Anion water-soluble polyurethane disperse system for finishing leather and method for preparing same

A polyurethane dispersion, water-based polyurethane technology, applied in polyurea/polyurethane coatings, devices for coating liquids on surfaces, coatings, etc., can solve problems such as reducing mechanical properties, and achieve improved stability, high coating film strength, The effect of easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

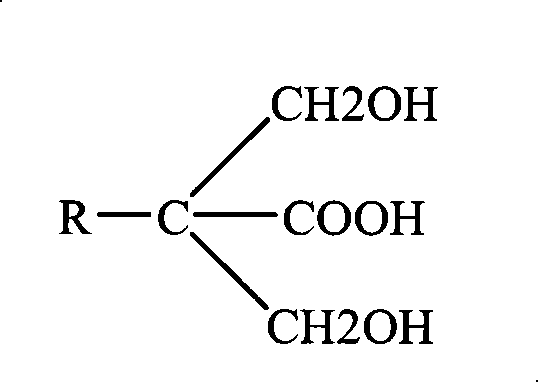

Method used

Image

Examples

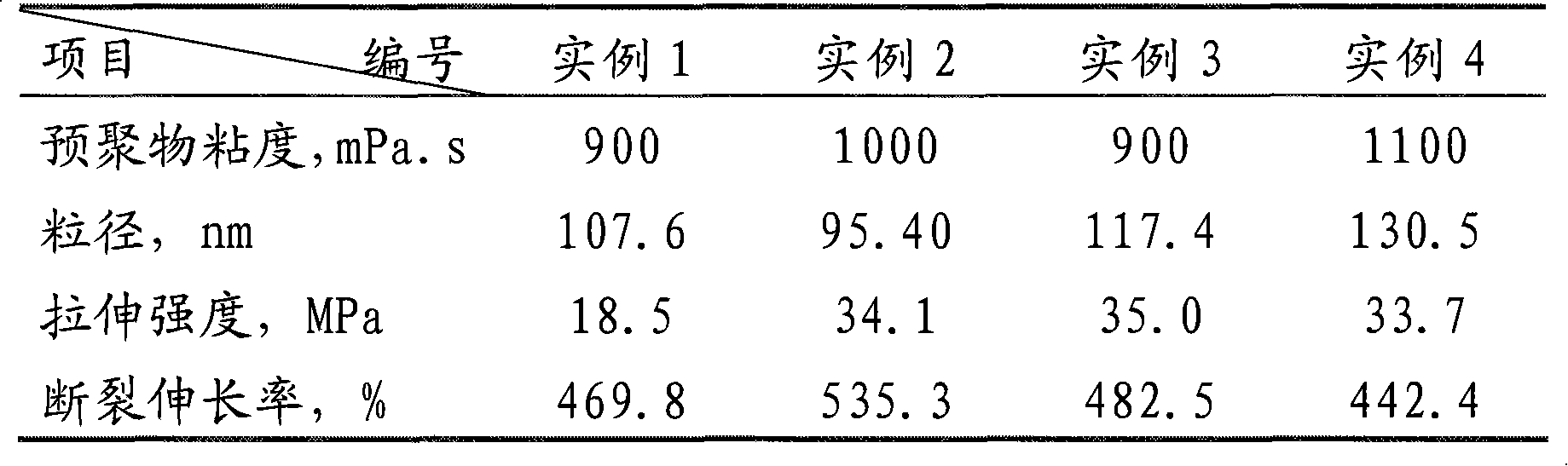

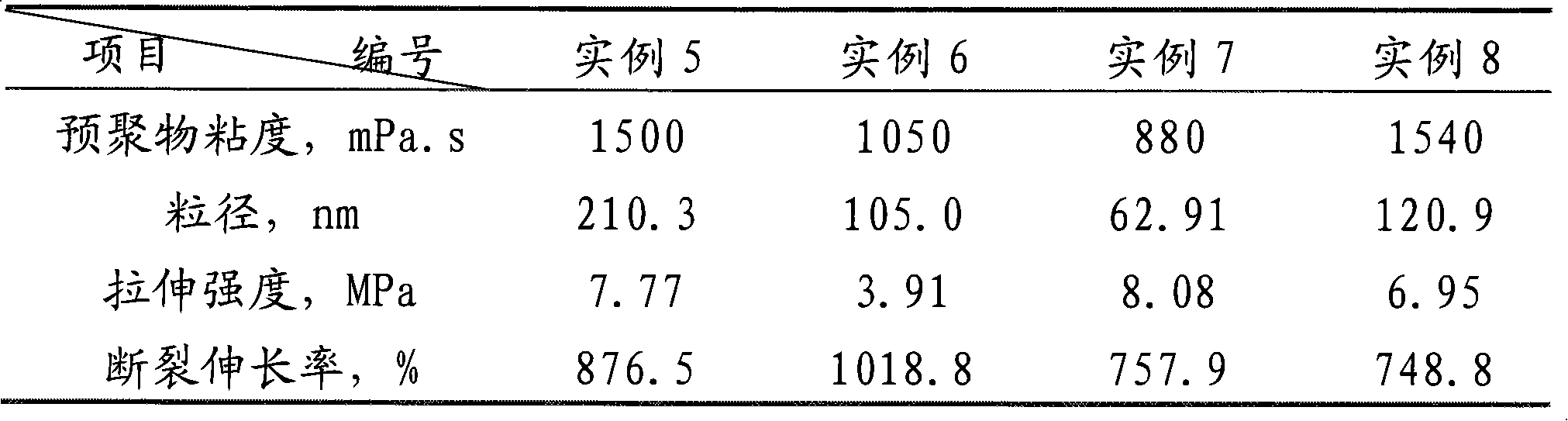

example 1-4

[0058] Example 1~4 adopts MDI-50 (2,4-diphenylmethane diisocyanate content 51.75%, 4,4-diphenylmethane diisocyanate content 48.13% and 2,2-diphenylmethane diisocyanate isomerization content of 0.12%) and DL1000P to prepare the dispersion, and the viscosity of the synthesized prepolymer, the particle size of the waterborne polyurethane dispersion, the mechanical properties of the waterborne polyurethane after film formation, the tensile strength and the elongation at break were characterized. The results are shown in Table 1.

example 1

[0060] Add 125.13 grams of MDI-50 and 204.64 grams of polypropylene oxide ether glycol DL1000P into the four-necked bottle, pass through dry nitrogen, start stirring and gradually raise the temperature to 70 ° C, after 2 hours, cool the reactant to 50 ° C, add 21.32 grams DMPA and 100 grams of acetone were kept at a reaction temperature of 60°C. After 1.5 hours of reaction, 95 grams of acetone was added to lower the temperature to 50°C, and 4.68 grams of 1,4-butanediol was added. After 1.5 hours of reaction, the chain extension reaction was considered complete.

[0061] Lower the temperature of the prepolymer below 40°C, add 16.06 grams of triethylamine, continue to cool down to below 30°C, use a FLUKO homogenizer, add deionized water to disperse under the condition of rapid stirring, the dispersion speed is 10000rpm, and then add 1.06 g of ethylenediamine. Finally, the acetone was distilled off under reduced pressure to obtain a stable aqueous polyurethane dispersion.

example 2

[0063] Add 130.78 grams of MDI-50 and 197.3 grams of polypropylene oxide ether glycol DL1000P into a four-necked bottle, add two drops of stannous octoate (about 0.05g) dropwise, pass in dry nitrogen, start stirring and gradually heat up to 70°C, 2 After one hour, the reactant was cooled to 50°C, 21.43 grams of DMPA and 100 grams of acetone were added, and the reaction temperature was maintained at 60°C. After 1.5 hours of reaction, 95 grams of acetone was added again to lower the temperature to 50°C, and 6.77 grams of 1,4-butanediol was added. Alcohol, after 1.5 hours of reaction, the chain extension reaction was considered complete.

[0064] Lower the temperature of the prepolymer below 40°C, add 16.15 grams of triethylamine, continue to cool down to below 30°C, use a FLUKO homogenizer, add deionized water to disperse under the condition of rapid stirring, the dispersion speed is 10000rpm, and then add 0.82 grams of ethylenediamine. Finally, the acetone was distilled off un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com