Isomeric alcohol block polyether with excellent degreasing emulsion performance and preparation method and application of isomeric alcohol block polyether

A block polyether and isomeric alcohol technology, applied in chemical instruments and methods, transportation and packaging, and other chemical processes, can solve problems such as high pour point, high foam, unusable, etc., and achieve excellent oil removal ability, highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

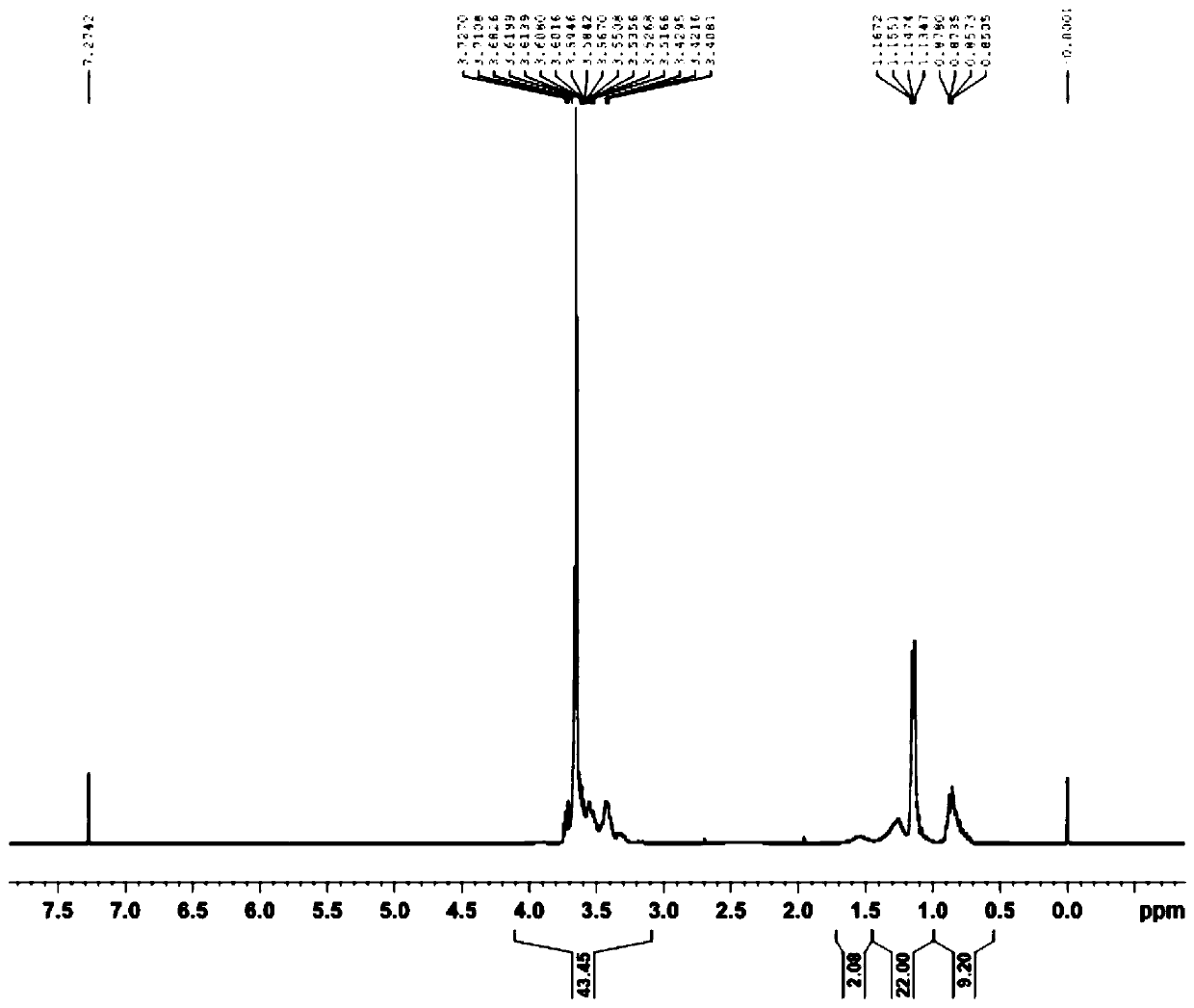

[0054] Example 1: Preparation of Isomerized Undecyl Alcohol Block Polyether

[0055]

[0056] The initiator isomerized undecyl alcohol (C 3 h 7 CH(CH 3 )CH 2 CH(CH 3 )C 3 h 6 OH, the average degree of isomerization is 2) 171g and catalyst (0.34g KOH aqueous solution, wherein the KOH concentration is 50wt%) mixed, 100 ℃ vacuum dehydration until the raw material moisture is lower than 0.1%, and then the dehydrated raw material is sucked into the alkane Oxygenation reactor, vacuumed and filled with N 2 Replacement, heat up to 130°C, slowly feed 290.3g of propylene oxide, control the reaction temperature at 130-140°C, pressure 40-60psi, aging for 60 minutes after adding propylene oxide to obtain the intermediate, and then pass the ring to the intermediate Oxygen 352g, control reaction temperature 140-150°C, pressure 40-60psi, aging for 30 minutes after adding ethylene oxide, cooling to 80°C, gas stripping, discharging, neutralization with acetic acid until pH is about 6....

Embodiment 2

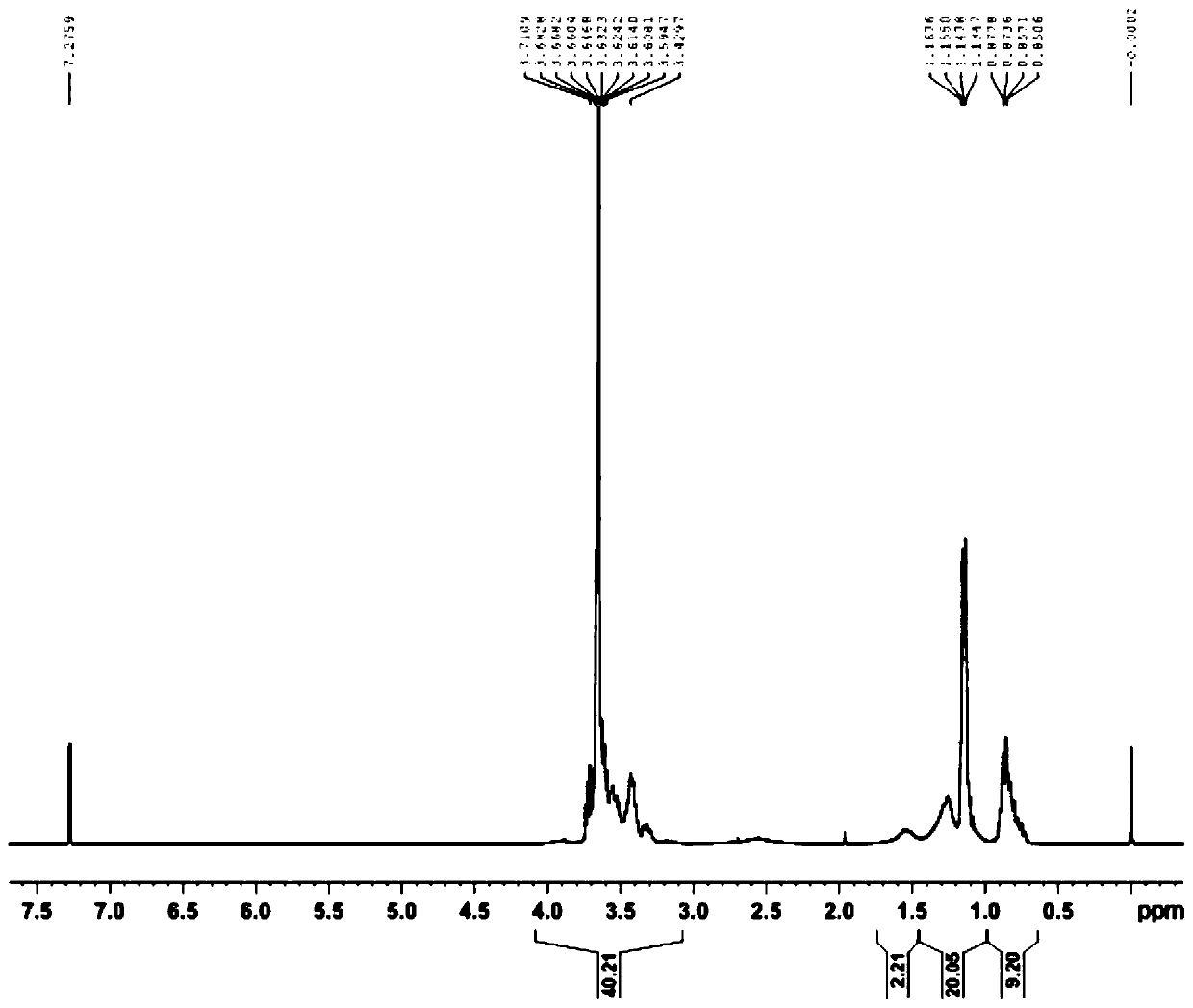

[0057] Example 2: Preparation of Isomerized Undecyl Alcohol Block Polyether

[0058]

[0059] The initiator isomerized undecyl alcohol (C 3 h 7 CH(CH 3 )CH 2 CH(CH 3 )C 3 h 6 OH, the average degree of isomerization is 2) 171g and catalyst (3.4g KOH aqueous solution, wherein the KOH concentration is 50wt%) mixed, 100 ℃ vacuum dehydration until the raw material moisture is lower than 0.1%, and then the dehydrated raw material is sucked into the alkane Oxygenation reactor, vacuumed and filled with N 2 Replacement, heat up to 130°C, slowly feed 232g propylene oxide, control the reaction temperature 130-140°C, pressure 40-60psi, after adding propylene oxide, age for 60 minutes to obtain the intermediate, and then pass epoxy to the intermediate 308g of ethane, controlled reaction temperature 140-150°C, pressure 40-60psi, aging for 30 minutes after adding ethylene oxide, cooling to 80°C, gas stripping, discharging, neutralizing with acetic acid until the pH is 5.0-7.0, and ...

Embodiment 3

[0060] Example 3: Preparation of isomeric tridecanol block polyether

[0061]

[0062] The initiator isomerized tridecyl alcohol (C 3 h 7 CH(CH 3 )CH 2 CH(CH 3 )CH 2 CH(CH 3 )C 2 h 4 OH, the average degree of isomerization is 3) 100g is mixed with catalyst (1.0g KOH aqueous solution, wherein the KOH concentration is 50wt%), vacuum dehydrated at 100°C until the raw material moisture is lower than 0.1%, and then vacuum sucks the dehydrated raw material into alkane Oxygenation reactor, vacuumed and filled with N 2 Replacement, heating up to 130°C, slowly feeding 61.0g propylene oxide, controlling the reaction temperature 130-140°C, pressure 40-60psi, aging for 60 minutes after adding propylene oxide, to obtain the intermediate, and then pass the ring to the intermediate Oxygen 176g, control reaction temperature 140-150°C, pressure 40-60psi, aging for 30 minutes after adding ethylene oxide, cooling to 80°C, air stripping, discharging, acetic acid neutralization to pH 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com