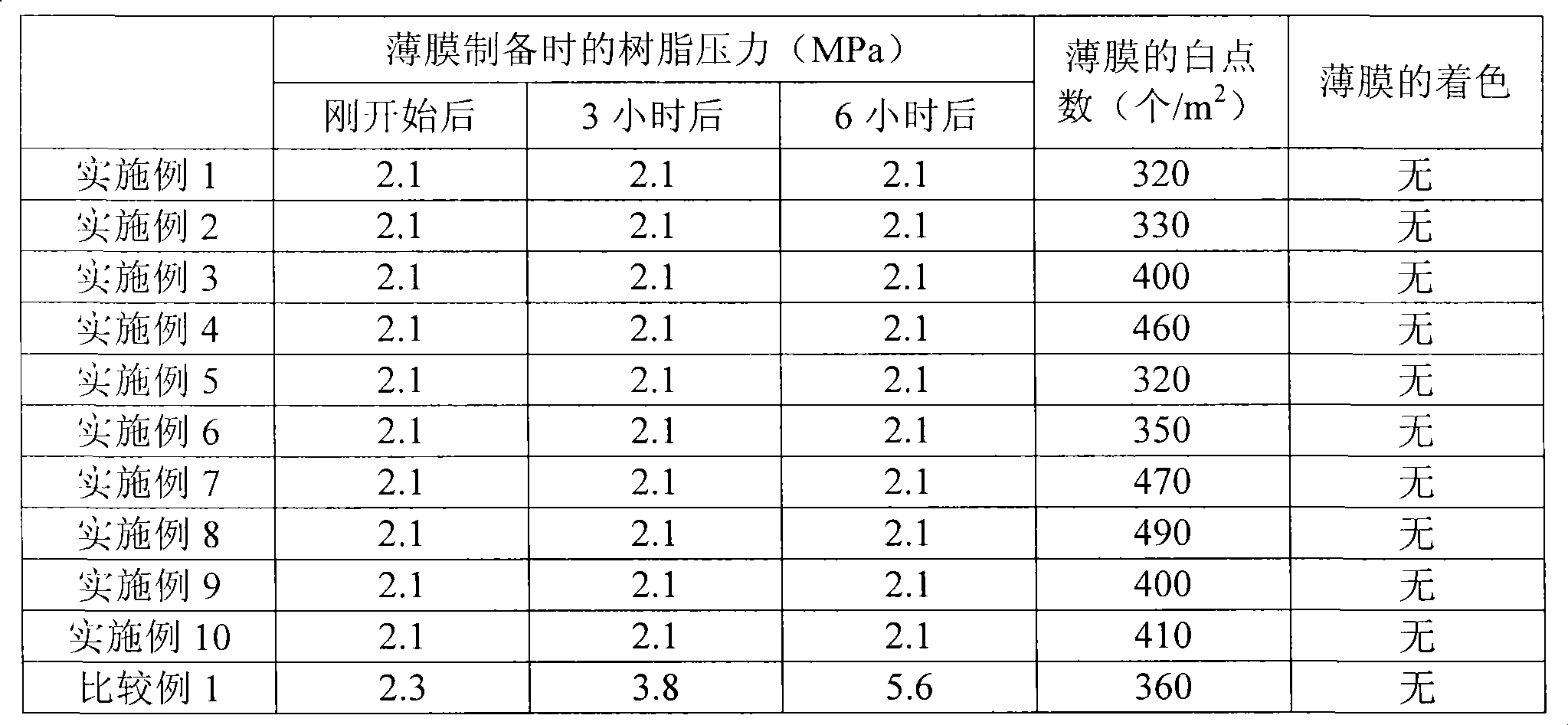

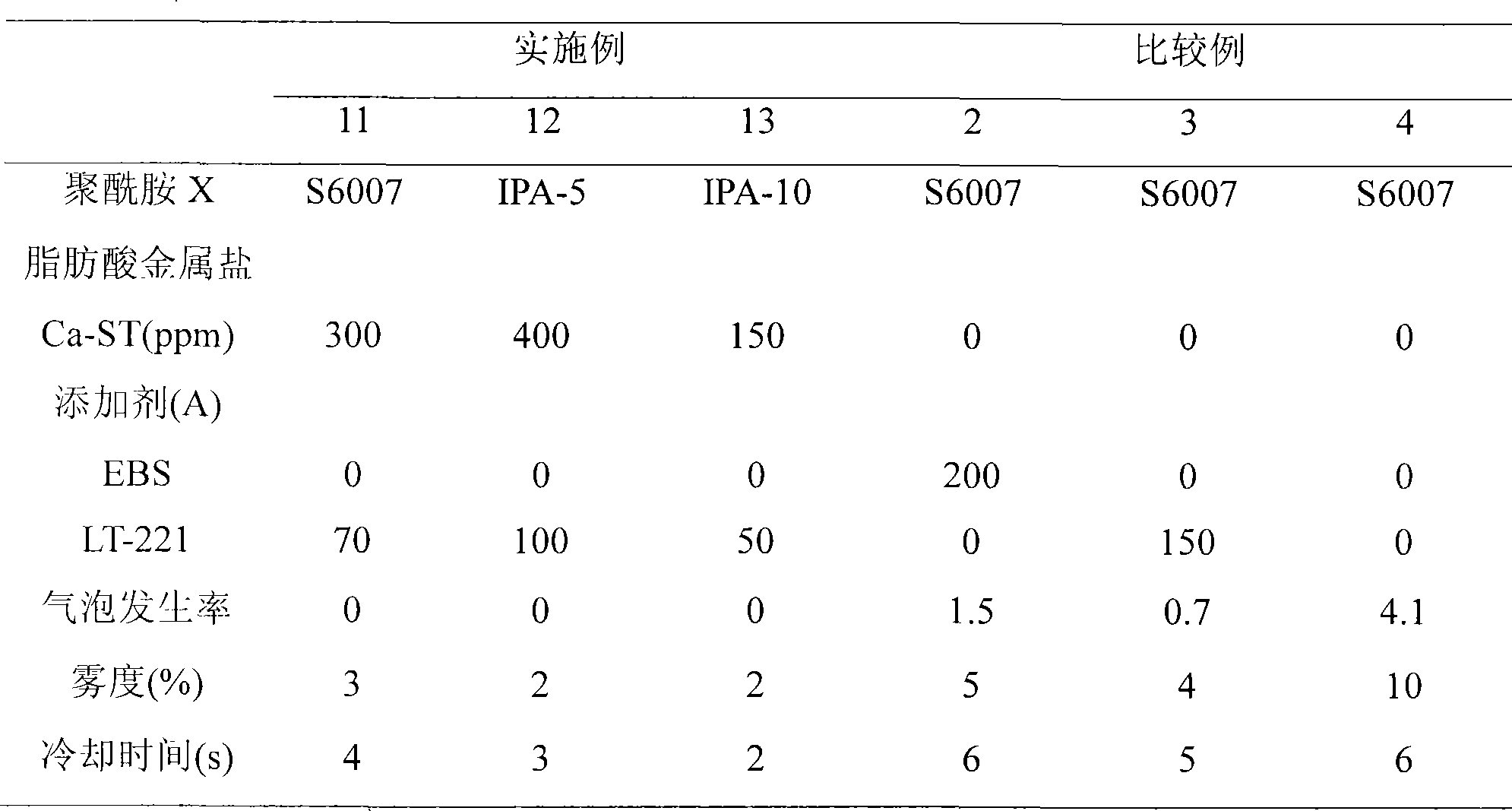

Polyamide resin composition

Disclosed is a polyamide resin composition comprising a resin component containing at least a polyamide (X) and a fatty acid metal salt having 10-50 carbon atoms. This polyamide resin composition may optionally contain an additive (A) and / or an additive (B). The polyamide (X) is obtained by melt polycondensation of a diamine component containing not less than 70 mol% of meta-xylylenediamine and a dicarboxylic acid component containing not less than 70 mol% of an alpha,omega-linear aliphatic dicarboxylic acid. The additive (A) is composed of one or more compounds selected from the group consisting of diamide compounds obtained from a fatty acid having 8-30 carbon atoms and a diamine having 2-10 carbon atoms, diester compounds obtained from a fatty acid having 8-30 carbon atoms and a diol having 2-10 carbon atoms, and surface active agents. The additive (B) is composed of one or more compounds selected from the group consisting of metal hydroxides, metal acetates, metal alkoxides, metal carbonates, and fatty acids.

Owner:MITSUBISHI GAS CHEM CO INC

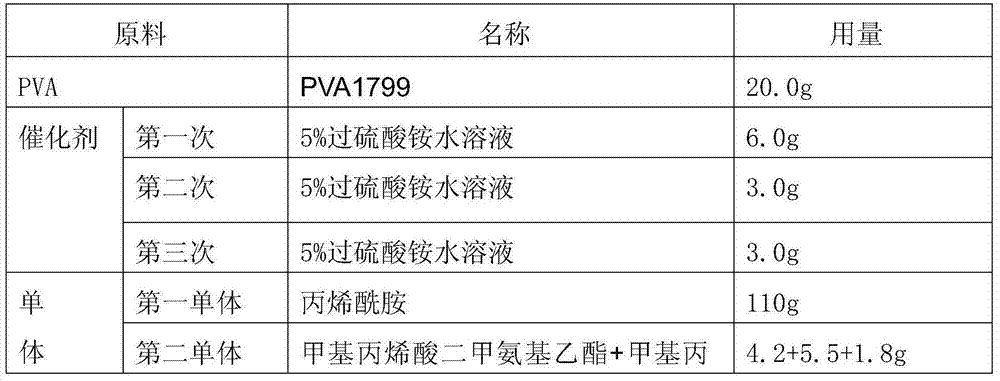

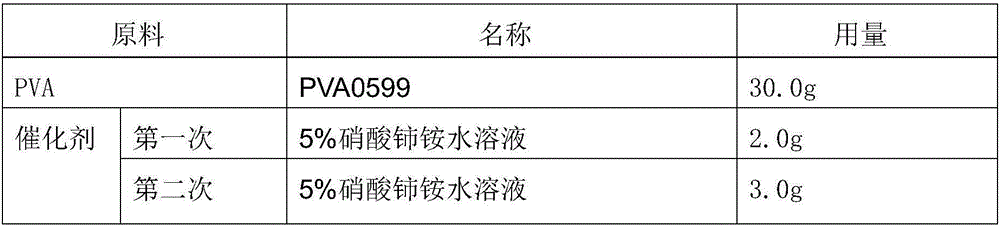

High-branch type polyvinyl alcohol-acrylamide graft copolymer, preparing method thereof and applications of the copolymer

ActiveCN104119480AIncrease the lengthReduce homopolymerizationReinforcing agents additionPaper/cardboardInterference resistancePapermaking

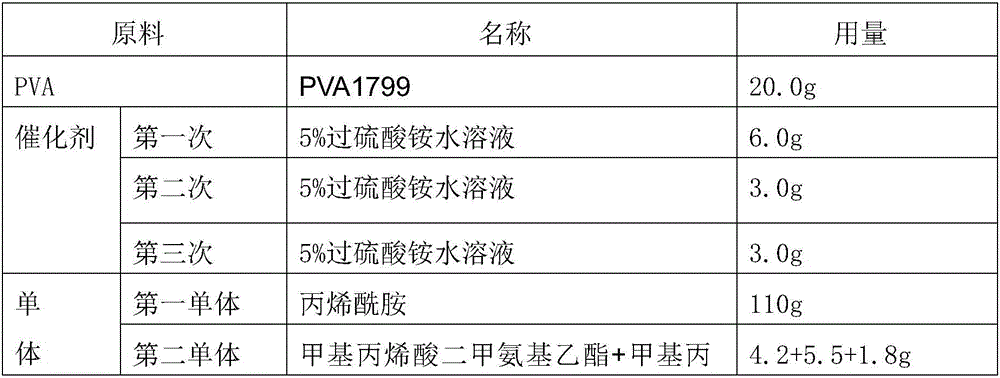

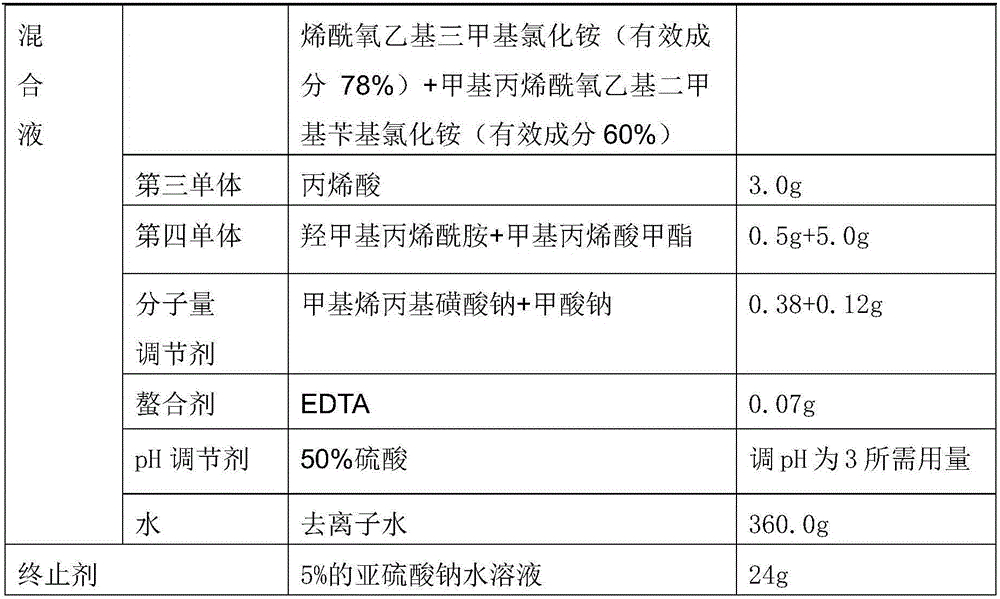

The invention relates to a preparing method of a high-branch type polyvinyl alcohol-acrylamide graft copolymer. The preparing method includes: dissolving polyvinyl alcohol with water, feeding nitrogen, cooling, adding a catalyst, reacting for 10-30 min, adding dropwise a monomer mixture solution with the adding time being controlled to be 30-90 min and the reaction temperature during addition being controlled to be 65-95 DEG C, reacting at 85-95 DEG C for 20-30 min after the addition is finished, adding the catalyst, reacting at 80-95 DEG C for 15-25 min, adding the catalyst, sampling in the reaction process and measuring viscosity, adding a terminating agent when the viscosity at 25 DEG C reaches 1500-15000 mPa*s to stop the reaction, and adjusting the solid content. The graft copolymer has characteristics of high molecular weight, more branches, low viscosity, less gel, good retention property, and high interference resistance to hetero-ion, and can achieve satisfied enhancing effects even when being used as a papermaking dry strength agent in a bad high-temperature high-conductivity environment for manufacturing paper with pulp.

Owner:九洲生物技术(苏州)有限公司

Polyamide resin composition

A polyamide resin composition comprising: a polyamide (X) having a diamine constituent unit which mainly comprises a metaxylylenediamine unit and a dicarboxylate constituent unit which mainly comprises an adipate constituent unit; and specific amounts of a phosphate-type antioxidant and alkaline component. The polyamide (X) is characterized by a specific terminal group concentration balance and a specific amino group reaction rate. By using the polyamide resin composition, both of the prevention of yellow discoloration and the reduction of gelatinization or fisheye formation can be achieved.

Owner:MITSUBISHI GAS CHEM CO INC

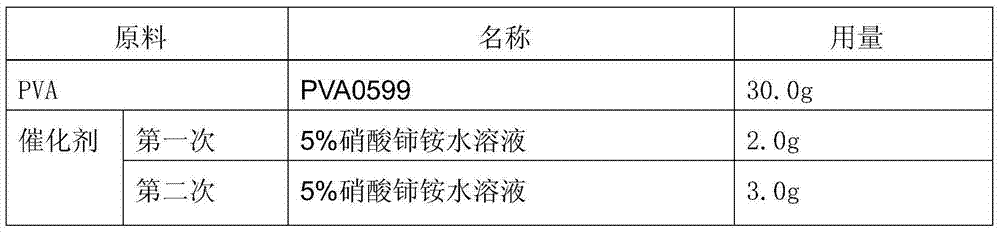

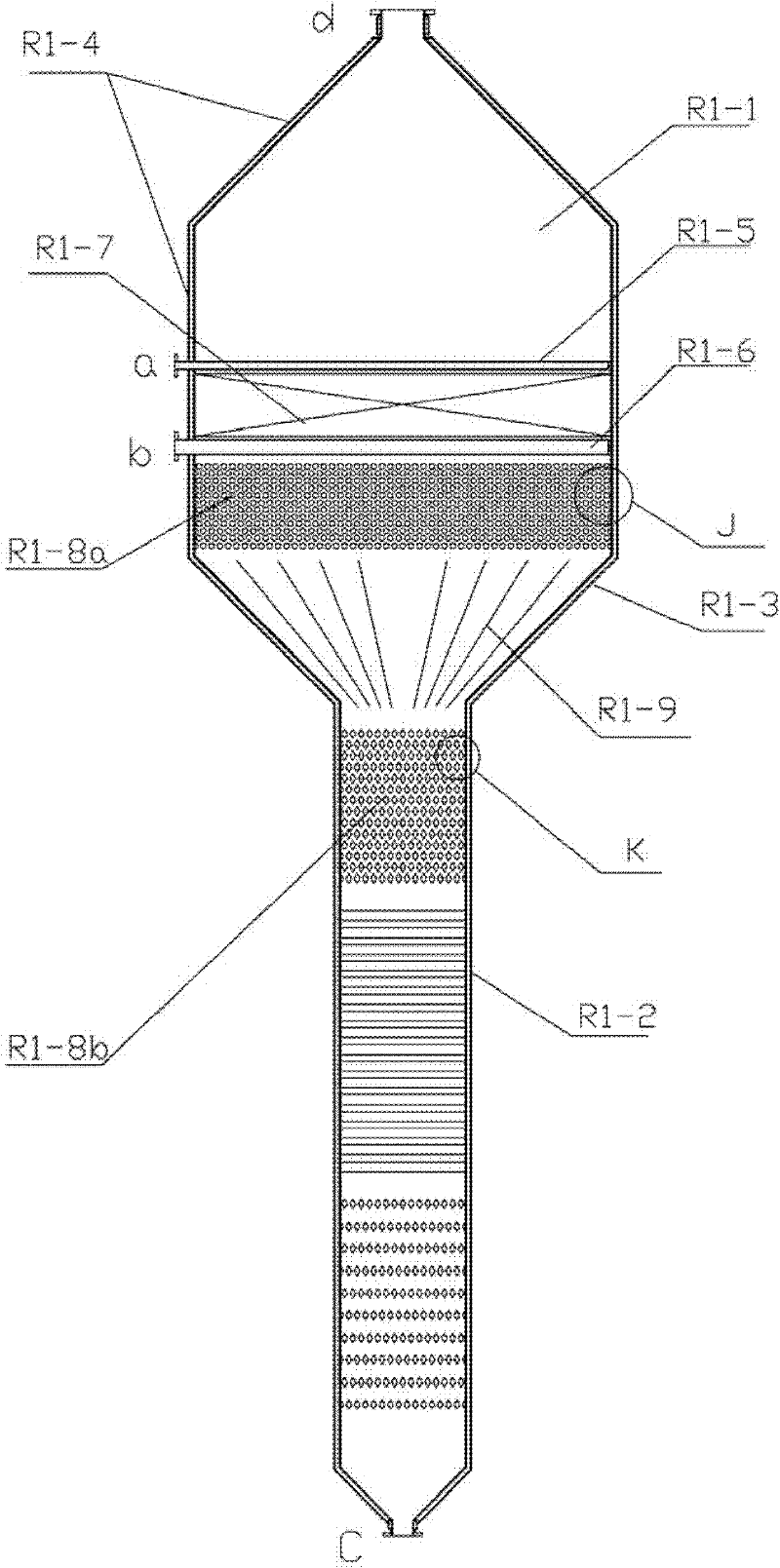

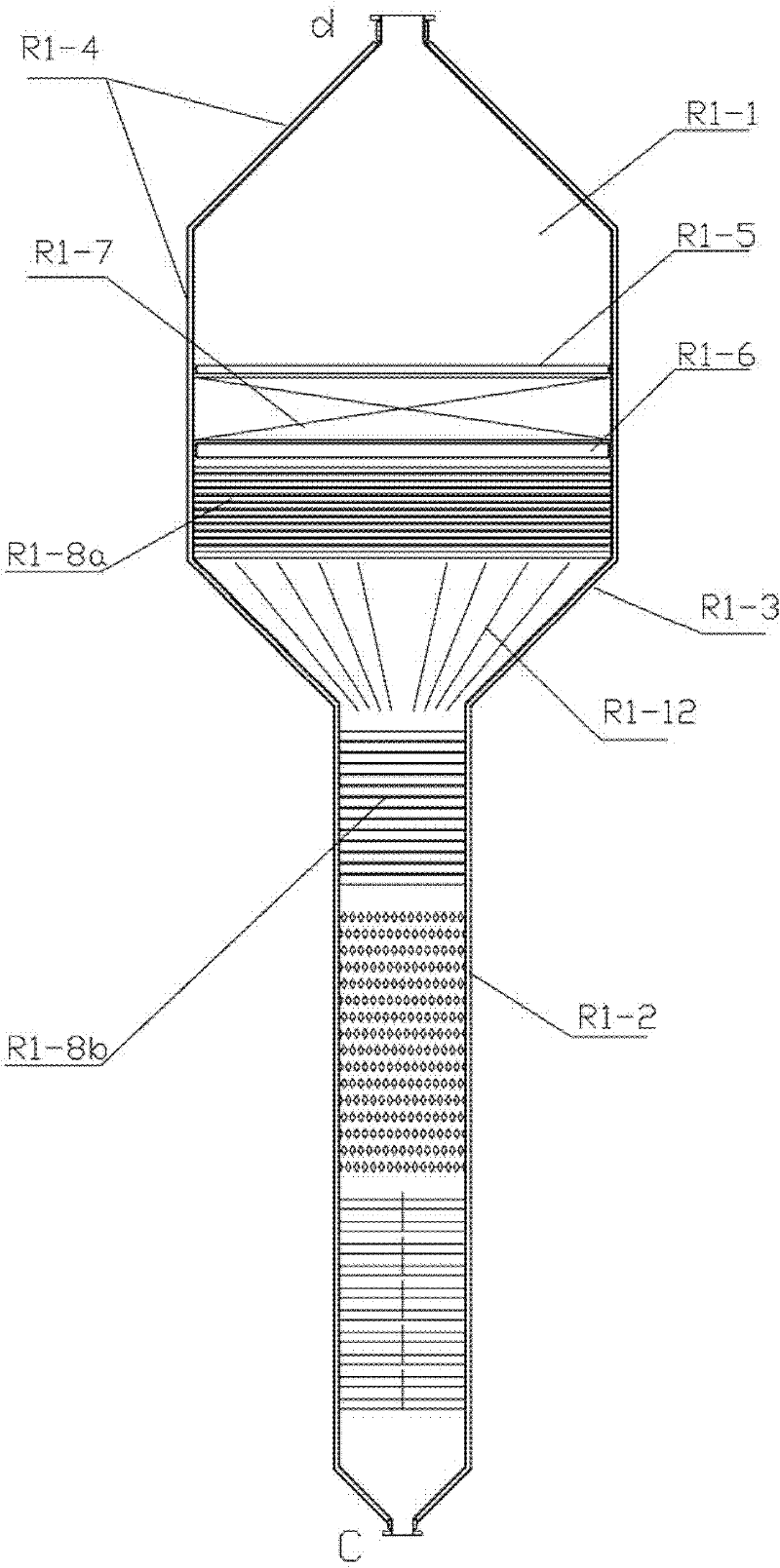

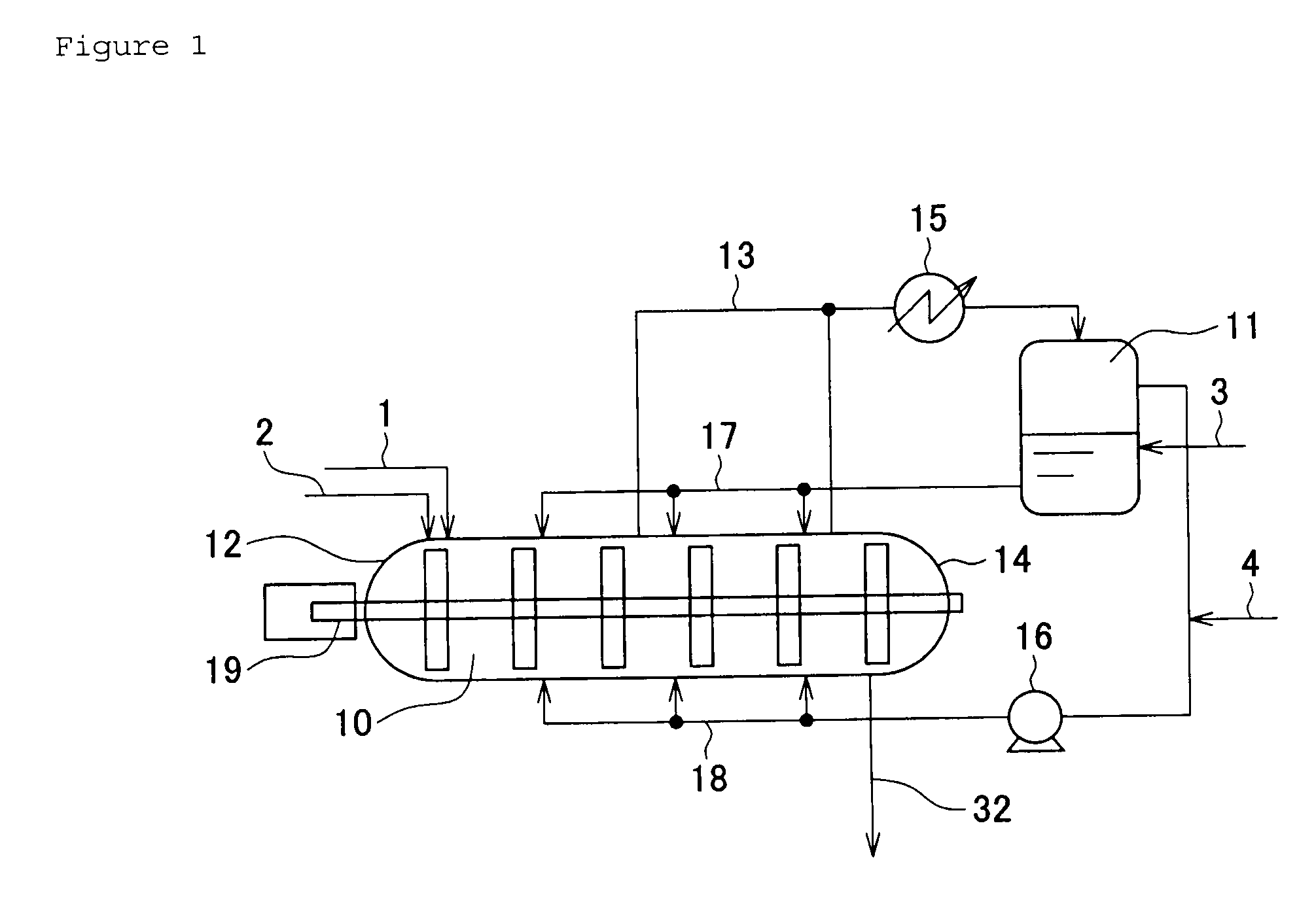

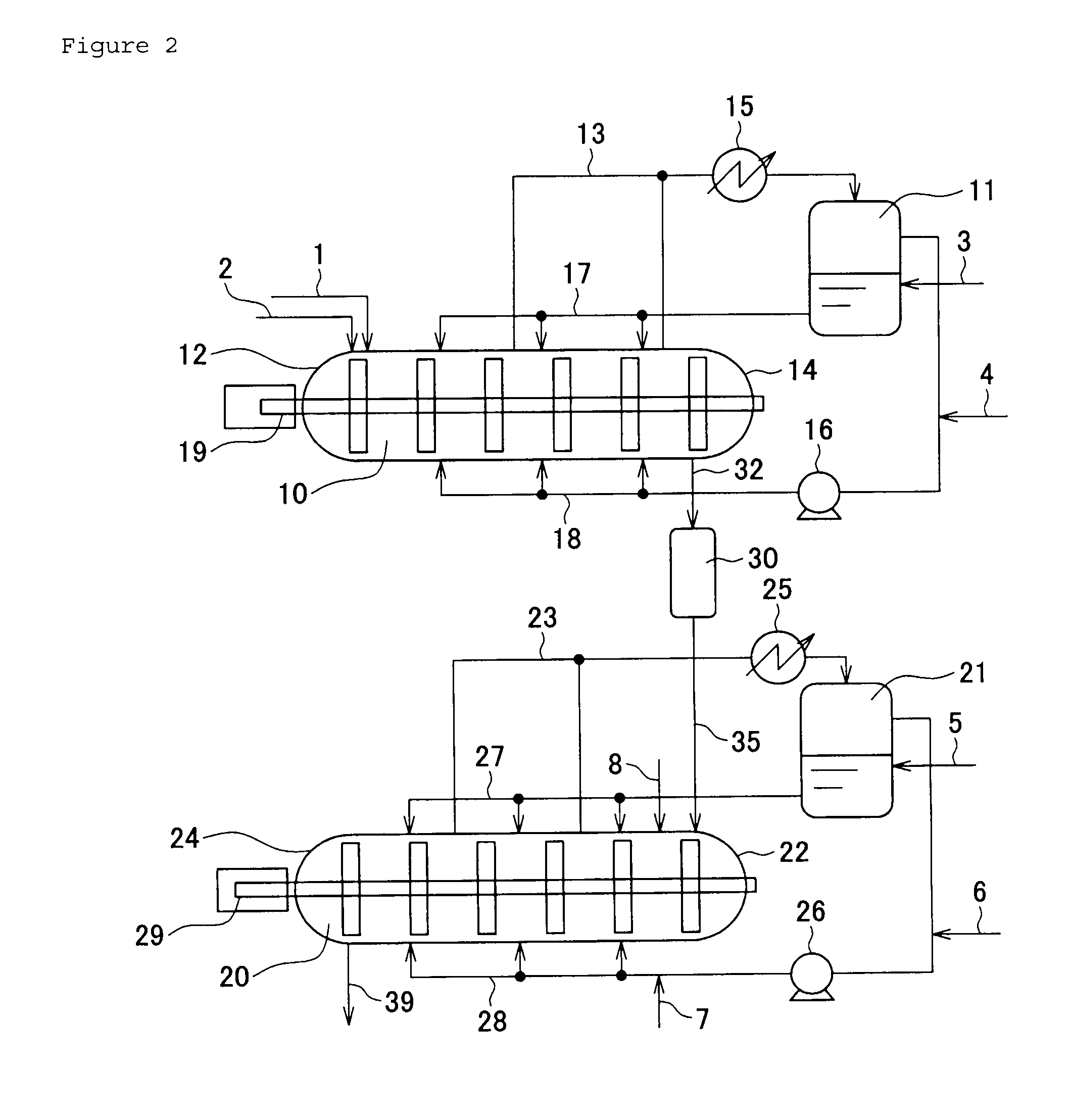

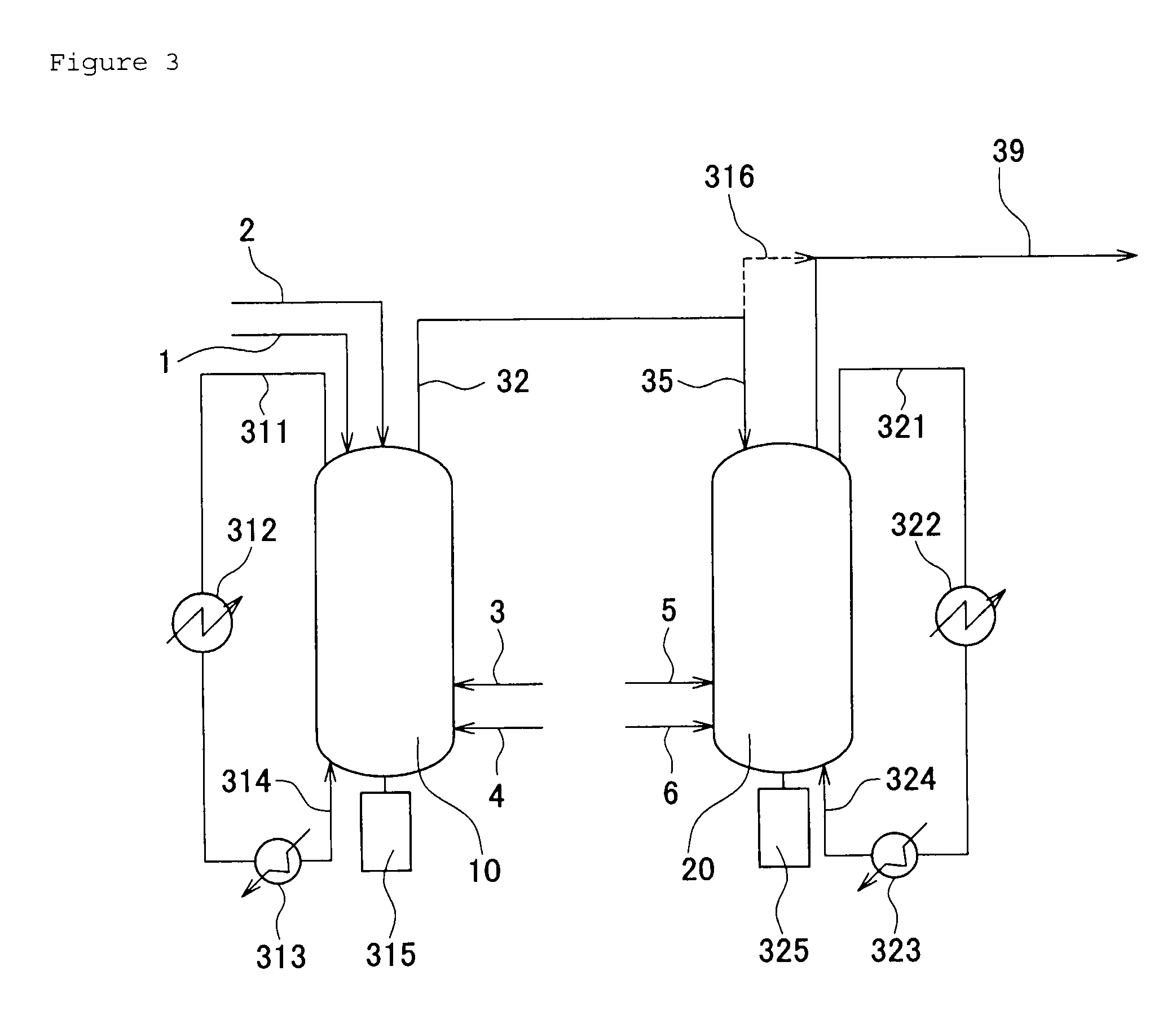

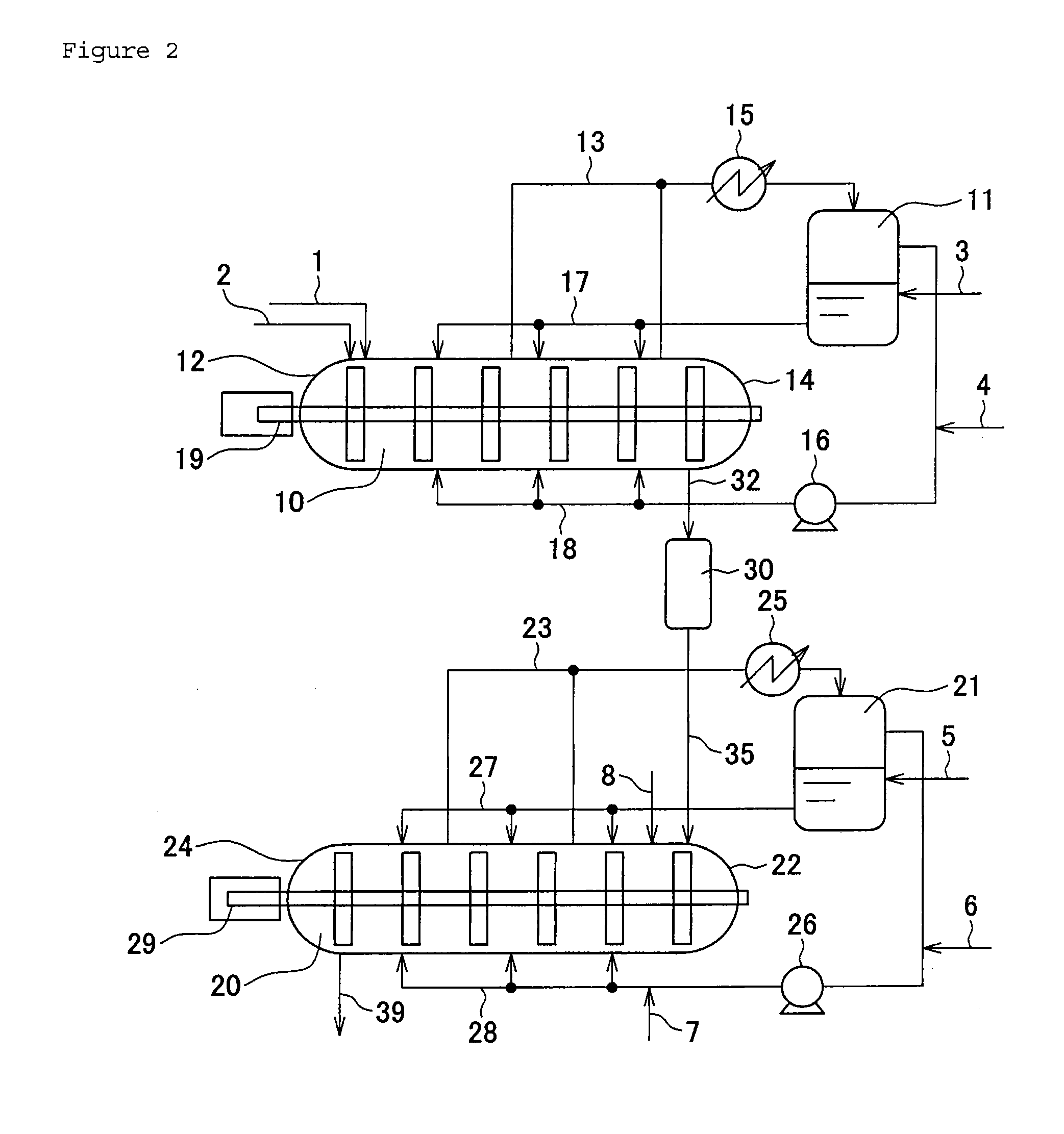

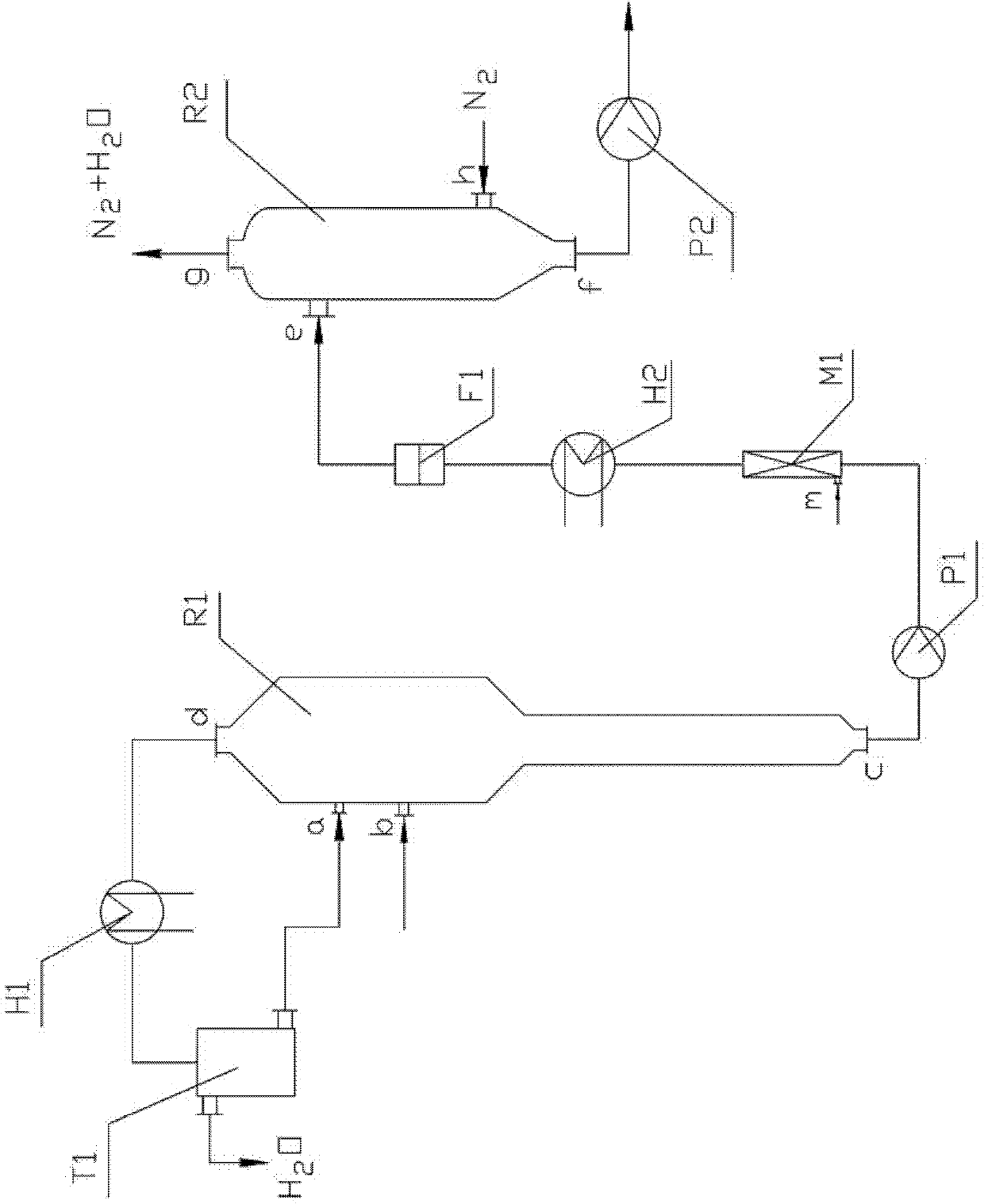

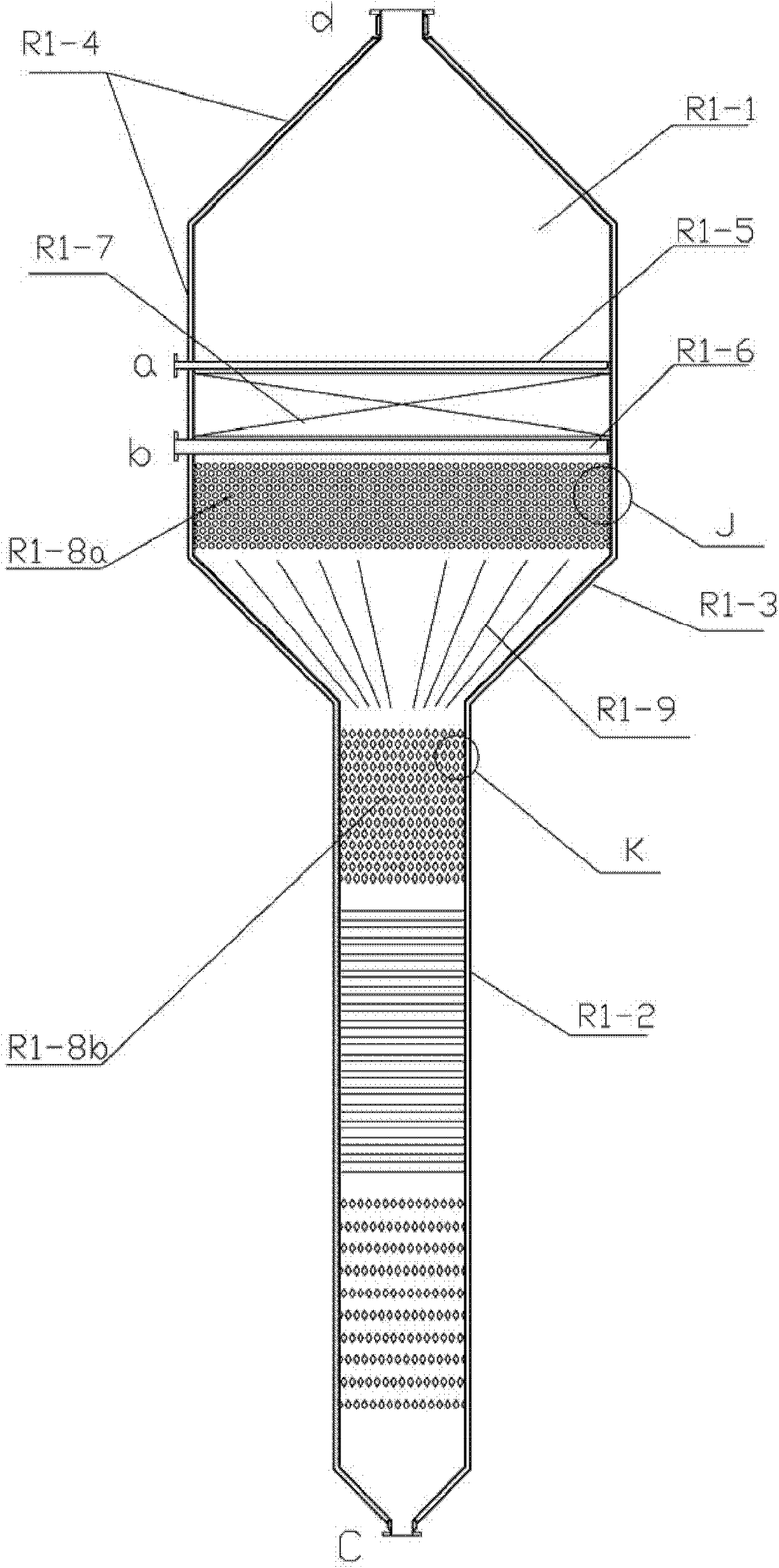

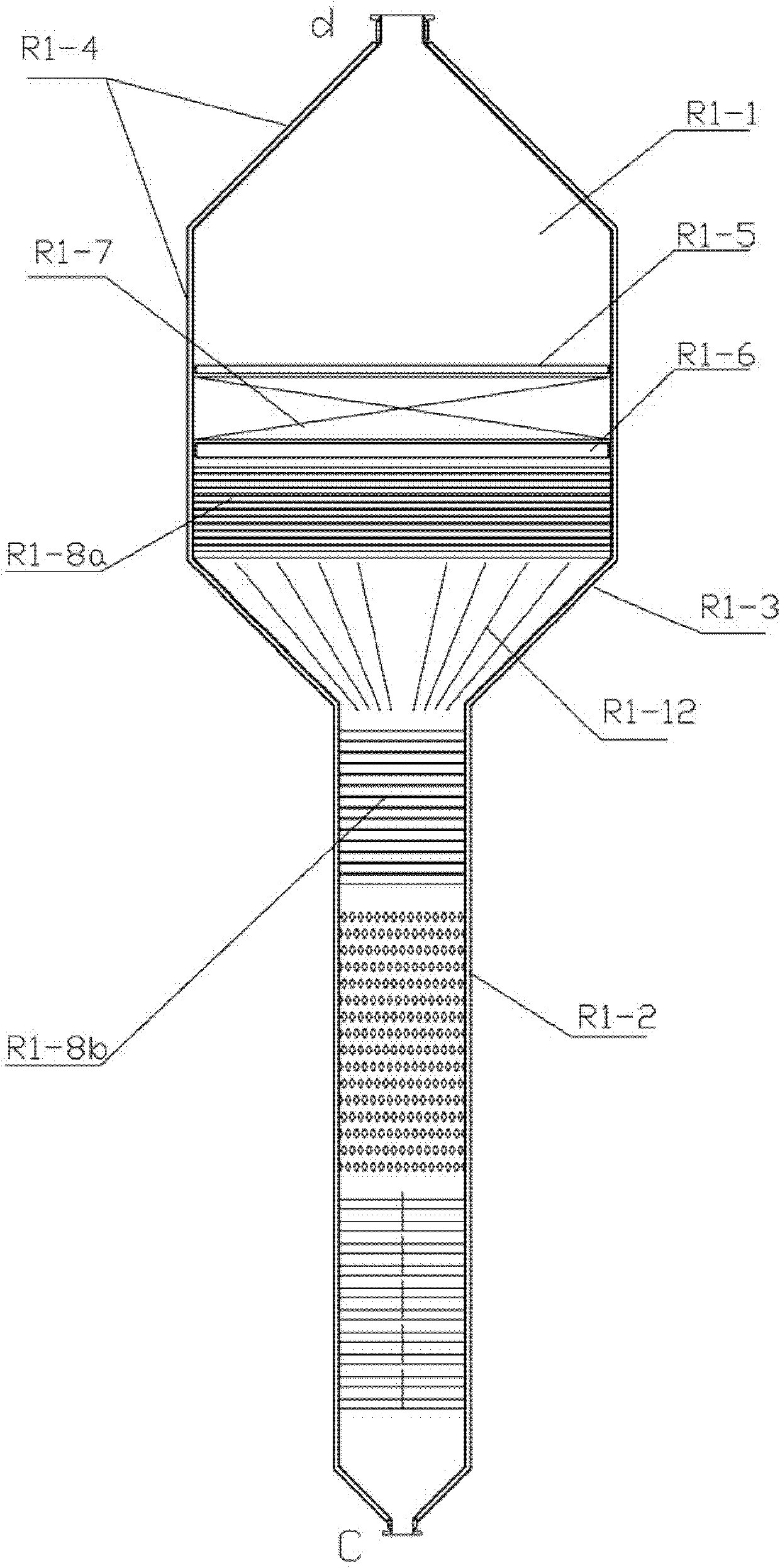

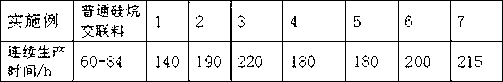

Method and equipment for nylon 66 short-flow continuous polymerization

The invention relates to a method and equipment for nylon 66 short-flow continuous polymerization. The method comprises the steps of carrying out heating, evaporation, concentration and polycondensation of 30-70% of a nylon 66 salt solution in a normal pressure pre-polypolycondensation tower by adopting a reaction distillation method to obtain a prepolymer with a polymerization degree of 5-50 (preferably 20-40) and equimolar terminal carboxy group and terminal amine group, and allowing the prepolyer to directly produce a polymer with a polymerization degree meeting technical indicators without flash distillation. A falling film devolatilization method is adopted in the polycondensation kettle to accelerate distillation out of condensation water, reduce reaction temperature, shorten reaction time and reduce gel; and the falling liquid film is used to seal and cover the kettle wall to avoid scarring of the kettle wall. Compared with the traditional nylon 66 continuous polymerization device, the method and the equipment provided by the invention has the advantages of short process, large single line scale, less investment, low operating cost, good product quality, long continuous operation cycle, and environmental friendliness.

Owner:XCEED CHEMTECH

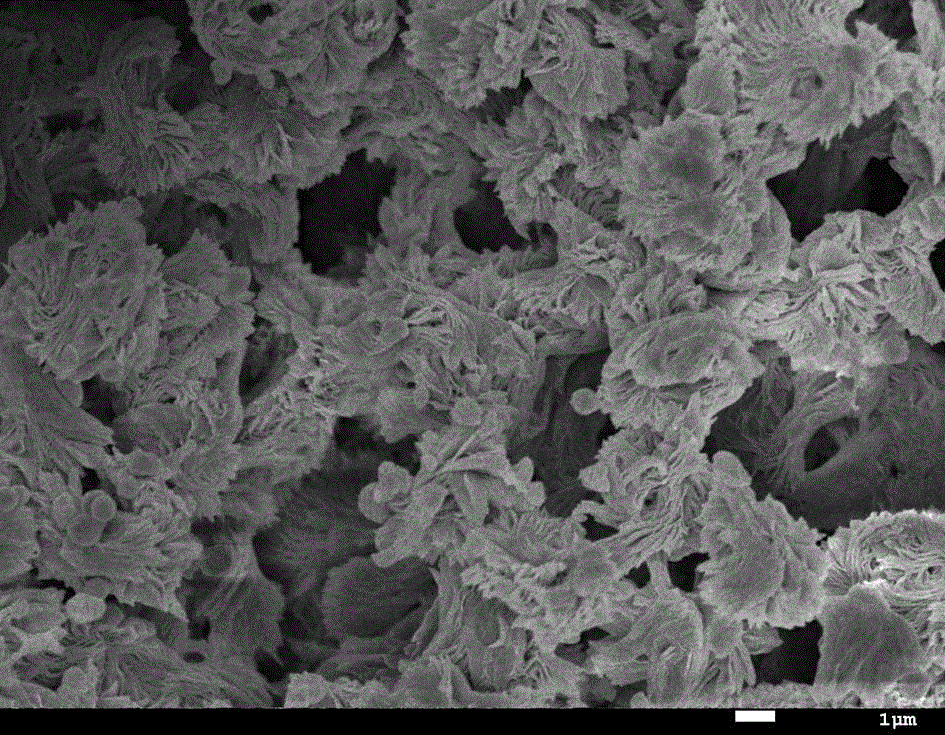

Method for preparing polylactic acid super-hydrophobic membranes by aid of phase separation process

The invention discloses a method for preparing polylactic acid super-hydrophobic membranes by the aid of a phase separation process, and belongs to the field of high-polymer materials. The method includes steps of (1), preparing pre-coating liquid, to be more specific, uniformly mixing poor solvents and good solvents with one another to prepare mixed solvents, and dissolving polylactic acid in the mixed solvents to obtain the pre-coating liquid; (2), preparing coating liquid, to be more specific, adding poor solvents in the pre-coating liquid, and uniformly stirring the poor solvents and the pre-coating liquid to obtain the coating liquid; (3), carrying smearing and drying, to be more specific, smearing the coating liquid on carriers, and drying the carriers to obtain the polylactic acid super-hydrophobic membranes. The method has the advantages that super-hydrophobic surfaces with micrometer-nanometer two-level structures are prepared by the aid of the non-solvent auxiliary process at one step, the method is easy to operate, conditions are mild, curing and steam inducing can be omitted in membrane forming procedures, gel procedures can be omitted, accordingly, the reaction time can be shortened, and the method is high in work efficiency; inorganic nanometer particles or substances with low surface energy can be omitted in super-hydrophobic membrane preparing procedures, and accordingly the polylactic acid super-hydrophobic membranes are low in manufacturing cost.

Owner:ZHENGZHOU UNIV

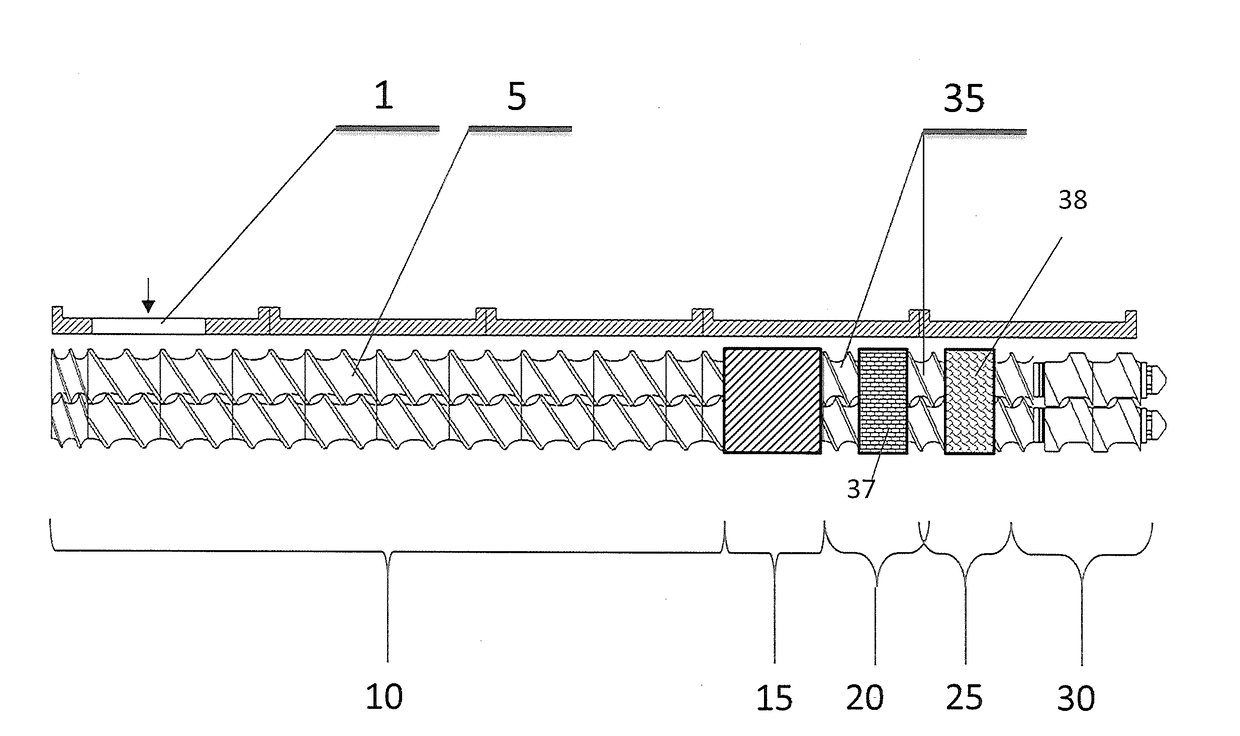

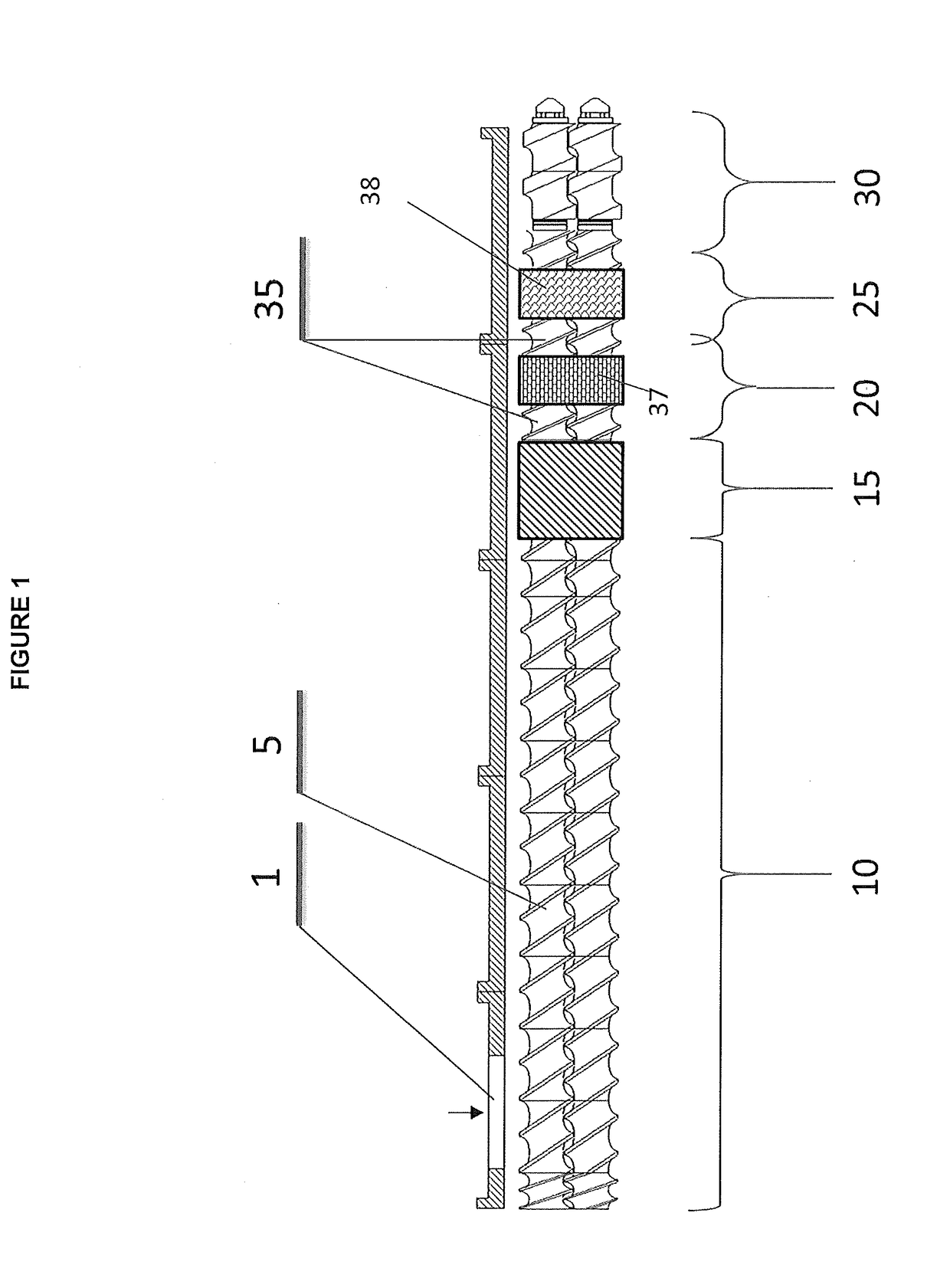

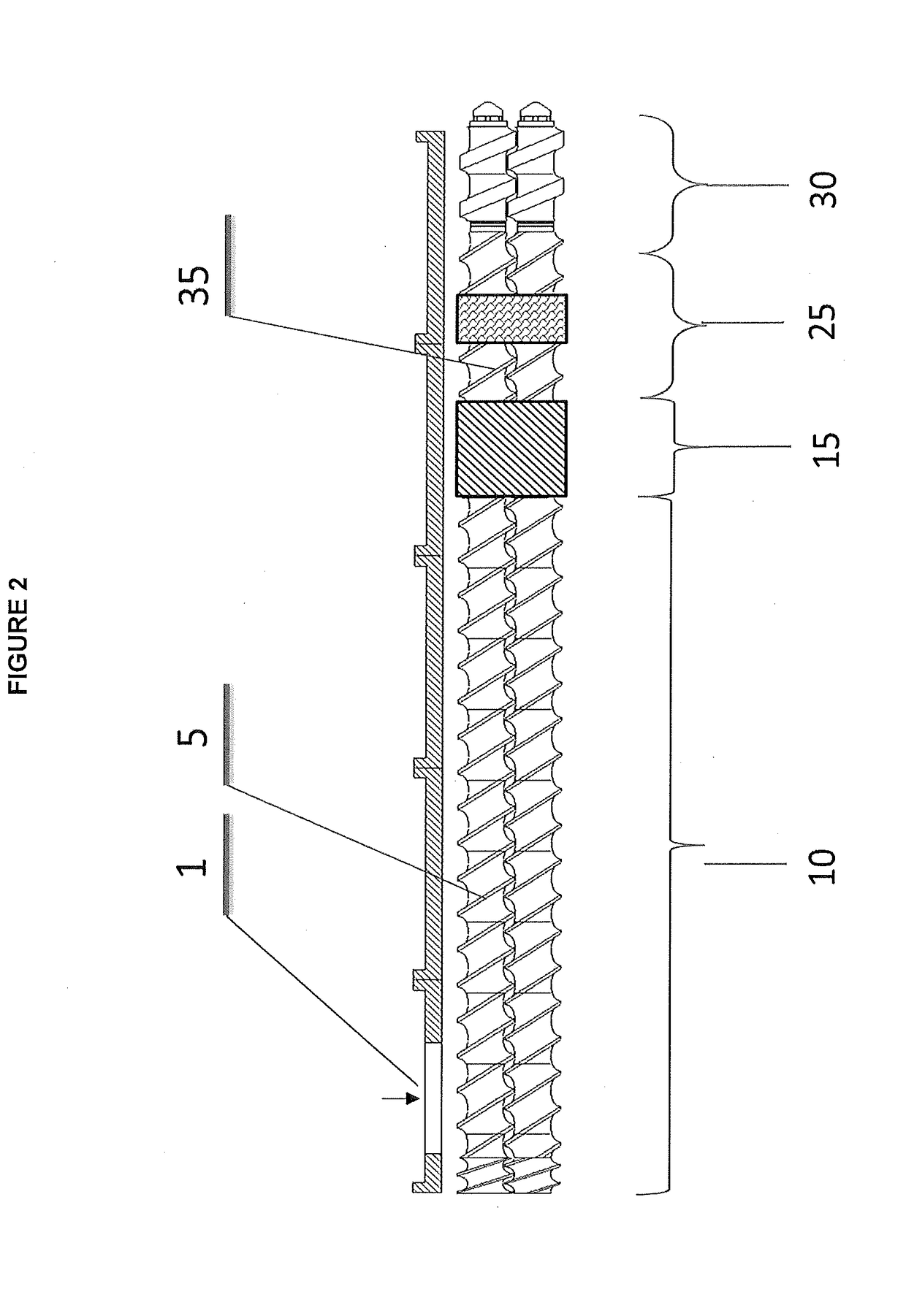

Extrusion process for polyethylene polymers

A method for the improved extrusion of polyethylene polymers comprising passing polyethylene through a single stage, twin screw extruder comprising a solid polymer conveying zone, a polymer melting zone, a dispersive mixing zone, and a distributive mixing / pumping zone, in which the throughput and screw speed are optimized to reduce the number of gels present, ensure complete polymer melting within the polymer melting zone, and to minimize polymer degradation.

Owner:NOVA CHEM (INT) SA

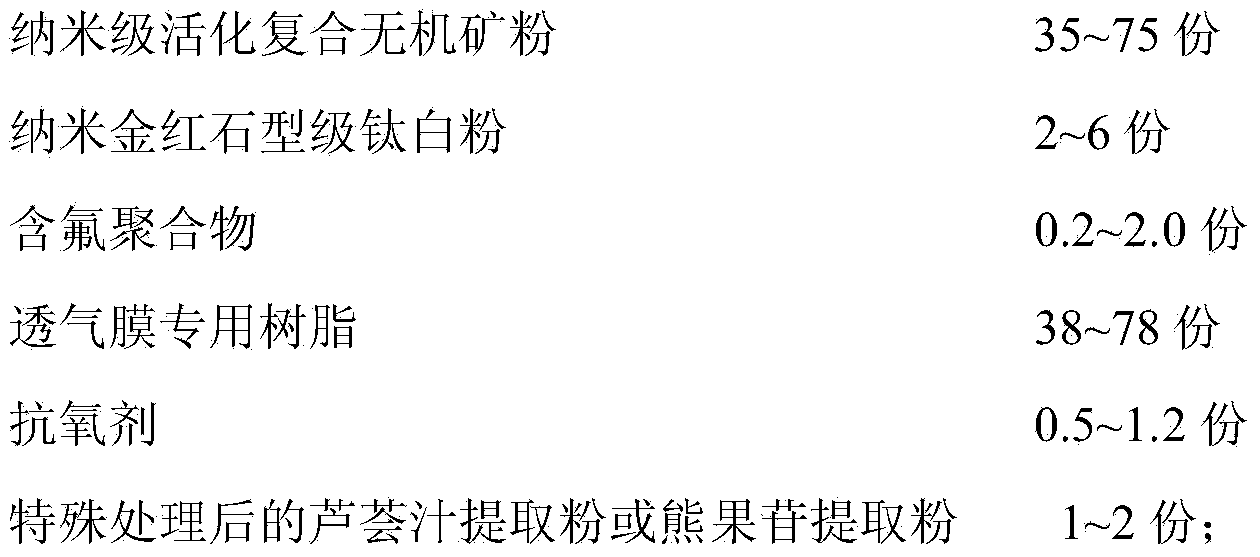

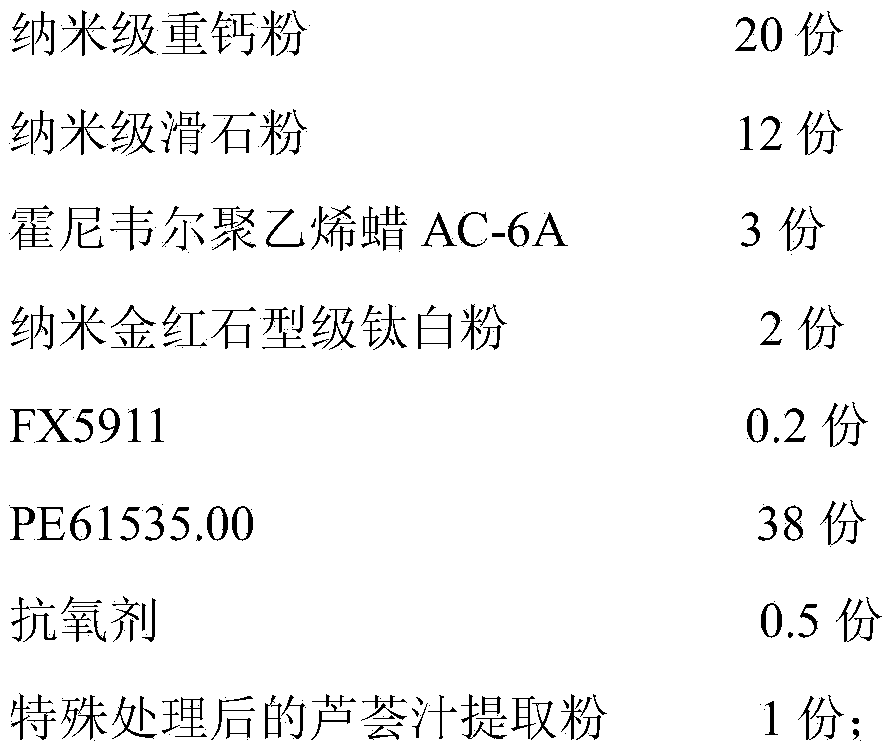

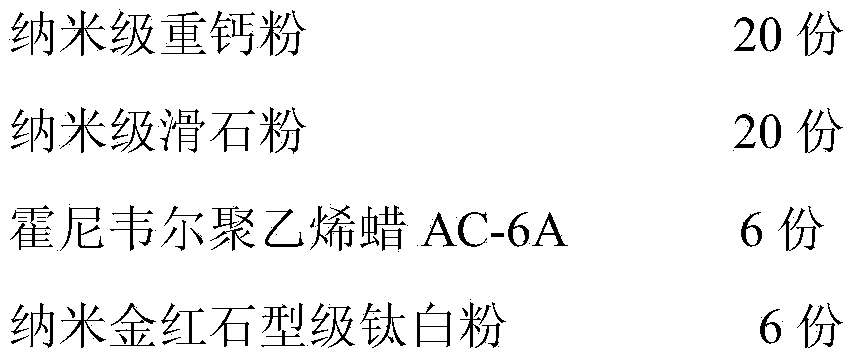

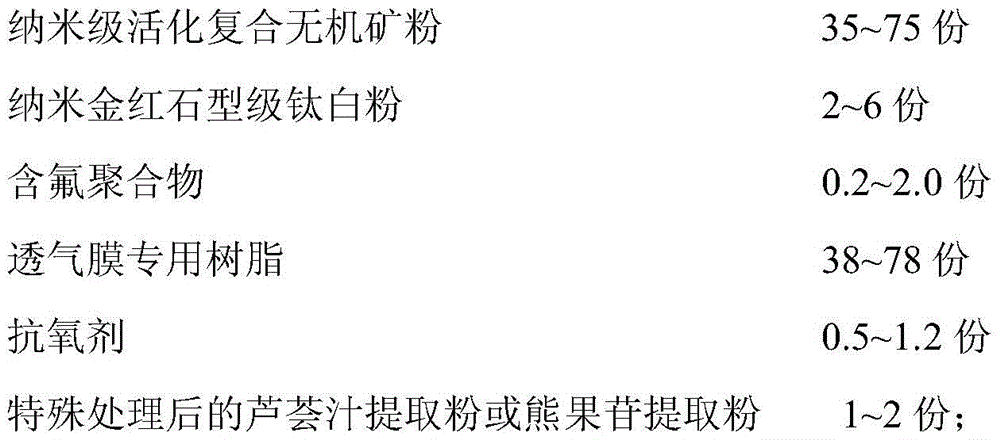

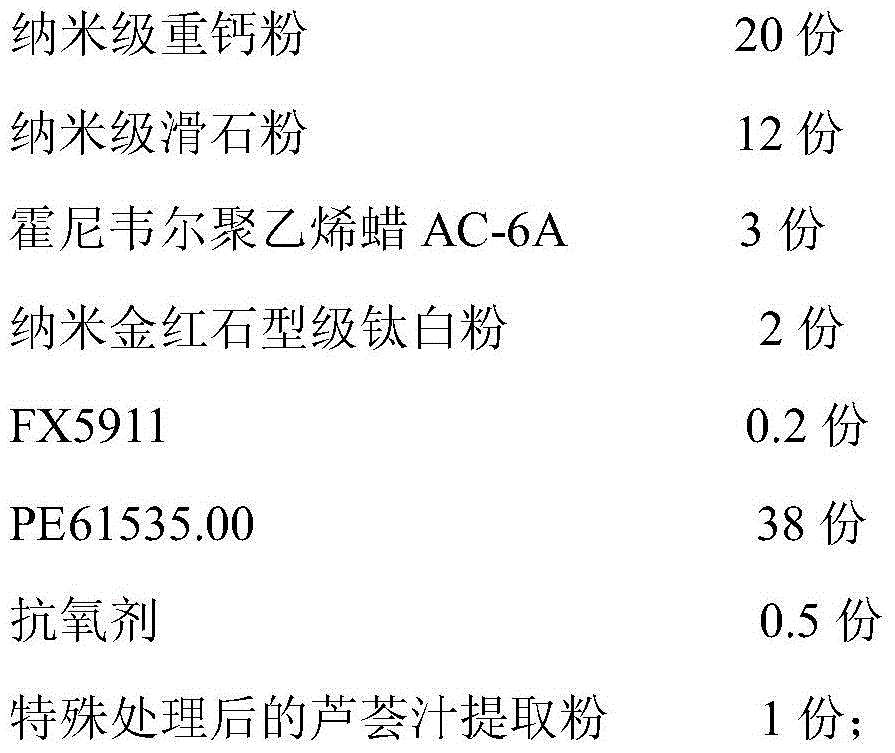

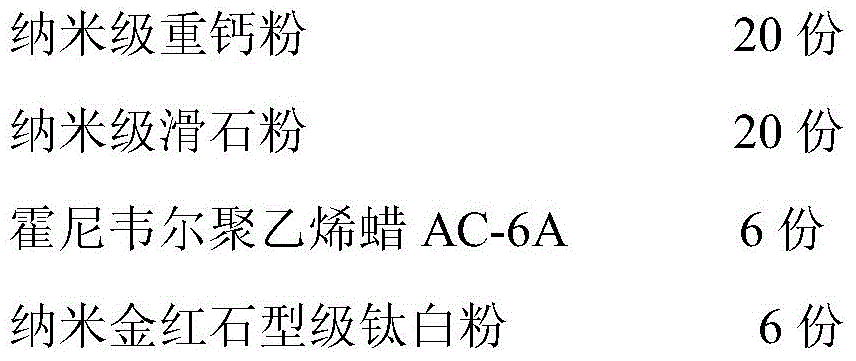

Medical grade gas-permeable membrane special material and preparation method thereof

The invention discloses a medical grade gas-permeable membrane special material. The medical grade gas-permeable membrane special material is prepared from the following components in parts by weight: 35-75 parts of nanoscale activated composite inorganic mineral powder, 2-6 parts of nano rutile type titanium dioxide, 0.2-2.0 parts of fluorine-containing polymer, 38-78 parts of gas-permeable membrane special resin, 0.5-1.2 parts of antioxidant and 1-2 parts of specially treated aloe juice extract powder or arbutin extract powder, wherein the nanoscale activated composite inorganic mineral powder comprises nanoscale ground calcium carbonate powder, nanoscale talcum powder and a surface active agent. A preparation method of the medical grade gas-permeable membrane special material comprises the following steps: firstly carrying out high-speed mixing on the nanoscale activated composite inorganic mineral powder for removing water; secondly, preparing a gas permeable membrane special material mixture; and thirdly, preparing a gas permeable membrane special material finished product. The medical grade gas-permeable membrane special material has the advantages that raw materials are simple, source of the raw materials is rich, a technology is simplified and cost is low.

Owner:广西工程技术研究院有限公司

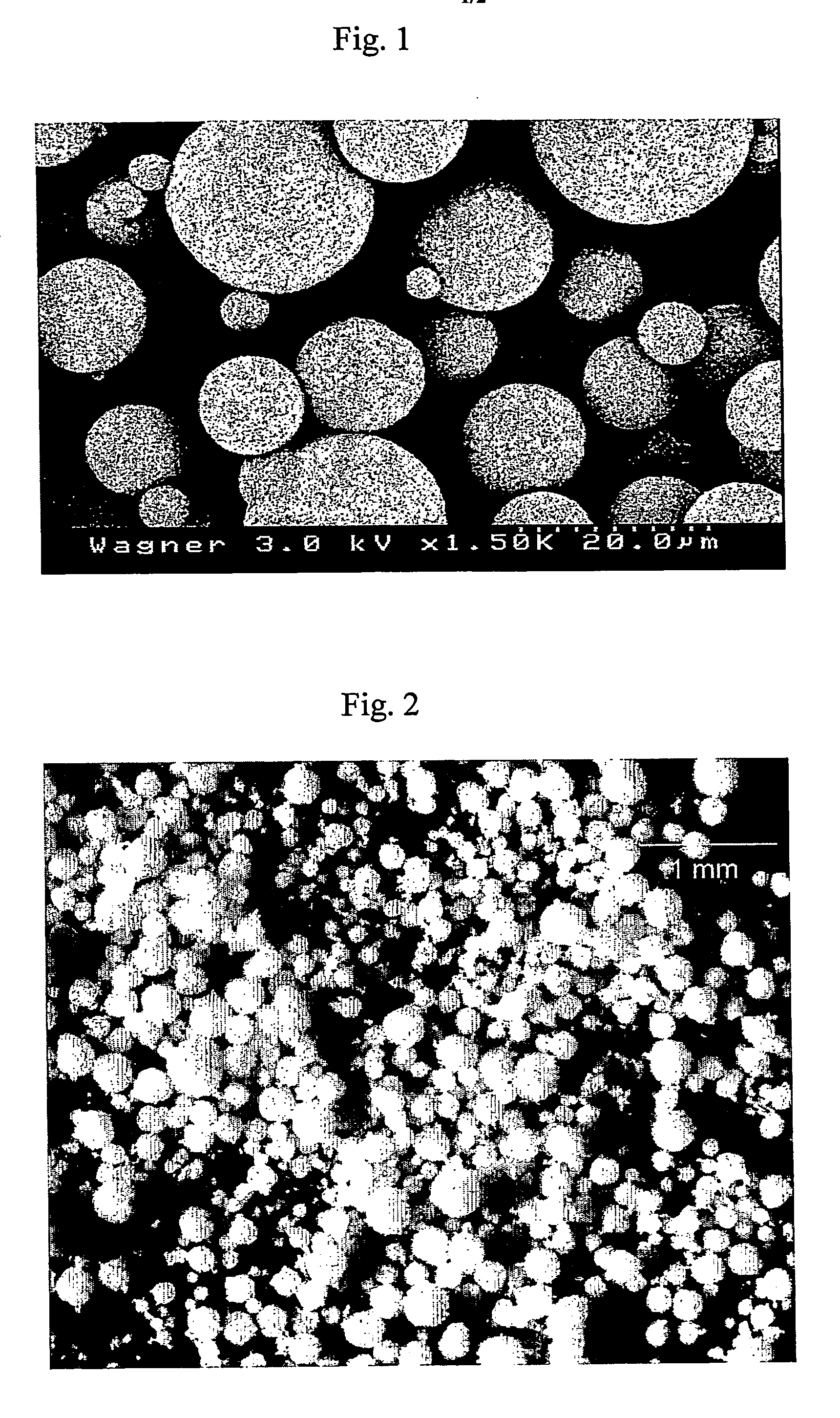

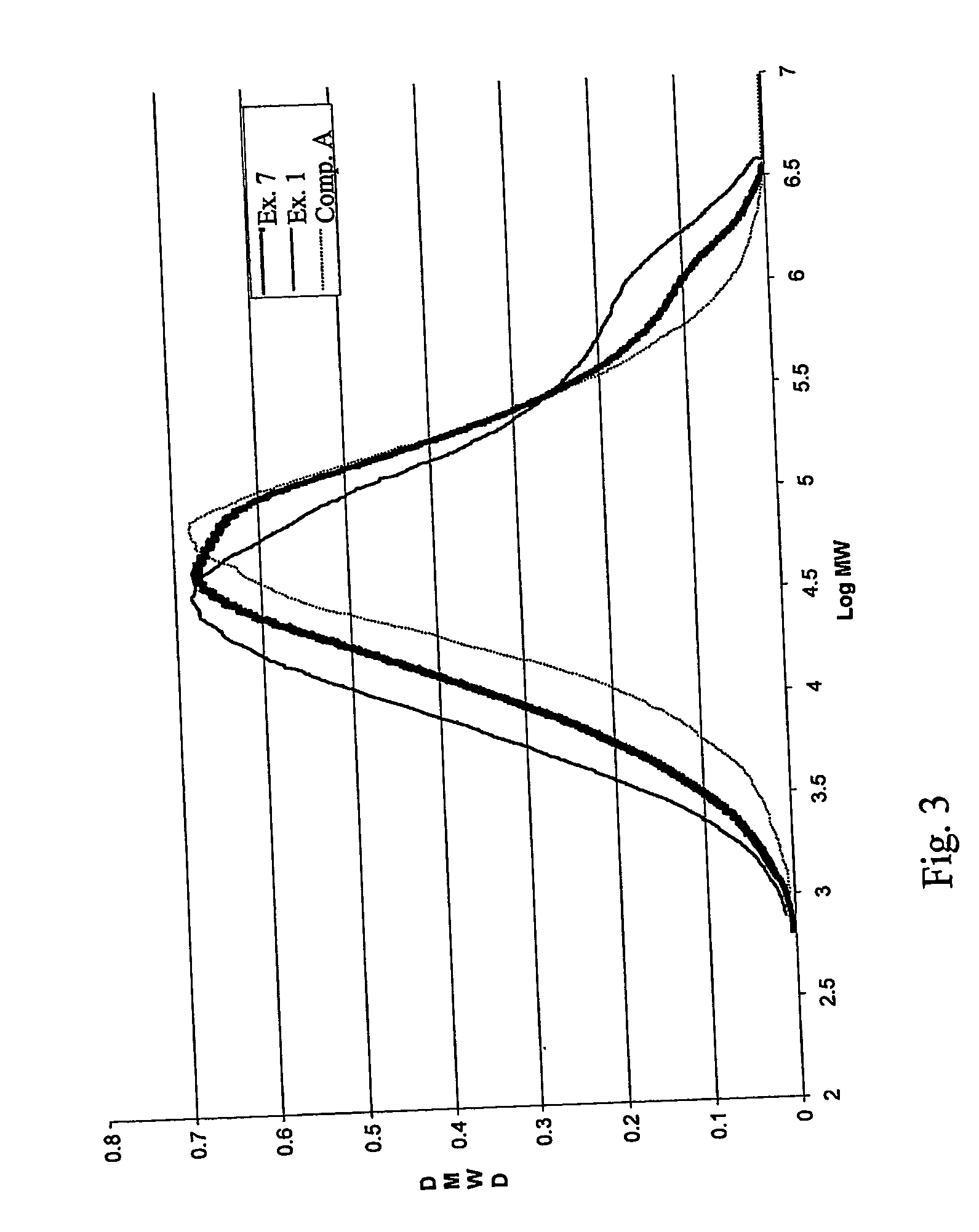

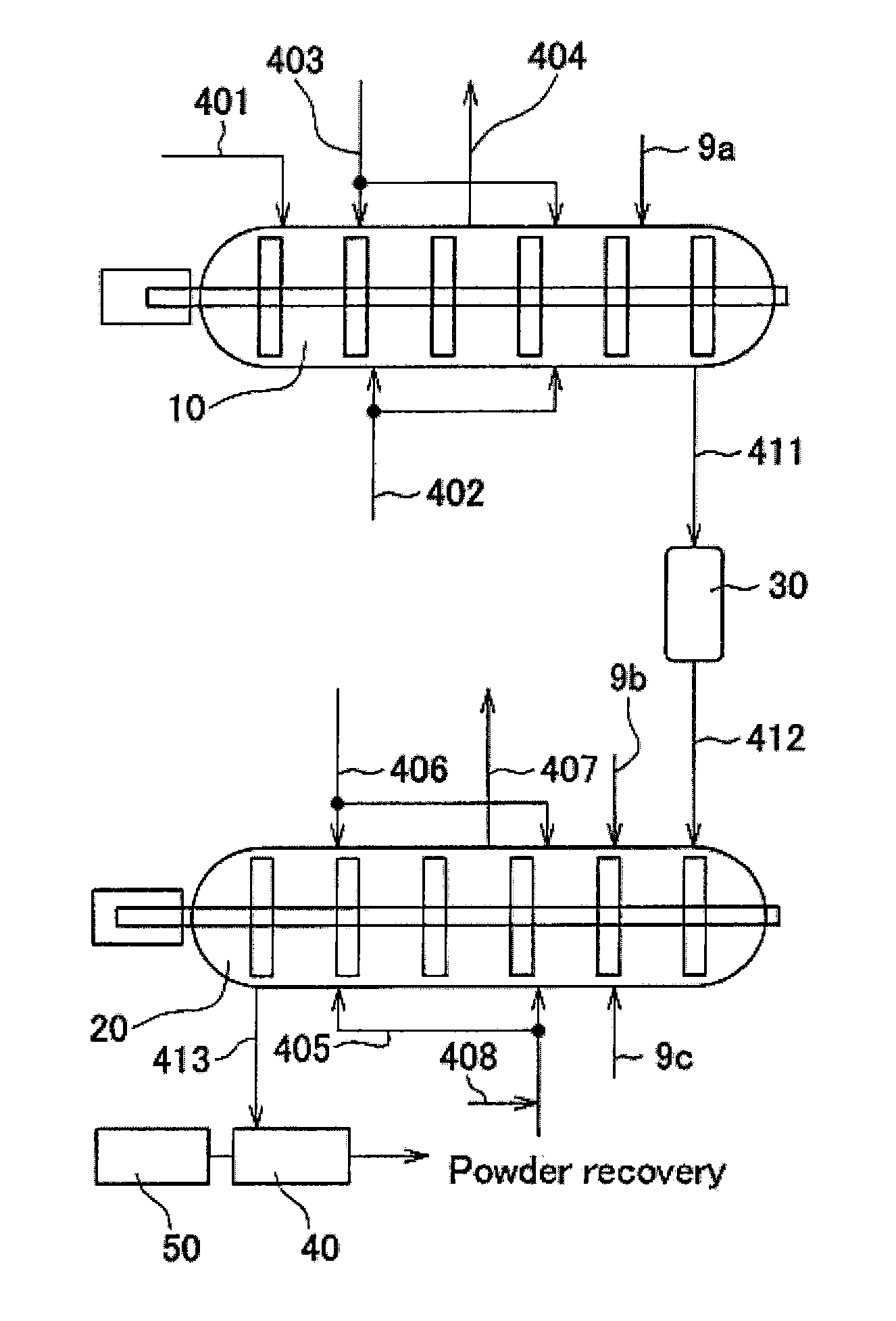

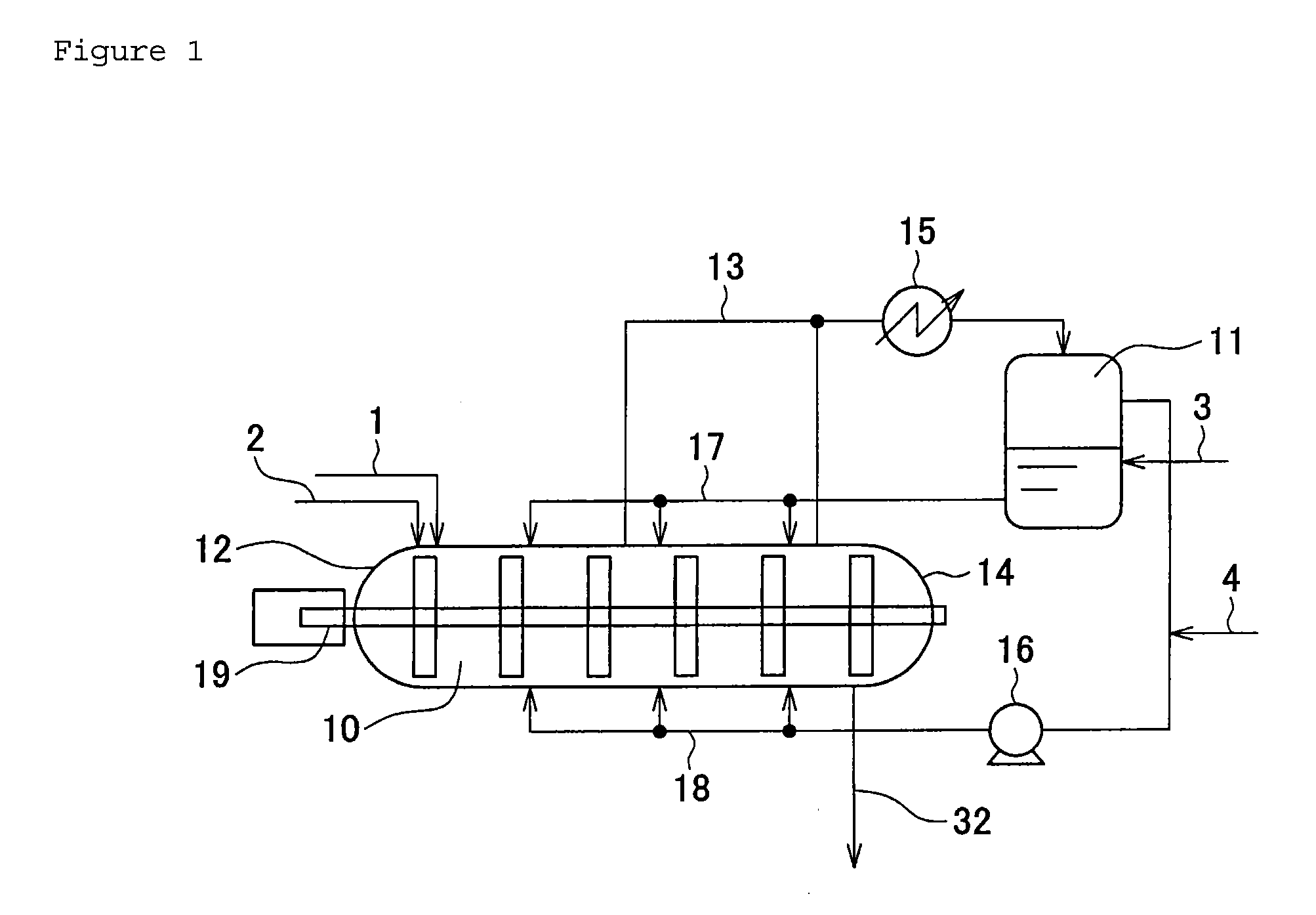

Propylene polymer, method for production of the propylene polymer, propylene polymer composition, and molded article manufactured from the composition

Disclosed is a production method of polypropylene having high MFR value and excellent product qualities with high productivity. The method enables to produce a propylene polymer by a gas phase process where the reaction heat is removed mainly by the heat of vaporization of liquefied propylene. The method is characterized by using a solid catalyst component (A) which is prepared by contacting components (A1), (A2) and (A3) shown below. Further disclosed are: a propylene polymer produced by the method; a propylene polymer composition; and a molded body of the composition. Component (A1): a solid component containing titanium, magnesium and a halogen as essential components. Component (A2): a vinyl silane compound. Component (A3): an organosilicon compound having an alkoxy group (A3a) and / or a compound having at least two ether bonds (A3b).

Owner:JAPAN POLYPROPYLENE CORP

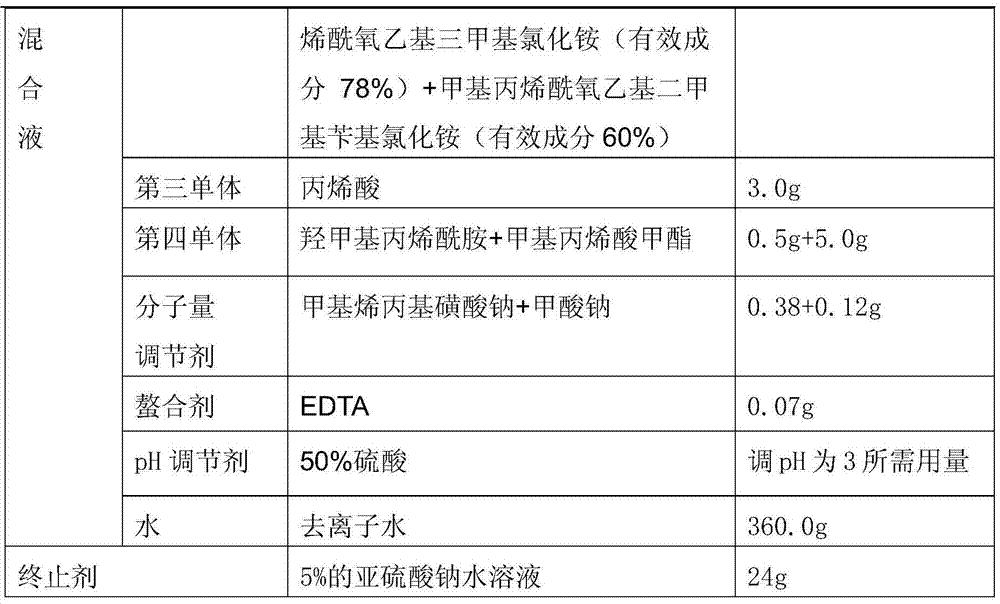

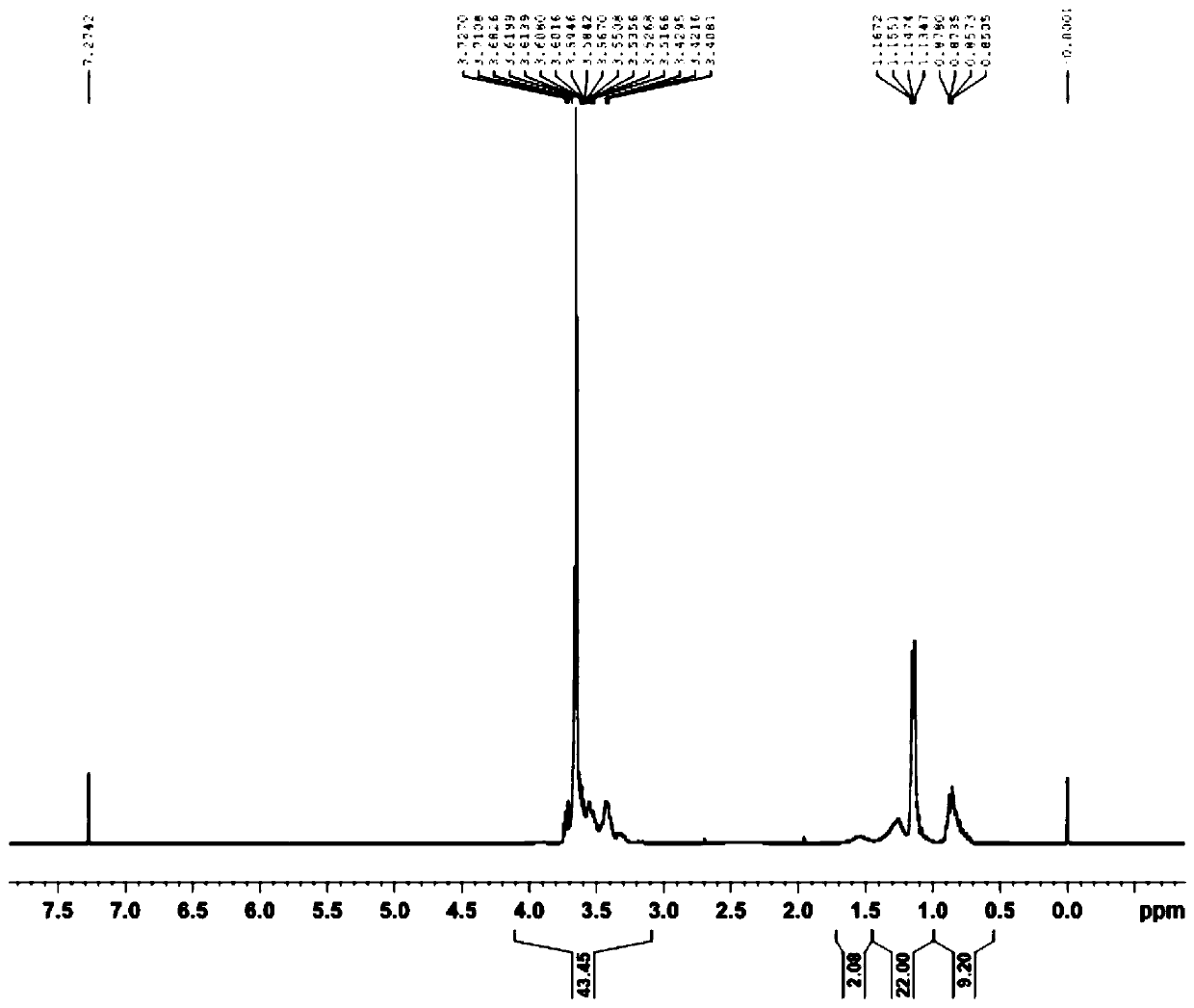

A kind of highly branched polyvinyl alcohol-acrylamide graft copolymer and its preparation method and application

ActiveCN104119480BHigh degree of branchingIncrease the lengthReinforcing agents additionPaper/cardboardInterference resistanceReaction temperature

The invention relates to a preparation method of a highly branched polyvinyl alcohol-acrylamide graft copolymer. After dissolving the polyvinyl alcohol in water, blowing nitrogen gas, lowering the temperature, adding a catalyst, reacting for 10-30 minutes, and then adding a monomer mixture solution dropwise , control the dropping time for 30-90 minutes, during which the reaction temperature is controlled between 65°C-95°C, after dropping, control the temperature between 85°C-95°C for 20-30 minutes, add catalyst, and continue at 80°C React at ‑95°C for 15-25 minutes, add catalyst, take samples during the reaction to measure the viscosity, after the viscosity reaches 1500-15000 mPa.s at 25°C, add a terminator to stop the reaction, adjust the solid content, and the product is ready. The graft copolymer of the present invention has high molecular weight, many branched chains, low viscosity, less gel, good retention, and strong anti-interference ability of impurities. As a dry strength agent for papermaking, it can also Satisfactory enhancement effect is achieved.

Owner:九洲生物技术(苏州)有限公司

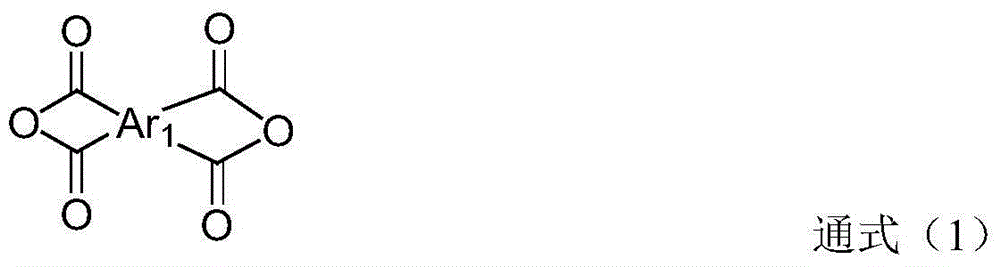

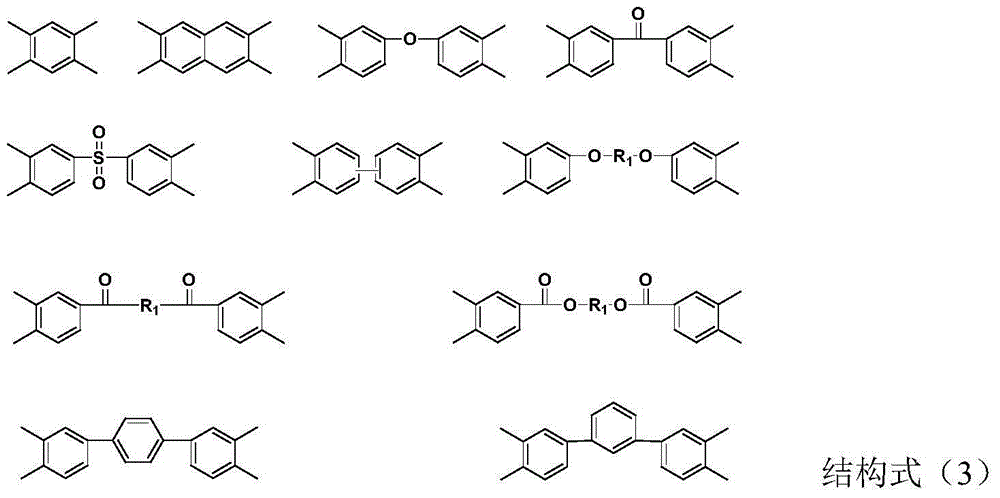

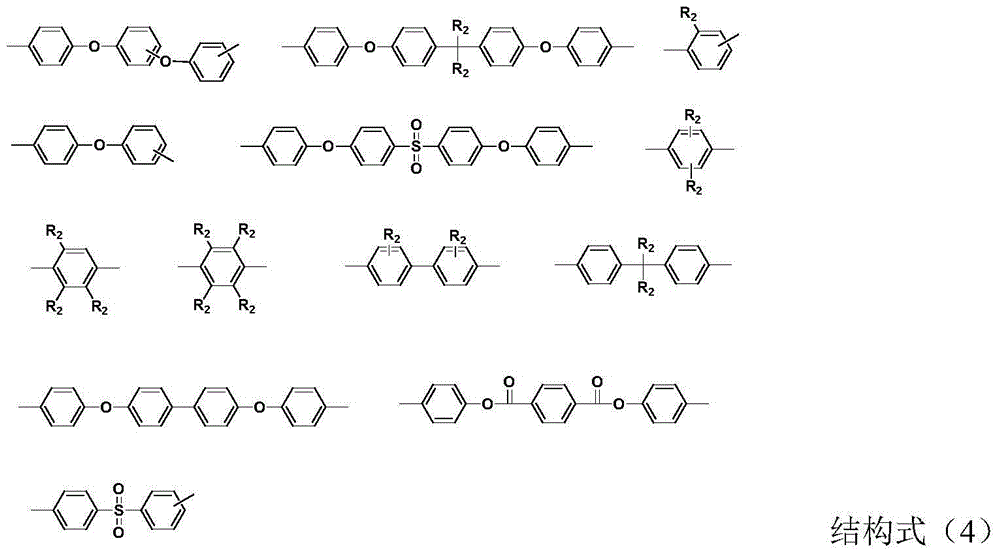

Preparation method of viscosity-controllable polyamide acid solution

InactiveCN105525382ALow intrinsic viscosityLow viscosityMonocomponent synthetic polymer artificial filamentSpinning solutions preparationFiberPolyamide

The invention relates to a preparation method of a viscosity-controllable polyamide acid solution for preparation of polyimide fibers. The preparation method mainly solves the problem that in the two-step polyimide fiber preparation method, a polyamide acid solution has unstable viscosity, overtop molecular weight, overtop viscosity and poor spinnability in preparation. The preparation method comprises that diamine as a polymerization raw material, a solvent and a conditioning agent are added into a reactor and are dissolved in a protective atmosphere of gas inert to the reaction substances, tetracarboxylic dianhydride is added into the solution at a temperature of -10 to 40 DEG C, the mixture undergoes a reaction for 2-10h and the reaction product is defoamed so that a polyamide acid spinning stock solution is obtained. The preparation method well solves the above problem and can be used for polyimide fiber industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

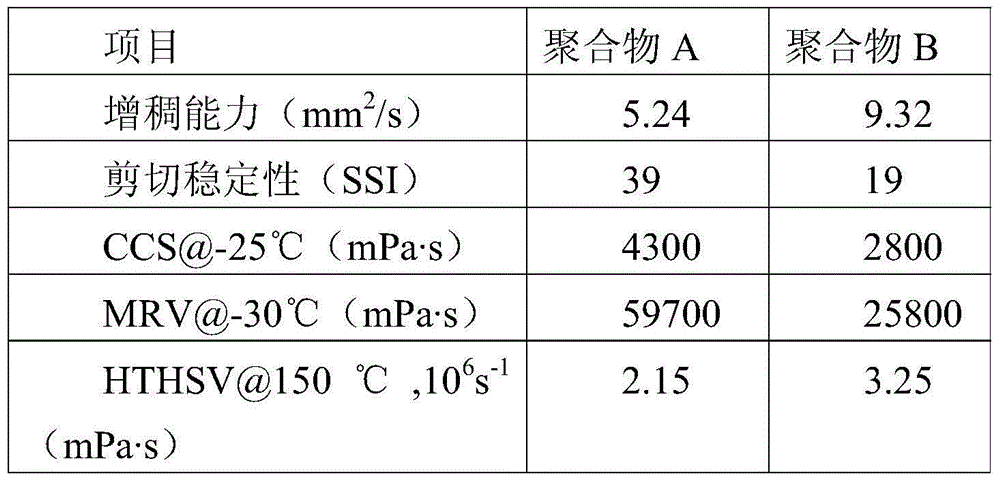

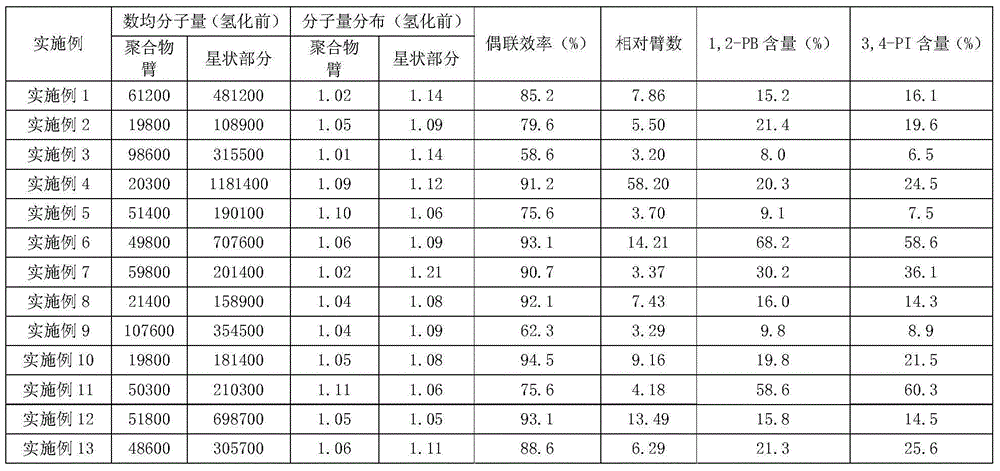

Star-shaped hydrogenated styrene diene copolymer and preparation method thereof

The invention relates to a star-shaped hydrogenated styrene diene copolymer which is used as a lubricating oil viscosity index improver. Each arm of the star-shaped hydrogenated styrene diene copolymer is a diblock copolymer including a block I being hydrogenated polyisoprene (EP) and a block II being and a block II being hydrogenated styrene-butadiene copolymer (SEB), and has a structural formula being (EP-SEB)n-C, wherein C is a core of a coupling agent, and n is the arm number of the copolymer and is no less than 3. The star-shaped hydrogenated styrene diene copolymer is finally prepared through polymerization, coupling, and hydrogenation. A novel copolymer is prepared through adjustment of numbers, ratio, and addition sequence of monomers in the arms of the copolymer and a microstructure. The copolymer is applied to a lubricating oil composition, and the thickening capacity, shear stability, low-temperature performance, and processing ability of lubricating oil are obviously improved. Meanwhile, the preparation method is simple and low in production cost.

Owner:PETROCHINA CO LTD

Propylene-based polymer and production method therefor, propylene-based polymer composition and molded body made thereof

ActiveUS20100099811A1Reduce the amount requiredImprove product qualityMixingSolid componentPolymer science

Disclosed is a production method of polypropylene having high MFR value and excellent product qualities with high productivity. The method enables to produce a propylene polymer by a gas phase process where the reaction heat is removed mainly by the heat of vaporization of liquefied propylene. The method is characterized by using a solid catalyst component (A) which is prepared by contacting components (A1), (A2) and (A3) shown below. Further disclosed are: a propylene polymer produced by the method; a propylene polymer composition; and a molded body of the composition. Component (A1): a solid component containing titanium, magnesium and a halogen as essential components. Component (A2): a vinyl silane compound. Component (A3): an organosilicon compound having an alkoxy group (A3a) and / or a compound having at least two ether bonds (A3b).

Owner:JAPAN POLYPROPYLENE CORP

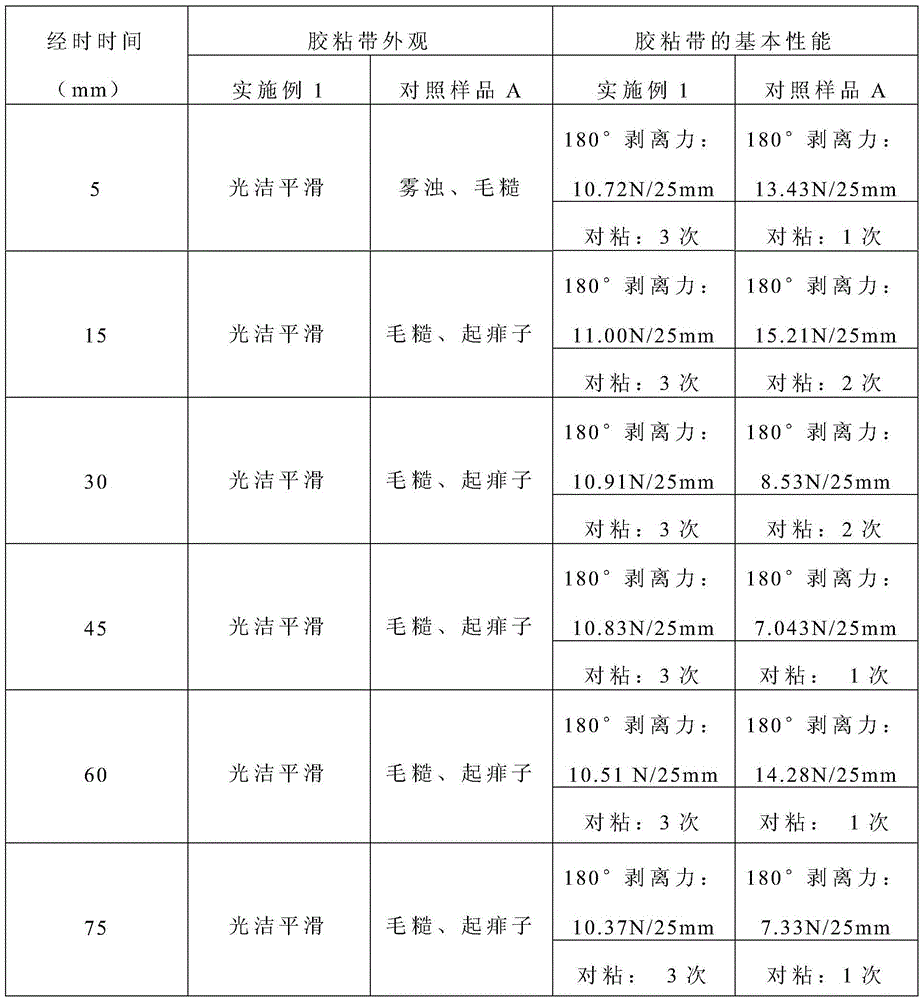

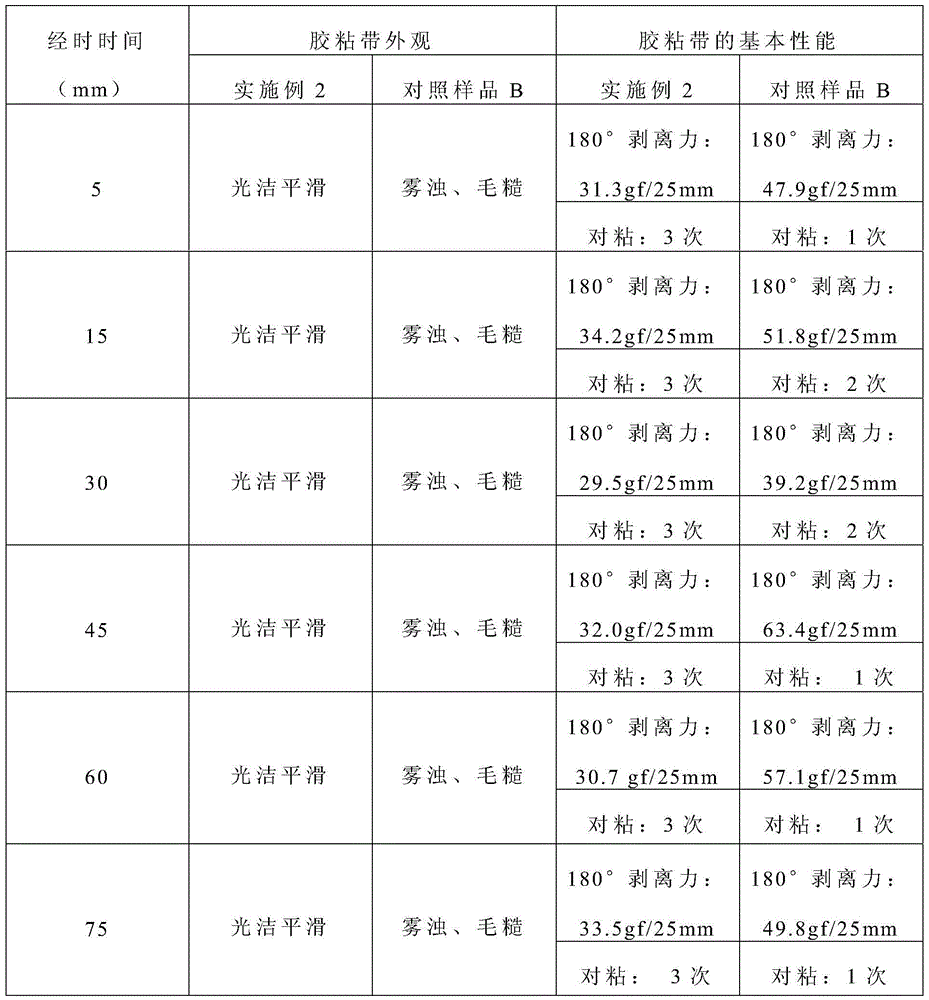

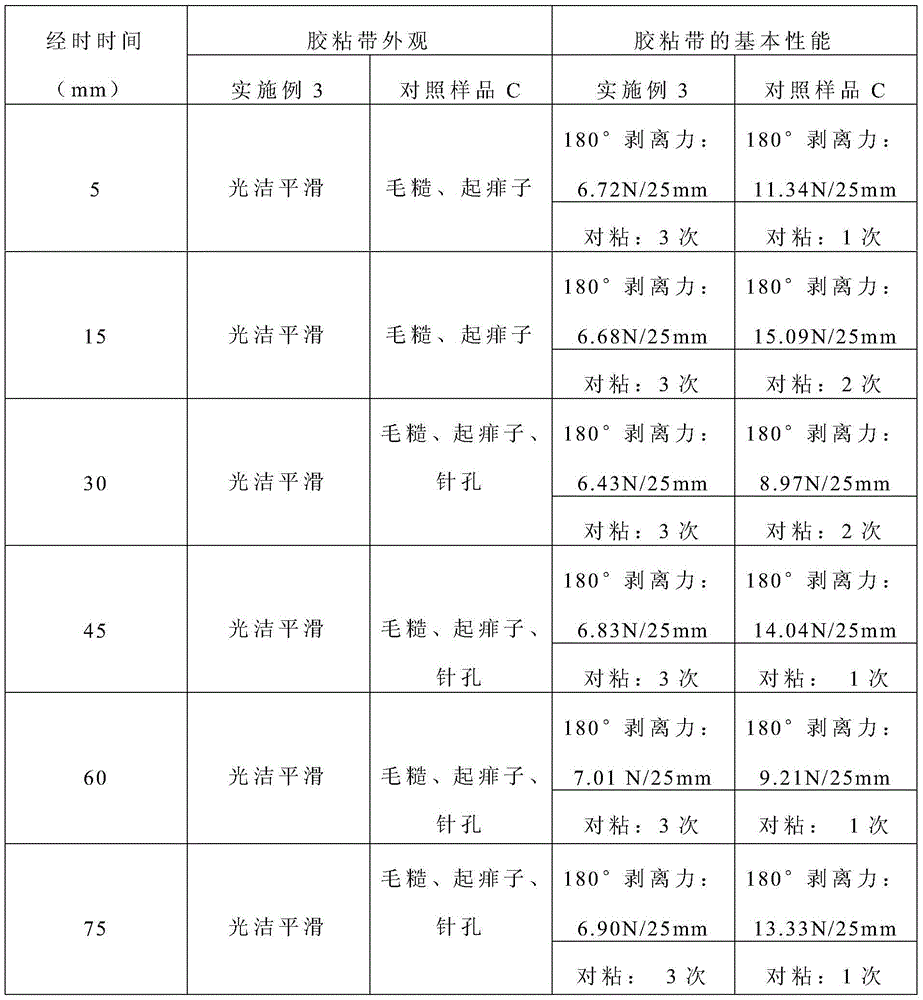

Application method of solvent type polymethacrylate pressure-sensitive adhesive

InactiveCN105602492AReduce the impactReduce gelNon-macromolecular adhesive additivesFilm/foil adhesivesIsocyanatePressure sensitive

The invention relates to an application method of a solvent type polymethacrylate pressure-sensitive adhesive. The method comprises the following steps: step 1, preparing adhesive diluent from a solvent type polymethacrylatepressure-sensitive adhesive and a solvent; step 2, dissolving a water reducing agent of which the mass percentage accounts for 0.5 percent to 5 percent of the dry weight mass of the solvent type polymethacrylate pressure-sensitive adhesive with the solvent, then adding into the adhesive diluent; steps 3, mixing an isocyanate curing agent with the solvent, adding into the adhesive diluent; step 4, adding a catalyst of which the mass percentage accounts for 0.01 percent to 1 percent of the dry weight mass of the solvent type polymethacrylate pressure-sensitive adhesive into the liquid prepared in the step 3, and obtaining adhesive coating liquid; step 5, adding a volatile organic acid substance which accounts for 1 percent to 5 percent of the dry weight mass of the polymethacrylate pressure-sensitive adhesive into the adhesive liquid under a state of being stirred; step 6, coating a substrate surface with the adhesive coating liquid, and performing solvent removal, solidification and post curing in an oven, so that an adhesive product is obtained.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

Anion water-soluble polyurethane disperse system for finishing leather and method for preparing same

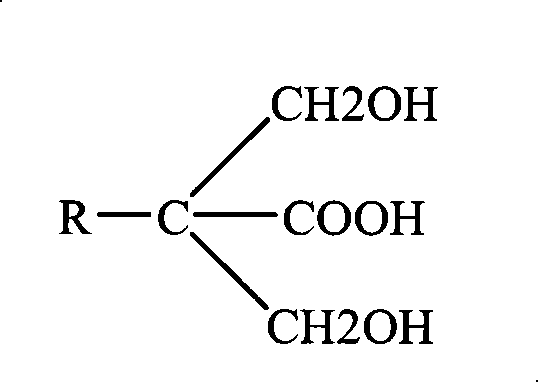

ActiveCN101307130BReduce reactivitySmall particle sizeLiquid surface applicatorsPolyurea/polyurethane coatingsPolyurethane dispersionPolymer science

The invention relates to an anion aqueous polyurethane dispersoid for leather finishing. The anion aqueous polyurethane dispersoid mainly is mainly prepared by the following raw materials by mass portion: 100 mass portions of polyether polyalcohol, 30 to 80 mass portions of diphenylmethane diisocyanate isomer combination, 6 to 15 mass portions of diol containing carboxyls, 0.5 to 6 mass portions of micromolecular cross-linker and 0.2 to 4 mass portions of amine chain extender; and 0.001 to 1 mass portion of catalyzer is an alternative. The dispersoid has the advantages of good mechanical performance, solvent resistance, hydrolysis resistance, high strength, rapid solidification, etc.

Owner:WANHUA CHEM BEIJING +1

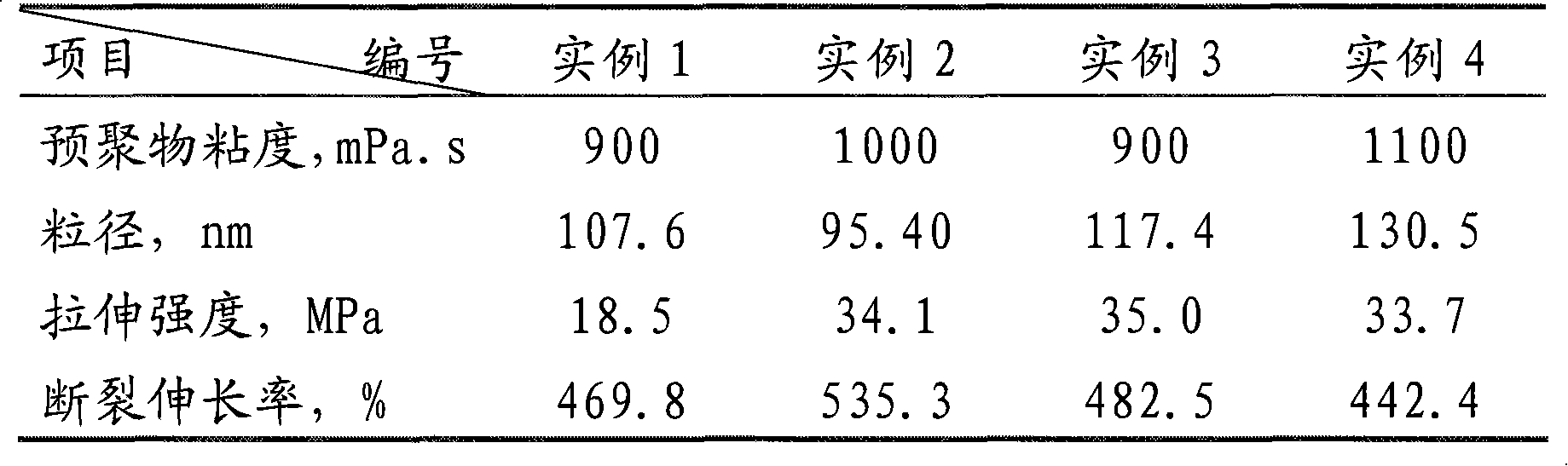

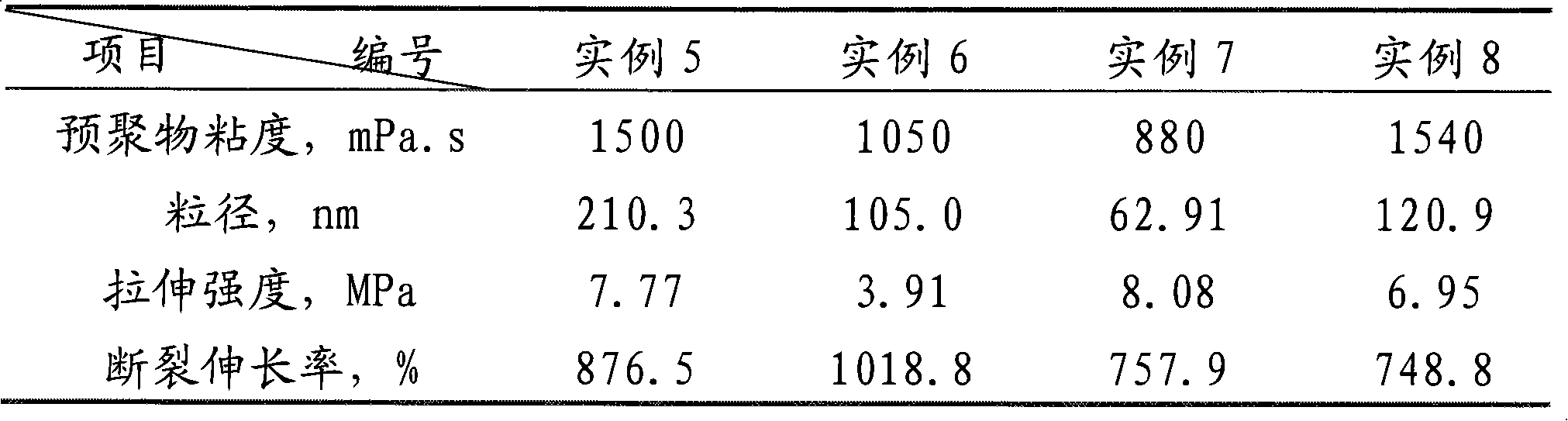

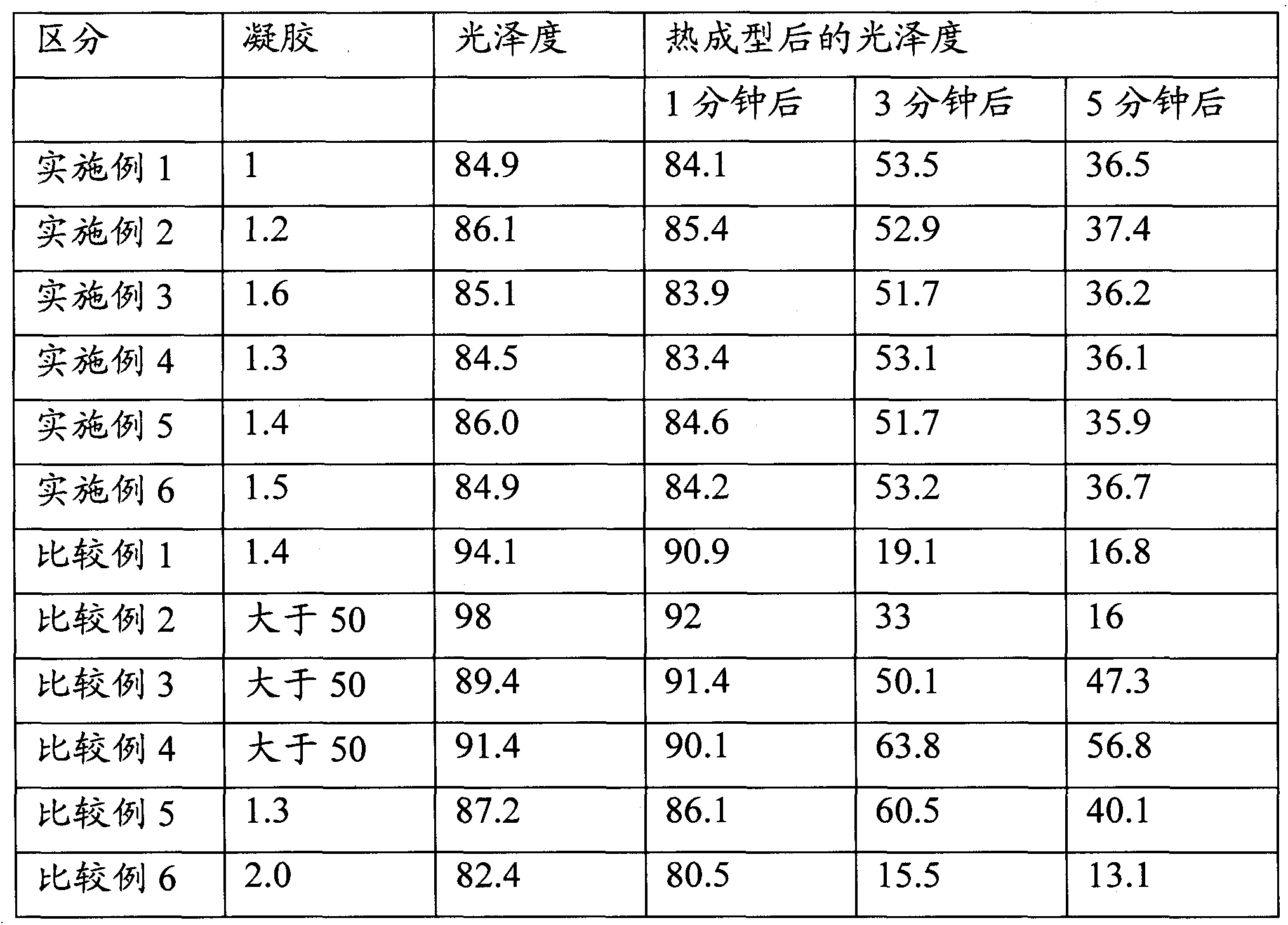

ABS resin composition capable of maintaining high glossiness in thermoforming and ABS sheet using same

Disclosed are an ABS resin composition and an ABS sheet using the same, wherein the ABS resin composition has an excellent surface quality and enables the manufacture of a sheet with excellent glossiness even in thermoforming. The ABS resin composition according to the invention comprises a) 50-80 weight% of an acrylonitrile-butadiene-styrene (ABS) resin, b) 10-30 weight% of a styrene-acrylonitrile (SAN) copolymer, and c) 10-20 weight% of a rubber resin, wherein the ABS resin is a bulk polymerization-type ABS resin.

Owner:LG HAUSYS LTD

Method and equipment for nylon 66 short-flow continuous polymerization

The invention relates to a method and equipment for nylon 66 short-flow continuous polymerization. The method comprises the steps of carrying out heating, evaporation, concentration and polycondensation of 30-70% of a nylon 66 salt solution in a normal pressure pre-polypolycondensation tower by adopting a reaction distillation method to obtain a prepolymer with a polymerization degree of 5-50 (preferably 20-40) and equimolar terminal carboxy group and terminal amine group, and allowing the prepolyer to directly produce a polymer with a polymerization degree meeting technical indicators without flash distillation. A falling film devolatilization method is adopted in the polycondensation kettle to accelerate distillation out of condensation water, reduce reaction temperature, shorten reaction time and reduce gel; and the falling liquid film is used to seal and cover the kettle wall to avoid scarring of the kettle wall. Compared with the traditional nylon 66 continuous polymerization device, the method and the equipment provided by the invention has the advantages of short process, large single line scale, less investment, low operating cost, good product quality, long continuous operation cycle, and environmental friendliness.

Owner:XCEED CHEMTECH

Isomeric alcohol block polyether with excellent degreasing emulsion performance and preparation method and application of isomeric alcohol block polyether

ActiveCN110452369ALow pour pointReduce gelOther chemical processesTransportation and packagingChemical structureIsomerization

The invention discloses an isomeric alcohol block polyether with excellent degreasing emulsion performance and a preparation method and application of the isomeric alcohol block polyether. The isomeric alcohol block polyether is of a chemical structure of a formula I shown in the specification, in the formula, R is selected from isomeric alkyl of which the average isomerization degree is greater than or equal to 2, n is selected from numbers of 1-8, and m is selected from a number of 2-15. The preparation method comprises the following steps: performing a polymerization reaction on isomeric alcohol R-OH and epoxypropane so as to obtain an intermediate, and performing a polymerization reaction on the obtained intermediate and ethylene oxide so as to obtain the isomeric alcohol block polyether. The obtained isomeric alcohol block polyether has the characteristics of being low in pour point, free of gel, low in foam and excellent in emulsification and degreasing capability, and a degreasing agent and emulsifier raw material with good operability can be provided for the market.

Owner:联泓(江苏)新材料研究院有限公司

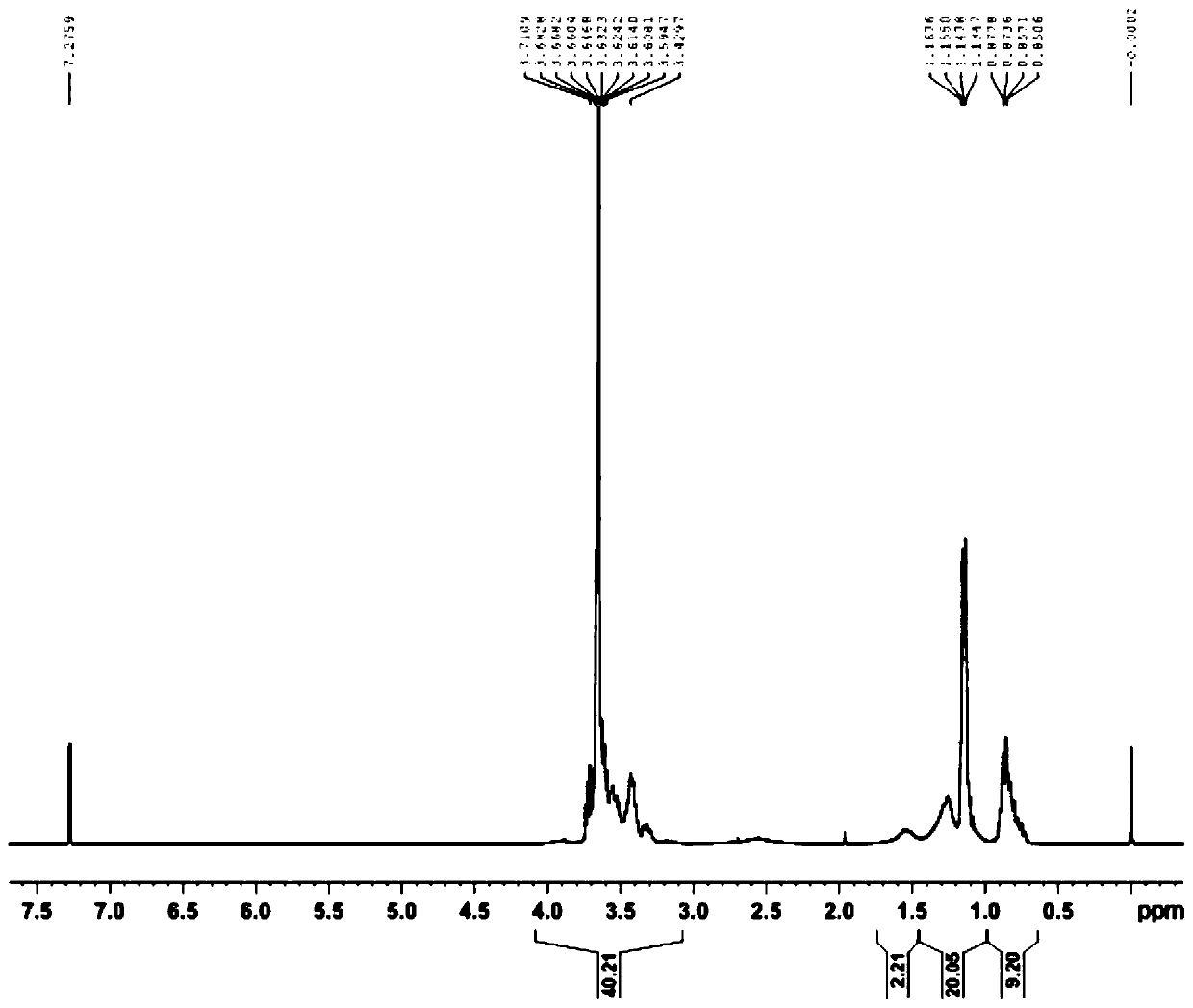

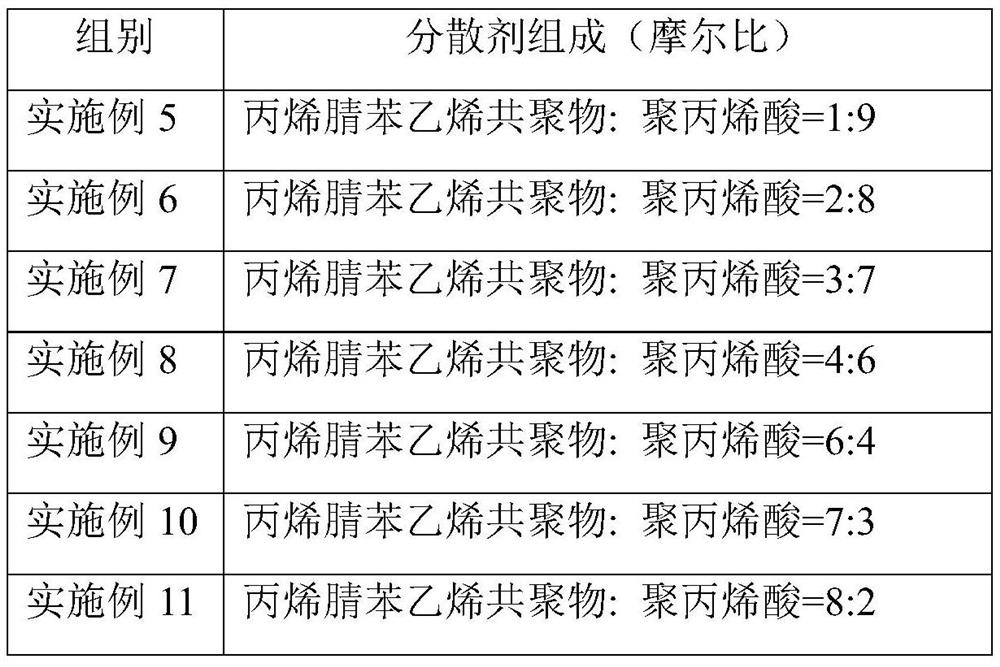

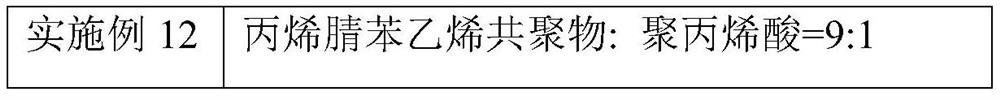

Dispersing agent, positive electrode slurry and lithium ion battery

ActiveCN113540463AImprove stabilityReduce gelSecondary cellsPositive electrodesPolystyreneAcrylonitrile

The invention discloses a dispersing agent, positive electrode slurry and a lithium ion battery. In the application, the dispersing agent is prepared from polyacrylonitrile and polystyrene; or the dispersing agent comprises a first copolymer, and the first copolymer is formed by copolymerization of an acrylonitrile monomer and a styrene monomer. When the dispersing agent is added into positive electrode slurry, the phenomena of material gelling and agglomeration in the slurry homogenizing process can be reduced, the viscosity of the slurry is reduced, and the stability of the slurry is improved; therefore, the dispersing capacity of the positive electrode material is improved, and the slurry viscosity is reduced.

Owner:ENVISION DYNAMICS TECH (JIANGSU) CO LTD +1

Light-shielding coating slurry and preparation method thereof

InactiveCN111304932AGood compatibilityIncrease coverageTextiles and paperPolymer scienceFunctional monomer

The invention relates to the field of fabric coatings and discloses light-shielding coating slurry. The light-shielding coating slurry is prepared from the following components in parts by weight: 2-3parts of an anionic emulsifier, 3-4 parts of a non-ionic emulsifier, 15-40 parts of a functional monomer, 155-200 parts of a soft monomer, 50-60 parts of a hard monomer, 0.05-0.15 part of a cross-linking agent, 6-10 parts of silicone oil, 0.2-0.25 part of an oxidant, 0.2-0.25 part of a reducing agent, 150-200 parts of a filler, 1-3 parts of a dispersant, 1-3 parts of a defoamer, 15-20 parts of athickener and 500-650 parts of water. The light-shielding coating slurry has relatively good light-shielding property, water resistance, anti-pollution performance and weather resistance, and a coatedfabric is good in hand. Through a semi-continuous polymerization process of positive emulsion pre-emulsification, the slurry is firstly synthesized into an acrylic emulsion of meeting the performancerequirements, then the filer and an assistant are added, and finally light-shielding coating gum with excellent performance is prepared. According to the method, a demulsification phenomenon generated in the polymerization process can be reduced to make a polymerization system more stable.

Owner:成都德美精英化工有限公司

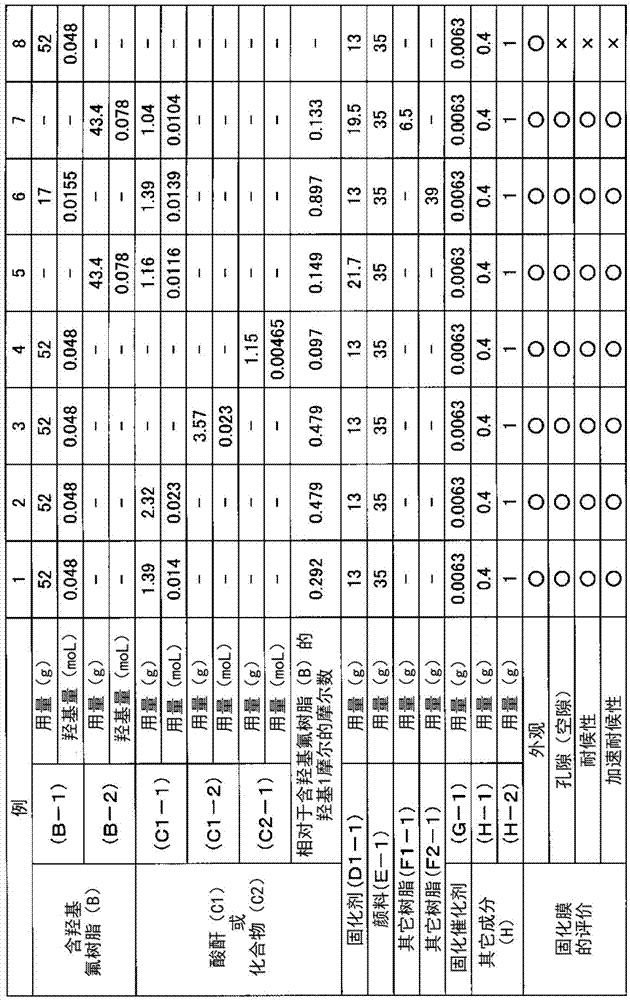

Method for manufacturing powder coating material, coated article and method for manufacturing same, and method for manufacturing carboxyl-group-containing fluororesin

InactiveCN105452405AGood weather resistanceReduce porosityPolyurea/polyurethane coatingsPowdery paintsWeather resistanceMetallurgy

Provided are: a method for manufacturing a powder coating material whereby a hardened film having excellent weather resistance and few voids (gaps) can be formed; a coated article having a hardened film having excellent weather resistance and few voids, and a method for manufacturing a coated article; and a method for manufacturing a carboxyl-group-containing fluororesin having minimal gelling. A method for manufacturing a powder coating material including a powder (X) comprising a composition ([alpha]) including a curing agent (D) and a fluororesin (A) having carboxyl groups or alkoxysilyl groups and urethane bonds, the method for manufacturing a powder coating material having (a) a step for melt-kneading a mixture including a hydroxyl-group-containing fluororesin (B), an acid anhydride (C1) or a compound (C2) having alkoxysilyl groups and isocyanate groups, and a curing agent (D), and obtaining a mixture comprising the composition ([alpha]), and (b) a step for pulverizing the mixture and obtaining a powder (X).

Owner:ASAHI GLASS CO LTD

Thermal-insulation energy-saving coating and preparation method thereof

PendingCN113292893AReduce damageGuaranteed stabilityAnti-corrosive paintsRadiation-absorbing paintsEmulsionHeat conservation

The invention relates to a thermal-insulation energy-saving coating and a preparation method thereof; the thermal-insulation energy-saving coating comprises a first coating agent which is used for coating a wall body to form a thermal-insulation base layer, and a second coating agent which is used for coating the thermal-insulation base layer to form a thermal-insulation protective layer, wherein the first coating agent is prepared from an acrylic emulsion, deionized water, propylene glycol, a resin material, nano titanium dioxide, 3-glycidyl propoxy trimethoxy siloxane, Na-montmorillonite, phosphoric acid, nano aerogel, ferrocene boric acid, xonotlite whiskers and an auxiliary agent. The first coating agent is coated to form a heat-insulating base layer, and the second coating agent is coated to form a heat-insulating protective layer. The heat preservation base layer and the heat preservation protection layer are combined to form good heat preservation performance, and the heat preservation protection layer protects the heat preservation base layer. Therefore, the damage of the thermal insulation base layer after long-term use is reduced, and the stability of thermal insulation performance is ensured.

Owner:SUZHOU BIZUNION ARCHITECTURAL ENG CO LTD

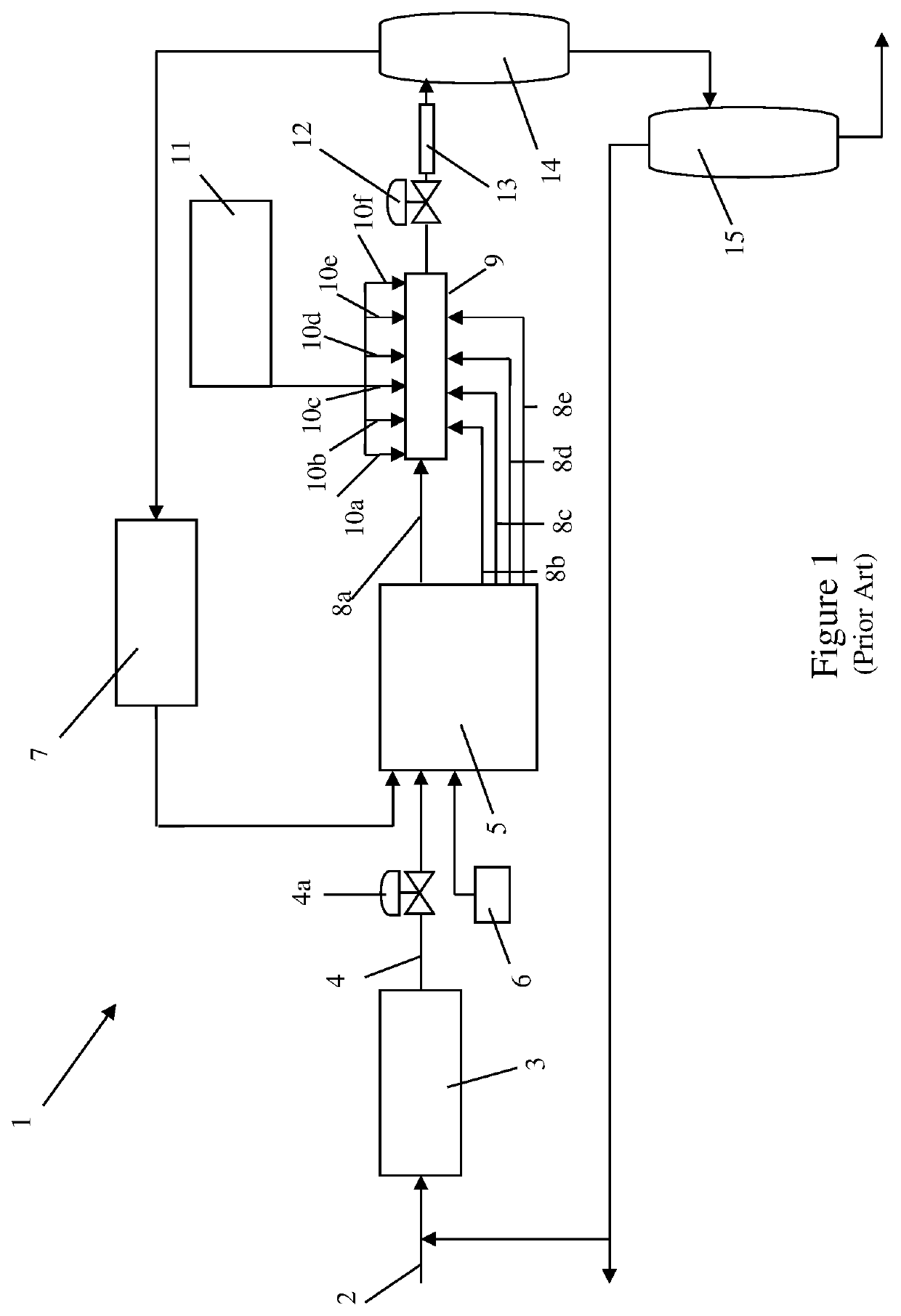

High pressure polyethylene product cooling

ActiveUS10766984B2Reduce pressureReduce gelProcess control/regulationChemical liquid solidificationThermodynamicsProcess engineering

This disclosure relates to systems and processes for cooling polymer product mixtures manufactured at high pressure. The processes of the invention involve cooling and then subsequently reducing the pressure of the product mixture from the reactor. In the systems of the invention, a product cooler is located downstream of the high pressure reactor and upstream of a high pressure let down valve.

Owner:EXXONMOBIL CHEM PAT INC

The defoaming method of polyacrylonitrile stock solution

ActiveCN104562226BReduce the presence of air bubblesImprove uniformitySpinning solution filteringCarbon fibersVacuum pump

The invention relates to a defoaming method for preparing a polyacrylonitrile stock solution, and aims at solving the problems that a stock solution in the prior art is not uniform, and an upper layer easily generates gel, or is even dried and hardened. According to the technical scheme, the defoaming method for preparing the polyacrylonitrile stock solution comprises the following steps: (a) starting a heating device, heating a defoaming kettle, starting a vacuum pump, vacuumizing the defoaming kettle, slowly conveying the polyacrylonitrile stock solution to the defoaming kettle from a demonomerisation kettle while vacuumizing, closing the vacuum pump after the polyacrylonitrile stock solution completely enters the defoaming kettle, introducing gas to the defoaming kettle, pressurizing and defoaming; (b) after pressurizing and defoaming are finished, starting the vacuum pump, vacuumizing the defoaming kettle, defoaming in vacuum, so as to obtain the final polyacrylonitrile stock solution, and the problems are relatively well solved; the defoaming method can be applied to industrial production of a carbon fiber precursor.

Owner:CHINA PETROLEUM & CHEM CORP +1

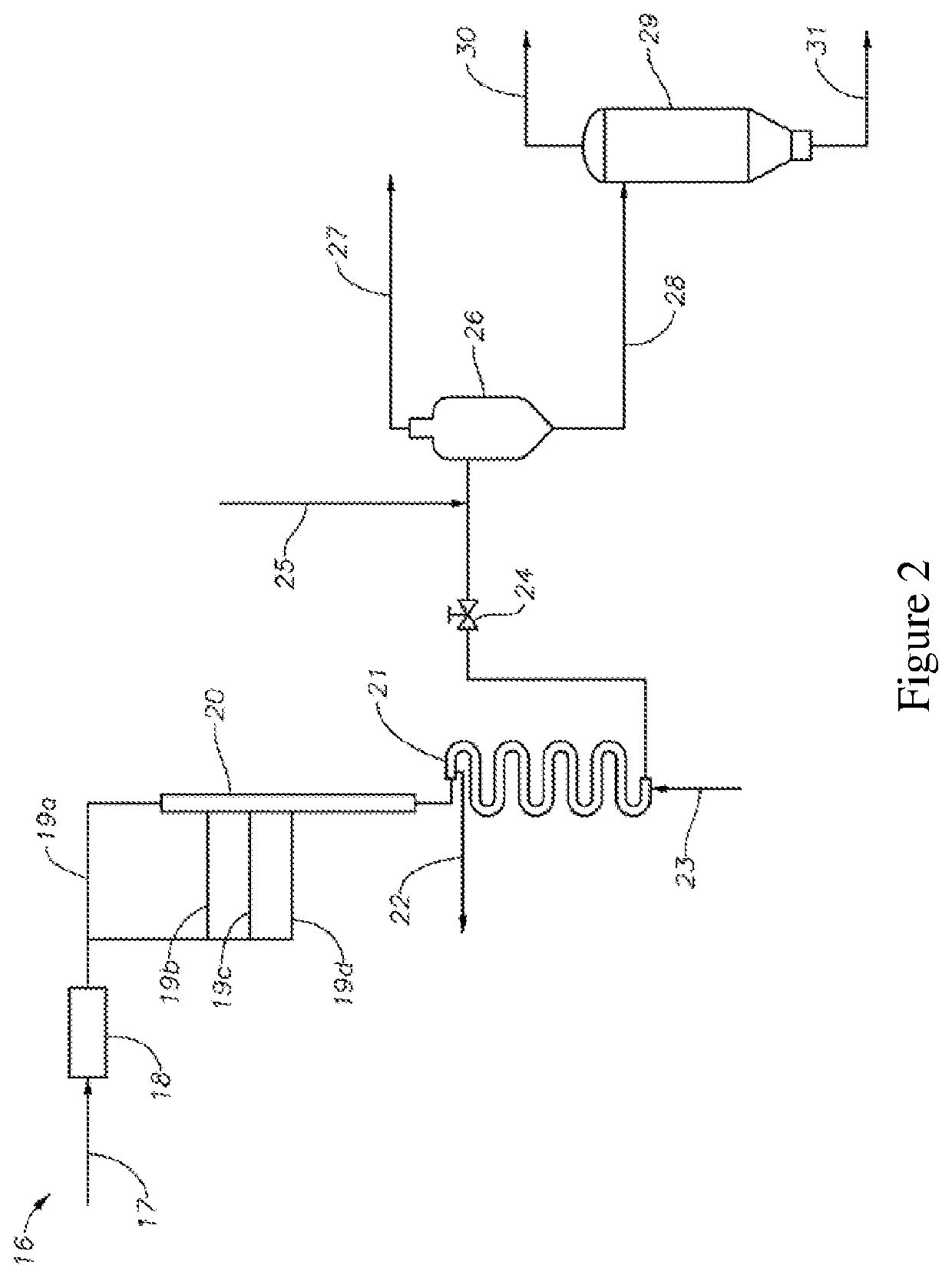

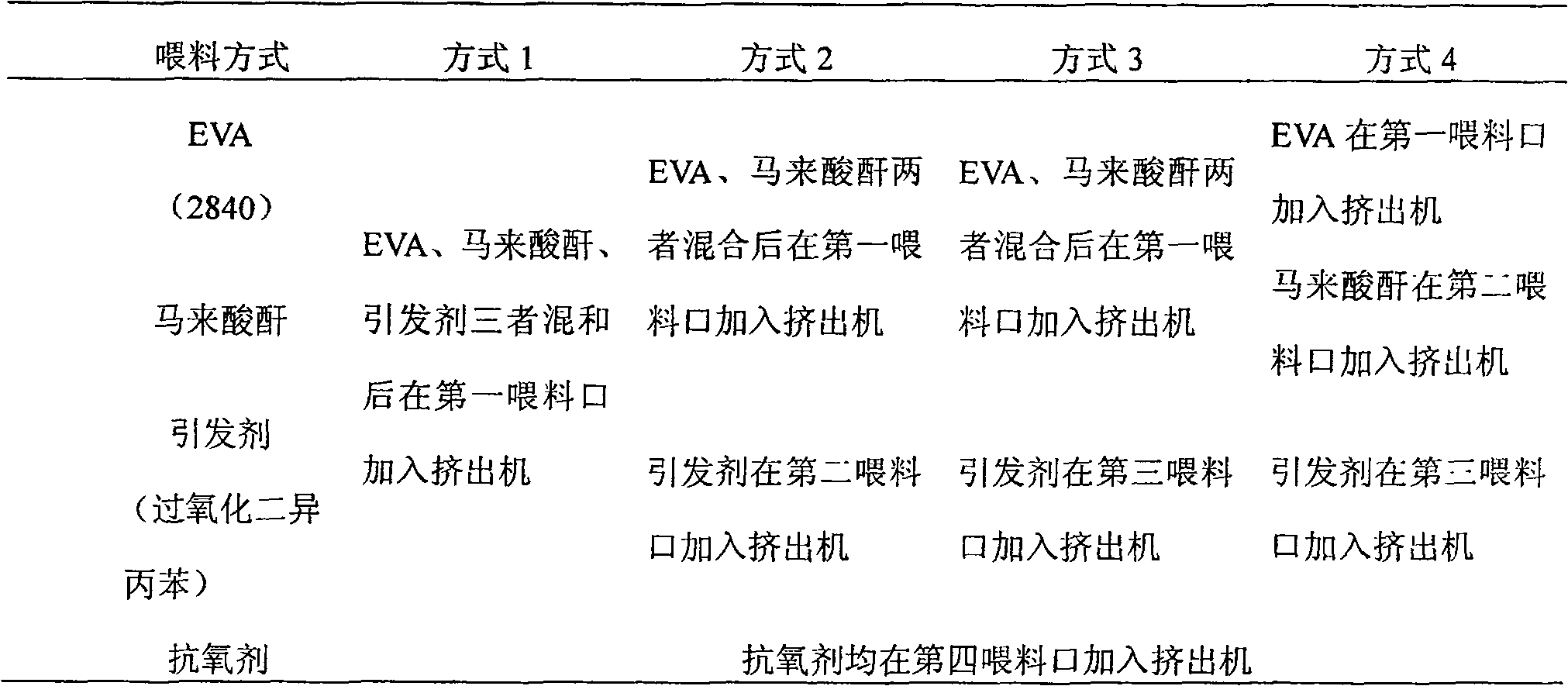

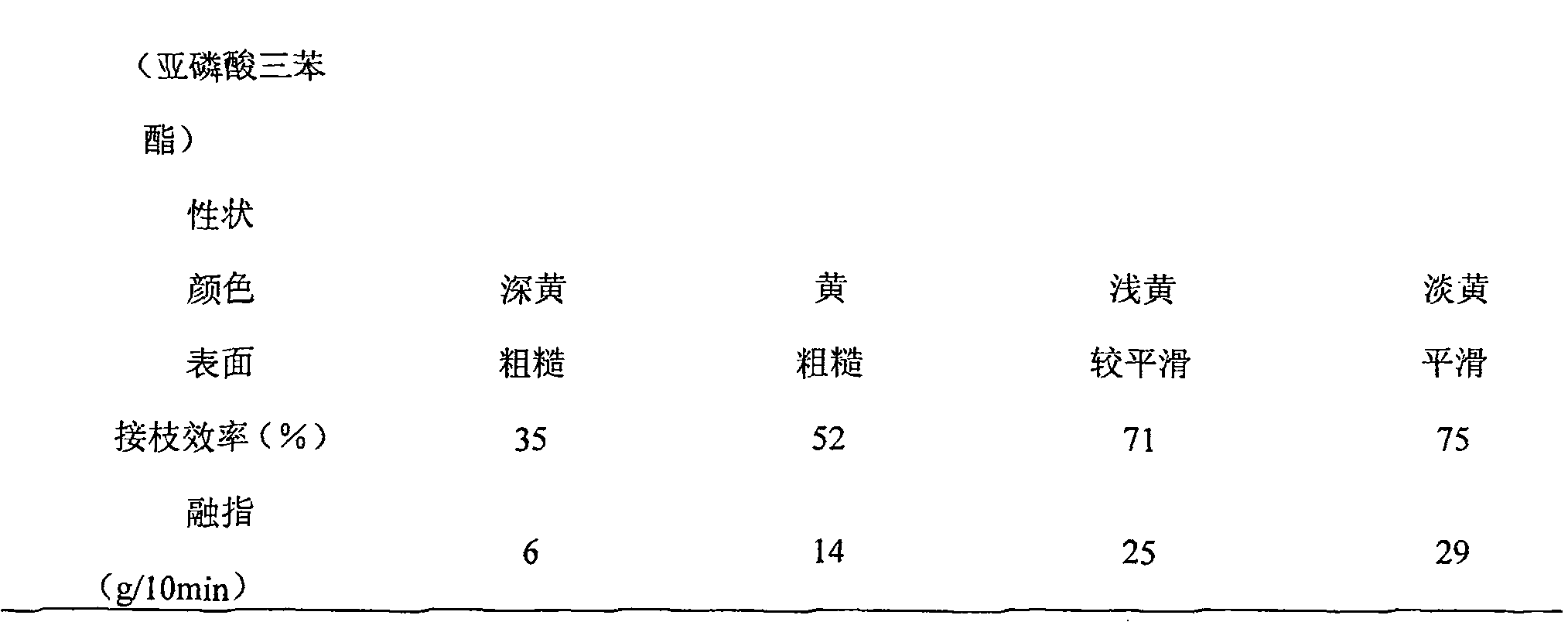

High-current ethylene-vinyl acetate copolymer grafted maleic anhydride product, preparation method and application thereof

ActiveCN101245125BImprove controllabilityImprove grafting efficiencyGraft polymer adhesivesAntioxidantCarvacryl acetate

The invention discloses a searching ethylene-vinylacetate copolymer grafted maleic anhydride product which is made of the raw materials with following weight percentage: ethylene-vinylacetate copolymer is 100 percent by weight, maleic anhydride is 0.5 to 5 percent by weight, an initiator is 0.03 to 0.4 percent by weight, and an antioxidant is 0.1 to 0.5 percent by weight. The preparation method is that the raw materials with the weight percentage are added into an extruder, reaction is carried out at the temperature between 150 DEG C and 190 DEG C, and then granulation is extruded to obtain the needed product. The searching ethylene-vinylacetate copolymer grafted maleic anhydride product of the invention can be applied for preparing hot-melt adhesive. The entire preparation process of theproduct has the advantages of high controllability and little gelatinization in the reaction product; the grafting efficiency of maleic anhydride can reach as high as 75 percent. The prepared searching ethylene-vinylacetate copolymer grafted maleic anhydride product can be easily dispersed on the interfaces of multiple blends containing polar polymers, so as to improve the cohesive force among interfaces, thus promoting the overall property of the blends.

Owner:合诚技术股份有限公司

Method for preparing coarse denier spandex fiber for hygienic material by adopting spandex silk waste

ActiveCN104073904AExtended stabilization periodReduce gelMonocomponent synthetic polymer artificial filamentDry spinning methodsMaterials preparationFiber

The invention belongs to the field of material preparation, and relates to a preparation method for coarse denier spandex fiber, in particular to a method for preparing coarse denier spandex fiber for a hygienic material by adopting spandex silk waste. The method comprises the following steps: (1) pre-processing; (2) pre-polymerizing; (3) polymerizing; (4) spinning. In the preparing process of spandex fiber, as the spandex silk waste is treated by a cosolvent, a silicone oil removing additive and a catalyst respectively according to the method, the stable period of a prepared polymer solution is greatly improved, and is longer than 20 days, the fluidity of a polymer stock solution prepared from the spandex silk waste is improved, gelatin in the polymer stock solution is reduced, the spinnability of the polymer stock solution is improved, and the hard segments and the soft segments of the spandex fiber molecular chains obtained by adopting the method are enabled to be structured and ordered.

Owner:JIANGSU QIAOXIN FIBER

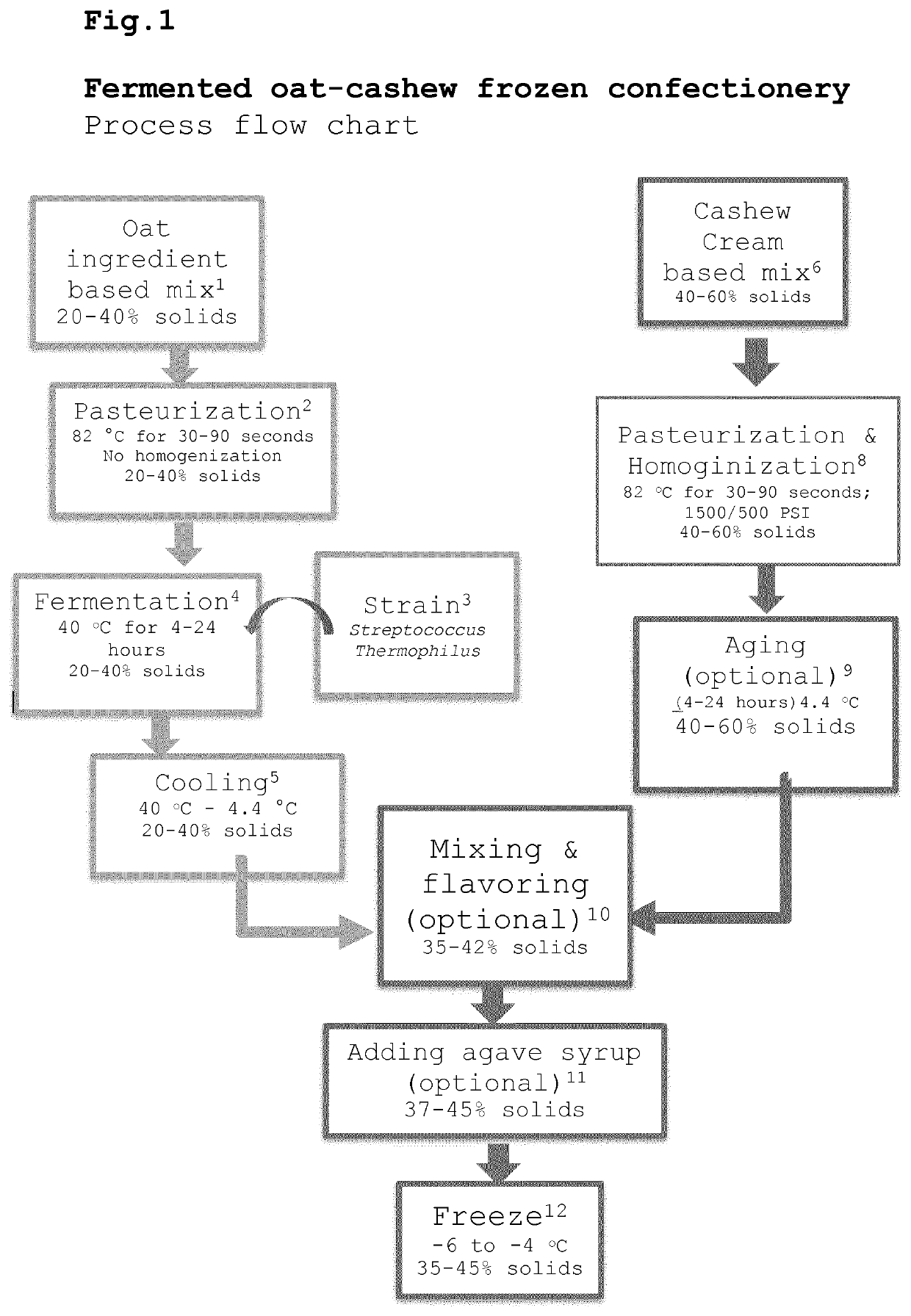

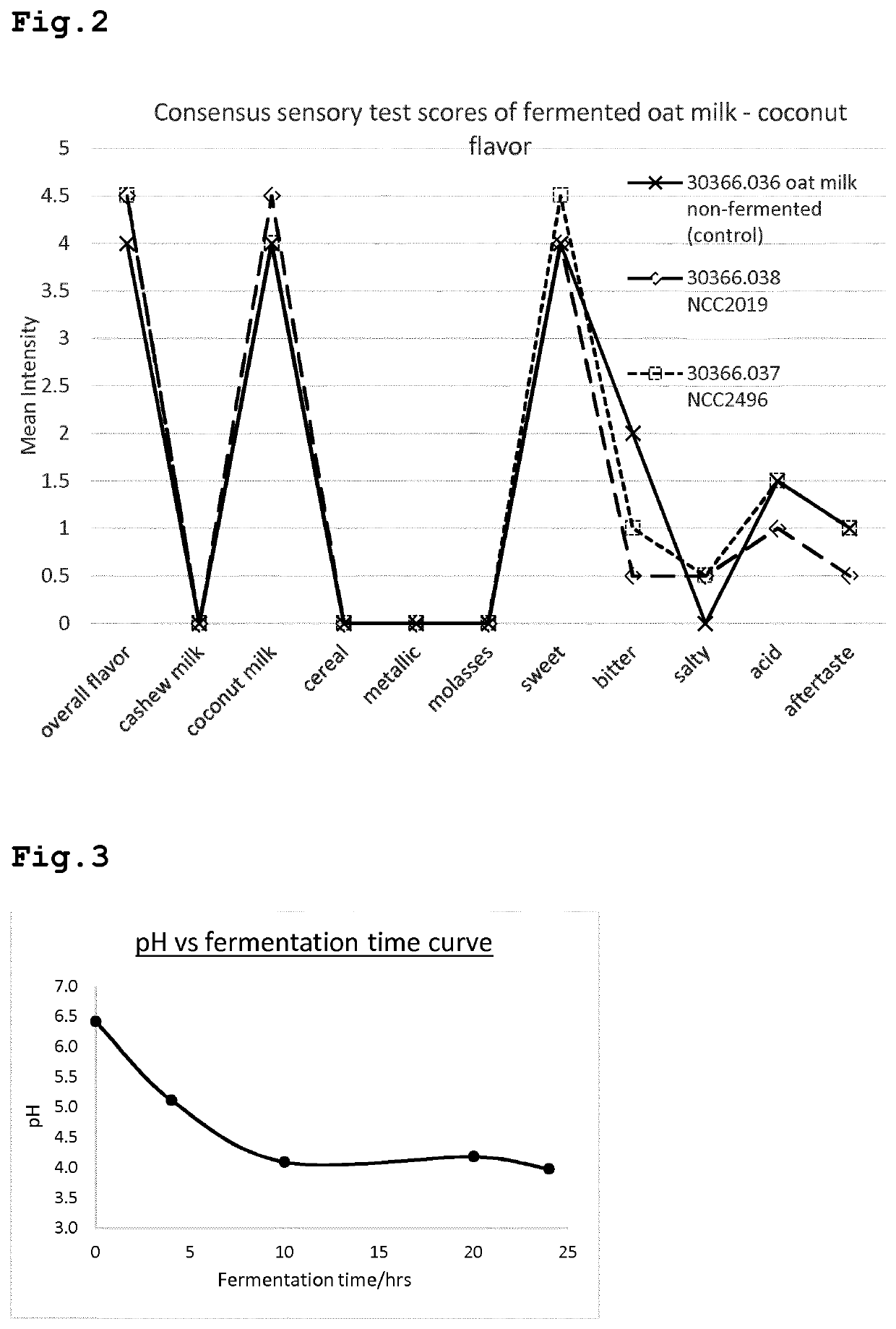

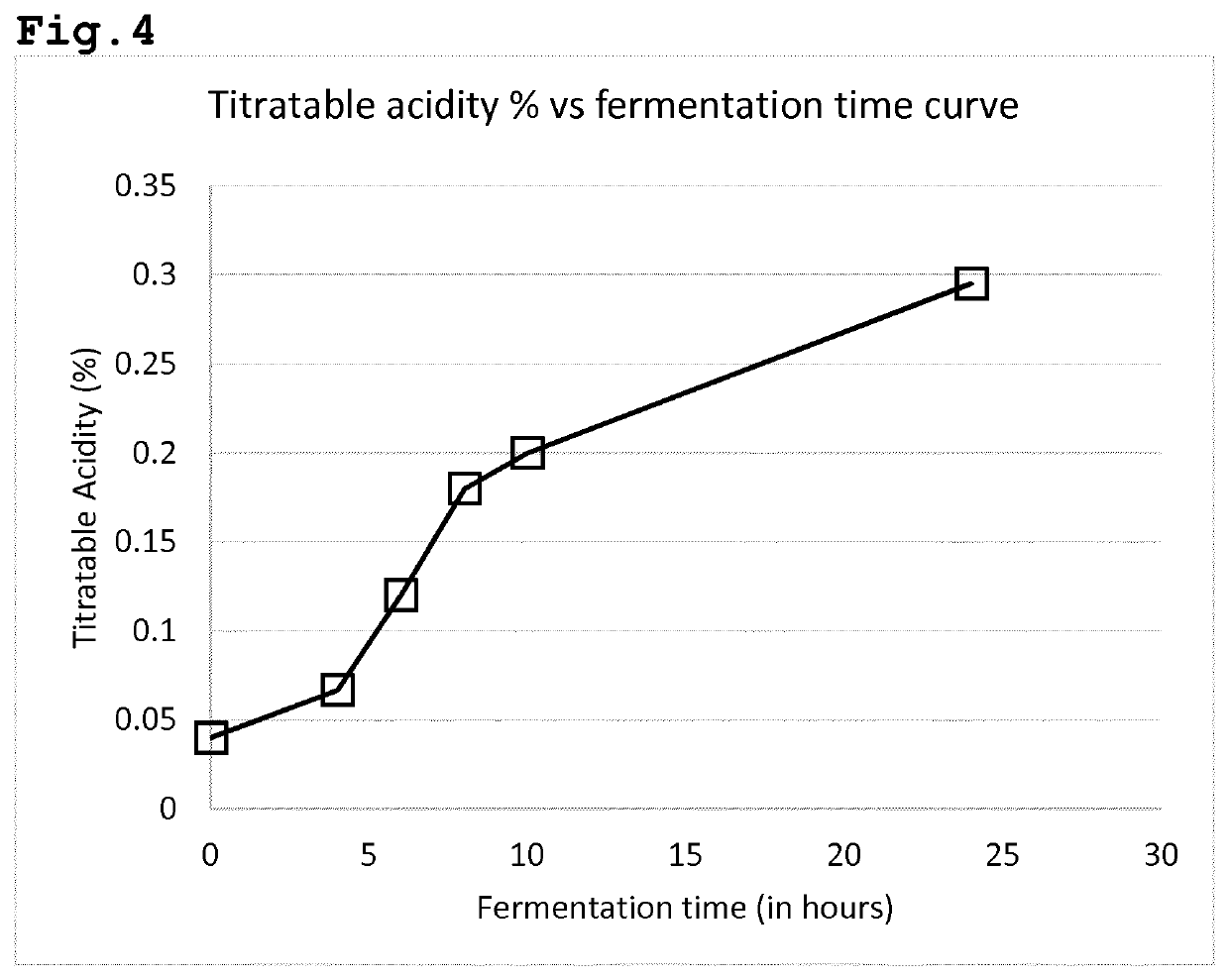

A method of producing fermented non-dairy frozen confectionery

PendingUS20220022489A1Total calories lowImprove nutritional statusFrozen sweetsCocoaStreptococcus thermophilusBiotechnology

The present invention relates to a method of producing a non-dairy frozen confectionery, the method comprising the steps of: 1) providing a grain based ingredient mix comprising plant syrup and having 20-40 wt. % solids, pasteurizing the grain based ingredient mix, fermenting the pasteurized grain based mix with a culture, and cooling the fermented grain ingredient based ingredient mix, and 2) providing a nut and / or seed based ingredient mix comprising 40-60 wt. % solids and 3) combining it with the cooled fermented grain based ingredient mix, and freezing while optionally aerating the combined grain and nut and / or seed based mixes, to form a frozen confectionery. The invention also relates to a non-dairy frozen confectionery comprising 3-20 wt. % grain fermented with Streptococcus thermophilus, and 4-40 wt. % seed and / or nuts.

Owner:SOC DES PROD NESTLE SA

Functional master-batch for organosilane crosslinked polyethylene pipe, and preparation method and application of functional master-batch

The invention discloses functional master-batch for an organosilane crosslinked polyethylene pipe, and a preparation method and application of functional master-batch, which belong to the technical field of master-batch for engineering plastics. 100 parts of high density polyethylene, 25-35 parts of an adsorbing agent, 5-10 parts of a lubricating agent, 2-5 parts of an antioxidant, 2-5 parts of a light stabilizer and 3-6 parts of a crosslinking accelerant are stirred through a high stirring machine, subjected to twin-screw extrusion, pelleted and the like to obtain the functional master-batch; and the functional master-batch is used for extrusion molding of the large-caliber organosilane crosslinked polyethylene pipe. The preparation method of the functional master-batch is simple and suitable for industrial production; the method is applied to the extrusion molding of the large-caliber organosilane crosslinked polyethylene pipe; the pipe processing stability is good; the extension rate and the self-crosslinking speed of the obtained pipe are far better than those of a common pipe; and the functional master-batch facilitates a pipe manufacturer and can be added according to different devices and pipe specifications, and 2-5% of the master-batch can be added directly into a common silane crosslinking material, so that a pipe can be extruded after uniform stirring.

Owner:LINHAI WEIXING NEW BUILDING MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com